Laser welding system and method

A technology of laser welding and laser devices, applied in the field of mechanical processing, to achieve the effect of ensuring welding reliability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

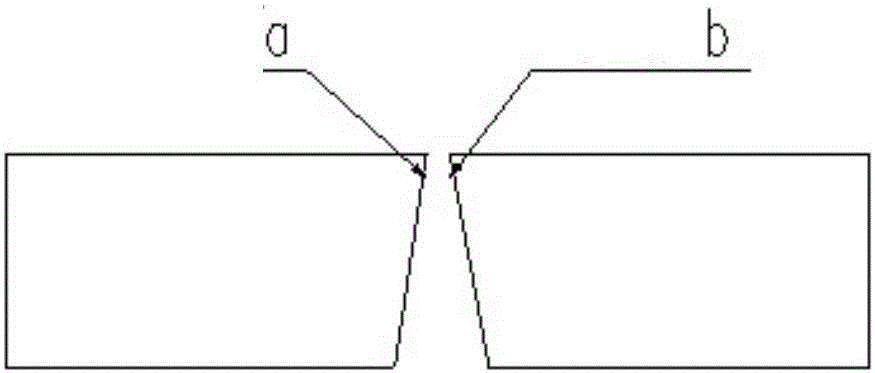

[0042] The laser welding system provided by the embodiment of the present invention is generally as follows Figure 6 As shown in , it includes a laser device 9 , a workpiece positioning device, a servo mechanism, a visual seam optical detection device 10 , and a welding shielding gas channel 7 .

[0043] The laser device 9 is used for welding the first workpiece 1 and the second workpiece 2 . The laser device 9 can be fixed on the fixed plate 12 and driven by the servo motor 11 to move parallelly or vertically above the welding seam along the guide rail 13 relative to the welding seam. The laser device 9 includes a laser head and a focusing lens arranged in front of the laser head.

[0044] The workpiece positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com