Row tube type normal-pressure coal economizer

An economizer and tube-and-tube technology, which is used in feedwater heaters, preheating, steam generation, etc., can solve problems such as hindering heat transfer between flue gas and heat exchange tubes and fins, increasing maintenance costs, and reducing production efficiency. , to achieve the effect of improving heat exchange effect, saving metal consumption and improving heat supply coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

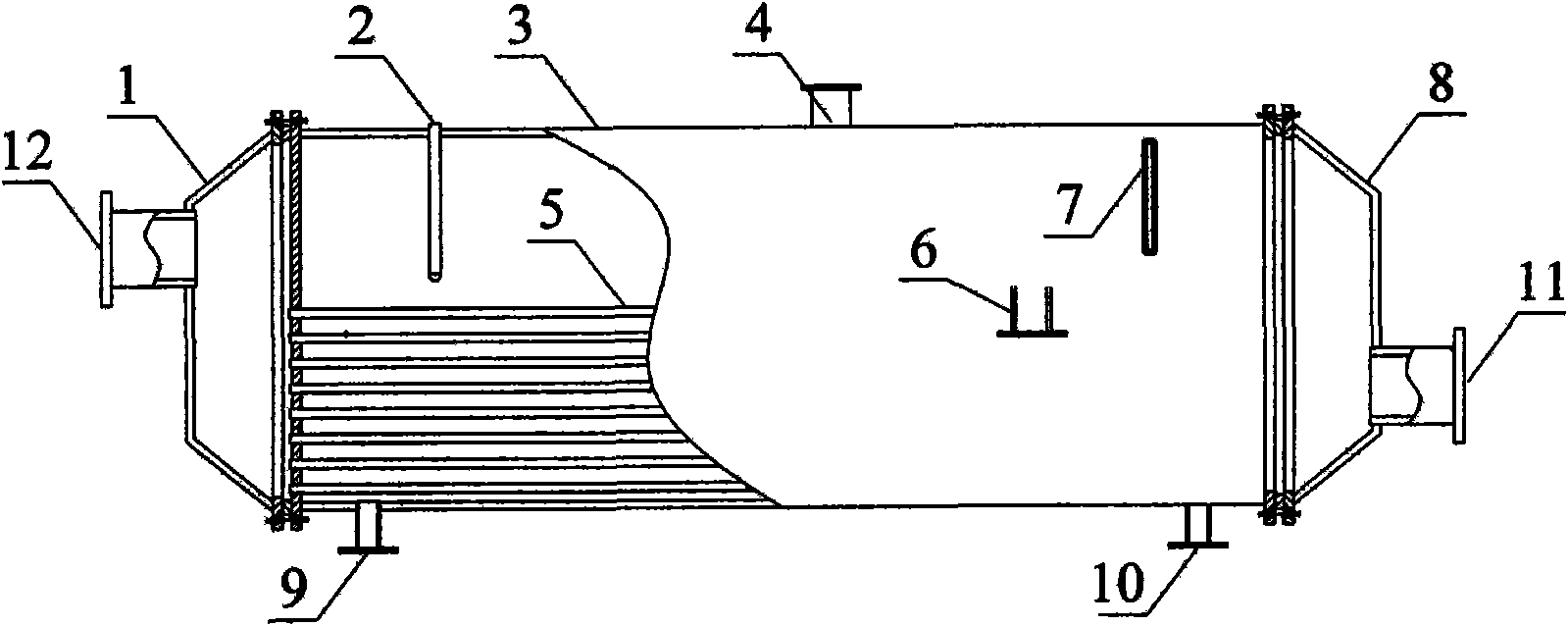

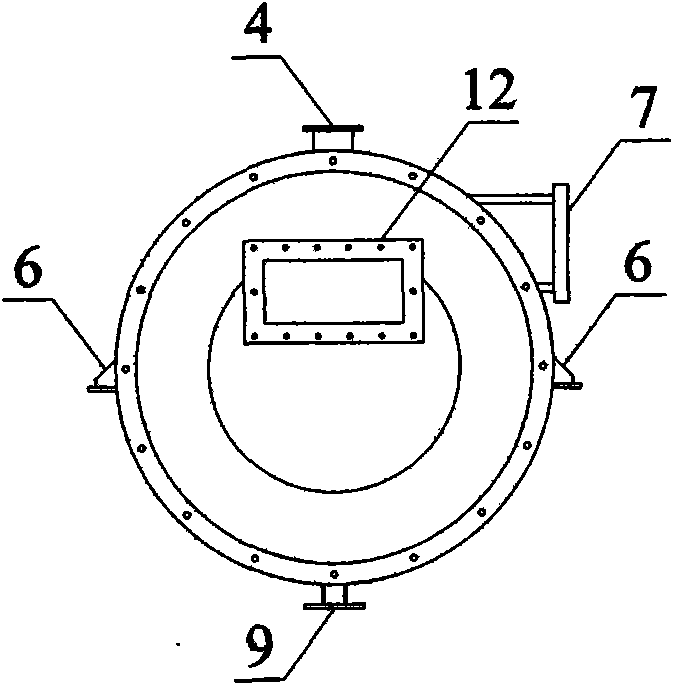

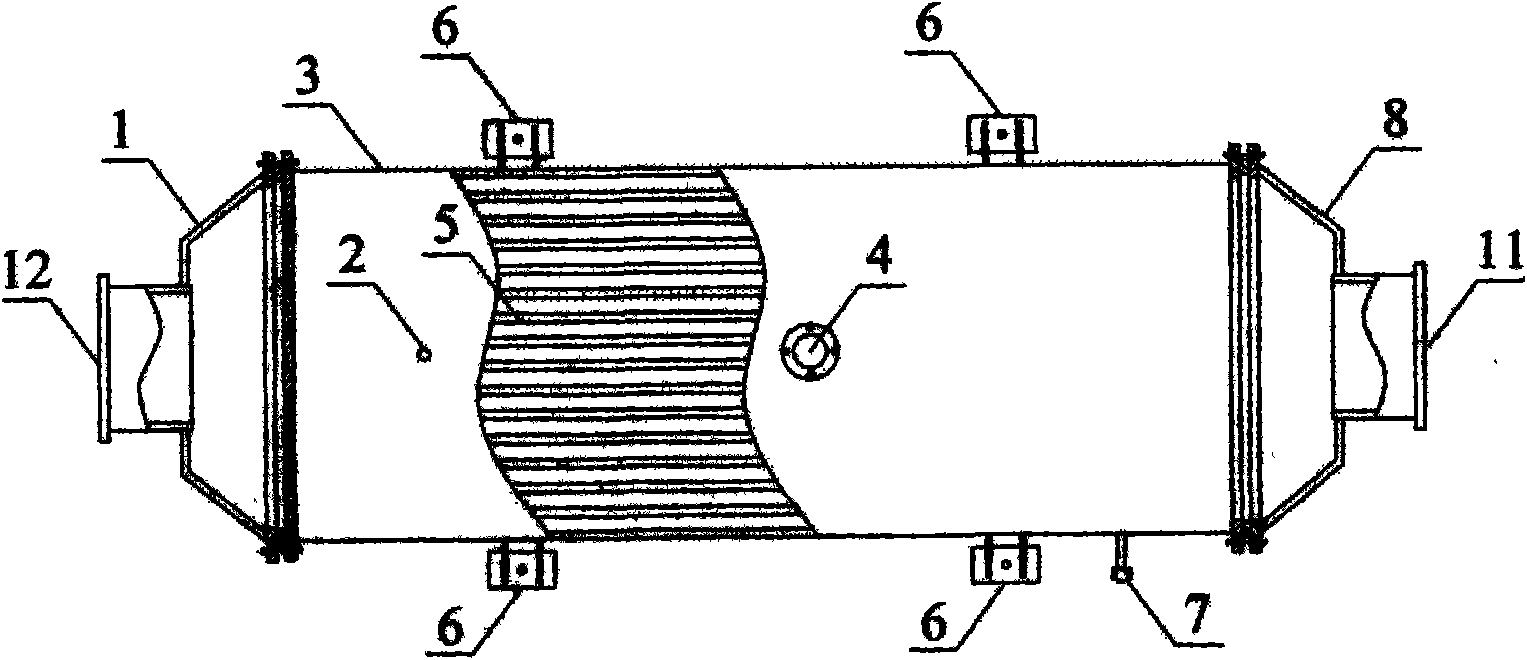

[0018] See attached figure 1 to attach image 3 Shown: a tube-and-tube atmospheric economizer, including a pipe box 3, a flue gas inlet header 1 and a flue gas outlet header 8 welded to both ends of the pipe box 3, and the flue gas inlet header 1 is connected with The flue gas interface 12, the flue gas outlet header 8 is provided with a fan interface 11, the lower part of the pipe box 3 is provided with a water outlet 9 near the flue gas inlet header 1, and a water inlet 10 is provided near the flue gas outlet header 8, Inside the pipe box 3, there is a tube 5 connected to the flue gas interface 12 at one end and connected to the fan interface 11 at the other end. circulation.

[0019] The tube array 5 is arranged within the range from the bottom of the tube box 3 to the height of 4 / 5 of the top of the tube b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com