Liquid-phase dust removing system and liquid-phase dust removing method of pyrolysis coke-oven gas

A dust removal system and raw gas technology, which is applied in the field of coal chemical industry, can solve the problems of inability to run for a long time, high cost of filter tubes, high equipment requirements, etc., and achieve stable and reliable dust removal effect, simple dust removal method, and simple system design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

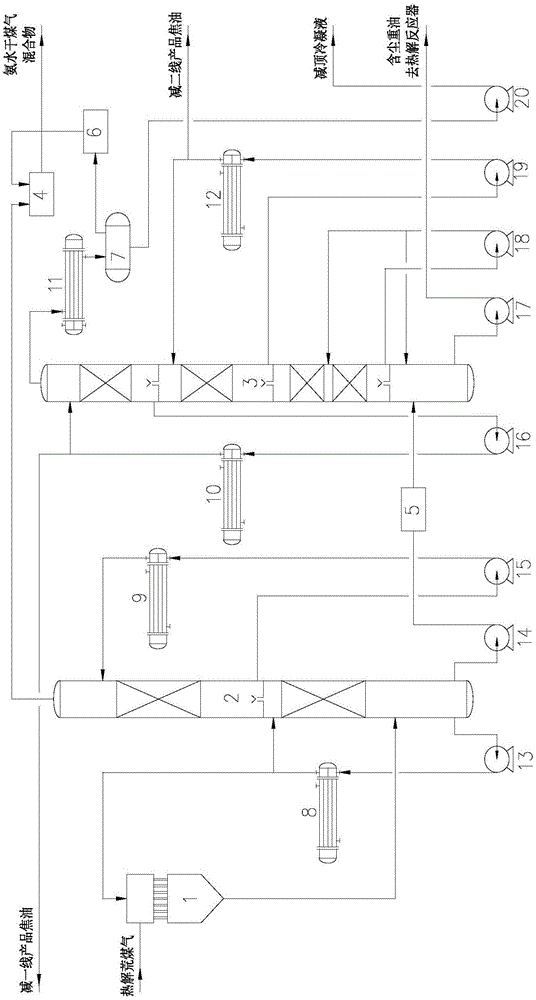

[0025] by figure 1 It can be seen that the liquid phase dust removal system of pyrolysis raw gas in this embodiment is composed of Venturi scrubber 1, tar heat exchanger 2, oil washing tower 3, pressurizing circulating pump 4, dust-containing tar pump 5, oil washing circulating pump 6. Oil washing heat exchanger 7, heating furnace 8, minus one-line circulating pump 9, minus one heat exchanger 10, decompression tower 11, condenser 12, ammonia scrubber 13, reducing roof buffer tank 14, vacuum pump 15, reducing The second heat exchanger 16, the dust-containing heavy oil circulating pump 17, the super-vaporized oil pressurizing pump 18, the reduced second line circulating pump 19, and the reduced top circulating pump 20 are connected by pipelines.

[0026] Specifically: the venturi scrubber 1 of this embodiment is a common device, which uses atomized tar to cool high-temperature raw gas and form dust-containing washing oil and gas, which includes an air inlet, a washing liquid inlet,...

Embodiment 2

[0035] The dust removal system for waste gas in this embodiment is the same as that in Embodiment 1. The method of using this system to remove waste gas from pyrolysis gas is realized by the following steps:

[0036] (1) The pyrolyzed high-temperature raw gas is cooled by the sprayed tar in the Venturi scrubber 1 and atomized to form dust-containing washing oil and gas, and then enters the oil washing tower 3 for oil washing;

[0037] (2) Dust-containing washing oil and coal gas from the bottom of the oil washing tower 3 enter the tower for circulating cooling and dust washing, so that the tar and dust in the raw gas are condensed into the washing oil, and the dry gas is separated, and the temperature of the tower kettle is controlled to 200℃. The tower kettle wash oil is pressurized by the pressurizing circulating pump 4 and cooled to 160°C by the tar heat exchanger 2, part of it goes to the Venturi scrubber 1 as the washing liquid, and the other part enters the tower kettle throug...

Embodiment 3

[0040] The dust removal system for waste gas in this embodiment is the same as that in Embodiment 1. The method of using this system to remove waste gas from pyrolysis gas is realized by the following steps:

[0041] (1) The pyrolyzed high-temperature raw gas is cooled by the sprayed tar in the Venturi scrubber 1 and atomized to form dusty washing oil and gas, and then enters the oil washing tower 3 for oil washing;

[0042] (2) Dust-containing washing oil and coal gas from the bottom of the oil washing tower 3 enter the tower for circulating cooling and dust washing, condensing the tar and dust in the raw gas into the washing oil, separating the dry gas, and controlling the temperature of the tower kettle to 220℃, After the tower kettle wash oil is pressurized by the pressurizing circulating pump 4 and cooled to 180℃ through the tar heat exchanger 2, part of it goes to the Venturi scrubber 1 as the washing liquid, and the other part enters the tower kettle through the tower reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com