Internal-circulation biological fluidized bed system used for VOCs and malodorous gas treatments

A technology of internal circulation biological fluidized bed and biological fluidized bed, applied in the field of internal circulation biological fluidized bed system, can solve the problems of affecting the air flow distribution of the reactor, reducing the removal efficiency of pollutants, and uneven distribution of microorganisms, etc., to achieve VOCs And odor treatment efficiency is high, it is conducive to diffusion, and the effect of accelerating degradation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

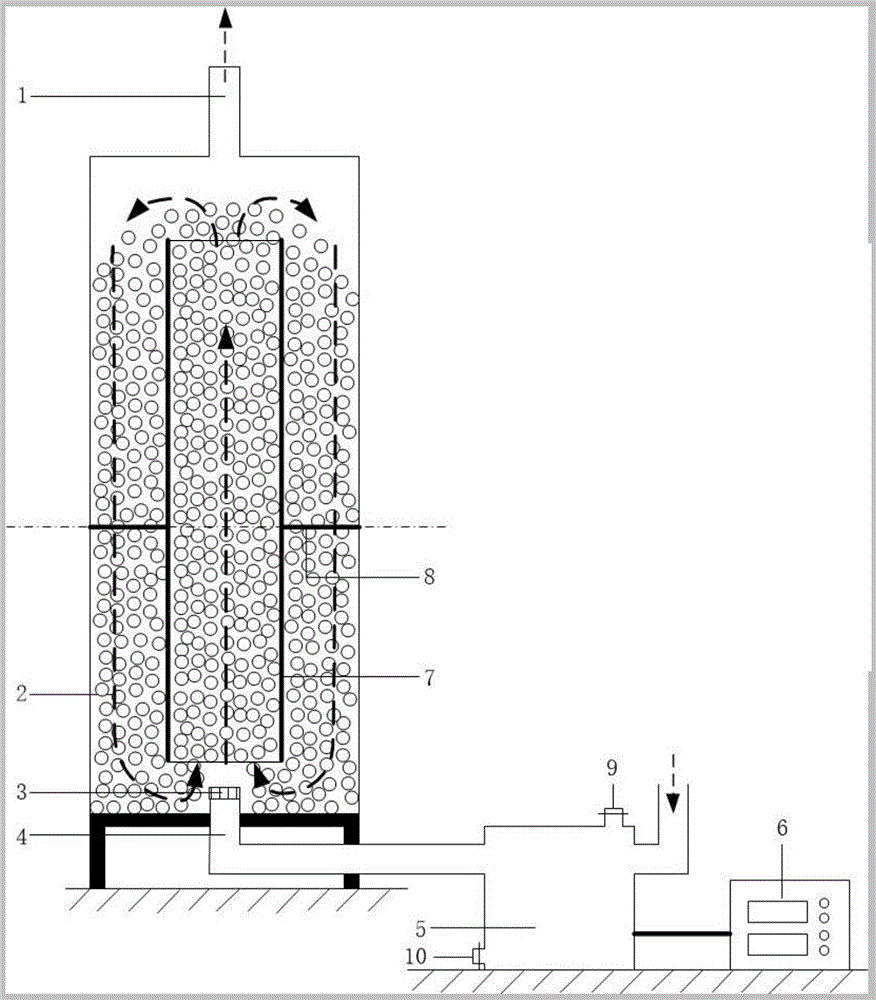

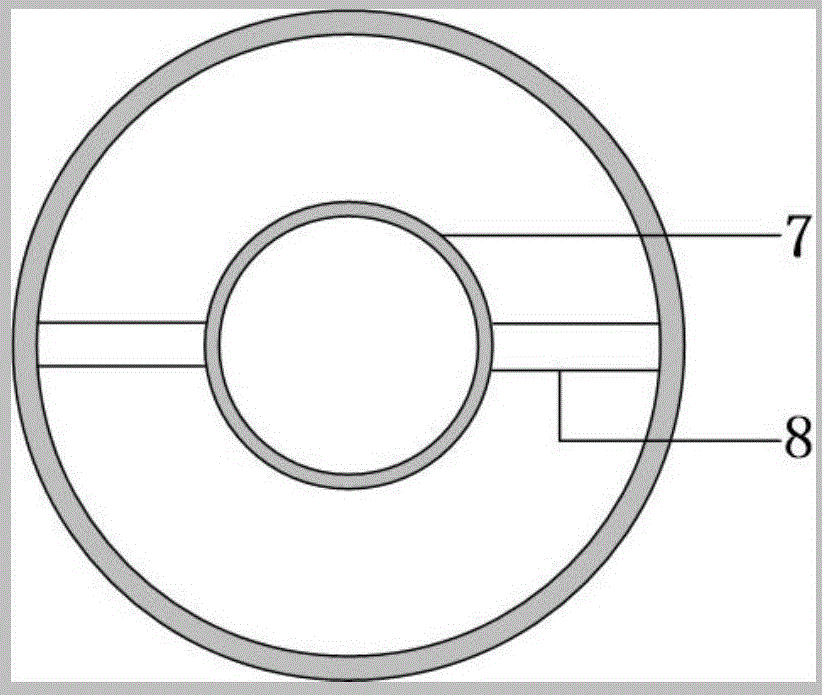

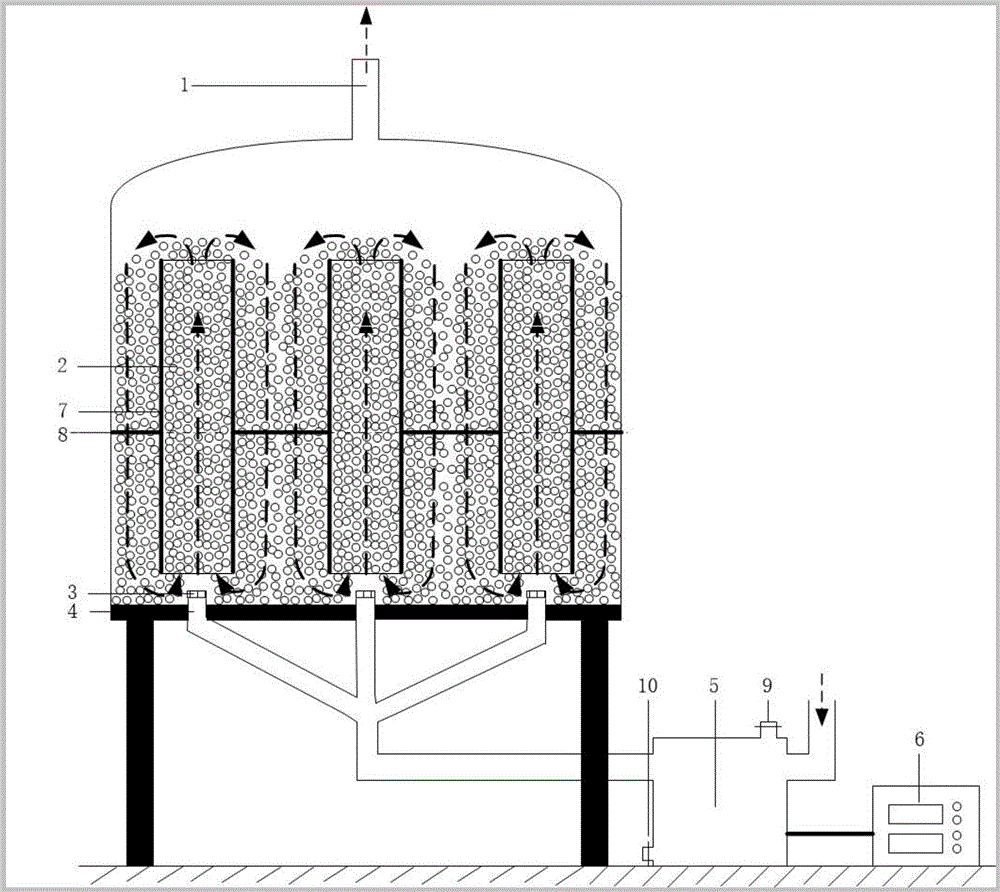

[0020] Such as figure 1 with figure 2 As shown, the present invention is a kind of internal circulating biological fluidized bed system for VOCs and malodorous gas treatment, the biological fluidized bed reactor adopts inner and outer sleeve structure, wherein, the inner layer sleeve 7 is used to form the fluidized packing The upflow zone, the outer layer of the sleeve is used as the downflow zone of the fluidized packing, the packing layer 2 in the biological fluidized bed reactor is polymer light packing, the air inlet 4 of the biological fluidized bed reactor is located at the bottom, and The humidification unit 5 is connected, and the air outlet 1 is located at the top, corresponding to the air inlet 4 .

[0021] Among them, the top of the inner sleeve of the biological fluidized bed reactor should have a height difference of more than 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com