Corrugated plate for wet processes desulphurization tower and airflow distributing device thereof

An air distribution device and wet desulfurization technology, applied in gas treatment, separation method, dispersed particle separation, etc., can solve the problem of reducing desulfurization efficiency, absorption tower synergistic dust removal efficiency, affecting gas-liquid two-phase mass transfer effect, and uneven distribution of flue gas. and other problems, to achieve the effect of improving the synergistic dust removal effect, convenient installation and disassembly and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0020] As a preferred embodiment of the present invention:

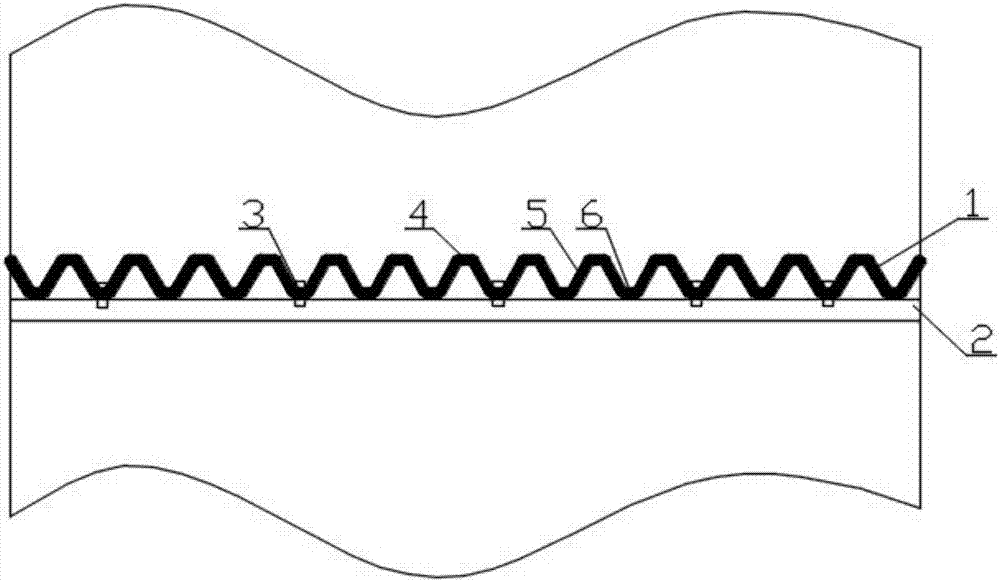

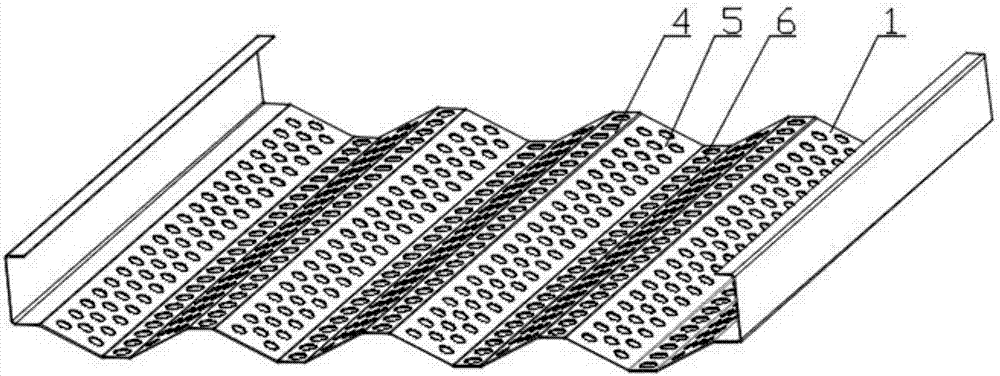

[0021] see figure 1 and figure 2 , a corrugated plate for a wet desulfurization tower, comprising a corrugated plate module, the corrugated plate module consists of a plurality of parallel valley plates 6 and peak plates 4 and connecting the valley plates 6 and the peak plates 4 with an inclined angle The side wall plate 5 is integrally formed, the ratio of the width of the peak plate 4 and the valley plate 6 to the width of the side wall plate 5 is 1 / 3 to 2 / 3, and the vertical distance between the peak plate 4 and the valley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com