Sample machine on basis of principle of nitrous oxide mono-component thruster and use method thereof

A nitrous oxide single and thruster technology, applied in machines/engines, mechanical equipment, jet propulsion devices, etc., can solve the problems of flammability, incomplete combustion, plume pollution, etc., and achieve self-sustaining and catalytic decomposition reactions. The effect of high decomposition temperature, risk reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

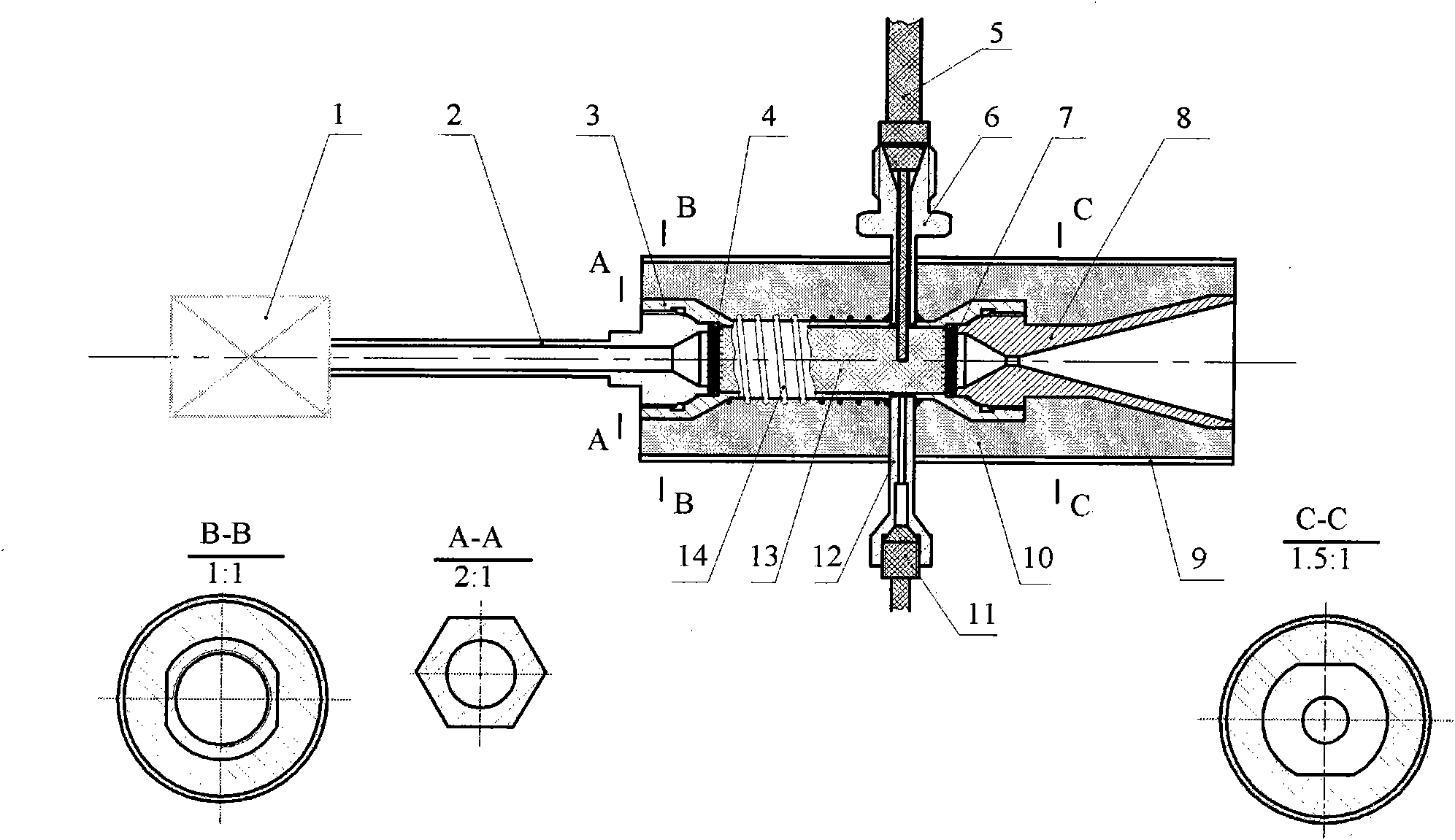

[0016] The use mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Shown in the figure is a principle prototype of a nitrous oxide single-component thruster related to the present invention, including: 1. Solenoid valve, 2. Propellant front conduit, 3. Decomposition chamber, 4. Front orifice plate, 5. Thermoelectric Couple, 6. Thermocouple nozzle, 7. Rear orifice plate, 8. Nozzle, 9. Aluminum foil layer, 10. High temperature resistant glass cloth layer, 11. Pressure sensor, 12. Pressure sensor nozzle, 13. Catalytic bed, 14. Armored heating wire.

[0018] Wherein, the two ends of the armored heating wire (14) are respectively connected with the positive and negative poles of the heating power supply. Before the thruster works, it is necessary to turn on the power to preheat the catalytic bed. The thermal insulation layer composed of the high temperature resistant glass cloth (10) and the aluminum foil (9) will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com