Clamp device for machining large-sized thin-walled impeller and finish machining method of large-sized thin-walled impeller

The technology of a fixture device and an impeller, which is applied in the direction of clamping device, positioning device, manufacturing tool, etc., can solve the problems of inaccurate positioning, reduced machining accuracy, and reduced machining accuracy, so as to improve the positioning quality, avoid direct damage, The effect of improving surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

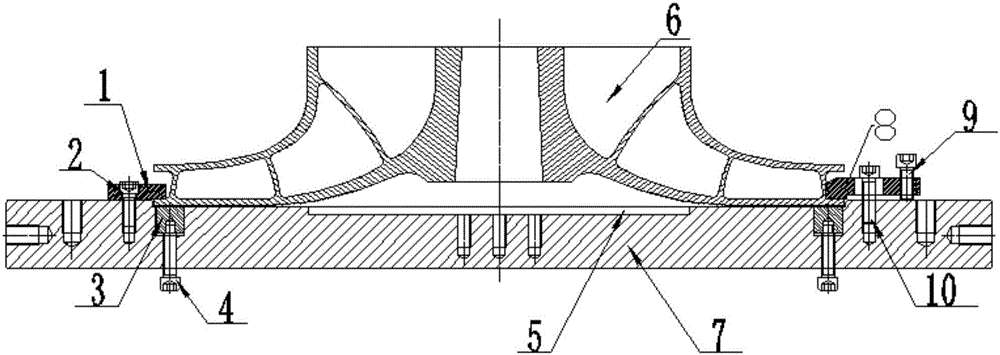

[0054] The fixture device for large-scale thin-walled impeller machining includes a base plate 7, on the upper surface of the base plate 7 there are two first and second recesses for clamping the end face of the impeller, because one end face of the impeller 6 is large and the other is small, Therefore, the first recess and the second recess are figure 1 The large positioning circle 13 and the small positioning circle 5 are movable on the working surface of the bottom plate 7. A plurality of pressing blocks 8 are used as the first pressing parts and a plurality of positioning blocks 1 are used as the positioning parts. The positioning blocks realize the alignment of the impeller. The positioning of the processing reference, the processing reference is the inner surface of the lower blade of the impeller, which can realize rapid positioning, the pressing block 8 can be rotatably fixed on the bottom plate 7, and when the small positioning circle 5 is matched with the second round...

Embodiment 2

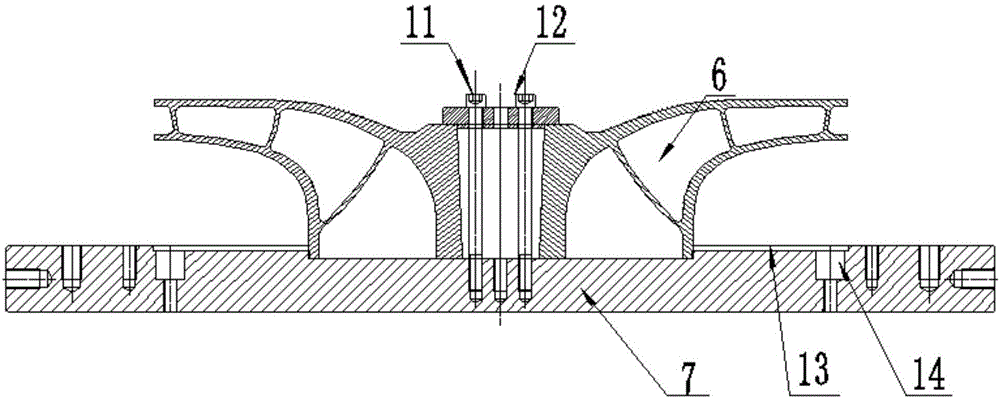

[0060] The fixture device for machining large thin-walled impellers includes a bottom plate. The working surface of the bottom plate is provided with a concave part. The concave part is matched with the working surface where the large round surface of the impeller end is located. The edge of the concave part is provided for locking the first round surface of the impeller end to the bottom plate. The first pressing part is detachably provided on the working surface of the bottom plate for locking the second round surface of the impeller end to the bottom plate. The second pressing part is provided with the second pressing part.

