Split self-suction type Venturi tube washer

A Venturi tube and self-priming technology, which is applied in the field of scrubbers, can solve the problems of unusable Venturi tube, complex structure, large pressure head loss, etc., and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described below in conjunction with accompanying drawing

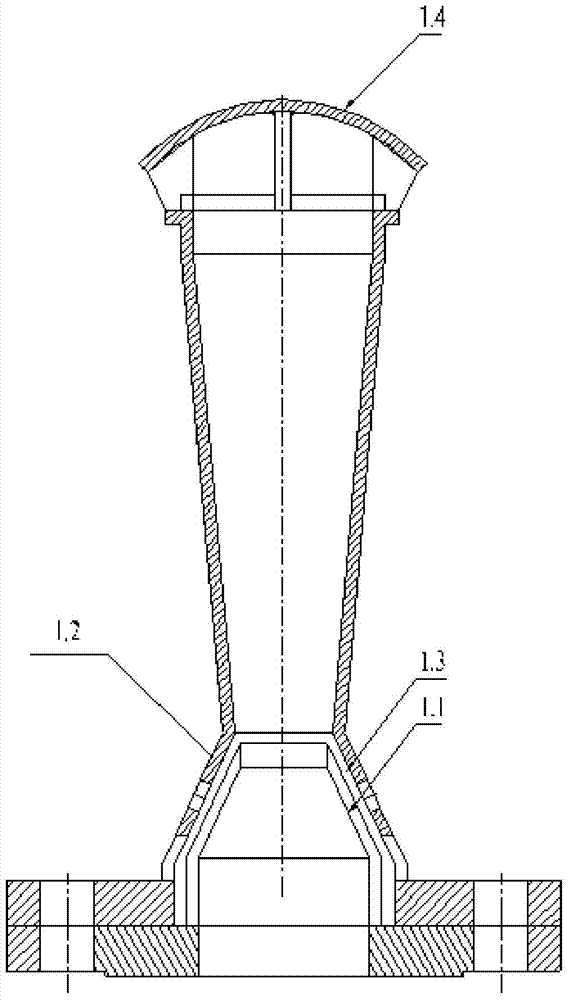

[0035] figure 1 Shown is a schematic diagram of the overall structure of the split self-priming Venturi tube scrubber. The conical independent shrinkage section 1.1 and the integrated outer sleeve 1.2 are coaxially assembled by bolts. During operation, the spacing of the annular liquid flow channel 1.3 can be adjusted by changing the thickness or the number of the gaskets. The outlet baffle 1.4 and the integrated outer casing 1.2 are connected by welding through the support rib 1.42. The thickness of the support rib 1.42 should be as small as possible under the premise of ensuring the strength. At the same time, the windward side of the support rib 1.42 adopts a streamline design, In order to reduce the flow resistance of gas at the outlet, the height value depends on the outlet design flow rate.

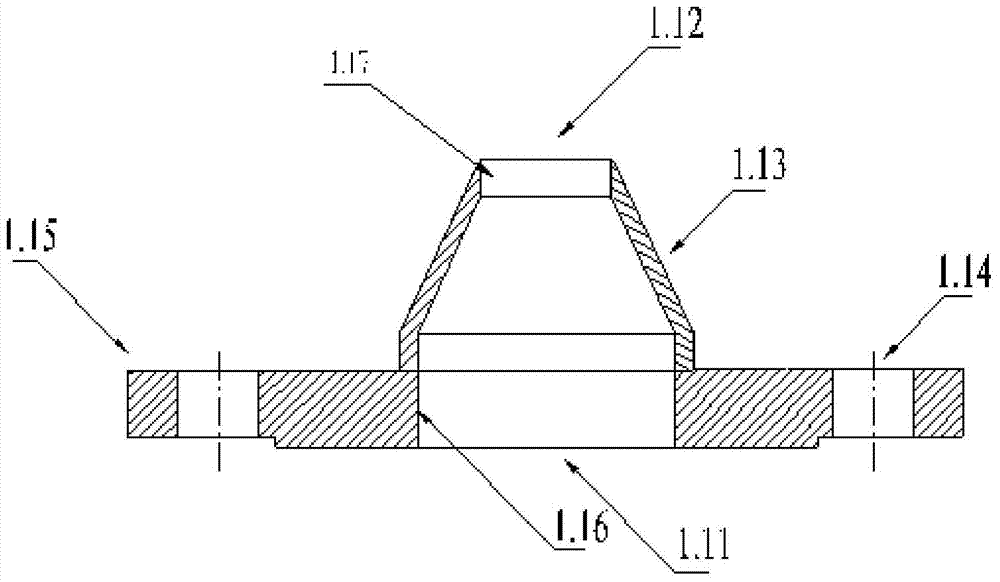

[0036] figure 2 Shown is a schematic diagram of the structure of the conical inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com