Patents

Literature

96results about How to "Low burst pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

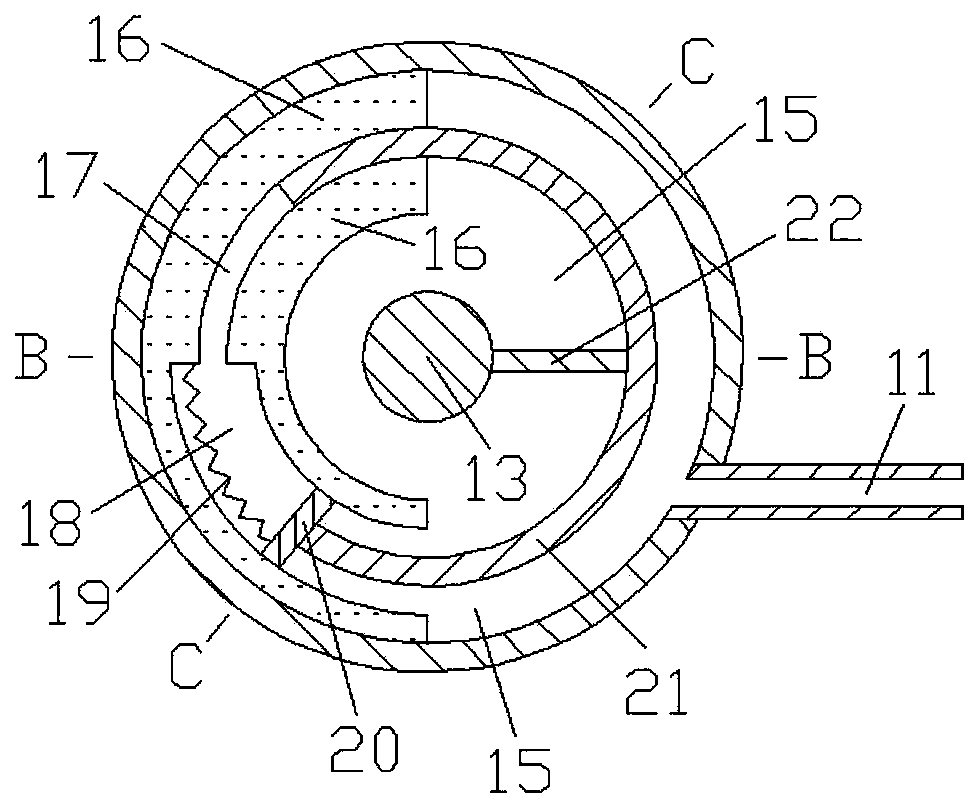

