Apparatus and method for continuously preparing thin-layer grapheme or hybrid combining thin-layer grapheme with thin-walled carbon nanotube

A thin-layer graphene and carbon nanotube technology, which is used in the preparation of thin-layer graphene or thin-layer graphene and thin-walled carbon nanotube hybrids, and the preparation of thin-layer graphene or thin-layer graphene and thin-walled carbon nanotubes. In the field of pipe hybrid devices, it can solve the problems of high cost, high price and long residence time, and achieve the effects of simple installation support, wide application range and low equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

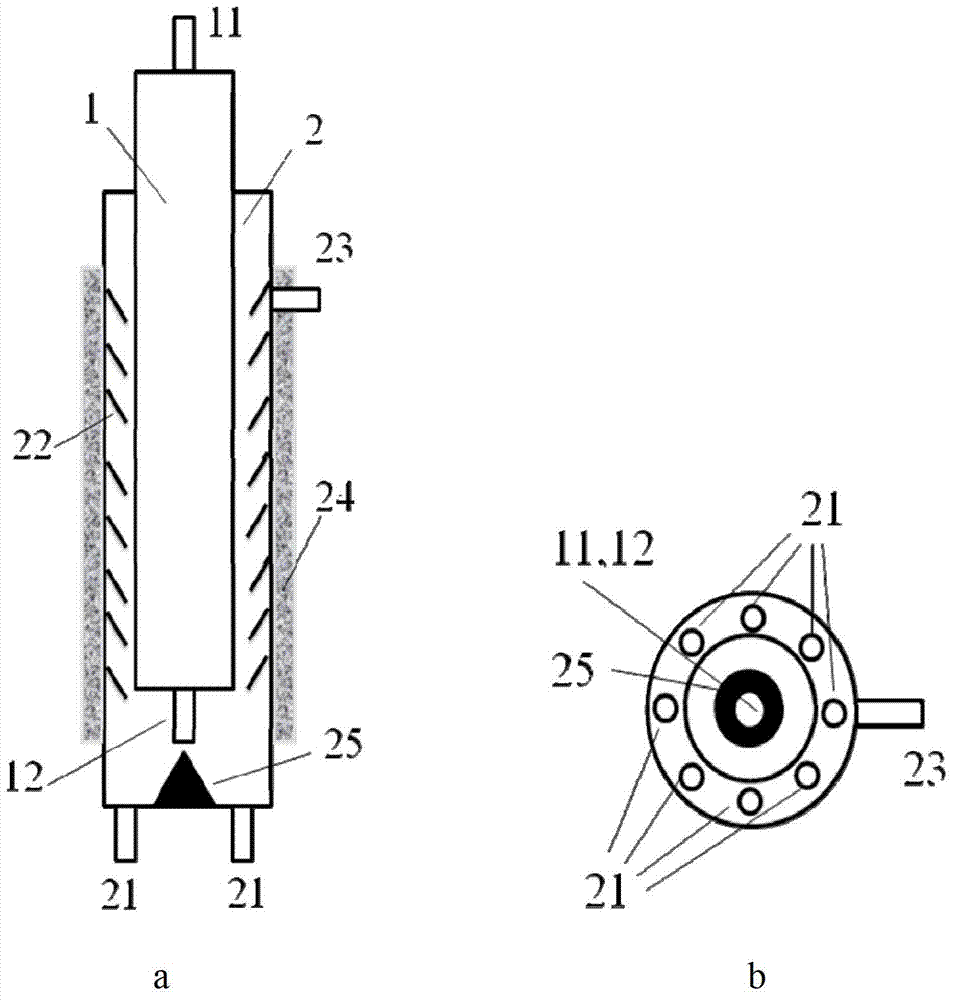

[0055] use as figure 1 The reaction device shown, wherein the ratio of the cross-sectional area of the down-bed 1 to the riser 2 is 3:1, uses Fe / MgO catalyst (the mass ratio of Fe is 1.2%, the rest is MgO, the particle size is 100 microns, and the bulk density is 1600 kg / m 3 ), the reaction gas is a mixture of methane, hydrogen, argon and nitrogen (the volume ratio of methane: hydrogen: argon: nitrogen is 2:7:300:100), and the total space velocity of carbon source is 300 g / gcat / h; Pass the reaction gas and catalyst into the down-bed 1, and generate a hybrid of single-layer graphene and single-walled carbon nanotubes at 800°C and a gas velocity of 0.1m / s; when the gas-solid mixture from the down-bed When the gas-solid mixture flowing out of the outlet 12 enters the bottom of the riser 2, methane is replenished through the gas inlet 21 of the riser, so that the volume ratio of methane:hydrogen remains at 2:7; at 800°C, the gas velocity is 1~1.5m / s Under certain conditions, p...

