Multi-pole buffering receiving machine for anode vertical formworks

A receiver and vertical mold technology, applied in the field of anode vertical mold multi-pole buffer receivers, can solve problems such as easy generation of safety, hidden dangers, unfavorable processing, etc., and achieve the effects of improving efficiency, reducing labor intensity, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

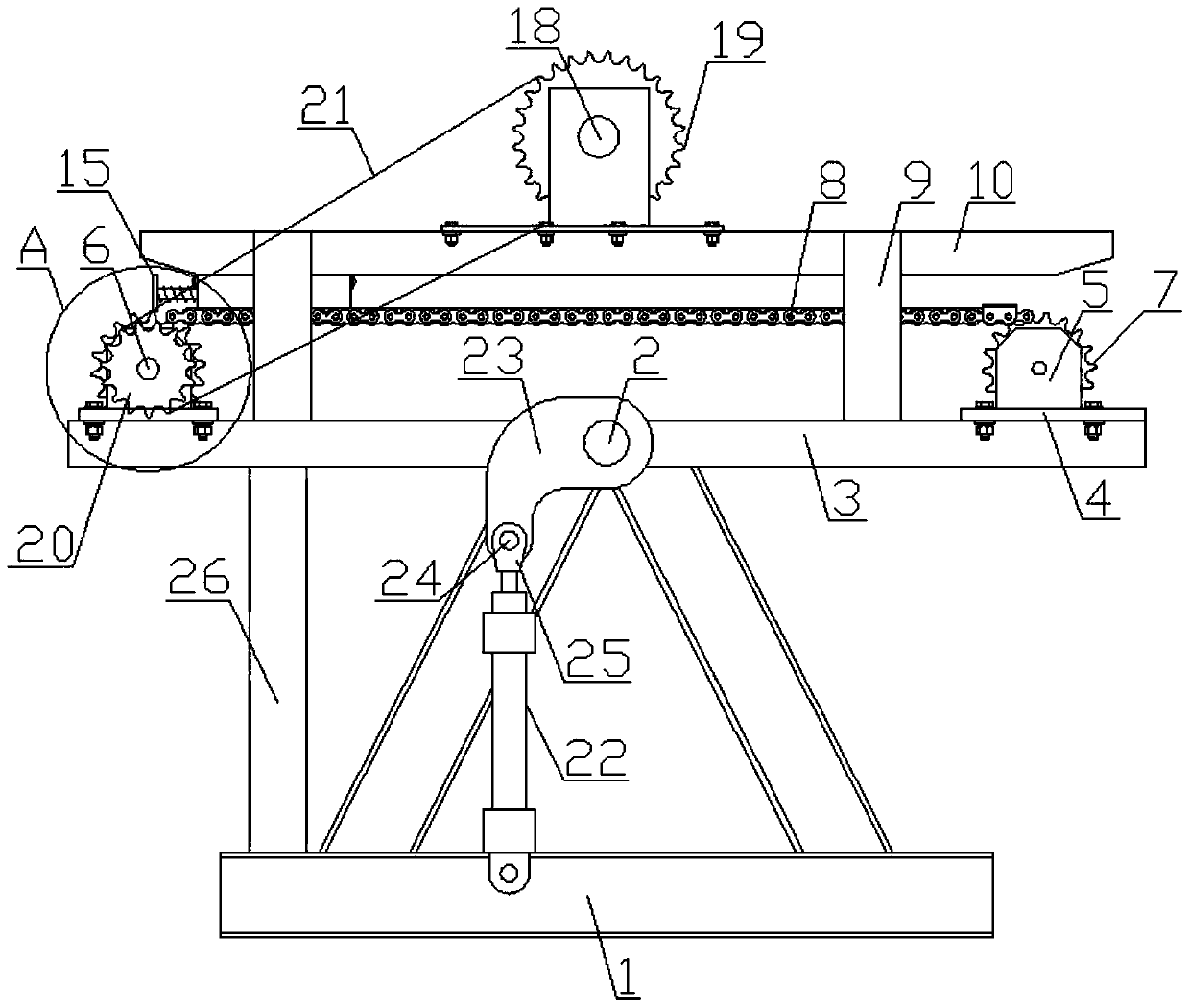

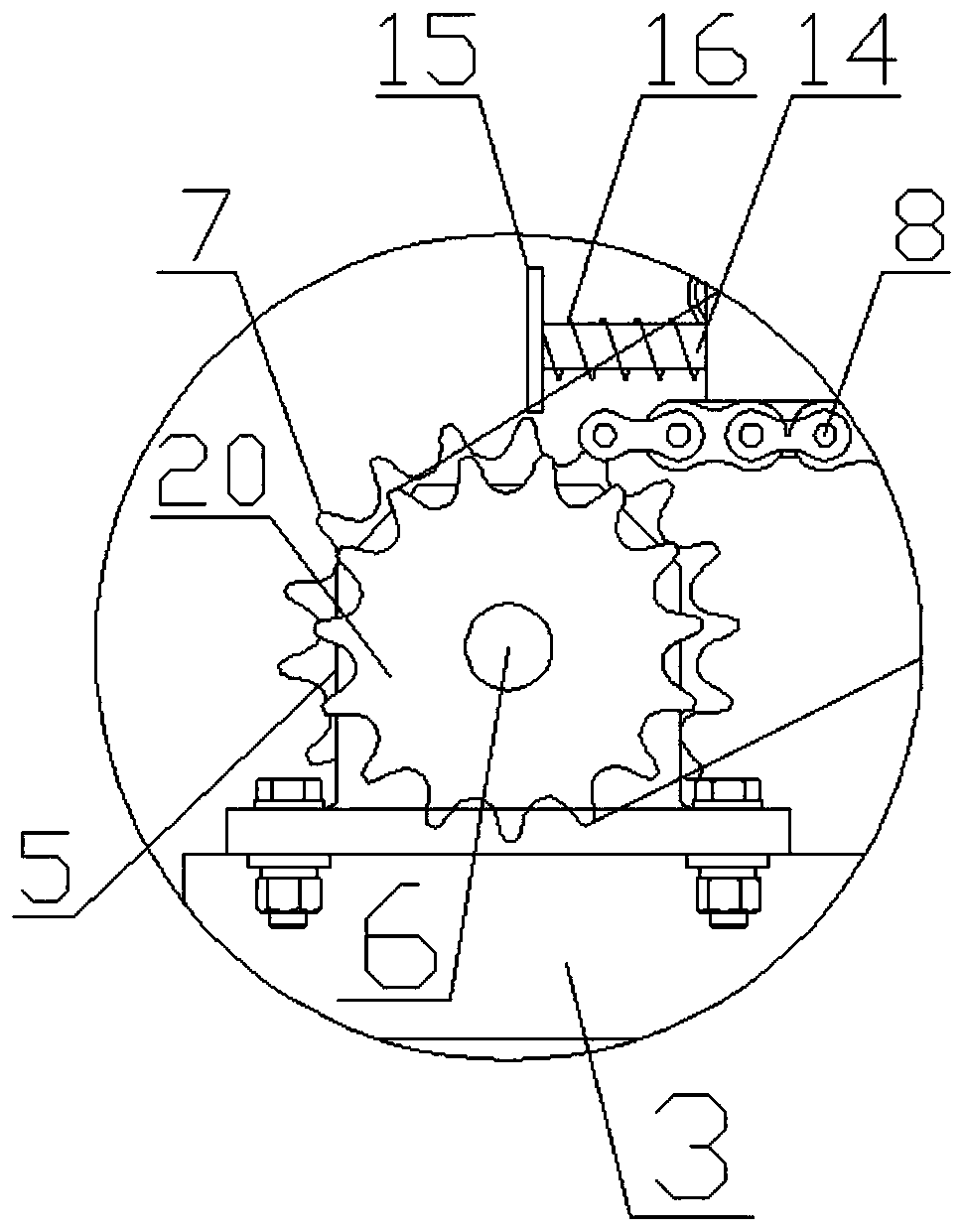

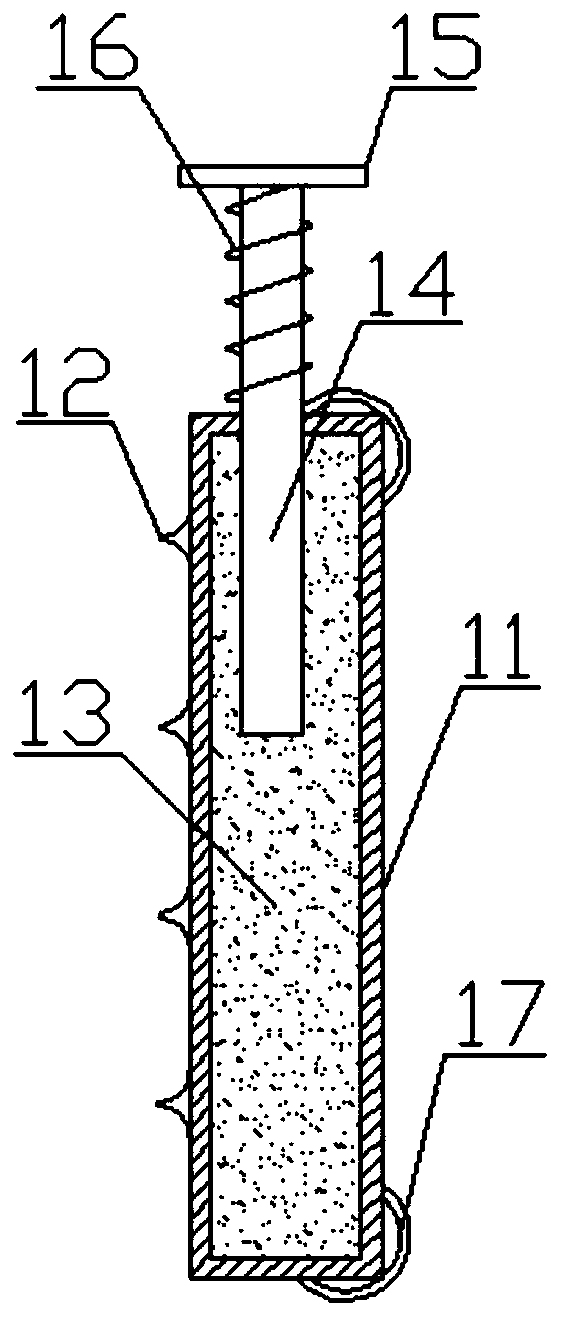

[0020] Basic as attached Figure 1 to Figure 3 Shown: the anode vertical mold multi-pole buffer receiver, including frame 1, and frame 1 is composed of three channel steel welded in pairs to form a triangle. The top of the frame 1 is rotatably connected with one end passing through the first rotating shaft 2 of the frame 1. The first rotating shaft 2 is covered with a support plate 3 located on the rear side of the frame 1. The left and right sides of the support plate 3 are bolted. Connected with a base plate 4, each base plate 4 is integrally formed with a fixed plate 5 with a cross-sectional shape of a "several" shape. The fixed plate 5 is rotatably connected with a second rotating shaft 6, and the second rotating shaft 6 is covered with a second rotating shaft. A sprocket 7, a first chain 8 is stretched between the two first sprockets 7. The left and right sides of the support plate 3 are welded with four rectangular fixed frames 9 symmetrically. The fixed frame 9 adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com