[0061] This solution omits the second recess in the first solution, which can also satisfy the rapid positioning of the impeller. At this time, the fastening plate in the second pressing part is preferably fastened by the bolts arranged in a triangle, so as to improve stability sex.

[0062] Other structures in this embodiment are the same as those in ...

Embodiment 3

[0064] A method for finishing a large thin-walled impeller, the specific steps are as follows:

[0065] 1. Fix the bottom plate 7 on the workbench of the machine tool and align it;

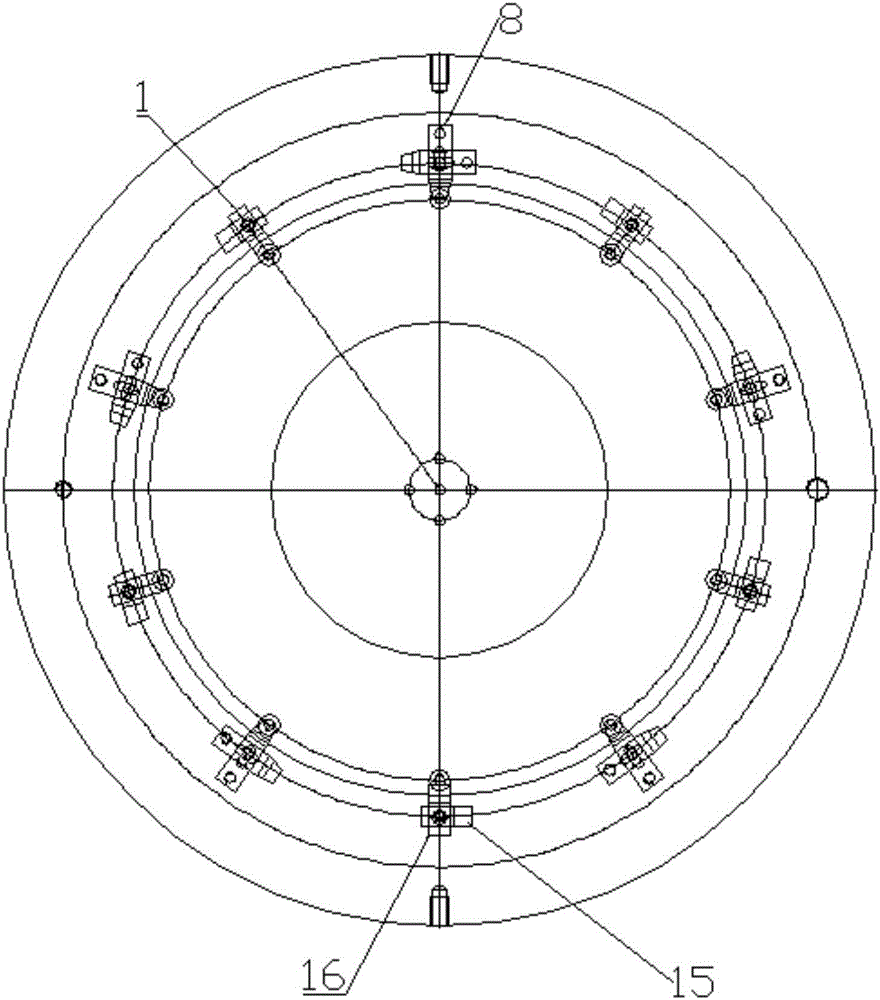

[0066] 2. Clean up the adjustment block groove 14, place the adjustment block 3 in the adjustment block groove 14, and adjust the positioning block 1 and the pressing block 8 to the open position 15;

[0067] 3. Clean the burrs on the bottom surface of the impeller 6, and place the large round bottom surface of the impeller 6 after rough turning in the large positioning circle 13;

[0068] 4. Adjust the positioning block 1 to the closed position 16, and then tighten the corresponding adjusting bolt 4 upwards, so that each adjustment block 3 is in contact with the lower blade of the impeller, and the positioning block is in close contact with the reference surface of the impeller;

[0069] 5. Adjust the compression block 8 to the closed position, then tighten the corresponding adjustment bolt 4 up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com