Washing treatment process for synthesis gas

A treatment process and synthesis gas technology, which is applied in the field of grey water classification, utilization and treatment, and achieves the effects of reducing environmental pollution and water resources consumption, eliminating scaling and increasing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

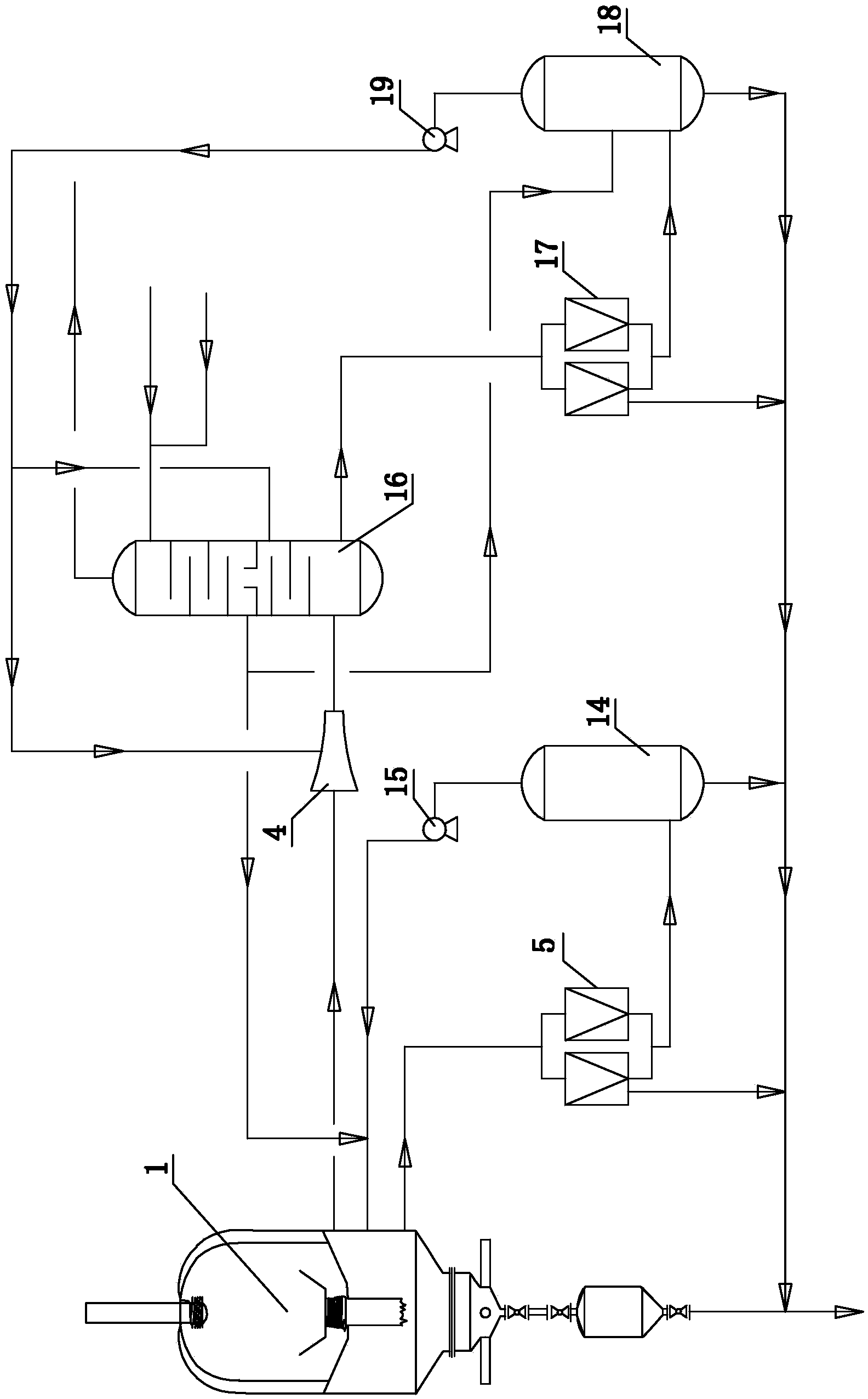

[0022] Such as figure 2 Shown, the coal gasification plant gray water treatment method process of the present invention is as follows:

[0023] a. The black water leaving the quenching chamber 1 of the gasifier is not subjected to decompression treatment nor lowered in temperature, and enters the quenching water buffer tank 14 after directly passing through the quenching water filter 5 to filter the ash, and the quenching water exiting the quenching water buffer tank 14 passes through After the quenching water circulation pump 15 is pressurized, the gray water in the quenching water buffer tank 14 is sent to the quenching chamber 1 of the gasification furnace for recycling to complete a cycle, and most of the ash filtered out by the quenching water filter 5 before the quenching water buffer tank 14 The slag is sent to the slag removal machine through the outlet at the bottom of the chilled water filter 5 for slag water treatment;

[0024] b. The synthesis gas coming out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com