Gas-phase combustion reactor for preparing nano granule and its industrial application

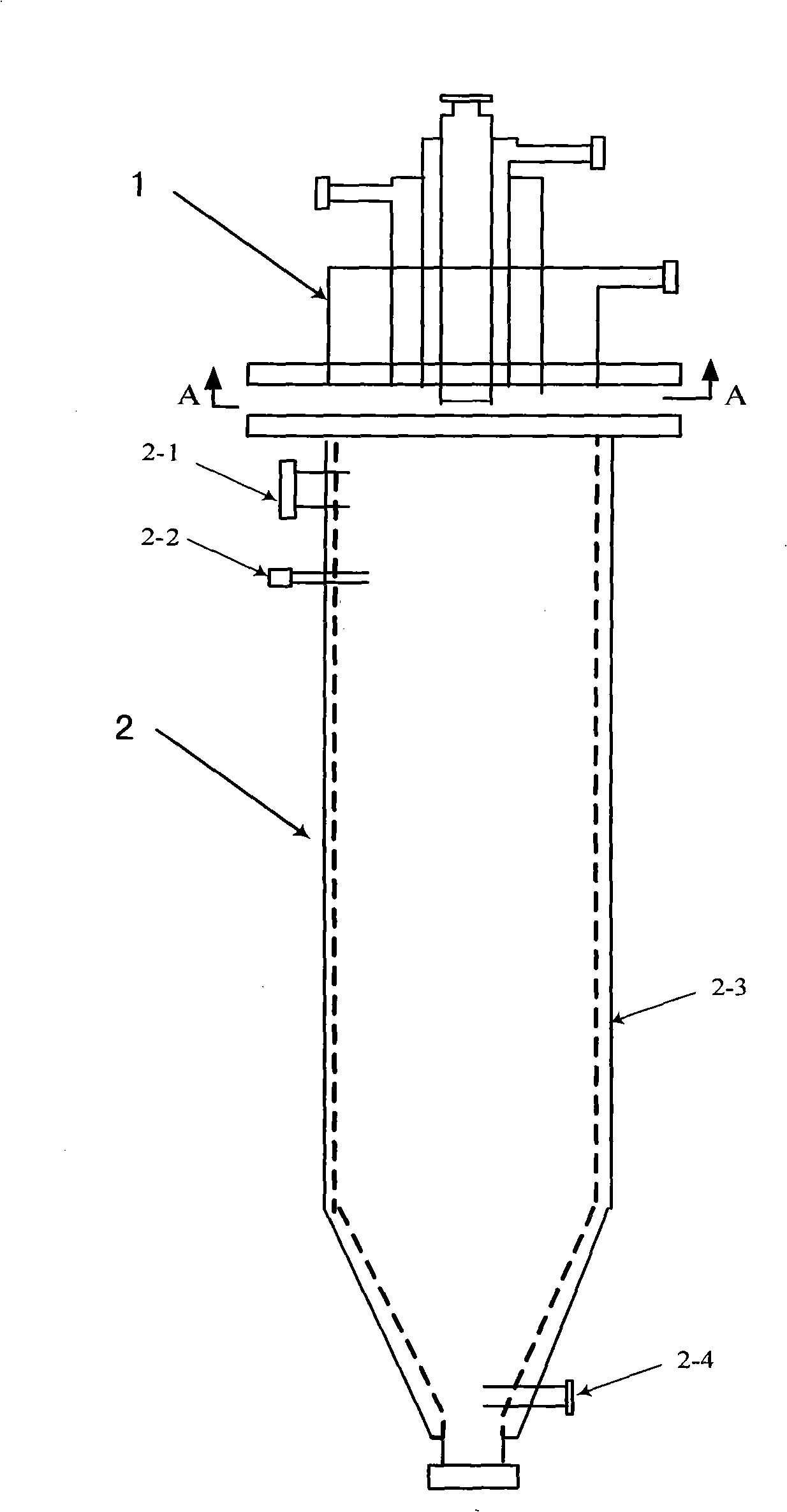

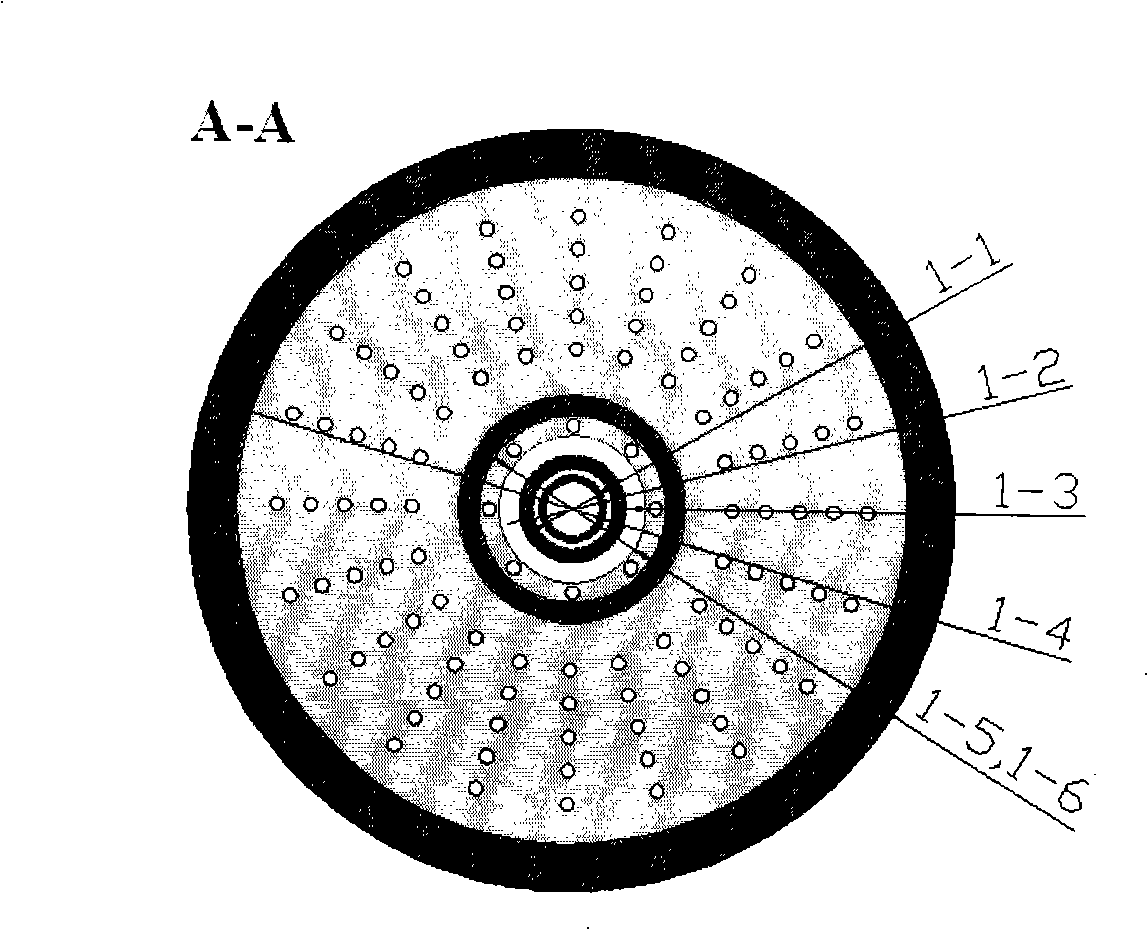

A gas-phase combustion and reactor technology, which is applied in the combustion of multiple fuels, the combustion of lump fuel and liquid fuel, the combustion of lump fuel and gaseous fuel, etc. Production requirements, uneven temperature field and concentration field, nozzle easily scarred and blocked nozzle, etc., to avoid burner scarring, overcome uneven temperature field and concentration field, and reduce temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

