Expansion cycle liquid oxygen and methane upper-stage engine system

An engine system, liquid oxygen methane technology, applied in the direction of machinery/engine, rocket engine device, mechanical equipment, etc., can solve the problem of not developing liquid oxygen methane propellant and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

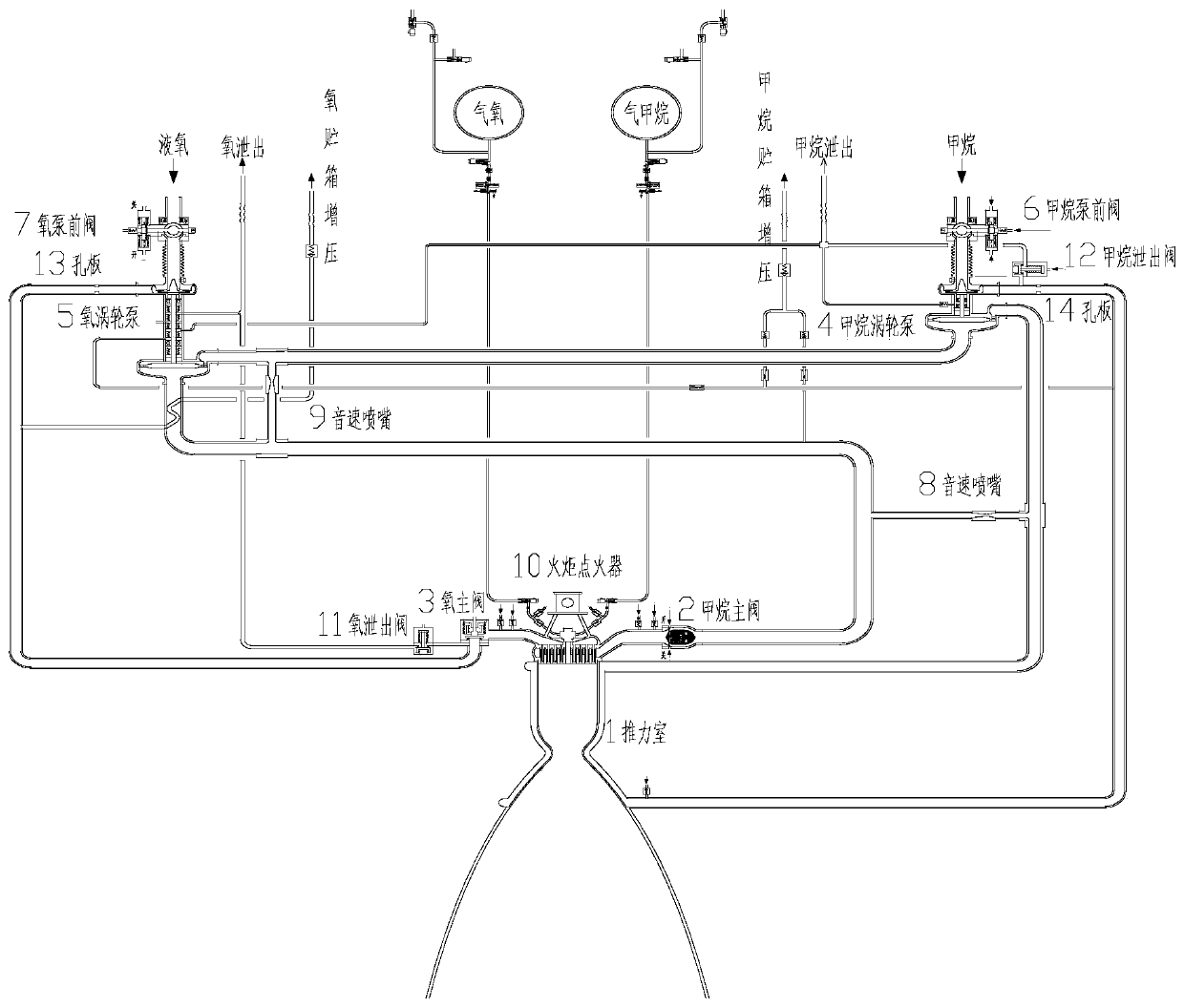

[0035] The present invention provides a pump pressure closed expansion cycle upper stage engine system, which mainly includes a propellant supply system, an ignition system and a thrust chamber 1 . The propellant supply system includes a methane supply system and a liquid oxygen supply system; the methane supply system pressurizes the low-temperature liquid methane from the external storage tank and supplies it to thrust chamber 1; the liquid oxygen supply system supplies the low-temperature liquid oxygen from the external storage tank After pressurization, it is supplied to the thrust chamber 1; the ignition system is located at the head of the thrust chamber 1, and is ignited under the control of the control system to ignite the liquid oxygen and methane entering the thrust chamber 1, and the high-temperature gas generated is ejected from the nozzle of the thrust chamber. Generate thrust.

[0036] Thrust chamber 1 is mainly composed of methane head chamber, liquid oxygen hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com