Monitoring camera mounting system

A monitoring camera and installation system technology, which is applied in the field of monitoring cameras, can solve problems such as shortening the service life of equipment, cumbersome operation procedures, and corrosion of support columns, and achieves simplified installation and disassembly procedures, firm fixing process, and a wide range of installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

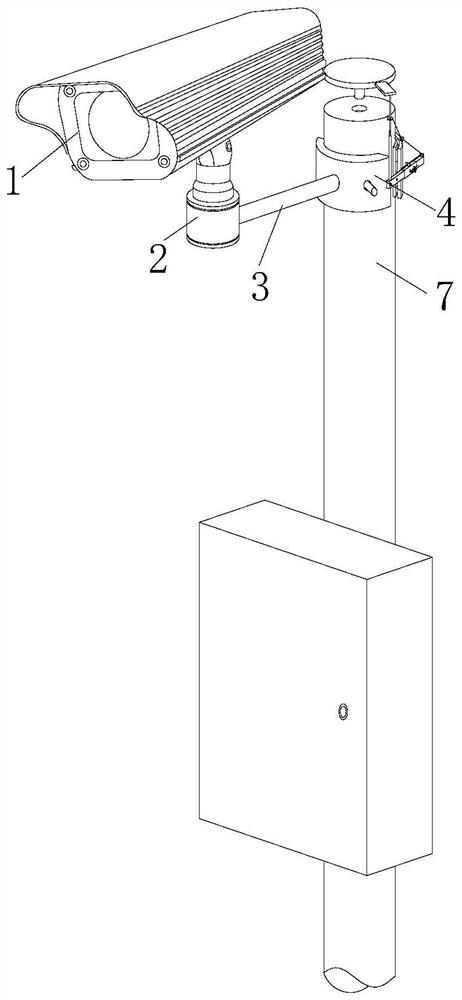

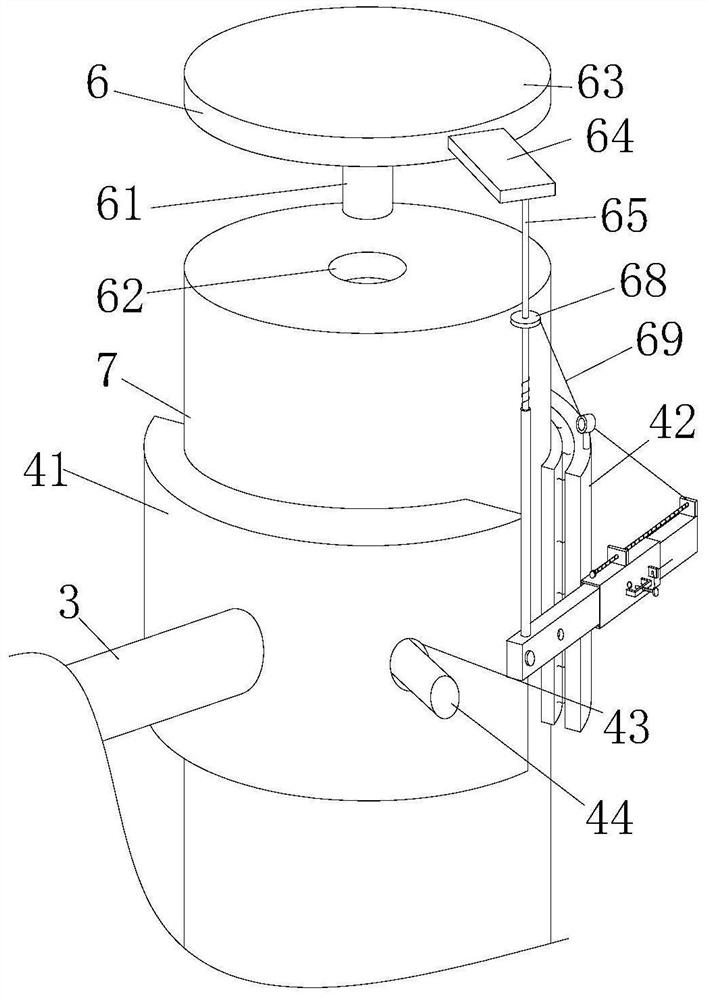

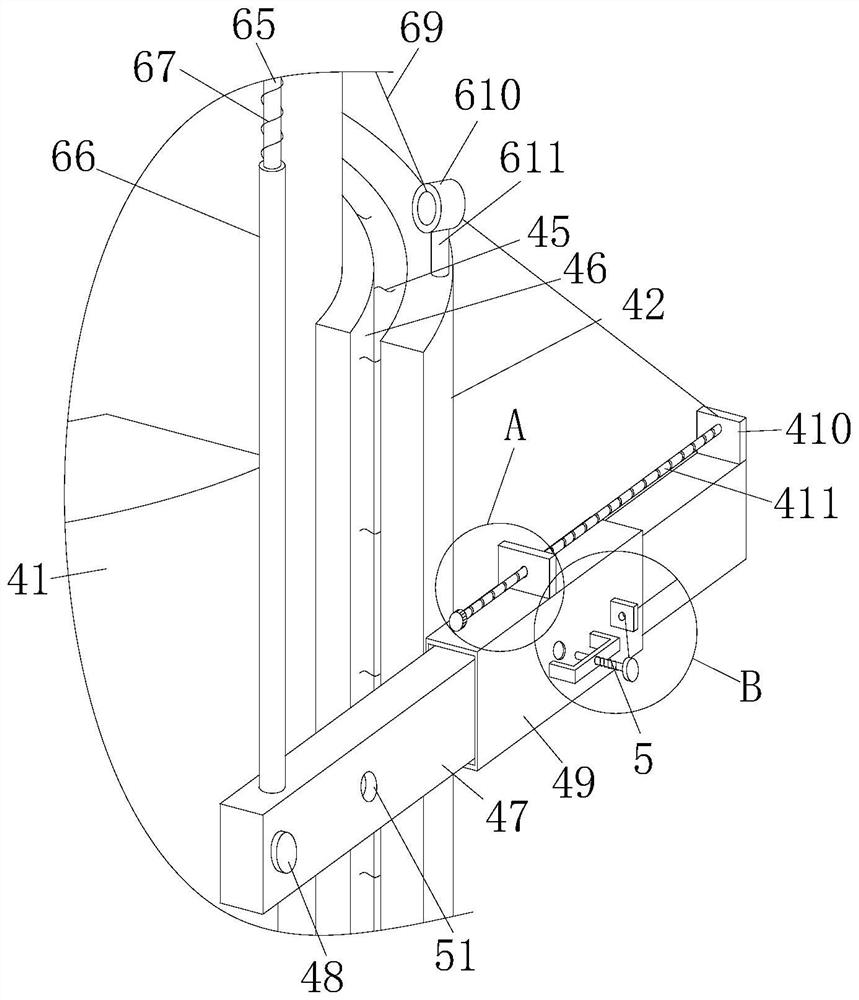

[0030] Attached below Figure 1-5 The present invention is further described with embodiment:

[0031] A monitoring camera installation system, comprising a monitoring camera body 1, a supporting rotating base 2 and a fixed connecting rod 3, the monitoring camera body 1 is arranged on the supporting rotating base 2, and the side wall of the supporting rotating base 2 is fixedly connected with Fix the connecting rod 3, the free end of the fixed connecting rod 3 is fixedly connected on the fixing mechanism 4, and the fixing mechanism 4 is detachably arranged outside the fixed support column 7, by optimizing the fixing method of the existing monitoring camera body 1 in the present invention, Specifically, the monitoring camera body 1 is fixedly arranged on the fixed support column 7 by avoiding punching holes, which can effectively avoid direct damage to the fixed support column 7, thereby making the service life of the equipment high and long, and the optimized fixed structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com