Method for improving washing effect of ammonium phosphate granulation tail gas

A technology for tail gas washing and process methods, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of poor washing effect and low ammonia absorption rate, reduce the specific gravity, stabilize the production system, and improve ammonia absorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

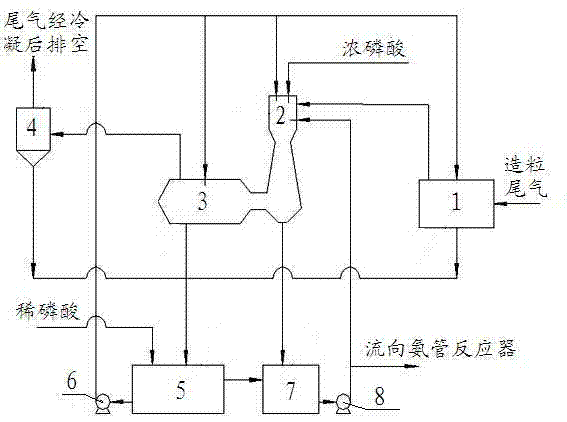

[0017] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0018] Such as figure 1 The tail gas scrubbing process of the ammonium phosphate plant shown in this method can be divided into a tail gas process and a scrubbing liquid process.

[0019] The tail gas process includes the following steps: the granulation tail gas enters the pre-stage scrubber 1, flows through the Venturi scrubber 2 and the horizontal scrubber 3, and after being washed step by step, enters the demister 4, decondenses, and enters the tail gas discharge main pipe, Finally, it is discharged into the atmosphere through the chimney.

[0020] The tail gas of the dryer goes through the drying and washing tower, and after being washed and dust-removed, it enters the tail gas discharge main pipe, and finally is discharged into the atmosphere through the chimney.

[0021] The washing liquid process includes the following steps: the dilute p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com