Dust removal process and system for trichlorosilane production

A trichlorosilane, dust removal system technology, applied in the direction of halosilane, halide silicon compounds, etc., can solve problems such as condenser blockage, achieve the effect of reducing load and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

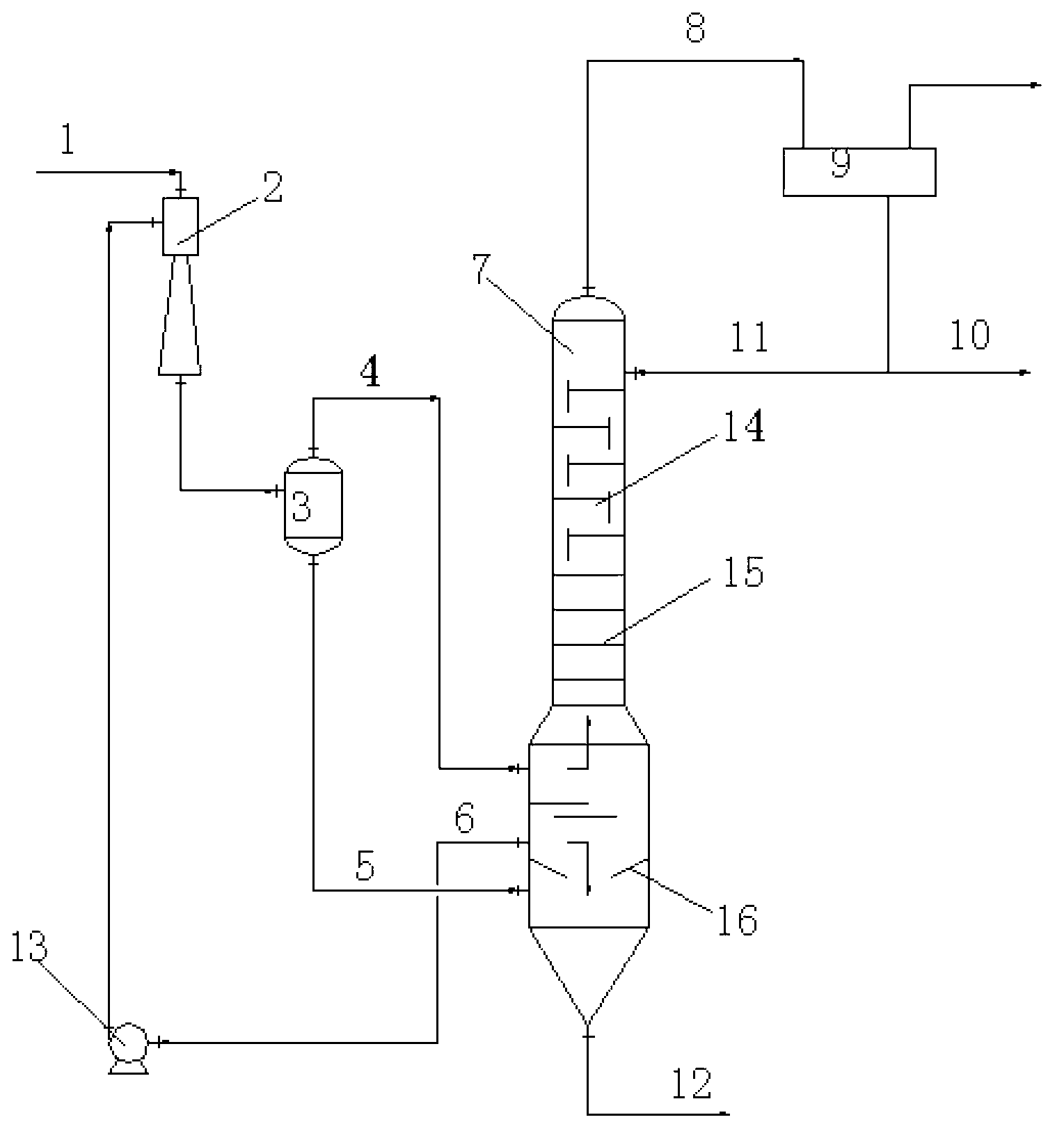

[0021] In order to further understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the dust-containing reaction gas 1 from the fluidized bed enters the Venturi scrubber 2 after cyclone dust removal or heat recovery, and at the same time, the circulation pump 13 sends the liquid from the washing tower 7 to the Venturi scrubber 2 to complete the reaction Preliminary scrubbing of gases. After being washed by the Venturi scrubber 2, the silicon powder with larger particles in the gas is removed, and the temperature of the reaction gas is lowered at the same time. The gas-liquid two-phase after washing is separated in the gas-liquid separation tank 3, the gas 4 enters the scrubber 7 from the gas inlet at the bottom of the scrubber 7, and the liquid 5 enters the scrubber 7 from the liquid inlet at the bottom of the scrubber 7. The gas 4 entering the washing tower 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com