Electrode step-by-step printing method of high-efficiency solar cell

A technology of solar cells and printing methods, applied to circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of improving conversion efficiency, high fault tolerance, and good lap reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Use 156.75*156.75mm size battery;

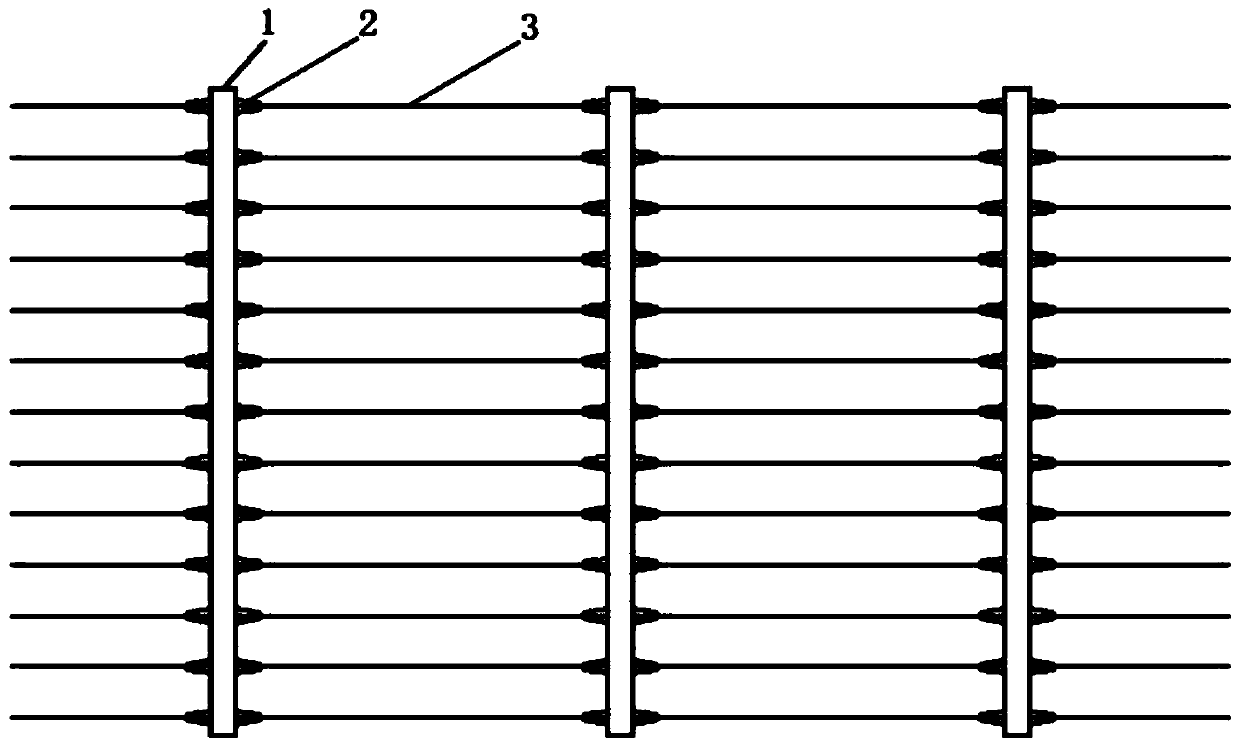

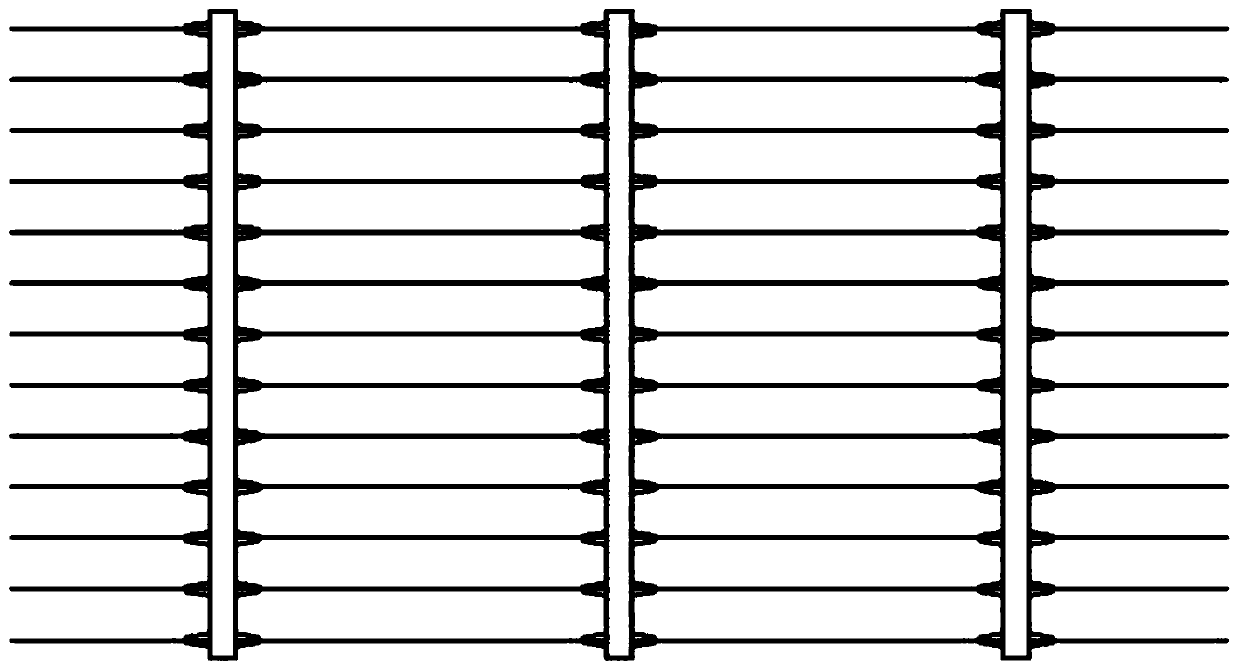

[0082] On the front of the battery, the busbar 1 is first printed according to the busbar pattern. The busbar 1 includes the busbar 11 in the welding area and the busbar lap structure 12. The width of the busbar 11 in the welding area is 700 μm, and the busbar lap structure 12 It is an isosceles triangle, the side length of the triangle is 713.5μm, and the apex angle is 60°. The paste for printing the busbar is non-burn-through silver paste, and the screen is a 325-mesh screen printing screen;

