Dust growing combined dust removal and demisting integrated device of desulfurization tower

A desulfurization tower and dust technology, which is applied in the fields of combined devices, gas treatment, chemical instruments and methods, etc., can solve the problems of difficult to remove fine dust and gypsum droplets, eliminate the phenomenon of gypsum rain, reduce the amount of gypsum carried, and improve synergy The effect of dust removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

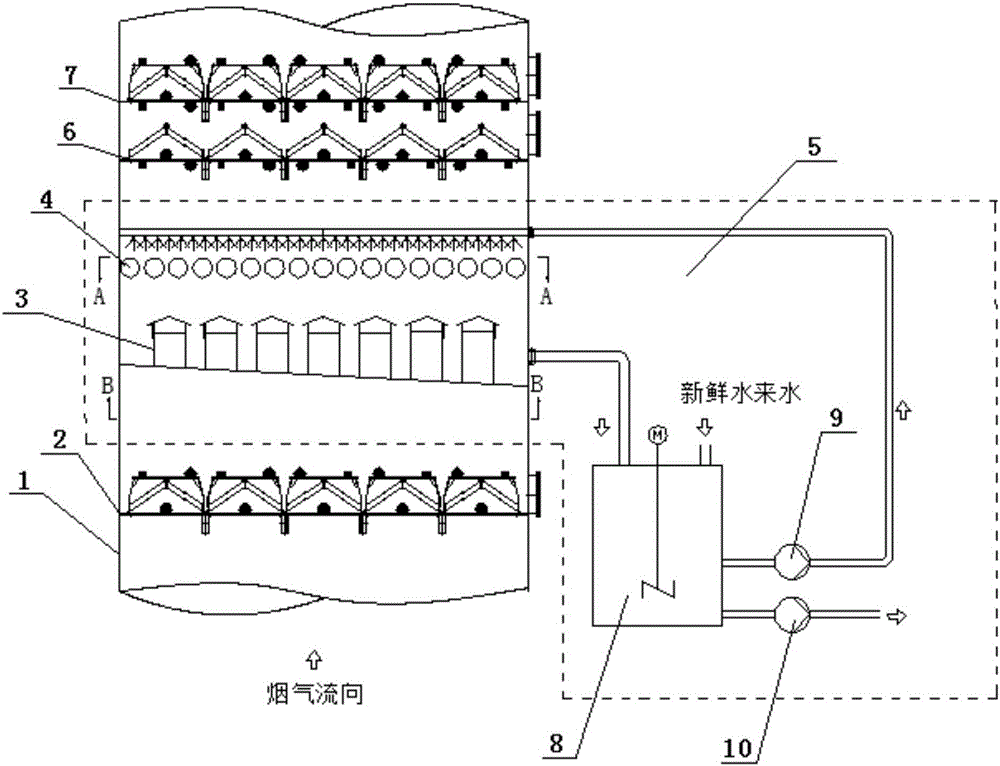

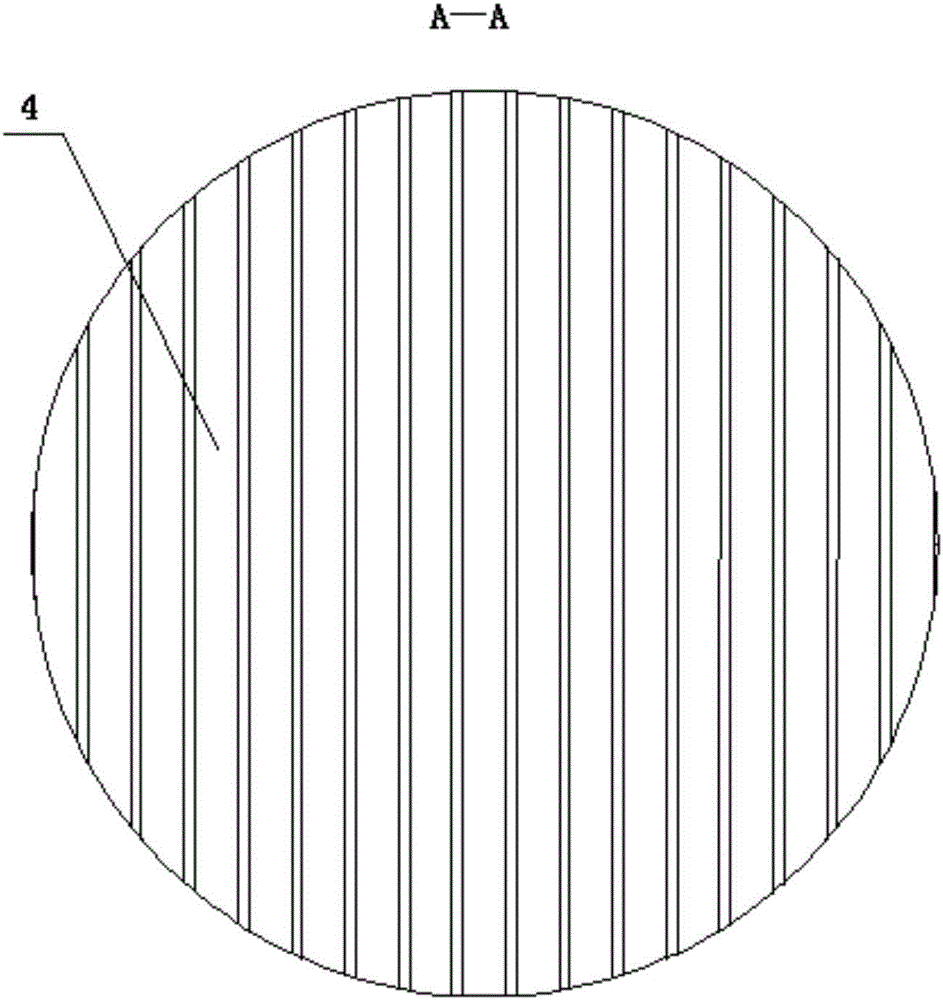

[0017] Such as Figure 1 to Figure 3 As shown, a kind of desulfurization tower dust growing combined dedusting and demisting integrated device described in the present invention comprises