Commutation wind pipe for cooker hood

A range hood and blower technology, applied in the field of range hoods, to achieve the effects of low turbulence formation probability, good range hood effect, and large suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

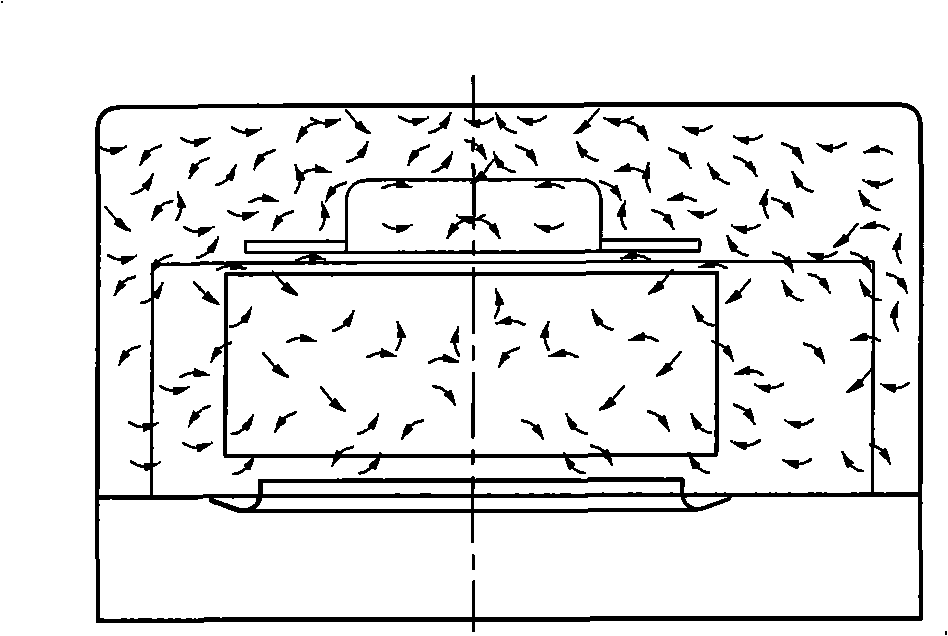

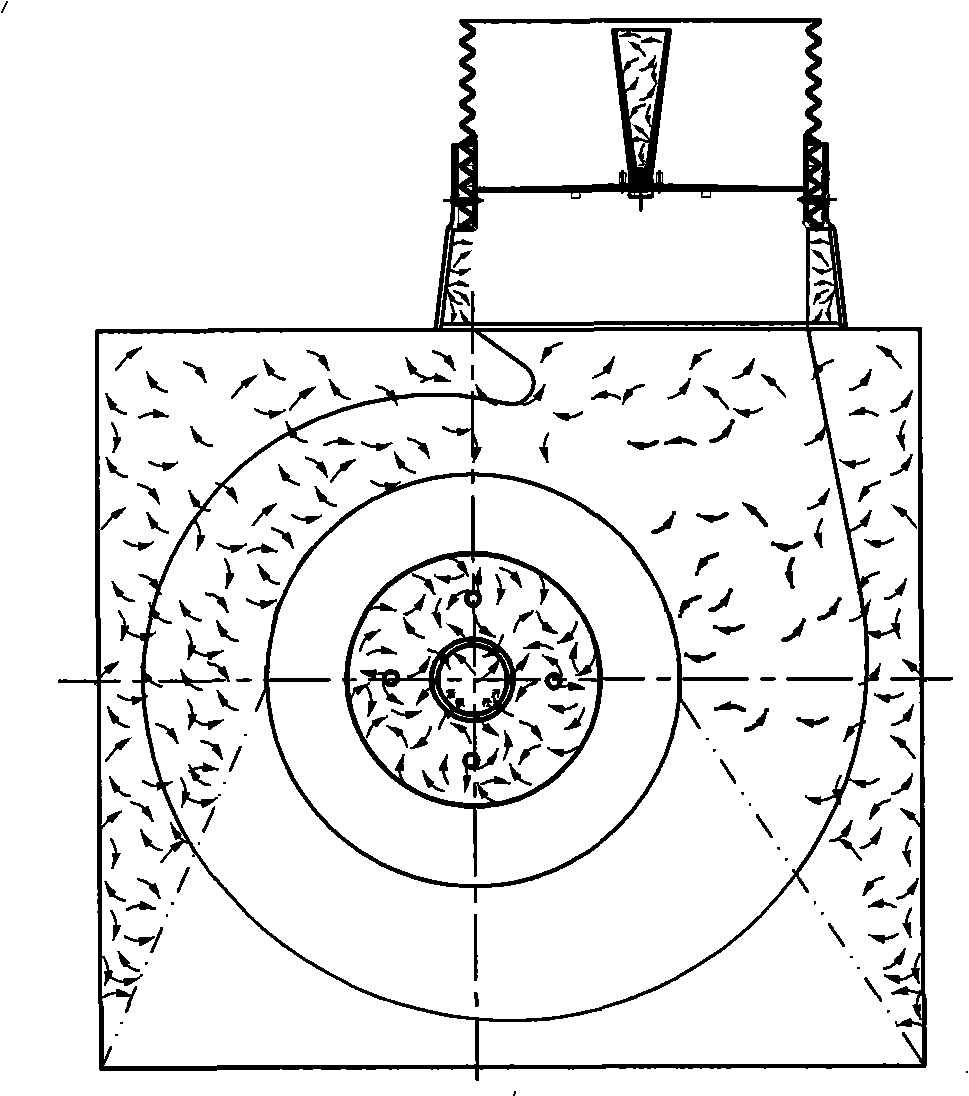

[0029] Depend on Figure 5-8 It can be seen that the rectifying air cylinder used by the rear air intake type range hood is composed of the following parts.

[0030] 1 air cylinder cover, 2 air cylinder, 3 upper cover, 4 valve plate, 5 intake deflector, 6 deflector cover, 7 volute, 8 conical deflector nut, 9 motor, 10 impeller, 11 exhaust Section, 12 air inlet section, 13 throat, 14A node, 15B node, 16C node, 17 wall hook, 18 smoke hood, 19 panel, 20 volute side plate, 21 connecting cylinder, 22 flue base plate, 23 volute Air inlet side panel, 24 separators, 25 left panel, 26 right panel.

