Mine-used automatic high-pressure washing camera device and its monitoring method

A technology of high-pressure flushing and camera device, applied in the direction of cleaning method using gas flow, cleaning method using liquid, cleaning method and utensils, etc., can solve the problems affecting mine monitoring and management, failure of mechanical joints, complex working conditions, etc. , to achieve the effect of improving cleanliness and clarity, extending protection length and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

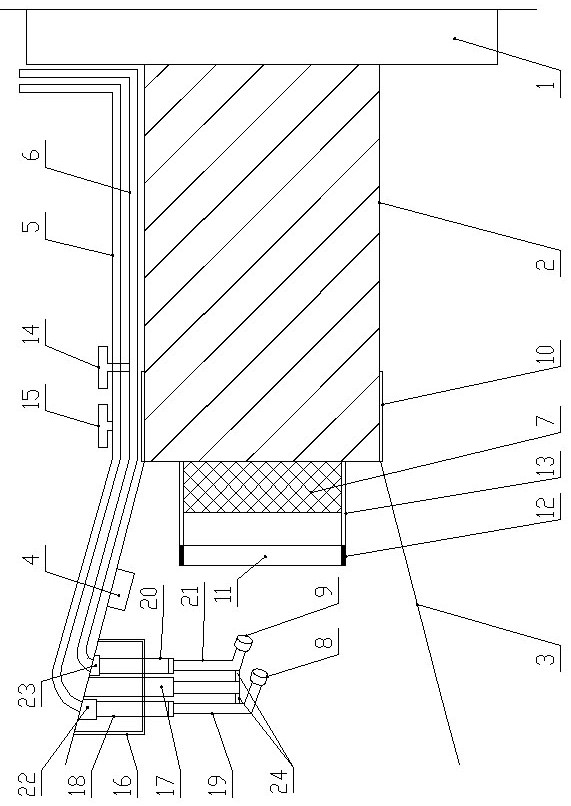

[0020] Such as figure 1 As shown, the mining automatic high-pressure flushing camera device of the present invention includes a base 1, a camera 2, a conical cover 3, a dust induction identifier 4, a controller, a high-pressure airflow hose 5, a high-pressure water flow hose 6 and a telescopic The nozzle mechanism, the camera 2 is installed on the left side of the base 1, the conical cover 3 is thin on the right and thick on the left, the right end of the conical cover 3 is connected with the left end of the shell of the camera 2, and the camera lens 7 on the left side of the camera 2 is located in the conical cover 3 , the left side of the camera lens 7 is provided with a dust-proof transparent component, and the dust induction recognizer 4 is arranged inside the conical cover 3 and is used to monitor the dust attached to the left surface of the dust-proof transparent component, and the telescopic nozzle mechanism is arranged on the conical cover 3. The top on the left side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com