Embodiment 2

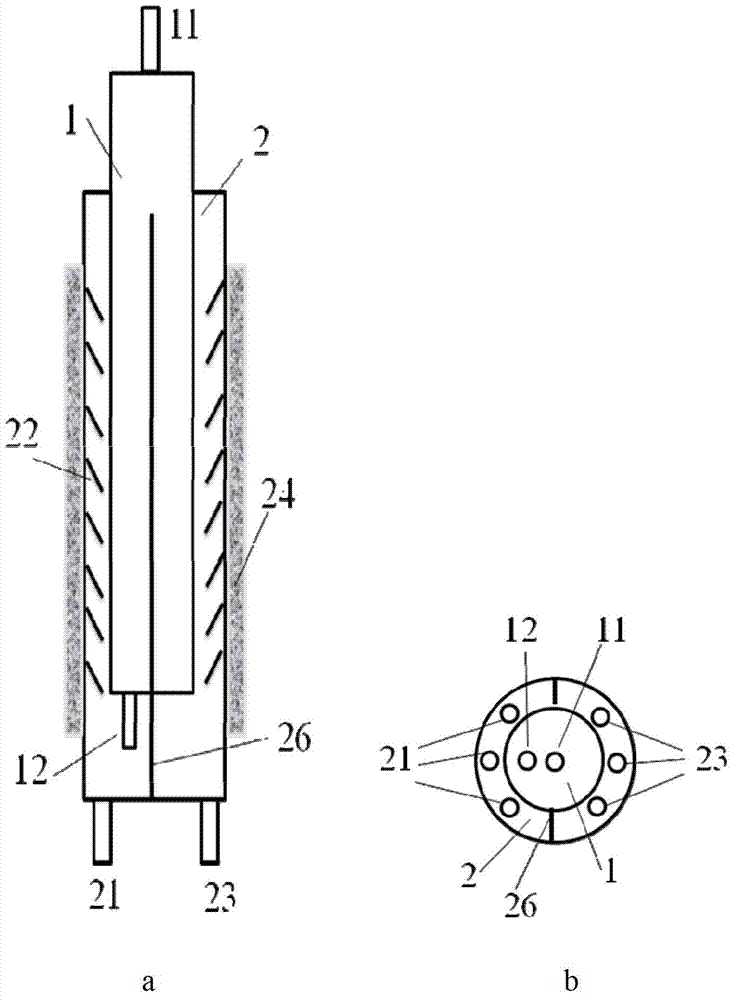

[0057] use as figure 2 The reaction device shown, wherein the ratio of the cross-sectional area of the down-bed 1 to the riser 2 is 1.2:1, using Ni / Mo / SiO 2 Catalyst (Ni mass proportion is 1%, Mo mass proportion is 0.5%, the rest is SiO 2 , with a particle size of 400 microns and a bulk density of 500 kg / m 3 ), the reaction gas is a mixture of acetylene, ethylene, and hydrogen (the volume ratio of acetylene: ethylene: hydrogen is 2:2:4), and the total space velocity of the carbon source is 20g / gcat / h; the reaction gas and the catalyst are passed down In bed 1, hybrids of graphene and carbon nanotubes are generated under the conditions of 450°C and gas velocity of 2m / s; , replenish acetylene and ethylene through the gas inlet 21 of the riser, so that the volume ratio of acetylene:ethylene:hydrogen remains at 2:2:4. The component area 22 at the inlet 21 end reaches the top of the riser 2, moves downward after passing through the top of the vertical partition 26, and then p...

Embodiment 3

[0059] use as figure 1 The reaction device shown, wherein the ratio of the cross-sectional area of the down-bed 1 to the riser 2 is 4:1, Fe / V / Al 2 o 3 Catalyst (the mass proportion of Fe is 1%, the mass proportion of V is 0.2%, and the rest is Al 2 o 3 , with a particle size of 500 nm and a bulk density of 500 kg / m 3 ), the reaction gas is a mixture of ethanol, methanol, and hydrogen (the volume ratio of ethanol:methanol:hydrogen is 2:0.5:500), and the total space velocity of the carbon source is 50 g / gcat / h; the reaction gas and the catalyst are passed into The down-bed 1 generates thin-walled carbon nanotubes at 900°C and the gas velocity is 1m / s; when the gas-solid mixture flowing out from the outlet 12 of the down-bed gas-solid mixture enters the bottom of the riser 2, it passes through the riser The gas inlet 21 of the riser of 2 is supplemented with ethanol and methanol, so that the volume ratio of acetylene: ethylene: hydrogen is still maintained at 2:0.5:500. At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com