Dust removal process of coal gas and process gas

A process gas and coal-to-gas technology, which is applied in gasification process, gas dust removal, and combustible gas production, etc., can solve the problems of poor separation effect of small particle size particles, easy dust accumulation in pre-variable tower, high investment cost, etc., and achieves Enhance the mixing contact effect, enhance the adsorption effect, and improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

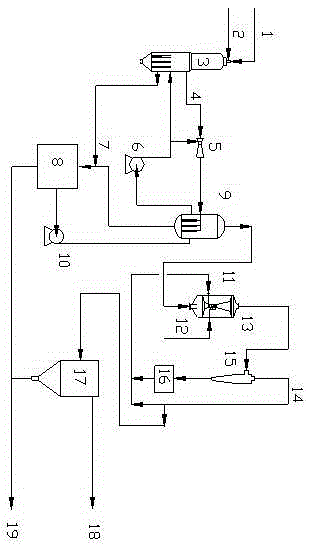

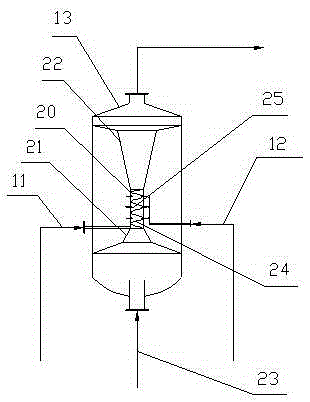

[0028] The process gas generated after the combustion reaction flows out of the gasifier 3 after being washed by the bottom water layer. The dust content of crude process gas 4 is 200g / m 3 , first enters the first-stage Venturi scrubber 5, fully contacts and mixes with the atomized washing water flowing out of the atomizing nozzle in the scrubber, and then flows into the water separation tank 9, after the washing effect of the water layer at the bottom of the tank, the condensed water-containing dust particles are washed by a large amount Removal, the dust content of the process gas 23 after the water separation tank is reduced to 2g / m 3. Then it is sent to the secondary Venturi dust collector 13, and the remaining small particle dust in the gas is first wetted by the atomized spray water 12, and collides with the sprayed adsorbent 11 for adsorption. The gas enters the cyclone separator 15 together with the adsorbent particles. After cyclone separation, the adsorbent partic...

Embodiment 2

[0035] The process gas generated after the combustion reaction flows out of the gasifier 3 after being washed by the bottom water layer. The dust content of crude process gas 4 is 300g / m 3 , first enters the first-stage Venturi scrubber 5, fully contacts and mixes with the atomized washing water flowing out of the atomizing nozzle in the scrubber, and then flows into the water separation tank 9, after the washing effect of the water layer at the bottom of the tank, the condensed water-containing dust particles are washed by a large amount Removal, the dust content of the process gas 23 after the water separation tank is reduced to 4g / m 3 . Then it is sent to the secondary Venturi dust collector 13, and the remaining small particle dust in the gas is first wetted by the atomized spray water 12, and collides with the sprayed adsorbent 11 for adsorption. The gas enters the cyclone separator 15 together with the adsorbent particles. After cyclone separation, the adsorbent parti...

Embodiment 3

[0042] The process gas generated after the combustion reaction flows out of the gasifier 3 after being washed by the bottom water layer. The dust content of crude process gas 4 is 300g / m 3 , first enters the first-stage Venturi scrubber 5, fully contacts and mixes with the atomized washing water flowing out of the atomizing nozzle in the scrubber, and then flows into the water separation tank 9, after the washing effect of the water layer at the bottom of the tank, the condensed water-containing dust particles are washed by a large amount Removal, the dust content of the process gas 23 after the water separation tank is reduced to 4g / m 3 . Then it is sent to the secondary Venturi dust collector 13, and the remaining small particle dust in the gas is first wetted by the atomized spray water 12, and collides with the sprayed adsorbent 11 for adsorption. The gas enters the cyclone separator 15 together with the adsorbent particles. After cyclone separation, the adsorbent parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com