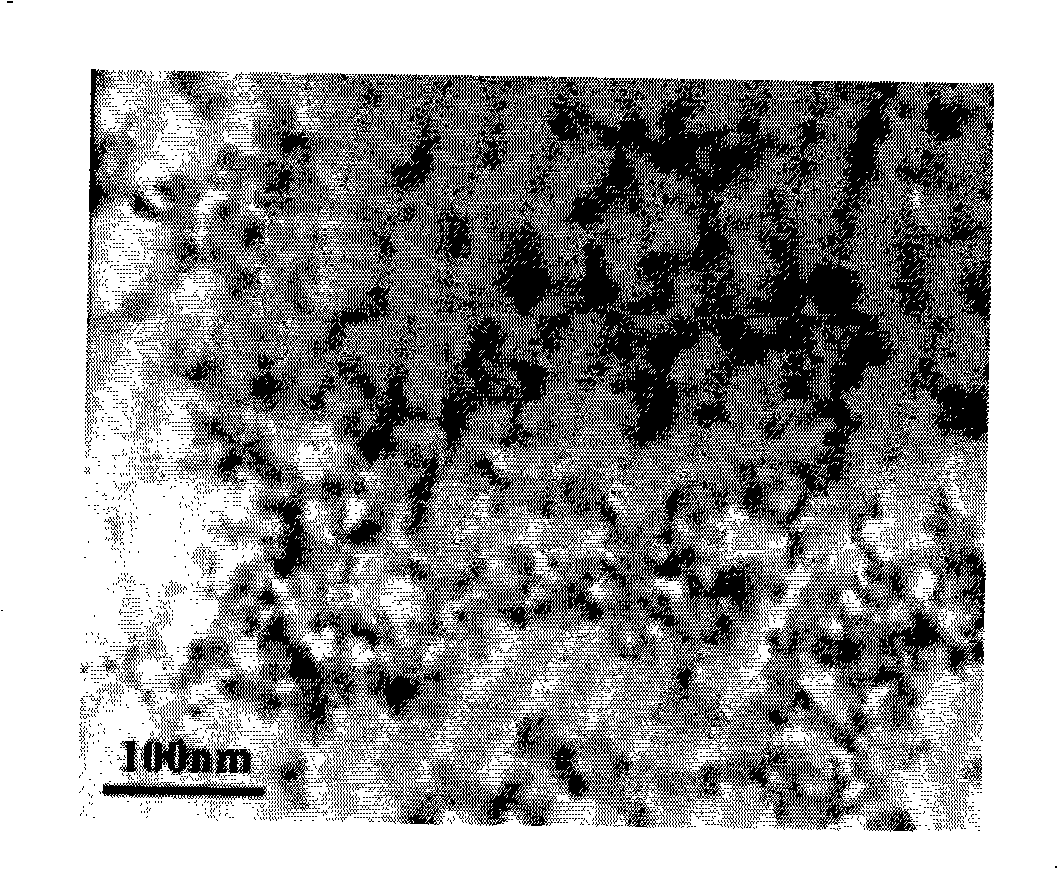

Embodiment 1

[0027] First add 20ml / min of TiCl 4 The evaporator is vaporized by electric heating, and the steam is mixed with the dried, purified and preheated air and hydrogen in a certain proportion in the mixer, and is ejected from the high-speed jet flame outlet to the combustion chamber at a high speed, and the outlet gas velocity is 110m / s; In addition, the purified and dried air and hydrogen are respectively passed into the combustion chamber through the auxiliary jet outlet and the auxiliary flame outlet, and ignited to form an auxiliary flame, and the outlet gas velocities are 80m / s and 30m / s respectively; Purified air is introduced to form an annular jet outside the flame to cool the reaction system. The gas velocity is 50m / s; the reaction temperature is 1000°C. Formation of nano-TiO by gas phase combustion 2 particles. The temperature of the circulating cooling water inside the combustion chamber and the burner is controlled at about 80°C. The resulting TiO 2 The primary pa...

Embodiment 2

[0029] First, 0.7g / min aluminum isopropoxide is vaporized by an electric heating evaporator, and the steam is mixed with the dried, purified, preheated air and hydrogen in a certain proportion in the mixer, and the high-speed jet flame exits to the combustion chamber. High-speed ejection, the outlet gas velocity is 140m / s; in addition, the purified and dry air and hydrogen are respectively passed into the combustion chamber through the auxiliary jet outlet and the auxiliary flame outlet, and ignited to form an auxiliary flame, and the outlet gas velocity is 100m / s respectively and 40m / s; the purified air is introduced into the cooling gas outlet to form an annular jet outside the flame to cool the reaction system, the gas velocity is 70m / s; the reaction temperature is 1200°C. Nano-Al formed by gas-phase combustion 2 o 3 particles. The temperature of the circulating cooling water inside the combustion chamber and the burner is controlled at about 80°C. Gained Al 2 o 3 The ...

Embodiment 3

[0031] First, 10ml / min of SnCl 4 and SbCl 3The ethanol solution is vaporized by an electrically heated evaporator, and the steam is mixed with the dried, purified, and preheated air and hydrogen in a certain proportion in the mixer, and is ejected from the high-speed jet flame outlet to the combustion chamber at a high speed, and the outlet gas velocity is 160m / s; In addition, the purified and dried air and hydrogen are respectively passed into the combustion chamber through the auxiliary jet outlet and the auxiliary flame outlet, and ignited to form an auxiliary flame, and the outlet gas velocities are 120m / s and 50m / s respectively; in the cooling gas Purified air is introduced into the outlet to form an annular jet outside the flame to cool the reaction system. The gas velocity is 90m / s; the reaction temperature is 1800°C. Nano ATO particles formed by gas phase combustion. The temperature of the circulating cooling water inside the combustion chamber and the burner is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com