a desulfurization tower 1, a first-stage roof type demister 2, a new type Venturi scrubber 4, a second-stage roof type demister Mist device 6, third-stage ridge type mist eliminator 7 and water spray circulation system,

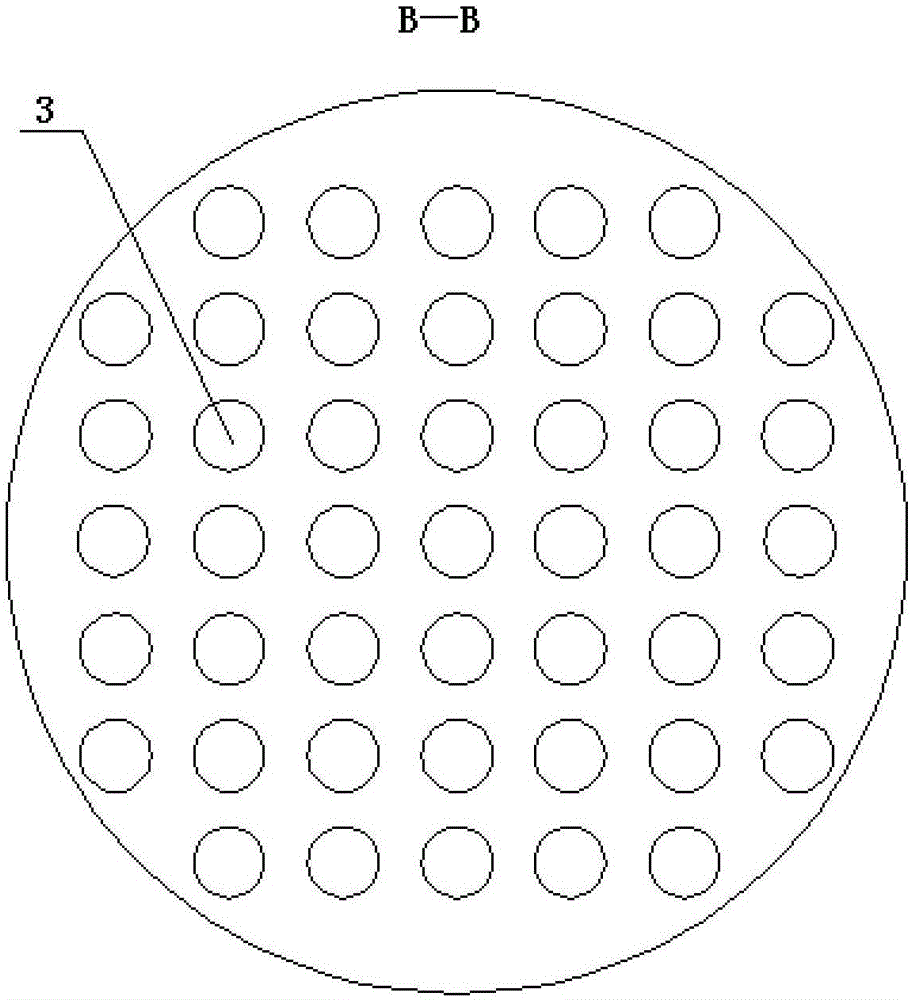

[0018] The water spray circulation system includes the return water layer 3 of the air cap, the water spray layer 5, the circulating water tank 8 and the circulating water pump 9;

[0019] The first-stage ridge-type demister 2 is installed on the upper part of the desulfurization tower 1, and the top of the first-stage ridge-type demister 2 is successively installed with a riser cap return water layer 3, a new Venturi scrubber 4, a water spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com