Venturi scrubber plate, waste capture system, and method

a waste capture system and scrubber plate technology, applied in the field of fluid curtain scrubbing, can solve the problems of high cost of downtime and filter requirements for general maintenance and cleaning of waste capture systems, droplets and/or particles, and ineffectiveness of such conventional waste capture systems including scrubbers to entrain and remove waste gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] 1. Venturi Scrubber Design Calculations:

[0054] The industry standard air velocity for effective water wash paint overspray scrubbing is 1500 linear feet per minute-7500 linear feet per minute. This is a linear velocity measured across the throat of the primary scrubbing section. Water and paint-laden air will not effectively impact and mix below this stated velocity. The velocity must be high enough for the kinetic impact energy of the paint particles and wash water to overcome surface tension.

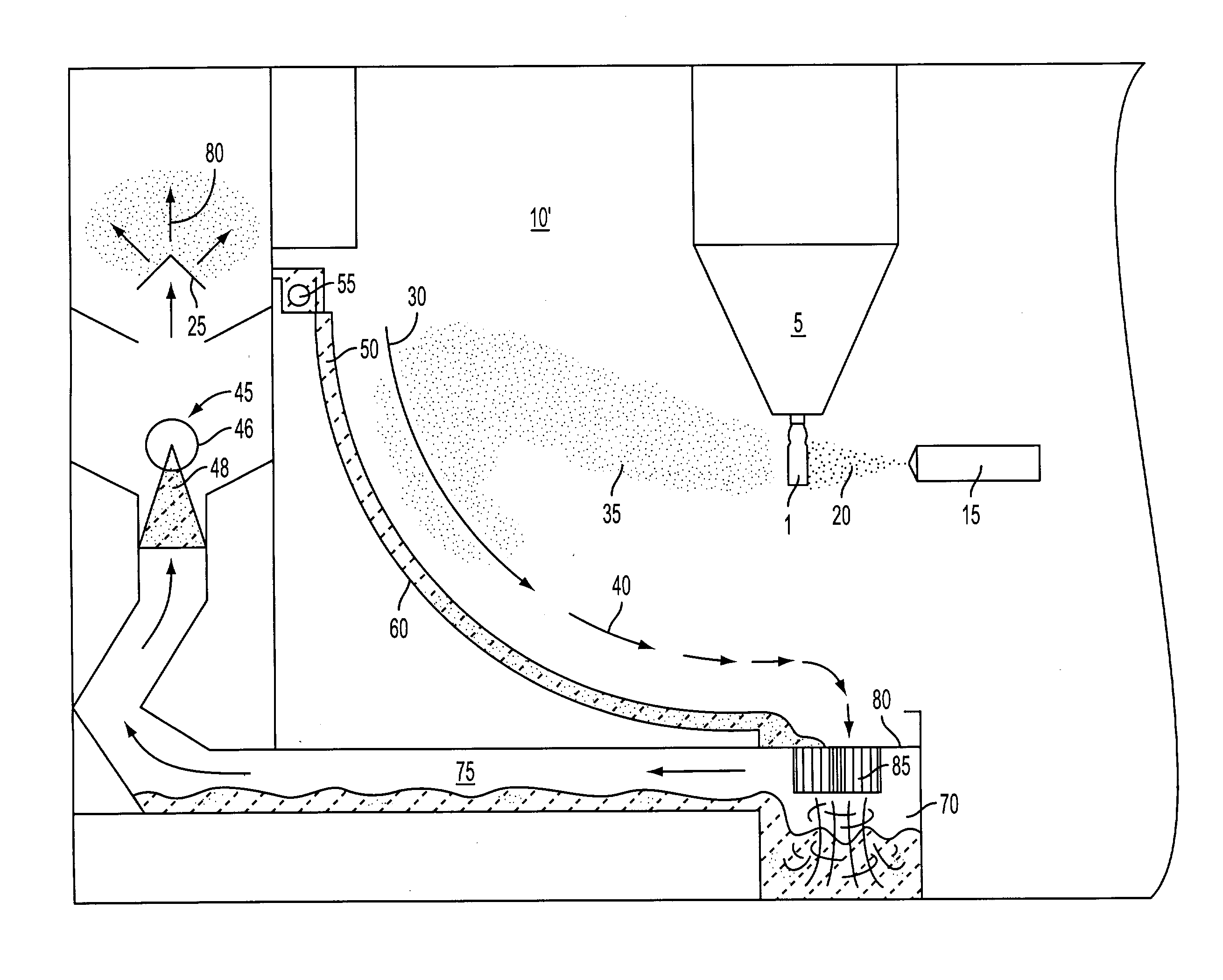

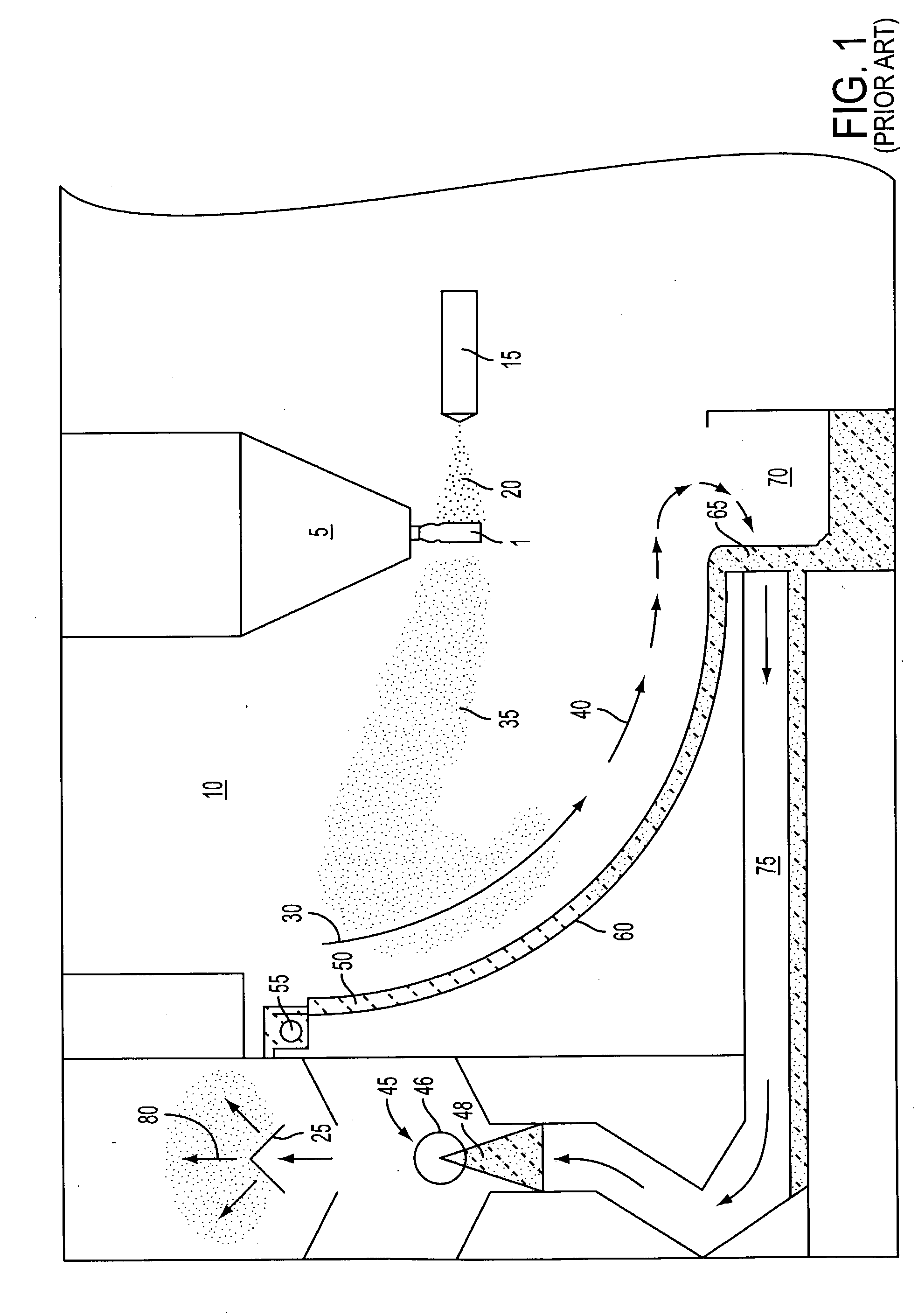

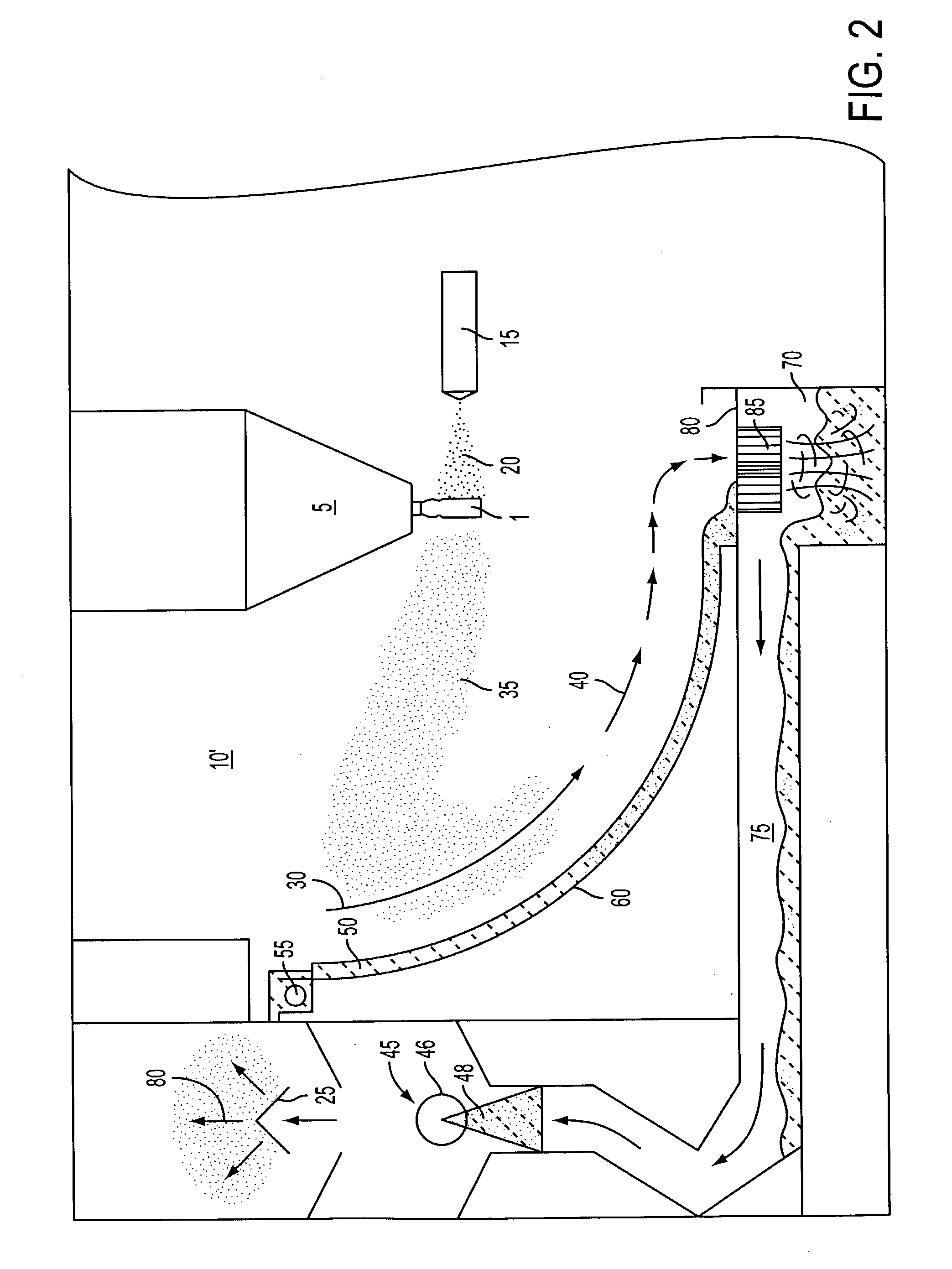

[0055] 2. Booth Configuration:

[0056] The throat width is 16 feet. The throat height is 0.75 feet. The effective throat area is 12 square feet. The booth evacuation volume is 7000 cubic feet per minute. Thus, the effective air flow velocity at the throat is 7500 cubic fee per minute.times.12 sq.ft.=625 linear feet per minute.

[0057] 3. The Venturi Scrubber Plate:

[0058] The effective throat area is 3.98 square feet. The venturi area for a 5.63 inch diameter orifice is 0.173 square feet. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com