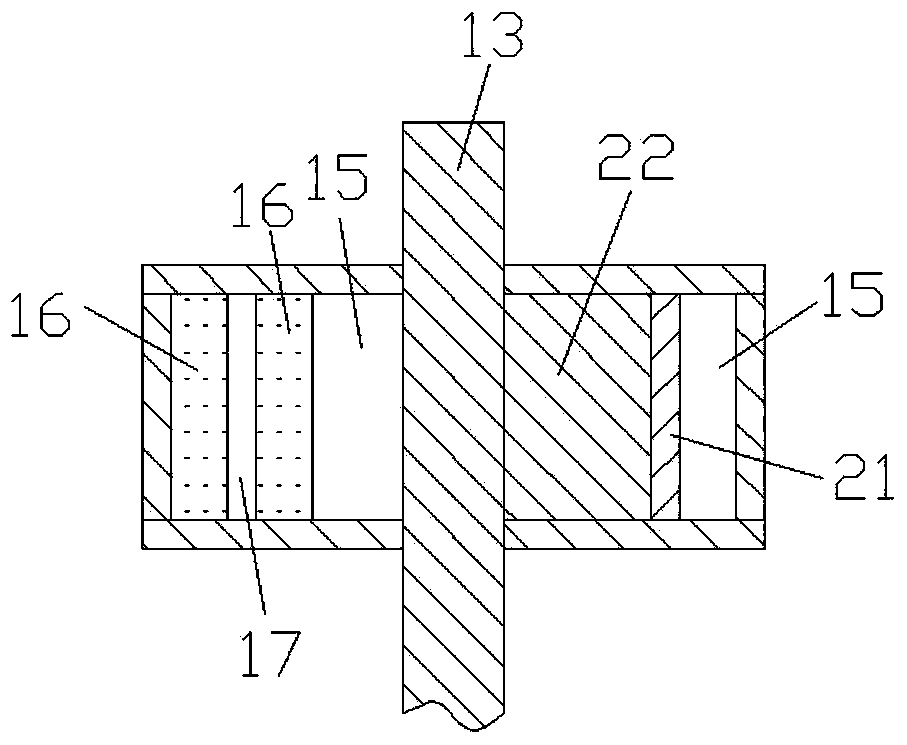

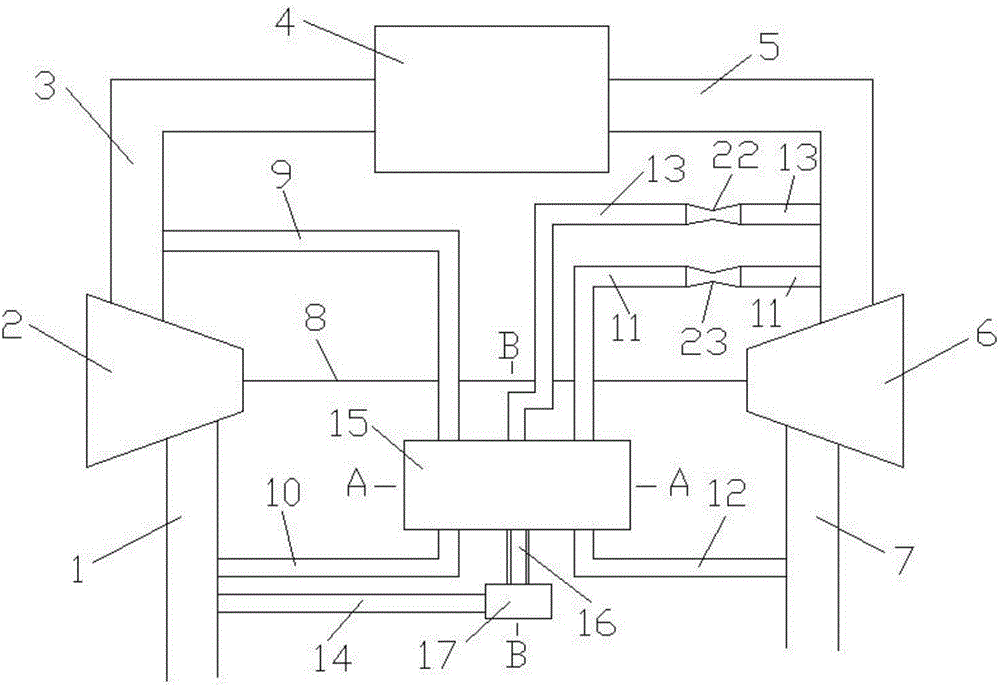

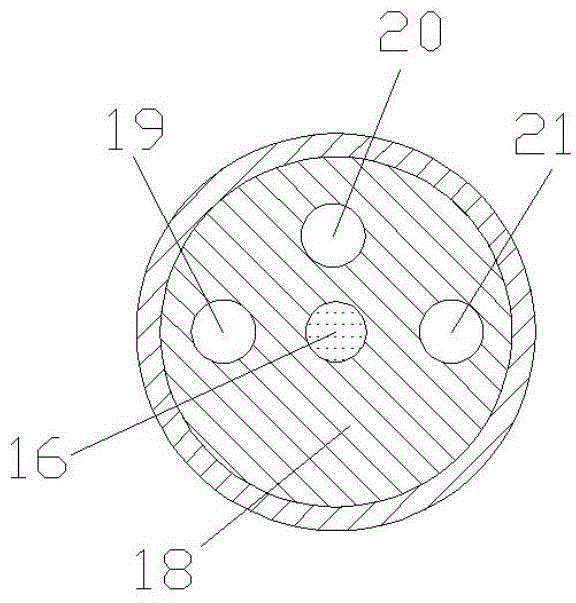

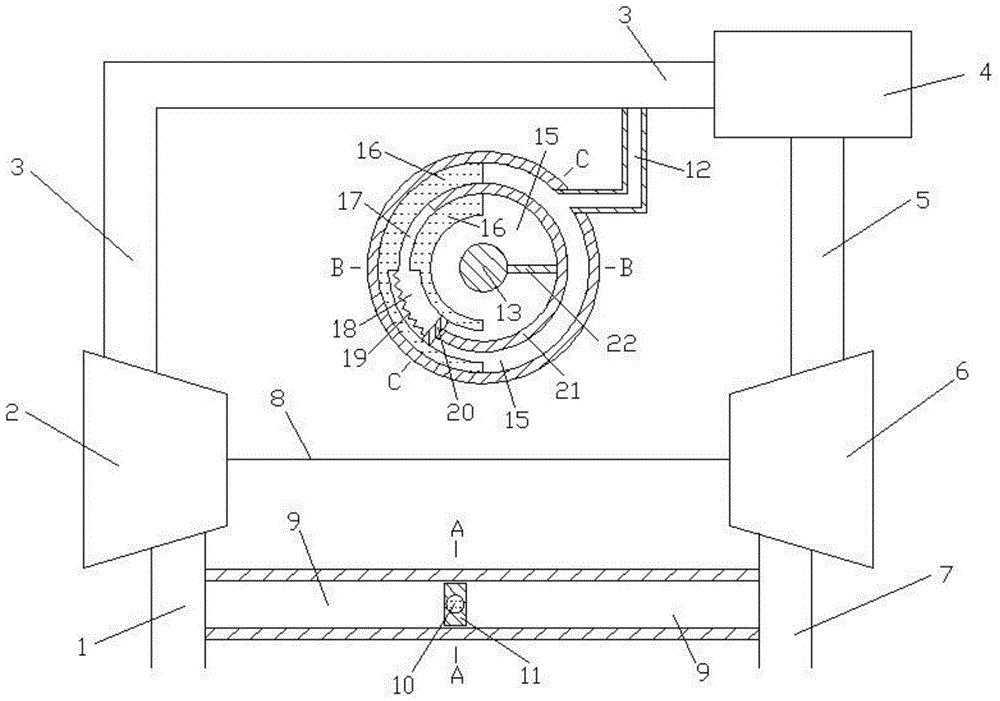

