Two-section biomass cyclone high-temperature pyrolysis gasification furnace

A technology of pyrolysis gasification and biomass gas, which is applied to the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry, and can solve the problems of reducing tar content and high tar content in biomass gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

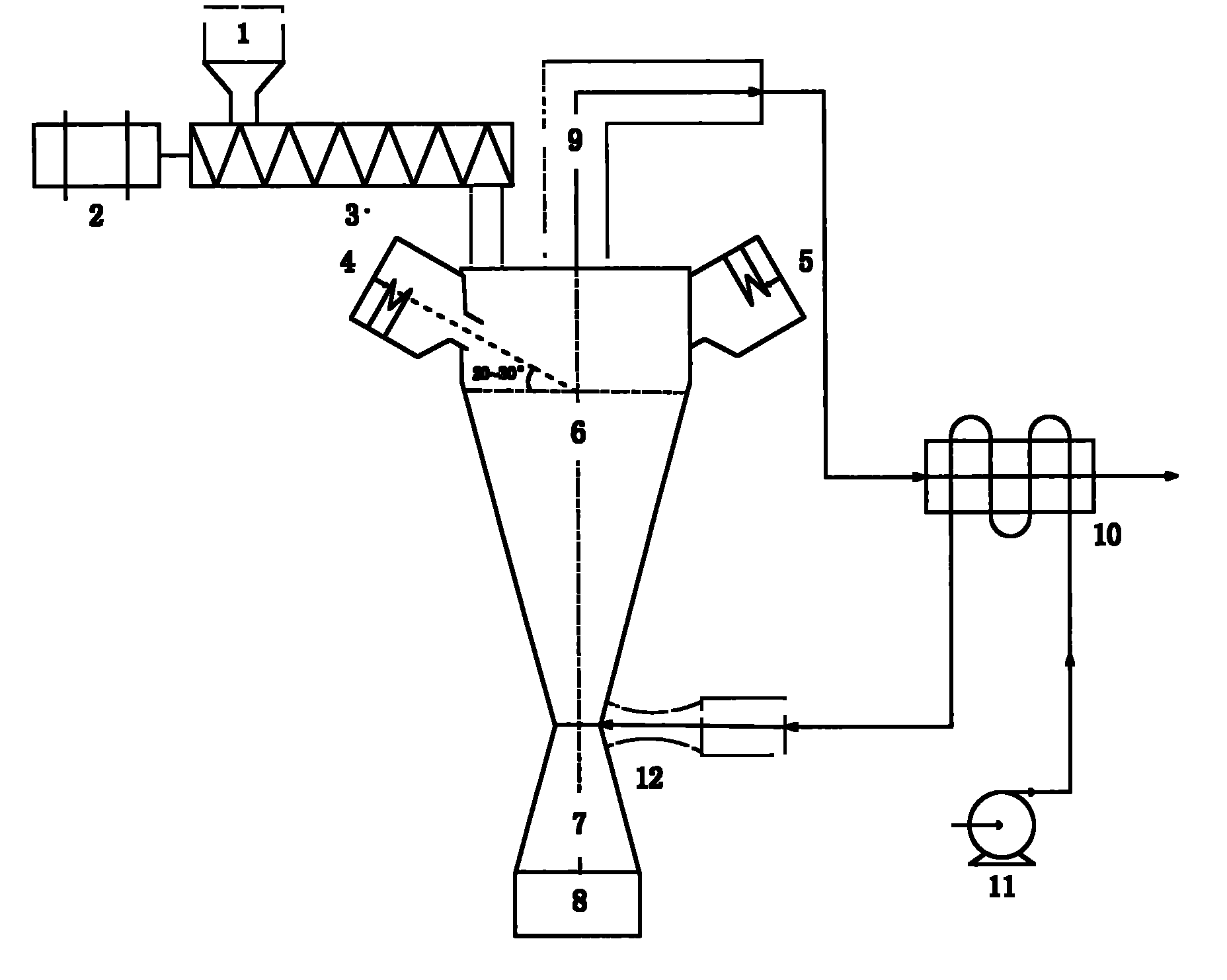

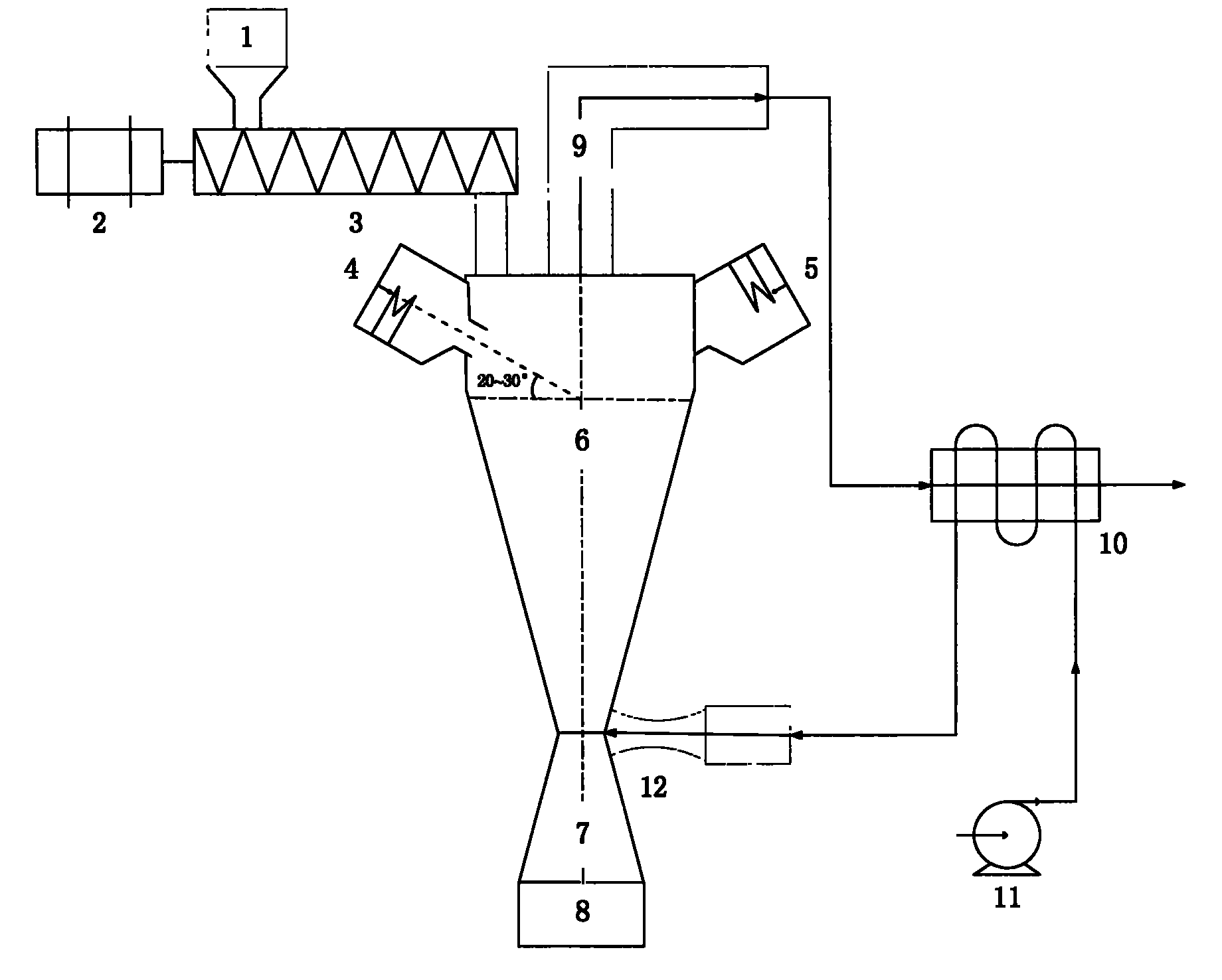

[0011] The two-stage biomass high-temperature pyrolysis gasification furnace consists of a cyclone high-temperature pyrolysis gasification chamber 6 in the form of upper and lower cylinders and cones, a lower water vapor spraying pyrolysis gasification chamber 7, and a screw feeder 3. Biomass gas Discharge pipe 9, gas fuel high velocity burner 4 and 5, ash box 8 are formed. Among them, the screw feeder 3 driven by the motor 2, the lower front end of the screw feeder 3 is connected with the top of the cyclone pyrolysis gasification chamber 6, and the upper rear end of the screw feeder 3 is connected with the biomass material bin 1 The lower part of the cyclone pyrolysis gasification chamber 6 communicates with the upper part of the water vapor spray pyrolysis gasification chamber 7 in the form of constriction, which is equivalent to the function of the Venturi tube; the ash box 8 is located in the water vapor spray pyrolysis gasification chamber The lower part of the chamber 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com