Coal gasification device for circulating fluidized bed and manufacturing method thereof

A circulating fluidized bed and coal gasification technology, applied in the direction of granular/powdered fuel gasification, energy input, etc., to achieve the effect of facilitating daily maintenance, improving gasification efficiency, and reducing the carbon content of fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

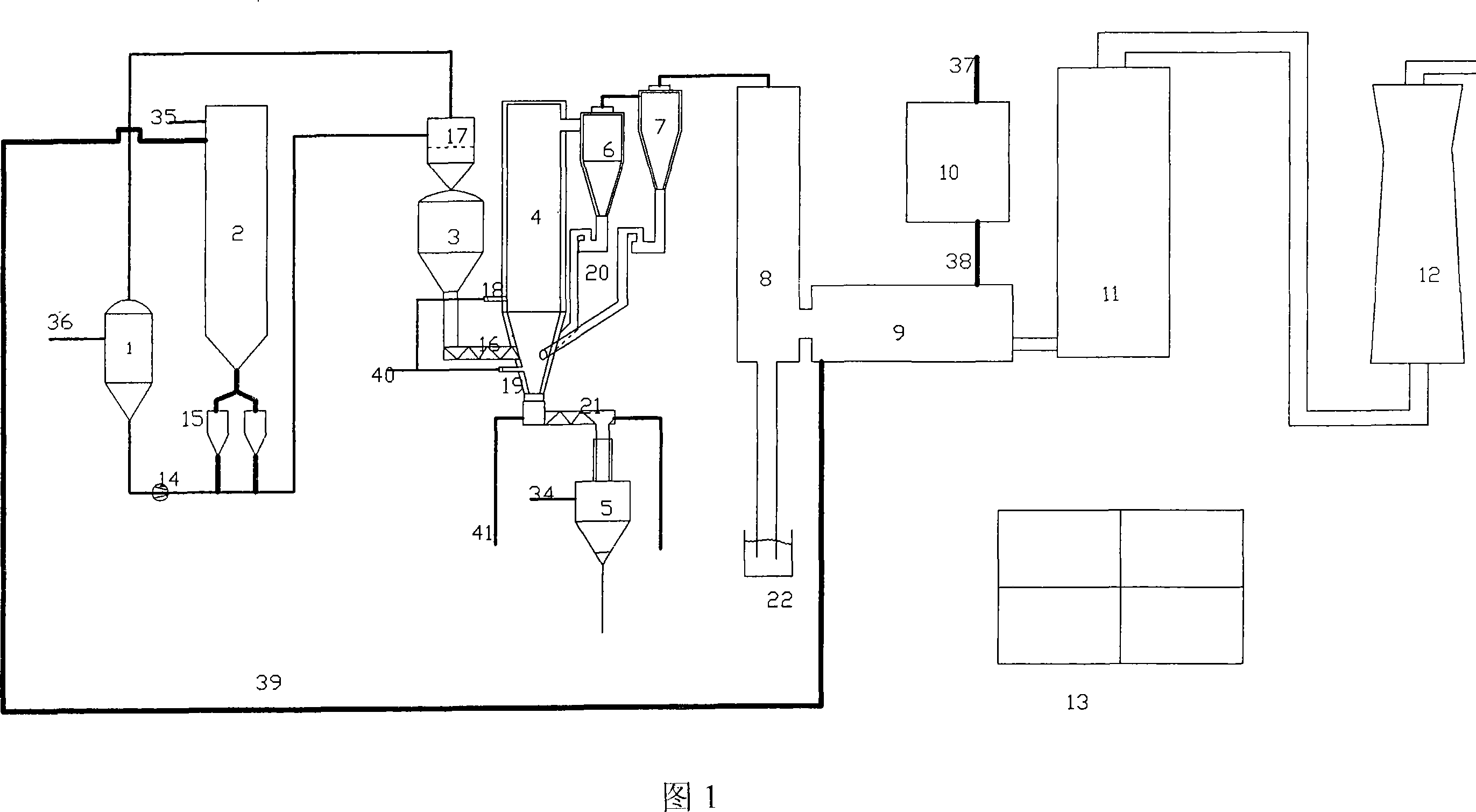

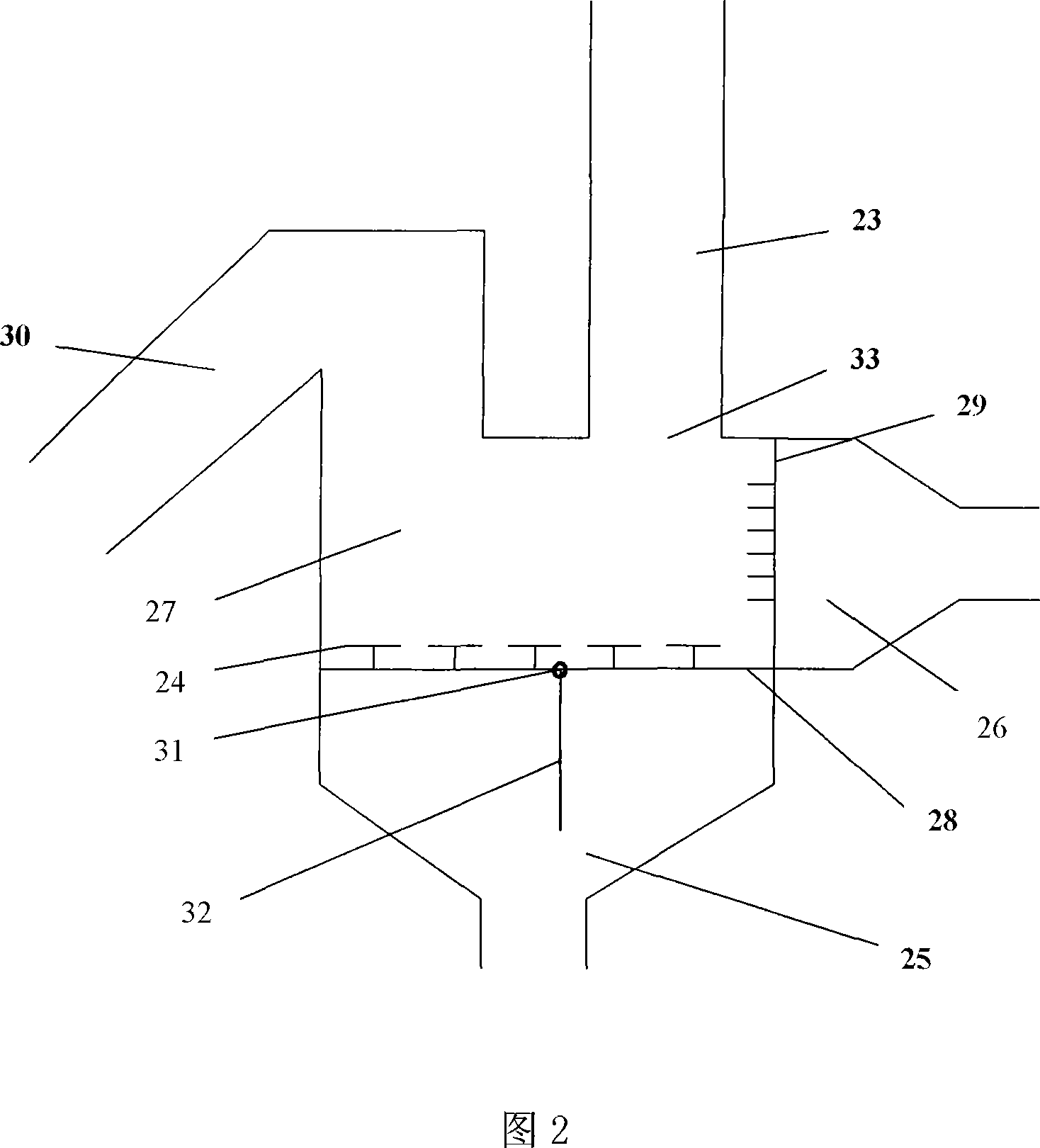

[0028] As shown in Figure 1, this circulating fluidized bed coal gasification device includes a coal loading system composed of coal crushing and screening equipment 10, coal storage tank 2 and feeding bin 3, and is equipped with upper and lower gasification agents. The generator 4 of the nozzles 18 and 19, the cyclone dust collector composed of two sets of cyclone dust collectors 6 and 7 connected in series, the waste heat boiler 8, the water cooling tower 11 and the Venturi scrubber 12, wherein the bottom of the feeding bin 3 is provided with The spiral coal stoker 16 that sends coal to the generator 4, the bottom of the generator 4 is provided with a spiral ash remover 21 and the ash storage tank 5, and the upper part of the generator 4 is provided with a gas pipe communicating with the upper end of the previous group of cyclone dust collectors 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com