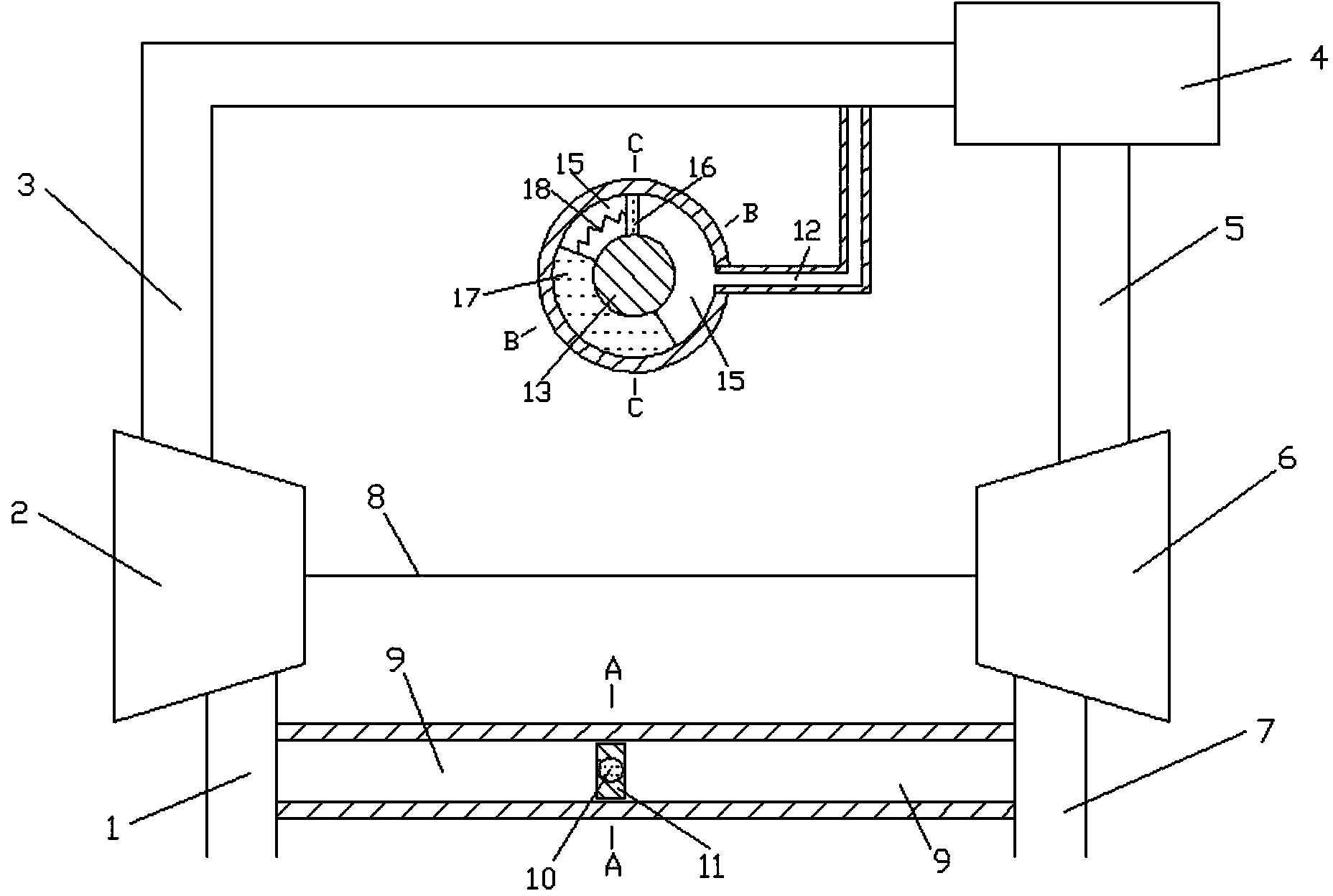

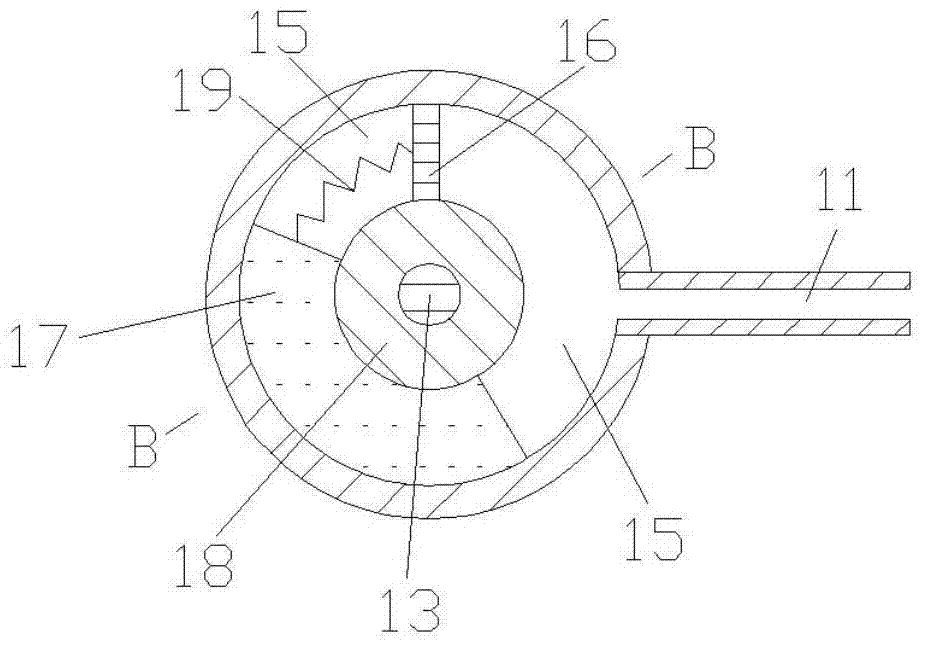

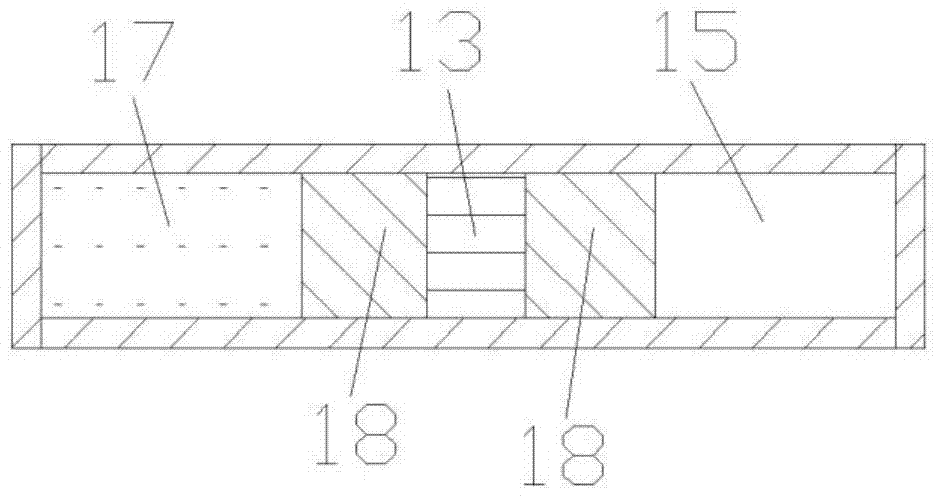

Rotary gas valve control mechanism

ActiveCN103291469ATaking into account low and medium speed conditionsReasonable designEngine controllersMachines/enginesElastic componentGas compressor

