Gas-liquid separation tank for cold hydrogenation process

A gas-liquid separation tank and process technology, which is applied in the direction of using liquid separation agent, separation method, and dispersed particle separation, can solve the problems of space occupation and large size, and achieve the effect of saving space, small equipment size, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

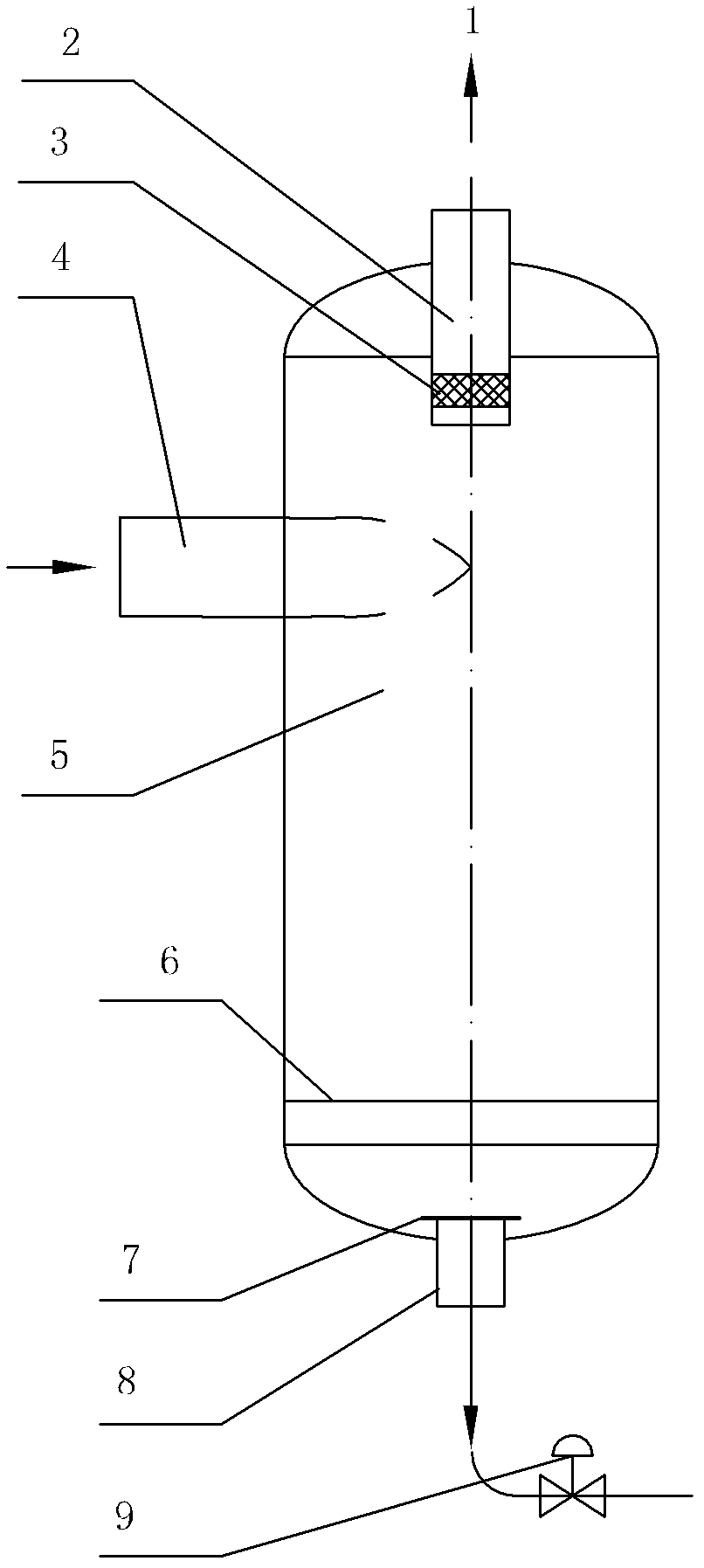

[0016] The invention is applied to the cold hydrogenation process of polysilicon, and is used for separating the gas-liquid two-phase medium discharged from the Venturi scrubber.

[0017] The structure of the separation tank is as follows: the equipment is an upright structure, the gas-liquid mixture is carried out by the tangential inlet, the gas phase outlet 1 is located at the top of the tank body 5, the liquid phase outlet 8 is located at the bottom of the tank body, and the gas phase outlet and the liquid phase outlet are on the same axis;

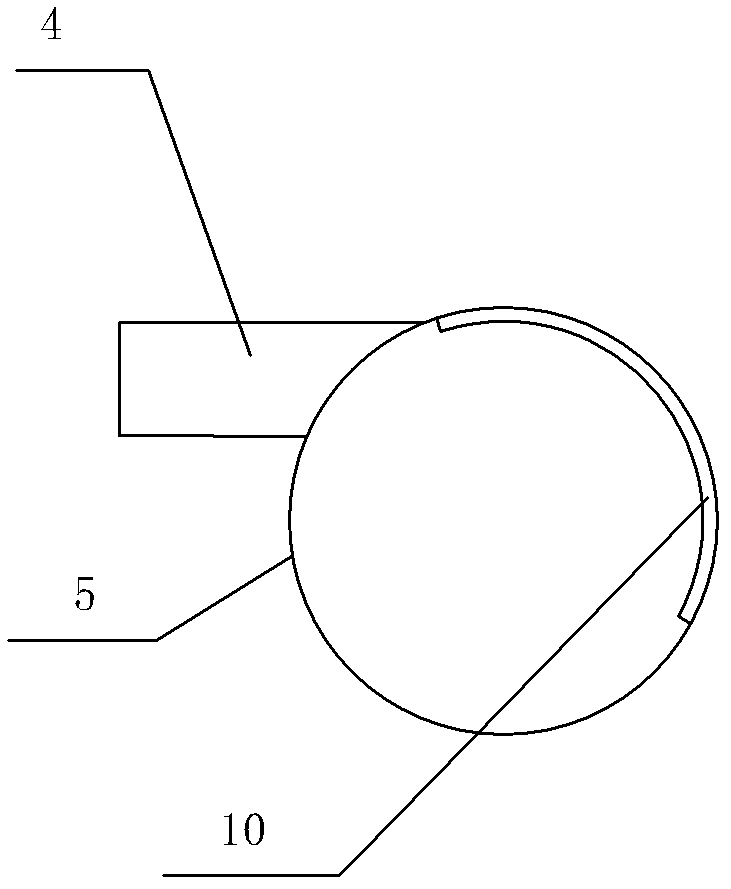

[0018] The inner surface of the equipment opposite to the tangential inlet has an anti-shock plate 10 attached to the inner surface of the equipment; the gas phase outlet has an overflow pipe 2 extending into the equipment tank for a certain length, and the overflow pipe is used to form a separation space to provide separation efficiency. It is also beneficial to replace the filter screen; the gas-liquid filter screen 3 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com