Method for metalizing surface of aluminum nitride ceramic

A technology of aluminum nitride ceramics and surface metals, which is applied in the field of ceramic materials, can solve problems such as difficult mutual integration, low chemical reactivity, and difficulty in metallization of aluminum nitride ceramics, so as to ensure welding strength and reliability, Meet special requirements, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

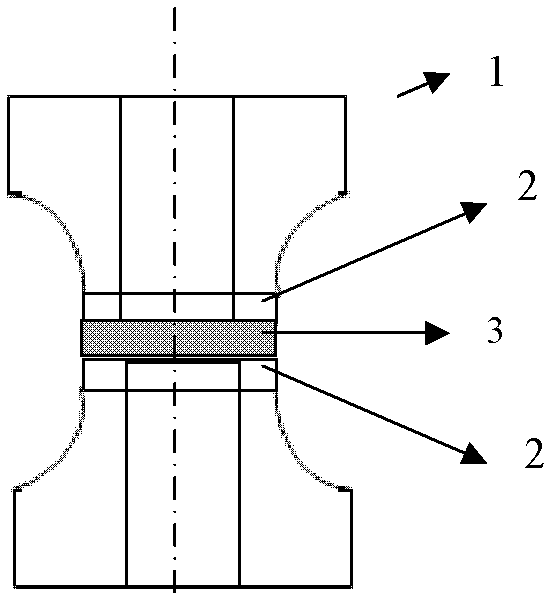

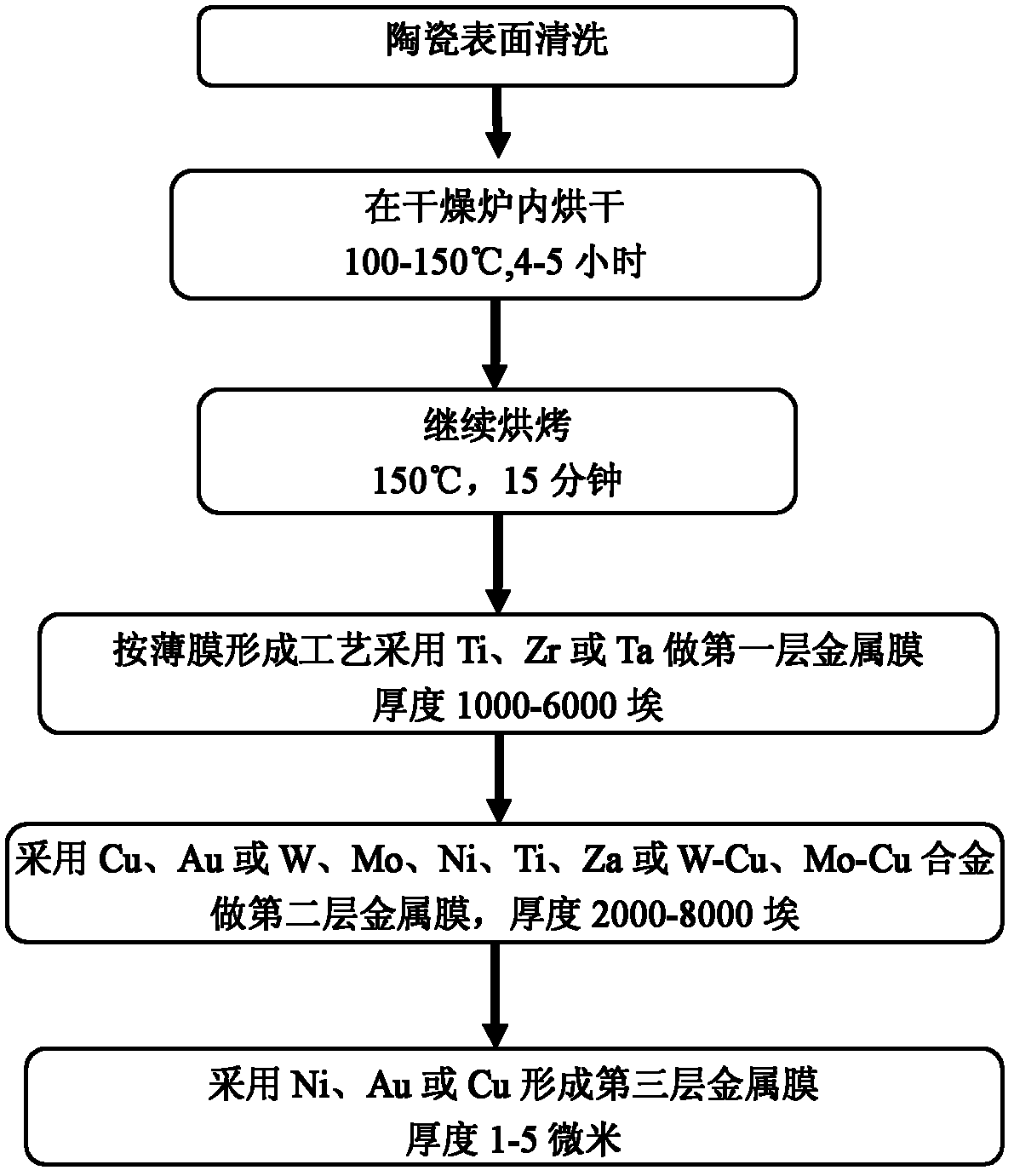

[0020] refer to figure 1 , represents the schematic diagram of the tensile strength test assembly, and 1 in the figure is 95Al 2 o 3 Ceramic standard tensile parts, 2 is a Cu sheet, and the middle part is an aluminum nitride ceramic sheet 3. refer to figure 2 , represents