Titanium dioxide acidolysis tail gas treatment method

A technology for exhaust gas treatment and titanic acid. It is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve problems such as affecting the health of employees, polluting the operating environment, and the inability of instantaneous cooling of flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

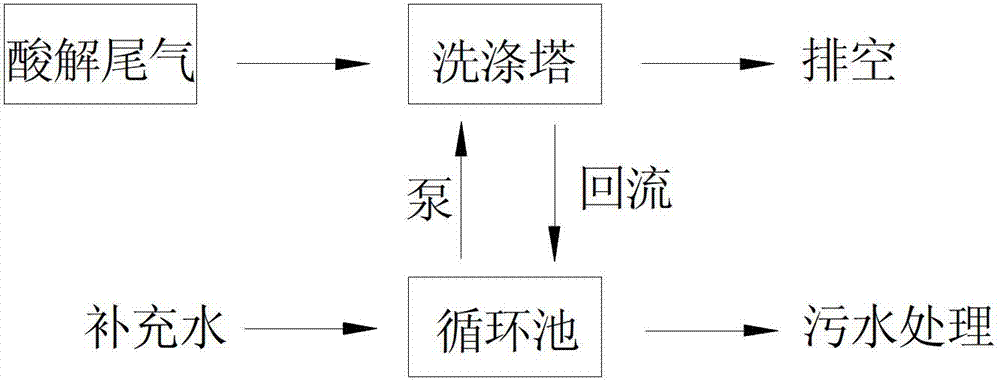

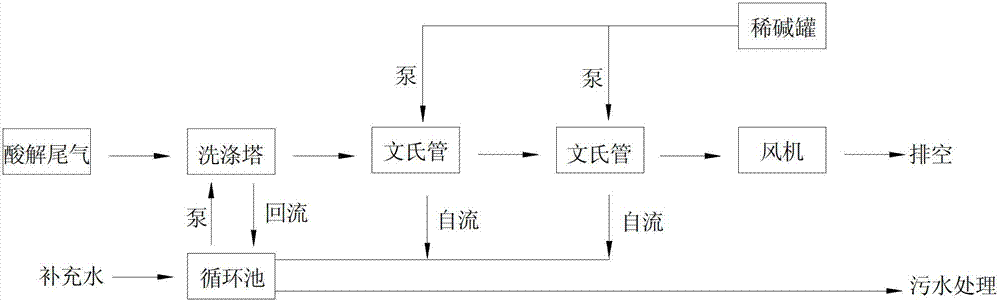

[0018] Such as figure 2 In the process flow chart shown, the high-temperature acidolysis tail gas produced by the sulfuric acid titanium dioxide process enters the scrubber, and the absorption liquid is pumped from the circulation pool to the scrubber to generate atomized contact with the tail gas, absorbing part of sulfur dioxide and most of the sulfuric acid mist. The temperature of the acidolysis tail gas after being washed by the washing tower is 0-90°C, the temperature of the absorption liquid is 0-45°C, and the liquid-gas ratio in the washing tower is 1:1-1.5L / m 3 The exhaust gas after washing is passed into the secondary venturi tube. At the same time, the pump extracts dilute alkali with a concentration of 2-10% from the dilute alkali tank to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com