Cavity type phase shifter

A phase shifter and cavity-type technology, which is applied to waveguide-type devices, multi-core cable end parts, electrical components, etc., can solve the problem of affecting the phase adjustment function of the phase shifter, increasing the sliding friction force of the medium, and the thermal deformation of the sliding medium. and other problems, to achieve the effect of simple machining boundary, guaranteed welding strength, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

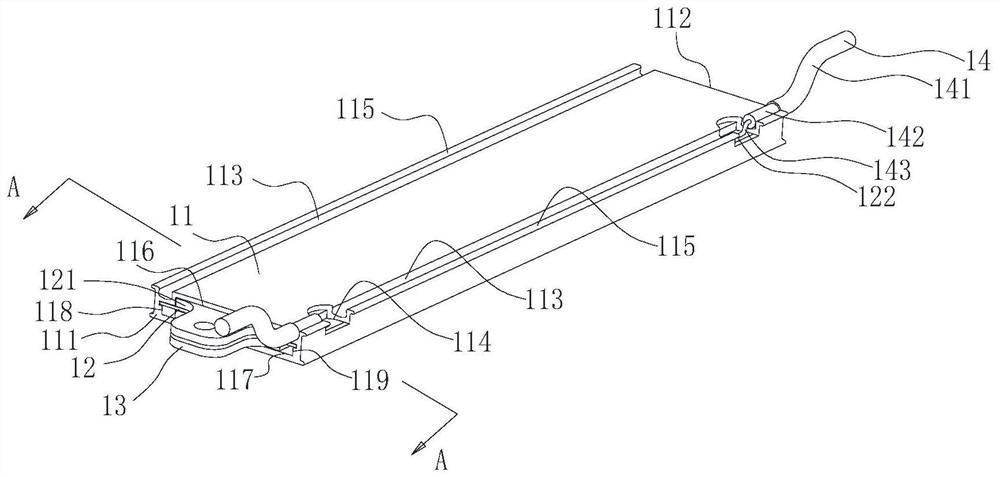

[0049] Please refer to figure 1 The cavity-type phase shifter 1 of the present invention includes a cavity 11, a radio frequency circuit 12 built in the cavity, and a sliding medium 13 attached to the radio frequency circuit and sliding on its surface. In order to better illustrate the structure and principle of the present invention, the present invention also discloses the transmission cable 14 assembled with the phase shifter, and other embodiments can also be described by the transmission cable.

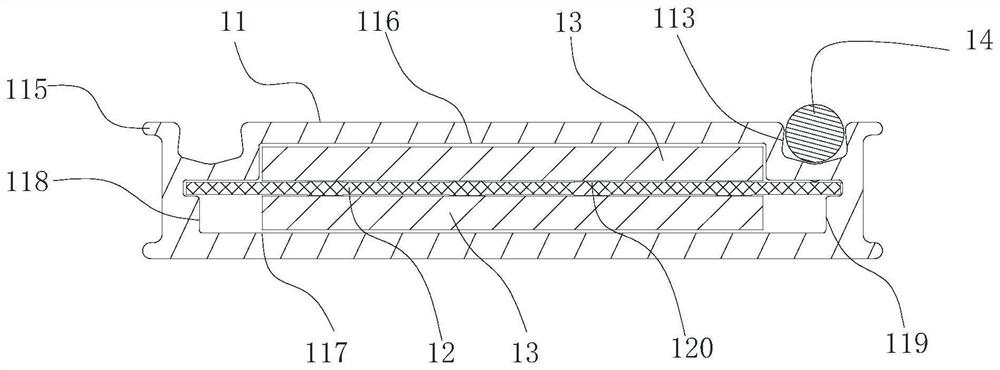

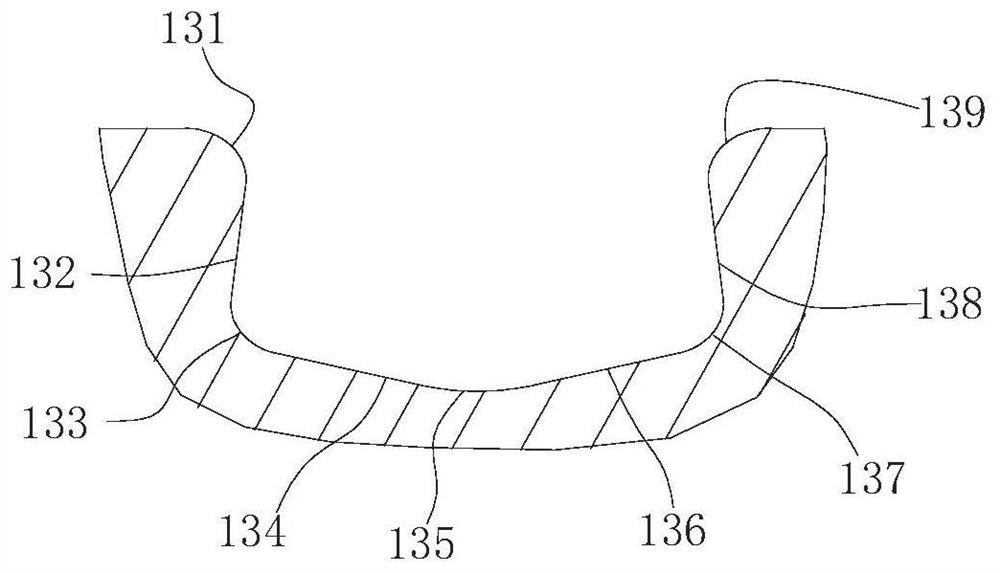

[0050] Please refer to figure 1 , combined with figure 2 , image 3 with Figure 4 , Figure 5 , the cavity 11 is integrally formed by aluminum alloy extrusion or broaching, and the cavity has four sides of the package wall (upper package wall 116, lower package wall 117, left package wall 118 and right package wall 119). The enclosure walls define a cavity (not numbered) for accommodating the radio frequency circuit board and other related components (such as sliding medi...

Embodiment 2

[0060] Please refer to Figure 7 , the cavity type phase shifter of the present invention is a four-port phase shifter 2, including a cavity 21, a radio frequency circuit 22 disposed in the cavity 21, and a sliding medium 23 between the cavity 21 and the radio frequency circuit 22.

[0061] The cavity 21 is integrally formed by extrusion or broaching of aluminum alloy, and a cavity (211, 212) arranged in layers along the upper and lower packaging walls is formed inside the cavity 21 along the longitudinal direction. . The same radio frequency circuit 22 can be set in the upper cavity 211 and the lower cavity 212, so that the four-port phase shifter 2 is suitable for a single-frequency dual-polarized antenna; it can also be provided with different radio frequency circuits 22, so that the phase shifter 2 Suitable for multi-band antennas.

[0062] At least one pair of tongues 215 are provided on the outer side of the cavity 21 on the left and right packaging walls (not labeled)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com