Aqueous demolding agent and preparation method thereof

A release agent, water-based technology, applied in the field of water-based release agent and its preparation, can solve the problems of affecting concrete cohesion, affecting the quality of the project, and existing safety hazards, etc., achieving low pollution, low dosage, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

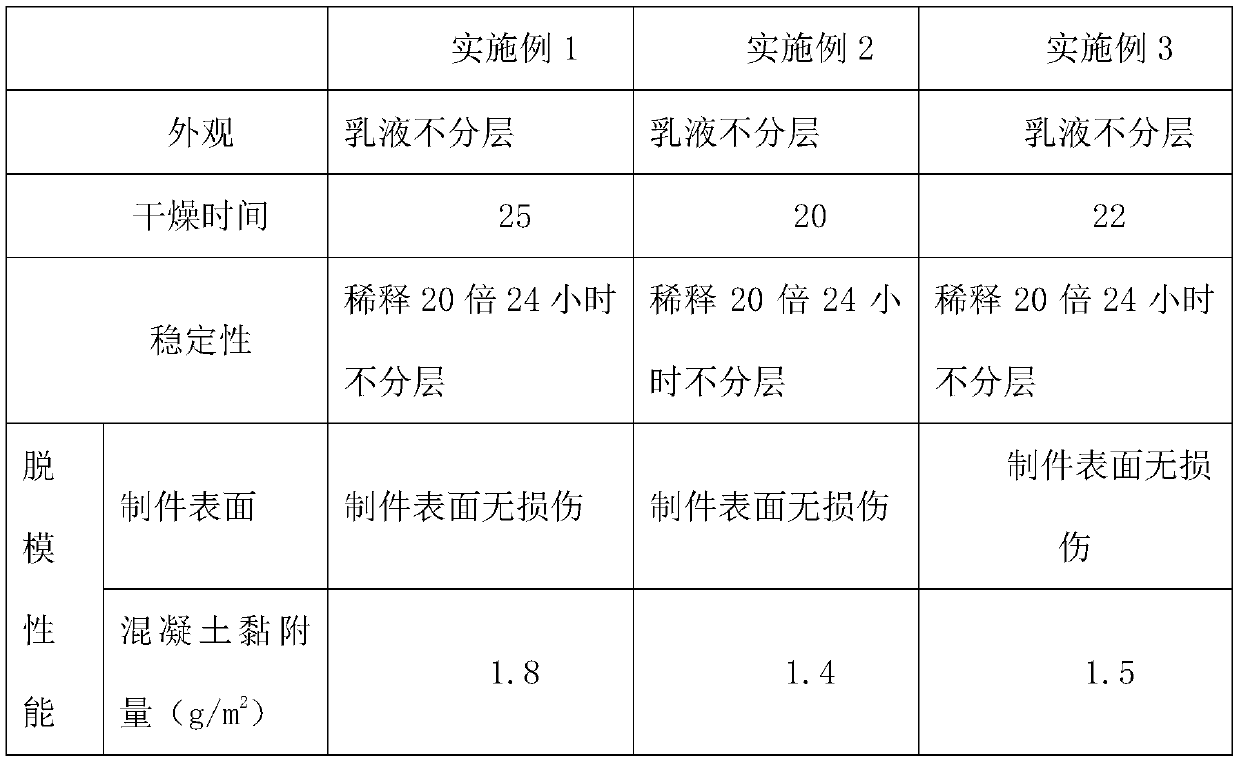

Examples

Embodiment 1

[0019] A water-based release agent, its raw materials are calculated as follows by weight: 40 parts of oil, 10 parts of film-forming material, 10 parts of emulsifier, 5 parts of auxiliary agent, 0.3 part of stabilizer, 0.5 part of antirust agent, and 0.2 part of preservative , 100 parts of water, the emulsification temperature is 70°C, and the rotation speed is 1000 rpm.

[0020] The oil is one or more of soybean oil, rapeseed oil and machine oil. The film-forming substance is one or more of polyvinyl alcohol, polyvinyl acetate, polyvinyl formal glue, and polyacrylate copolymer. Described emulsifier is Span 60, Span 80, Tween 60, Tween 80, polyoxyethylene alkylphenol ether, polyethylene glycol 400, polyethylene glycol 600, fatty alcohol polyoxyethylene ether, fatty alcohol One or more mixtures of sodium sulfate, SDBS, K12. The auxiliary agent is one or more of liquid paraffin, simethicone, isopropanol, ethylene glycol, and ethanol. The stabilizer is one or more of cellulose...

Embodiment 2

[0026] A water-based release agent, its raw materials are calculated as follows in parts by weight: 40 parts of oil, 5 parts of film-forming substance, 12 parts of emulsifier, 10 parts of auxiliary agent, 0.3 part of stabilizer, 0.5 part of antirust agent, and 0.2 part of preservative , 100 parts of water.

[0027] The oil is one or more of soybean oil, rapeseed oil and machine oil. The film-forming substance is one or more of polyvinyl alcohol, polyvinyl acetate, polyvinyl formal glue, and polyacrylate copolymer. Described emulsifier is Span 60, Span 80, Tween 60, Tween 80, polyoxyethylene alkylphenol ether, polyethylene glycol 400, polyethylene glycol 600, fatty alcohol polyoxyethylene ether, fatty alcohol One or more mixtures of sodium sulfate, SDBS, K12. The auxiliary agent is one or more of liquid paraffin, simethicone, isopropanol, ethylene glycol, and ethanol. The stabilizer is one or more of cellulose ether, polyvinyl alcohol, polyacrylamide, xanthan gum, sodium alg...

Embodiment 3

[0033] A water-based release agent, its raw materials are calculated as follows by weight: 40 parts of oil, 15 parts of film-forming substance, 6 parts of emulsifier, 20 parts of auxiliary agent, 0.3 part of stabilizer, 0.5 part of antirust agent, and 0.2 part of preservative , 120 parts of water.

[0034] The oil is one or more of soybean oil, rapeseed oil and machine oil. The film-forming substance is one or more of polyvinyl alcohol, polyvinyl acetate, polyvinyl formal glue, and polyacrylate copolymer. Described emulsifier is Span 60, Span 80, Tween 60, Tween 80, polyoxyethylene alkylphenol ether, polyethylene glycol 400, polyethylene glycol 600, fatty alcohol polyoxyethylene ether, fatty alcohol One or more mixtures of sodium sulfate, SDBS, K12. The auxiliary agent is one or more of liquid paraffin, simethicone, isopropanol, ethylene glycol, and ethanol. The stabilizer is one or more of cellulose ether, polyvinyl alcohol, polyacrylamide, xanthan gum, sodium alginate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com