A high-efficiency photovoltaic heterogeneous ribbon

A photovoltaic and heterogeneous technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as reducing welding stress, reducing welding fastness, reducing stress, etc., and achieves optimization guidance, guarantees welding strength, and reduces welding stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

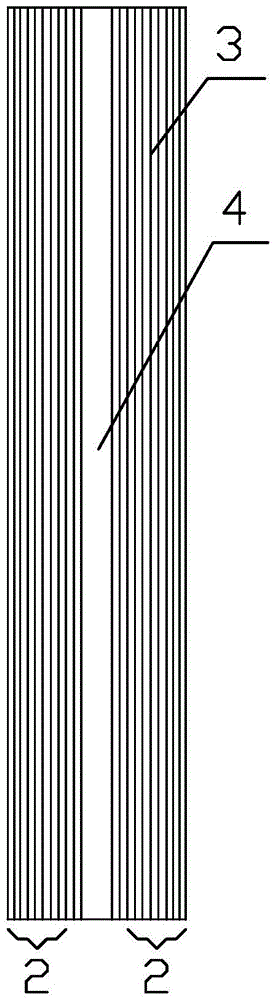

[0049] TU1 oxygen-free copper is selected as the conductive baseband 1, such as figure 1 As shown, there are two groove sets 2 along the length direction of the conductive substrate 1 on one of its wide surfaces, and the two groove sets 2 are respectively arranged on both sides of the wide surface. The V-shaped groove 3 is a linear V-shaped groove in which the intersection line of the two hypotenuses of the groove is a straight line. Of course, it can also be a curved V-shaped groove in which the intersection line of the two hypotenuses of the groove is a curve, etc. other variants.

[0050] A rectangular coupling platform 4 extending along the length direction of the conductive base strip 1 is left between the two groove sets 2. The height of the coupling platform 4 is equal to the highest point of the V-shaped groove 3. The coupling platform 4 The diameter of the largest inscribed circle of the V-shaped groove is 0.1mm; the V-shaped angle of the V-shaped groove is 138°, and...

Embodiment 2

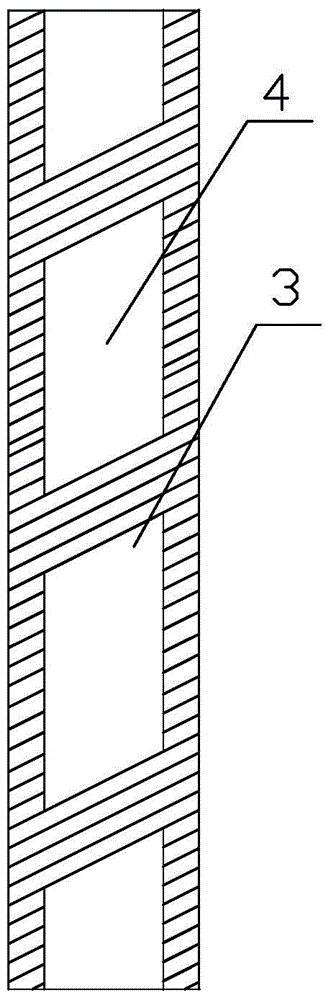

[0057] TU1 oxygen-free copper is selected as the conductive baseband 1, such as figure 2 As shown, there is a set of grooves 2 on one of its wide surfaces, each set of grooves 2 is composed of a plurality of continuous V-shaped grooves 3, and a parallelogram coupling platform 4 is left between different sets of grooves 2, the said The height of the coupling platform 4 is equal to the highest point of the V-shaped groove 3, the diameter of the largest inscribed circle of the coupling platform 4 is 0.5mm, and the maximum length along the length direction of the conductive base strip 1 is 3.0mm; the coupling platform 4 There are V-shaped grooves 3 all around; the V-shaped angle of the V-shaped groove 3 is 75°, the V-shaped groove 3 forms an angle of 30 degrees with the length direction of the conductive base strip 1, and the parallelogram has two sides and the direction of the V-shaped groove 3 Parallel; the depth h of the V-shaped groove 3 is 0.08 mm; the surface area of the ...

Embodiment 3

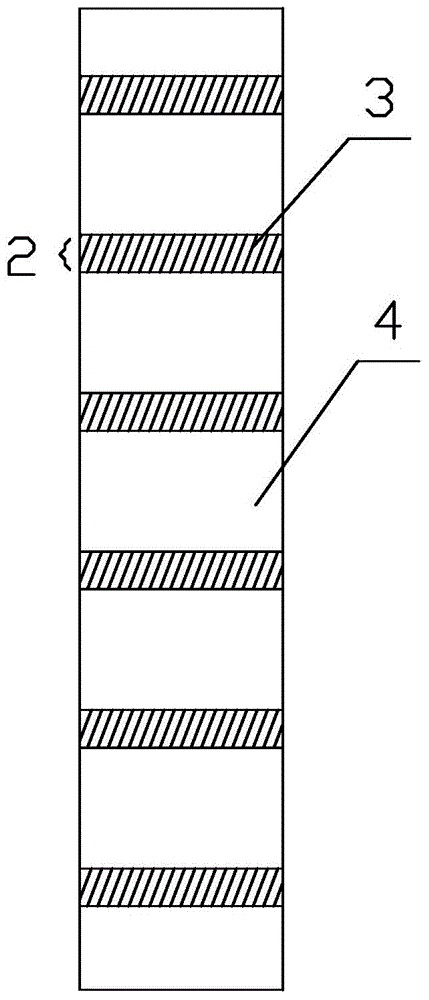

[0064] TU1 oxygen-free copper is selected as the conductive baseband 1, such as image 3 As shown, one wide surface has groove sets 2 arranged at intervals along the length direction of the wide surface, and each groove set 2 is composed of a plurality of continuous V-shaped grooves 3, and parallel gaps are left between different groove sets 2. A quadrilateral coupling platform 4, the length of the coupling platform 4 in the width direction of the wide surface is equal to the width of the wide surface, the width is 1.6 mm, and the diameter of the largest inscribed circle is 0.5 mm, which is smaller than the width of the wide surface where it is located. The maximum length along the length direction of the conductive base strip 1 is 0.5mm; the height of the coupling platform 4 is equal to the highest point of the V-shaped groove 3; the V-shaped angle of the V-shaped groove 3 is 120°, and the V-shaped groove 3 and the conductive base strip The length direction of 1 forms an angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com