Washing method and apparatus for phosphoric acid reacting trough extracting tail gas

A technology of phosphoric acid reaction tank and washing method, which is applied in separation methods, chemical instruments and methods, and phosphorus compounds, and can solve problems such as high operation and maintenance costs, failure to meet environmental protection requirements, and low fluorine washing efficiency, and achieve operation and maintenance The effect of low cost, less process equipment and compact device arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Adopt the 60,000 tons / year P of the present invention 2 o 5 Phosphoric acid extraction unit

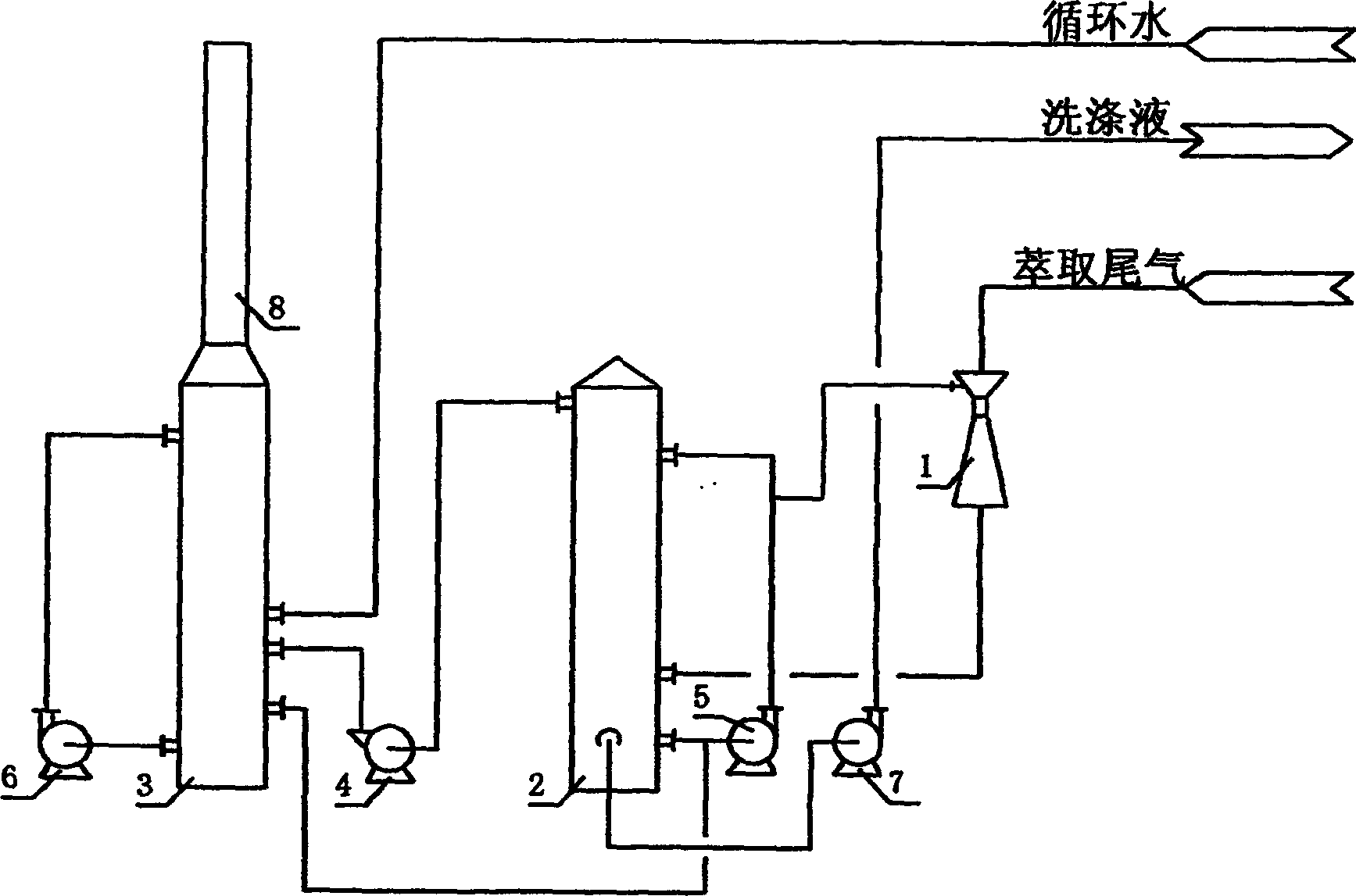

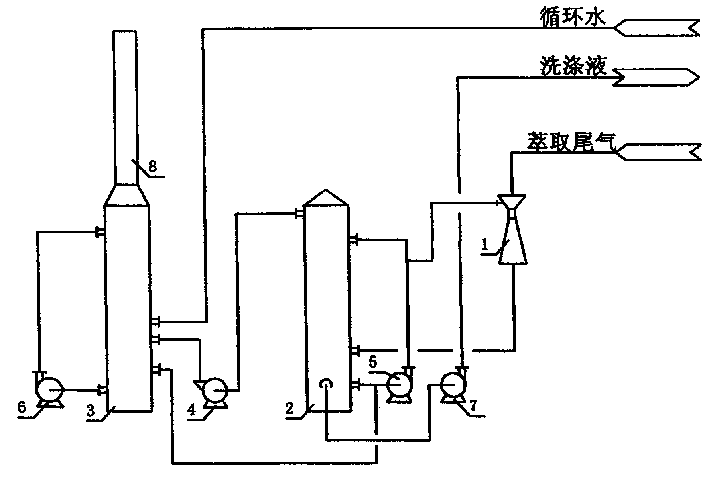

[0021] See attached picture. The extracted exhaust gas is washed through the combined process of Venturi scrubber 1, primary exhaust gas scrubber 2, exhaust fan 4, and secondary exhaust gas scrubber 3. A primary exhaust gas scrubbing circulation pump 5 is installed outside the primary exhaust gas scrubber. A secondary tail gas scrubbing circulation pump 6 is installed outside the scrubber, and an overflow pipe 9 on the secondary exhaust scrubber 3 leads to the primary exhaust scrubber 2, and a circulating water inlet pipe is connected to the secondary exhaust scrubber 3. An exhaust fan 4 is installed between the exhaust scrubber 2 and the secondary exhaust scrubber 3, and the primary exhaust scrubber 2 is connected with a recovery water pump 7, which is used to pump the washing liquid to the filtration system, the Venturi scrubber 1 and the primary exhaust The washing tower ...

example 2

[0024] Adopt 120,000 tons / year P of the present invention 2 o 5 Phosphoric acid extraction unit

[0025] See attached picture. The extraction tail gas is washed through the combined process of Venturi scrubber 1, primary tail gas scrubber 2, tail gas fan 4, and secondary tail gas scrubber 3. Venturi scrubber liquid / gas ratio is 1 / 1000m 3 Liquid / m 3 For gas, the throat airflow velocity is controlled at 51m / s, and the spray density of the scrubber is 15m 3 / (m 2 h), the superficial gas velocity is 3.8m / s, and the absorption height is 7.8m. The rest are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com