USB Type-C socket connector convenient for firm welding

A socket connector, strong technology, applied in the direction of connection, connection device parts, line/collector parts, etc., can solve difficult detection, unreliable welding, affecting the reliability and stability of USB Type C connectors, etc. problems, to achieve the effect of improving product reliability, reducing production difficulty and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

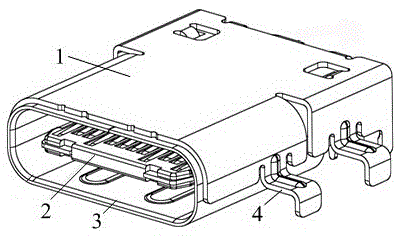

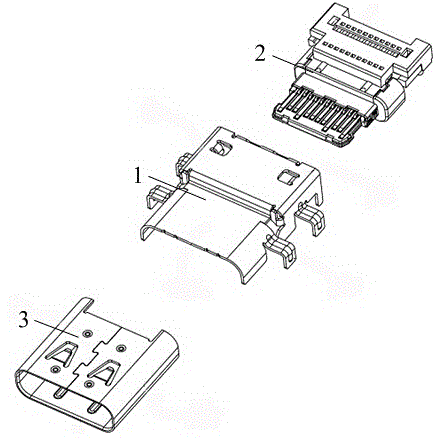

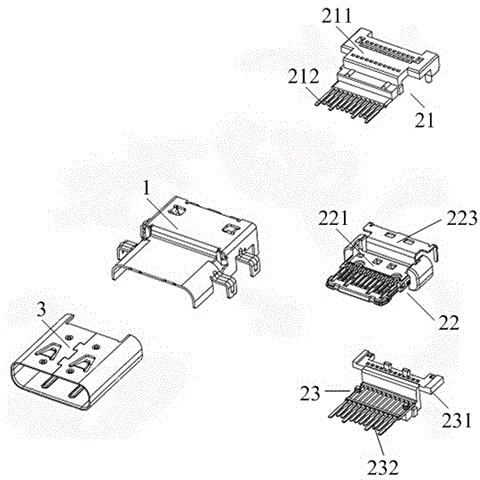

[0028] like Figure 1-Figure 8 As shown, the present invention provides a first embodiment of a USB Type C receptacle connector that is convenient for firm welding, which includes a metal shielding shell and an insertion assembly 2, and the insertion assembly 2 includes an upper insertion assembly 21, a middle insertion assembly 22 and a lower insertion component 23, the upper insertion component 21 includes an upper insulating body 211 and an upper row of conductive terminals 212 integrally formed with the upper insulating body 211, and the lower insertion component 23 includes a lower insulating body 231 and a lower insulating body 231 231 is integrally formed with the lower row of conductive terminals 232, the middle insertion component 22 includes a middle ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com