Methane and oxygen pre-mixer

An oxygen premixer and premixer technology, which is applied in the directions of gas and gas/vapor mixing, fluid mixer, mixer, etc., can solve the problems of inability to mix gas molecules horizontally and insufficient contact mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

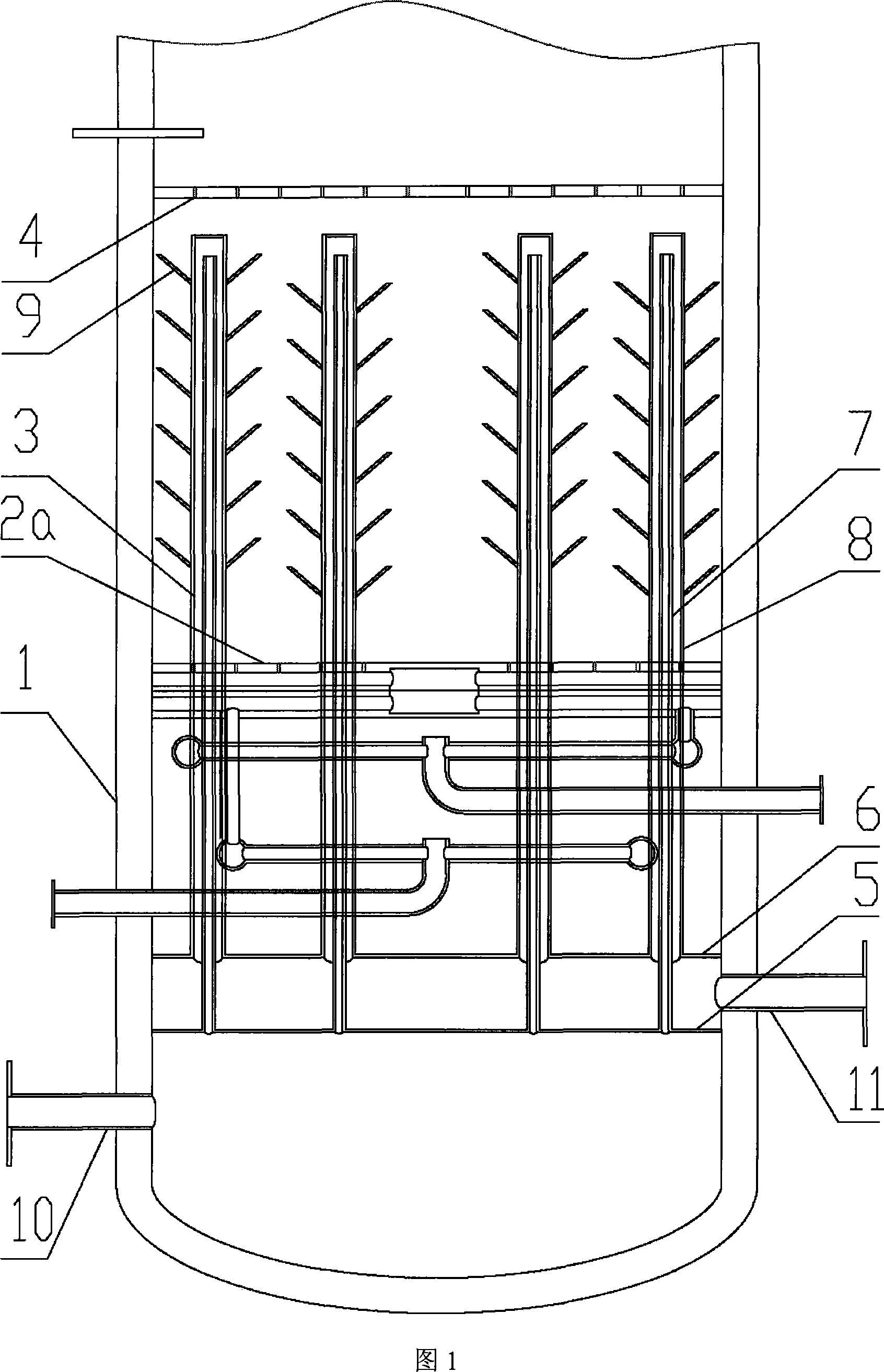

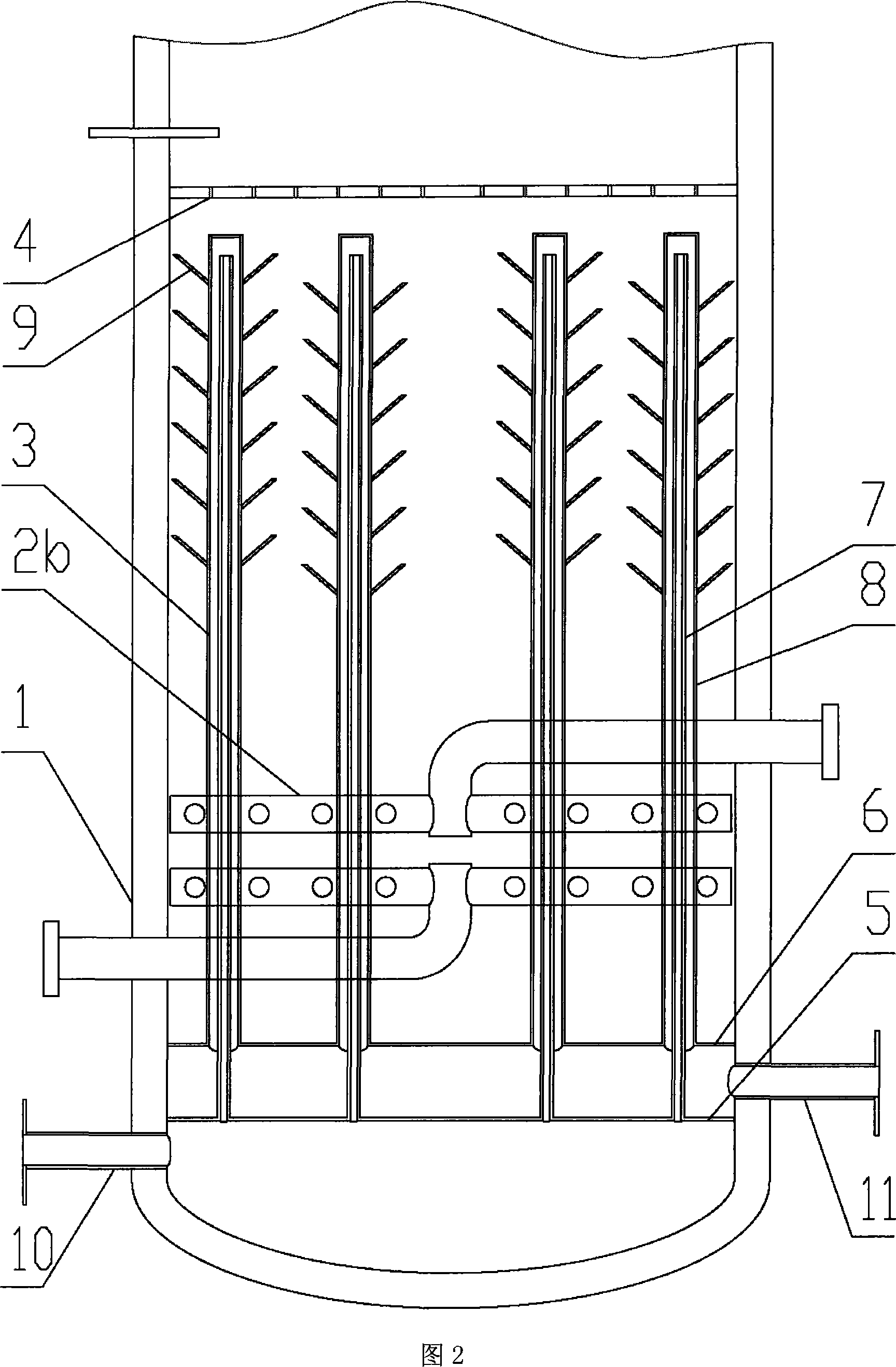

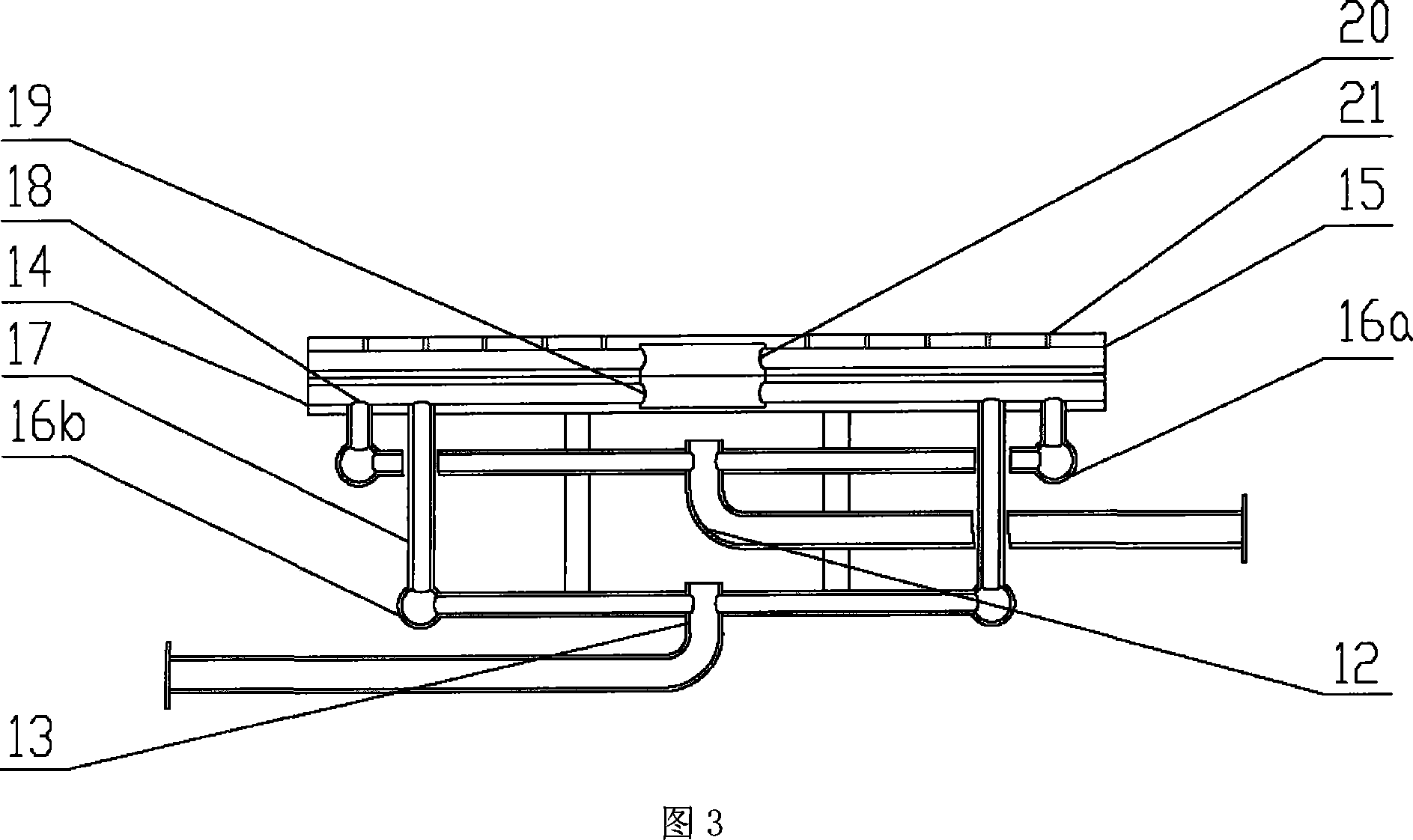

[0034] Using the methane and oxygen premixer of the present invention, the inlet distribution system of the premixer adopts annular gas distribution design and swirl gas distribution design respectively. The annular gas distributor has three layers of concentric rings, and each ring has 60 gas injection holes with a diameter of 1mm. The deflector of the swirling gas distributor has 24 gas channels, the channel size is 1mm*1mm, and the diameter of the central cylindrical cavity of the deflector is 15mm. The gas uses 99.99% methane and oxygen provided by Beijing Beiwen Gas Factory; the gas flow is controlled by the D07 mass flowmeter of Beijing Qixing Huachuang Electronics Co., Ltd., and the flow rate of methane and oxygen is 15L / min; the mixed gas passes through Shanghai Gas chromatograph type 7890II of Tianmei Scientific Instrument Co., Ltd. was used for analysis. A chromatographic sampler was used to randomly collect 10 samples from the gas outlet of each premixed layer for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com