the flow chart of the surface metallization method of aluminum nitride ceramics of the present invention. According to this process operation step, the following examples are given,

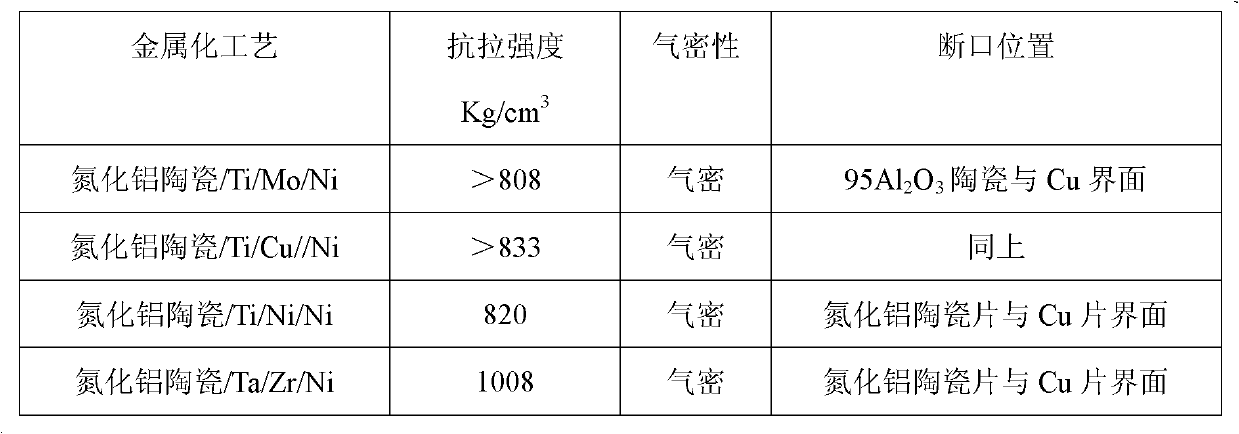

[0021] According to the metallization film layer sequence shown in the table, a multilayer composite metallization film is formed on the surface of the aluminum nitride ceramic sheet by magnetron sputtering coating and electroplating, and then according to figure 1 Structure, using Ag-Cu solder to weld in a high-temperature vacuum furnace to form a combined tensile structure. Use a helium mass spectrometer leak detector to test the air leakage rate of the combined tensile parts, and test the combined anti- Tensile strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com