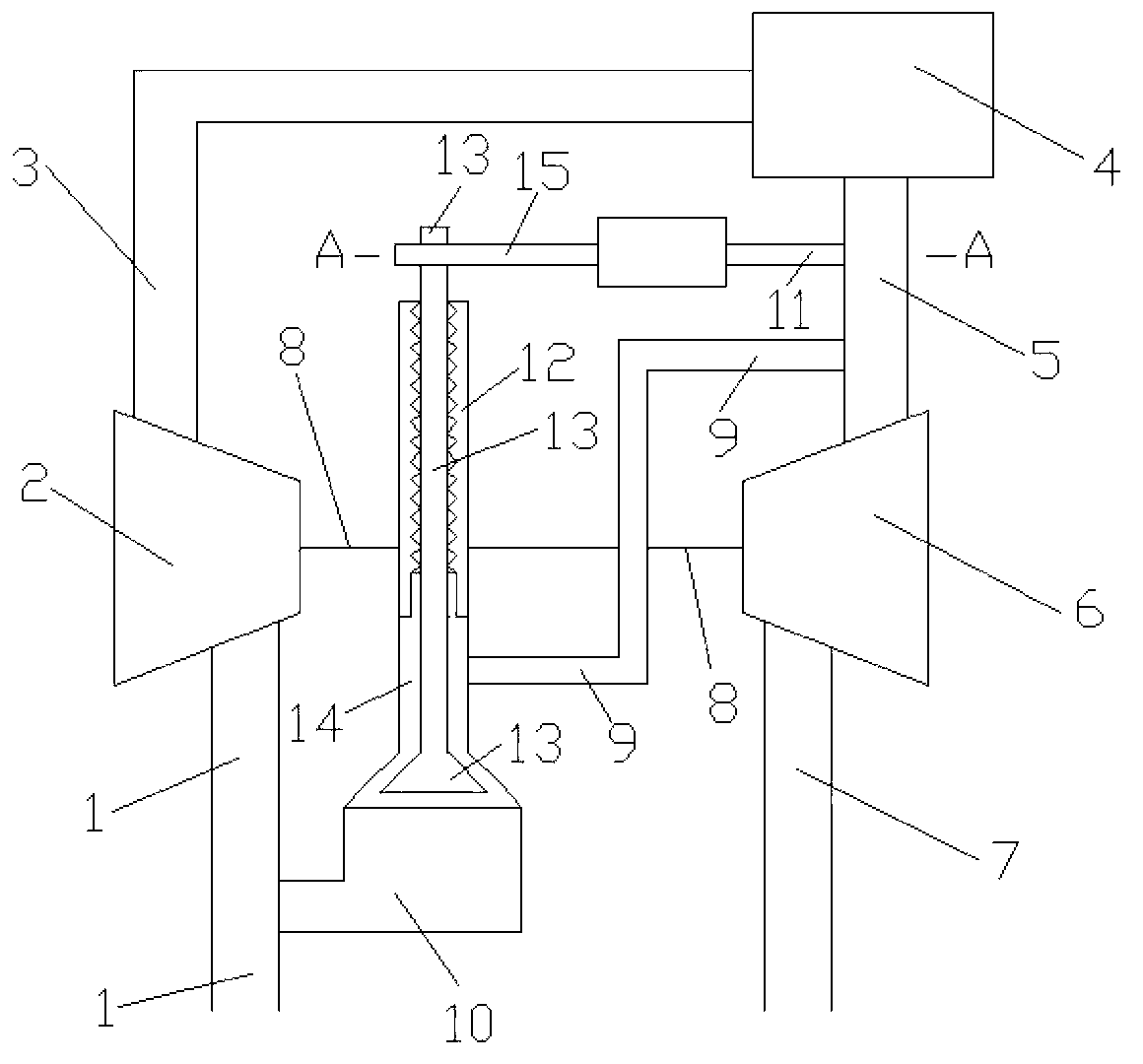