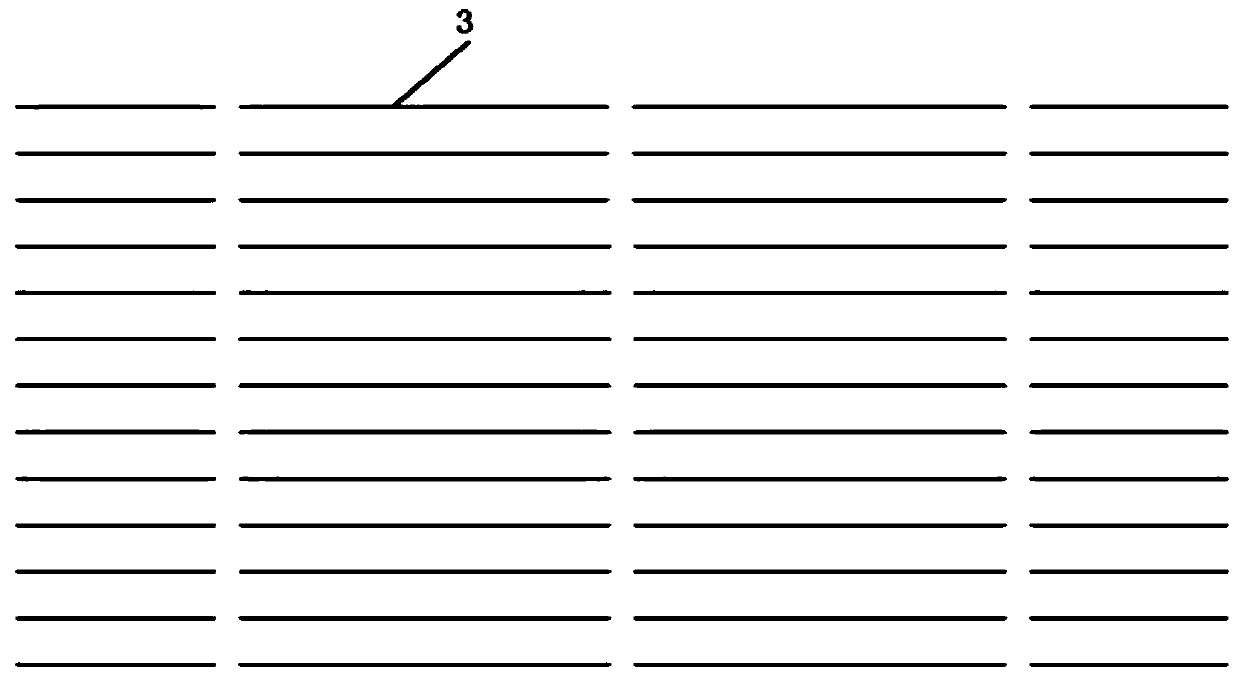

[0083] Then, the fine grid 3 is printed according to the fine grid pattern. The fine grid 3 includes a thin grid line 31 and a thin grid overlapping structure 32 connecting two adjacent thin grid lines 31. The width of the thin grid line 31 is 30 μm. The overlapping structure 32 is V-shaped, the line width of the fine grid overlapping structure is 100 μm, and the paste for printing the fine grid is a burn-through silver paste;

[0084] The co...

Embodiment 2

[0086] Use 158.75*158.75mm size battery;

[0087] On the front of the battery, the busbar 1 is first printed according to the busbar pattern. The busbar 1 includes the busbar 11 in the welding area and the busbar lap structure 12. The width of the busbar 11 in the welding area is 700 μm, and the busbar lap structure 12 It is an isosceles triangle, the side length of the triangle is 722.7μm, and the apex angle is 60°. The paste for printing the busbar is non-burn-through silver paste, and the screen is a 325-mesh screen printing screen;

[0088] Then, the fine grid 3 is printed according to the fine grid pattern. The fine grid 3 includes a thin grid line 31 and a thin grid overlapping structure 32 connecting two adjacent thin grid lines 31. The width of the thin grid line 31 is 30 μm. The overlap structure 32 is groove-shaped, the length of the top edge is 481.8 μm, the angle between the top edge and the waist edge is 120°, and the line width of the fine grid overlap structure ...

Embodiment 3

[0091] Use 161.7*161.7mm size battery;

[0092] On the front side of the battery, firstly, the thin grid 3 is printed according to the thin grid pattern. The thin grid 3 includes thin grid lines 31 and a thin grid overlapping structure 32 connecting two adjacent thin grid lines 31. The width of the thin grid lines 31 is 30 μm, the fine grid overlapping structure 32 is V-shaped, the line width of the fine grid overlapping structure is 100 μm, and the paste for printing the fine grid is a burn-through silver paste;

[0093] Then, the busbar 1 is printed according to the busbar pattern. The busbar 1 includes a busbar line 11 in the welding area and a busbar lap structure 12. The width of the busbar line 11 in the welding area is 700 μm, and the busbar lap structure 12 is an isosceles trapezoid. , the length of the base of the isosceles trapezoid is 736.2μm, the angle between the base and the waist is 60°, the paste for printing the busbar is non-burn-through silver paste, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com