[0031] The smoke collecting hood of the rectifying air duct used in the range hood is provided with an air duct, which is a rectangular duct and consists of a flue base plate 22, an upper cover 3, a left side plate 25, a right side plate 26 and a volute side plate 20. .

[0032] In the blower, the motor 9 is connected to the volute side plate 20, and the impeller 10 mounted on its shaft ...

Embodiment 2

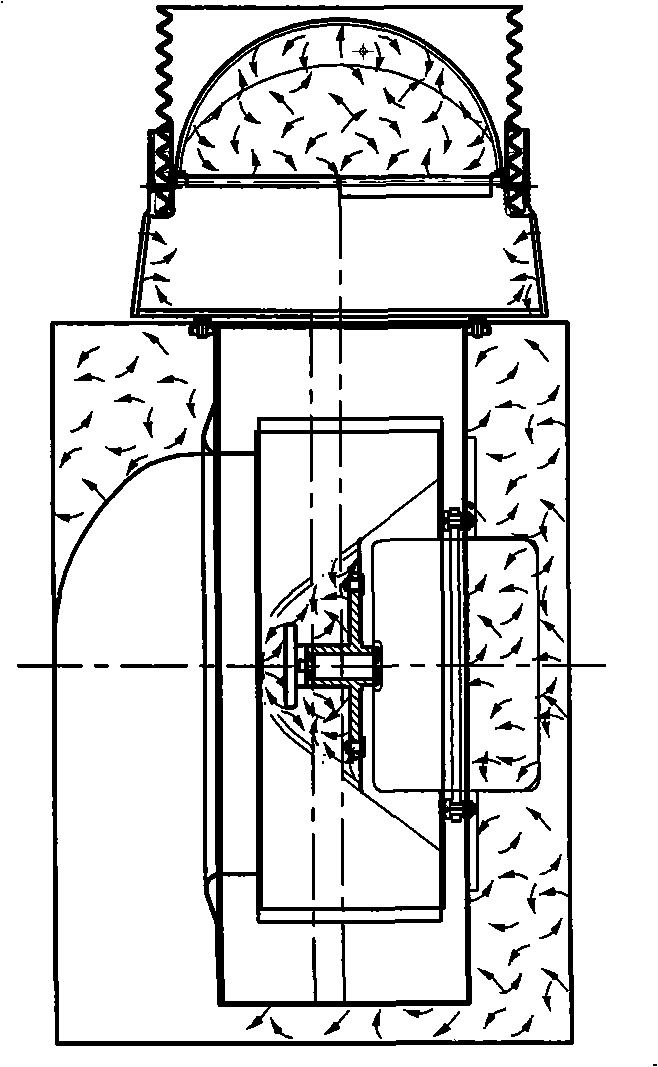

[0037] Depend on Figures 9 to 12 It can be seen that the rectifying air duct used for the range hood of the forward air type is the same as that of Example 1.

[0038] Wherein the air intake deflector 5 is inclined to the air intake direction, and the included angle with the flue base plate 22 is 120°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com