Method and device for regeneration of stainless steel mixed acid pickling waste acid by spray roasting process

A technology of spray roasting and pickling waste acid is applied in the field of stainless steel mixed acid pickling waste acid regeneration in the metallurgical industry, which can solve the problems of environmental pollution, large amount of sludge, waste of resources, etc., and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

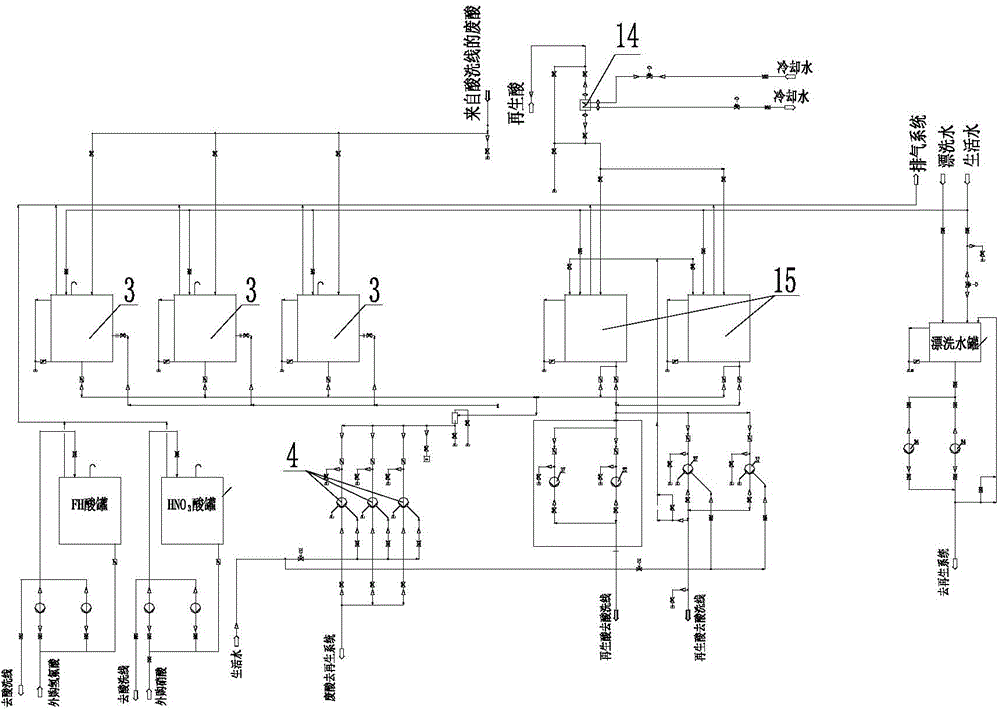

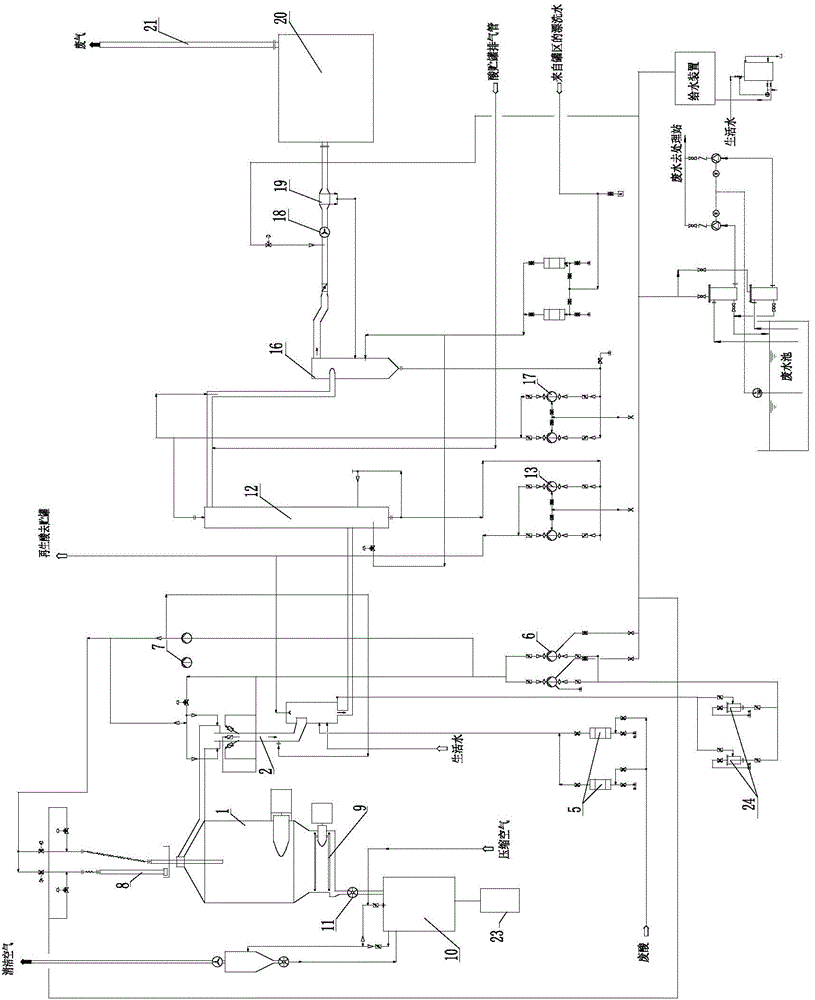

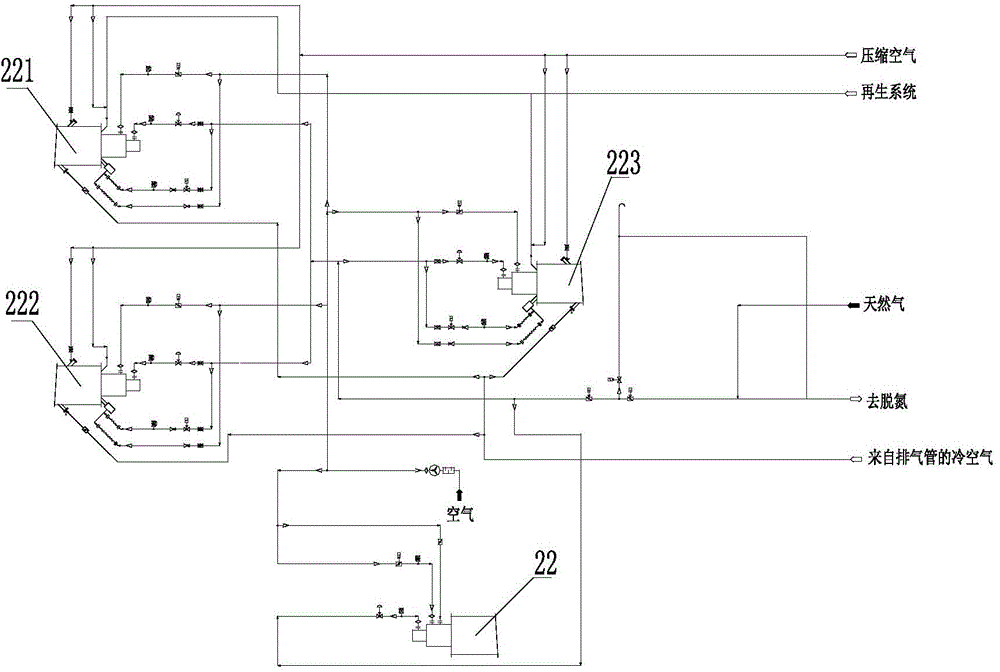

[0024] See Figure 1-Figure 3 The method for regenerating stainless steel mixed acid pickling waste acid by spray roasting method uses roasting furnace 1 to oxidize waste acid at high temperature to make it react into solid metal iron powder and acid gas, and then spray and absorb to generate regenerated mixed acid, which specifically includes the following steps:

[0025] 1) The waste mixed acid at 55°C to 65°C from the pickling line is sent to the waste acid tank 3 for storage, and the waste acid pump 4 sends the waste acid through the filter 5 to the lower part of the Venturi scrubber 2, and then the Venturi circulation pump 6 Circulate and spray on the upper part of the Venturi scrubber 2, and the spray pressure of the Venturi circulating pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com