A New Type of Precooling Air Combined Engine

A cold air and engine technology, applied in the direction of machine/engine, rocket engine device, mechanical equipment, etc., can solve the problems of difficult to achieve high system performance, low system specific impulse performance, high fuel consumption rate, and achieve improved specific impulse performance, The effect of avoiding fuel waste and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

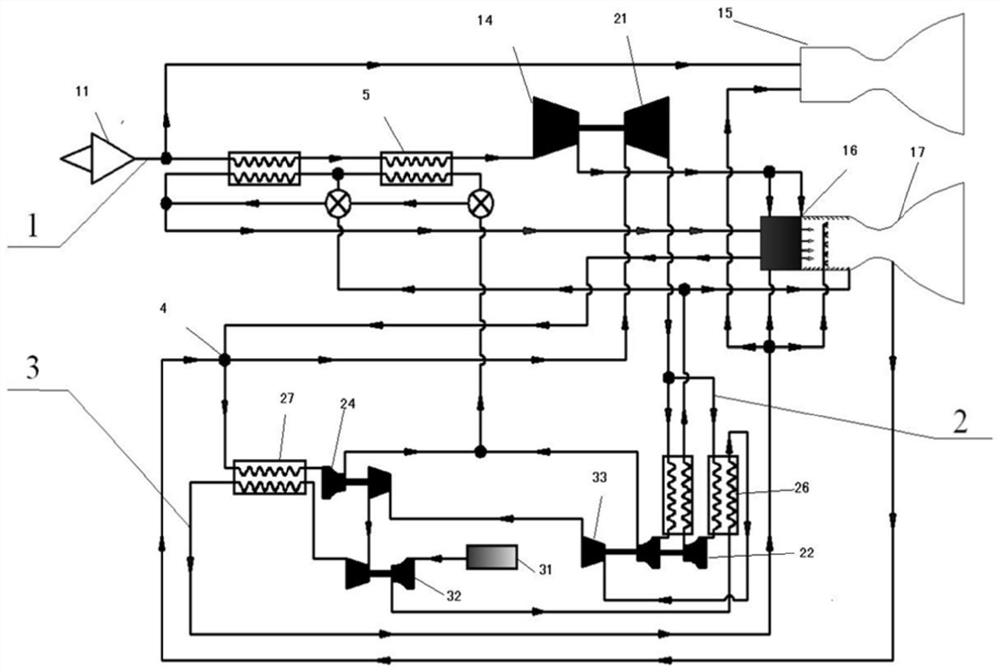

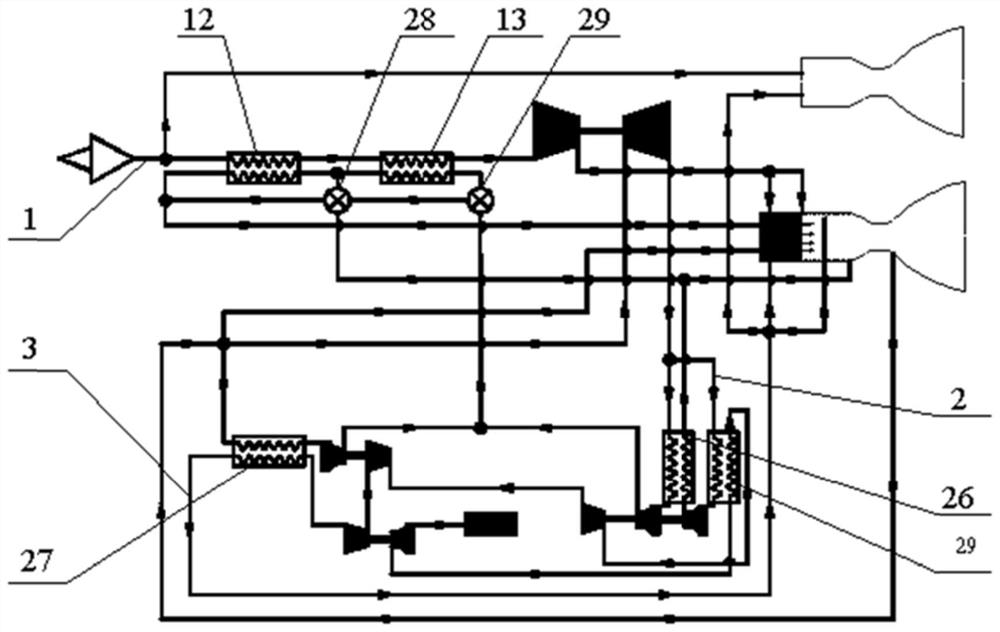

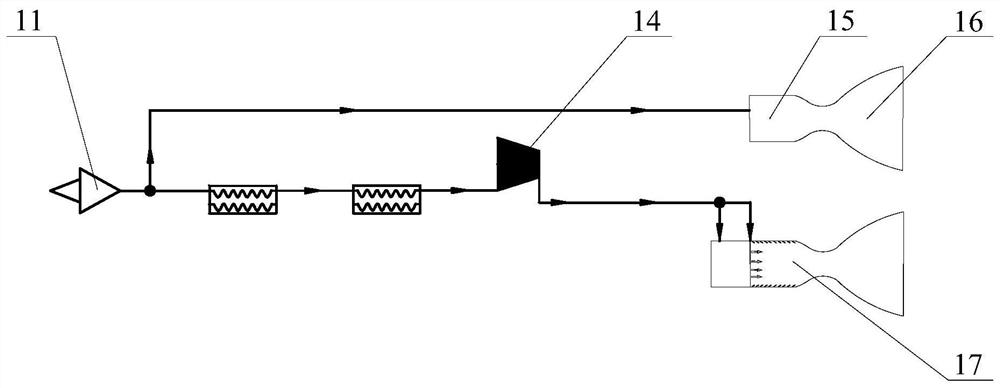

[0025] A new type of pre-cooled air combination engine, such as figure 1 As shown, it includes air combustion path 1, helium cooling path 2, and hydrogen energy supply path 3. Using the ultra-low temperature characteristics of liquid hydrogen fuel to absorb the heat in the high-temperature incoming air after stagnation in the intake port, it is introduced into the helium cooling path 2 As an intermediate cycle, the energy transfer and conversion between the air combustion path 1 and the hydrogen energy supply path 3 are carried out. Its characteristics are: the helium cooling circuit 2 adopts the circulation scheme of split flow and heat recovery, and uses the thrust chamber to replenish part of the heat for the helium cooling circuit 2; the hydrogen energy supply circuit 3 adopts the circulation scheme of staged cooling, and the hydrogen is absorbed in the heat exchanger After the waste heat from the helium enters the hydrogen turbine to expand and do work, the temperature dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com