Energy utilization in polysilicon hydrogenation process

A polysilicon and energy technology, applied in the direction of halogenated silicon compounds, silicon, etc., can solve the problem of waste of refrigerant and heating medium, and achieve the effect of reducing consumption, reducing operating cost and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

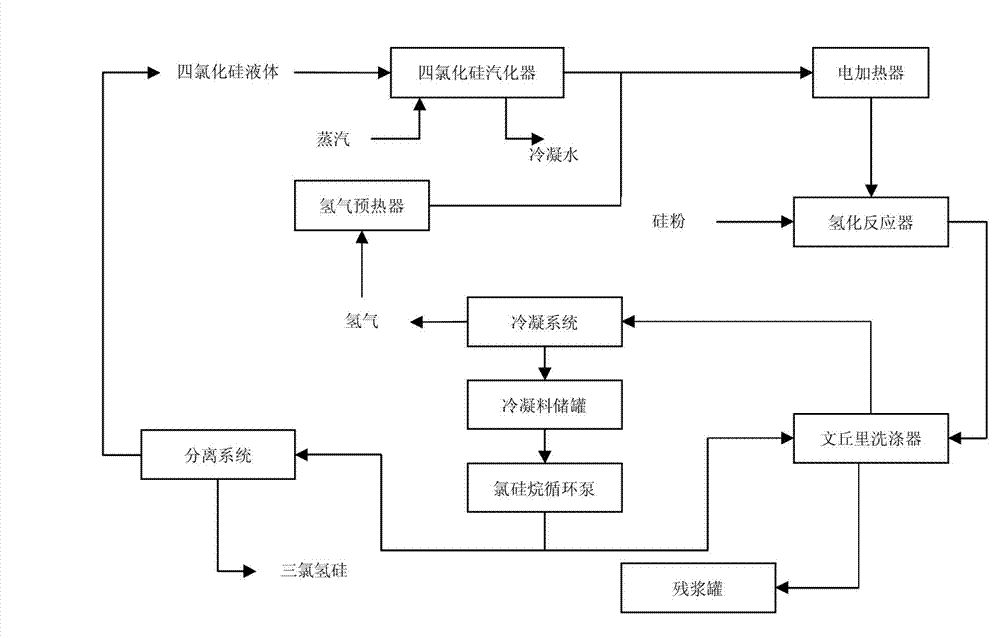

Problems solved by technology

Method used

Image

Examples

Embodiment 1

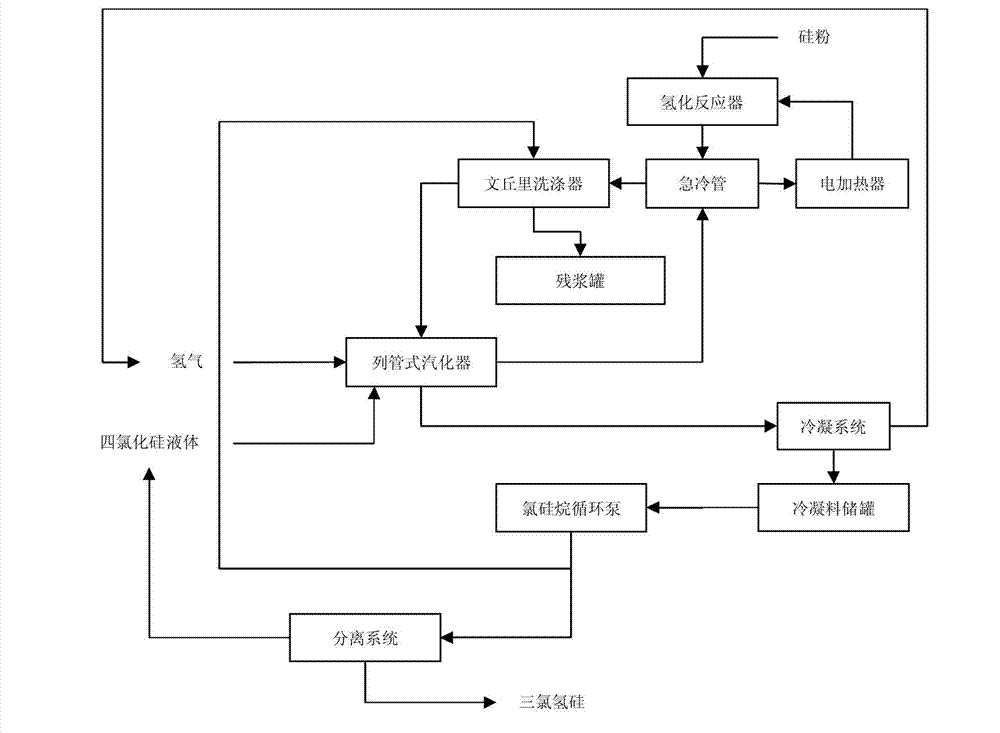

[0032] Example 1 A method for energy utilization in the polysilicon cold hydrogenation process, the process flow is as follows figure 2 As shown, it includes the following steps: (1) Silicon tetrachloride liquid and hydrogen gas enter the shell-and-tube vaporizer with a molar ratio of 1:3 and mix, control the pressure to 3.2MPa, and the temperature to 150°C, and then enter the quenching tube ;

[0033] (2) After the mixed gas of silicon tetrachloride and hydrogen entering the quenching tube exchanges heat with the reaction gas from the hydrogenation reactor, it enters the electric heater and is electrically heated to 600°C, and then enters the hydrogenation reactor and the silicon in it. The powder reacts;

[0034] (3) The reaction product gas from the hydrogenation reactor enters the quenching tube to exchange heat with the mixed gas of silicon tetrachloride and hydrogen, and then enters the Venturi scrubber. The washed silicon powder particles and a small amount of chloros...

Embodiment 2

[0039] Example 2 A method for energy utilization in the polysilicon cold hydrogenation process, the process flow is as follows figure 2 As shown, it includes the following steps: (1) Silicon tetrachloride liquid and hydrogen gas enter the shell-and-tube vaporizer with a molar ratio of 1:4, control the pressure at 2.0MPa, and the temperature at 160°C, and then enter the quenching tube ;

[0040] (2) After the mixed gas of silicon tetrachloride and hydrogen entering the quenching tube exchanges heat with the reaction gas from the hydrogenation reactor, it enters the electric heater and is electrically heated to 620°C, and then enters the hydrogenation reactor and the silicon in it. The powder reacts;

[0041] (3) The reaction product gas from the hydrogenation reactor enters the quenching tube to exchange heat with the mixed gas of silicon tetrachloride and hydrogen, and then enters the Venturi scrubber. The washed silicon powder particles and a small amount of chlorosilane re...

Embodiment 3

[0046] Embodiment 3 A method for energy utilization in the polysilicon cold hydrogenation process, which includes the following steps: (1) Silicon tetrachloride liquid and hydrogen gas are mixed in a tube-and-tube vaporizer at a molar ratio of 1:5, and the pressure is controlled to be 3.5MPa, the temperature is 140°C, and then enters the quenching tube;

[0047] (2) After the mixed gas of silicon tetrachloride and hydrogen entering the quenching tube exchanges heat with the reaction gas from the hydrogenation reactor, it enters the electric heater and is electrically heated to 580°C, and then enters the hydrogenation reactor and the silicon in it. The powder reacts;

[0048] (3) The reaction product gas from the hydrogenation reactor enters the quenching tube to exchange heat with the mixed gas of silicon tetrachloride and hydrogen, and then enters the Venturi scrubber. The washed silicon powder particles and a small amount of chlorosilane residue are regularly discharged to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com