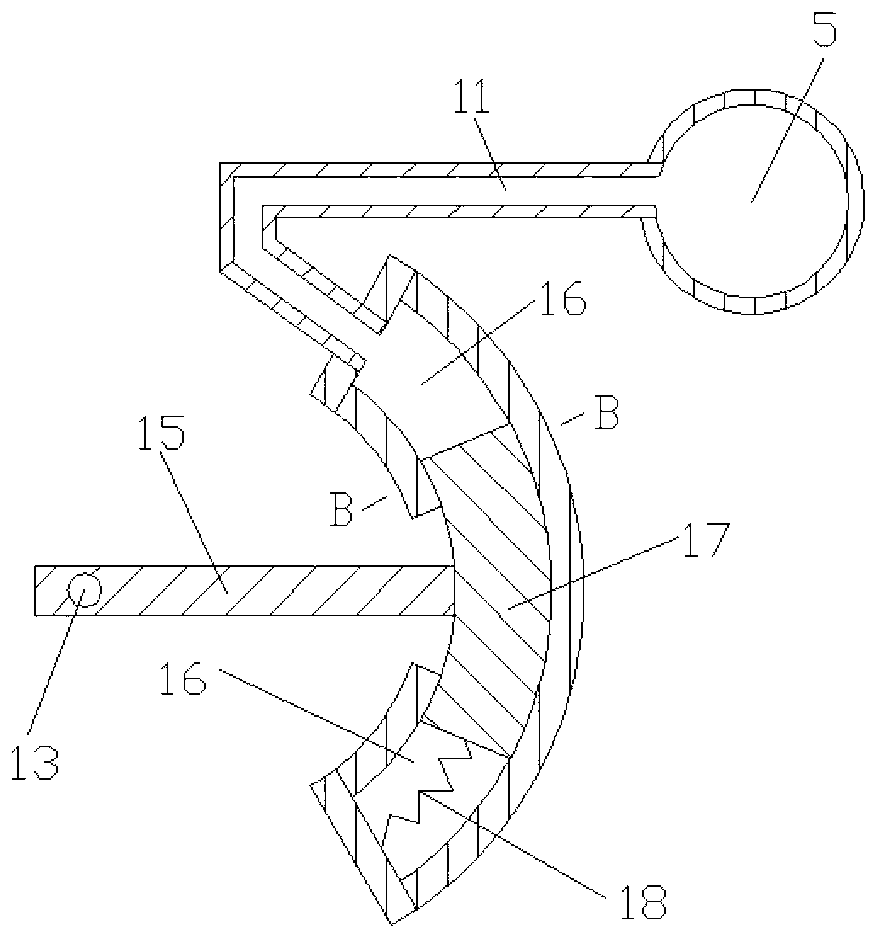

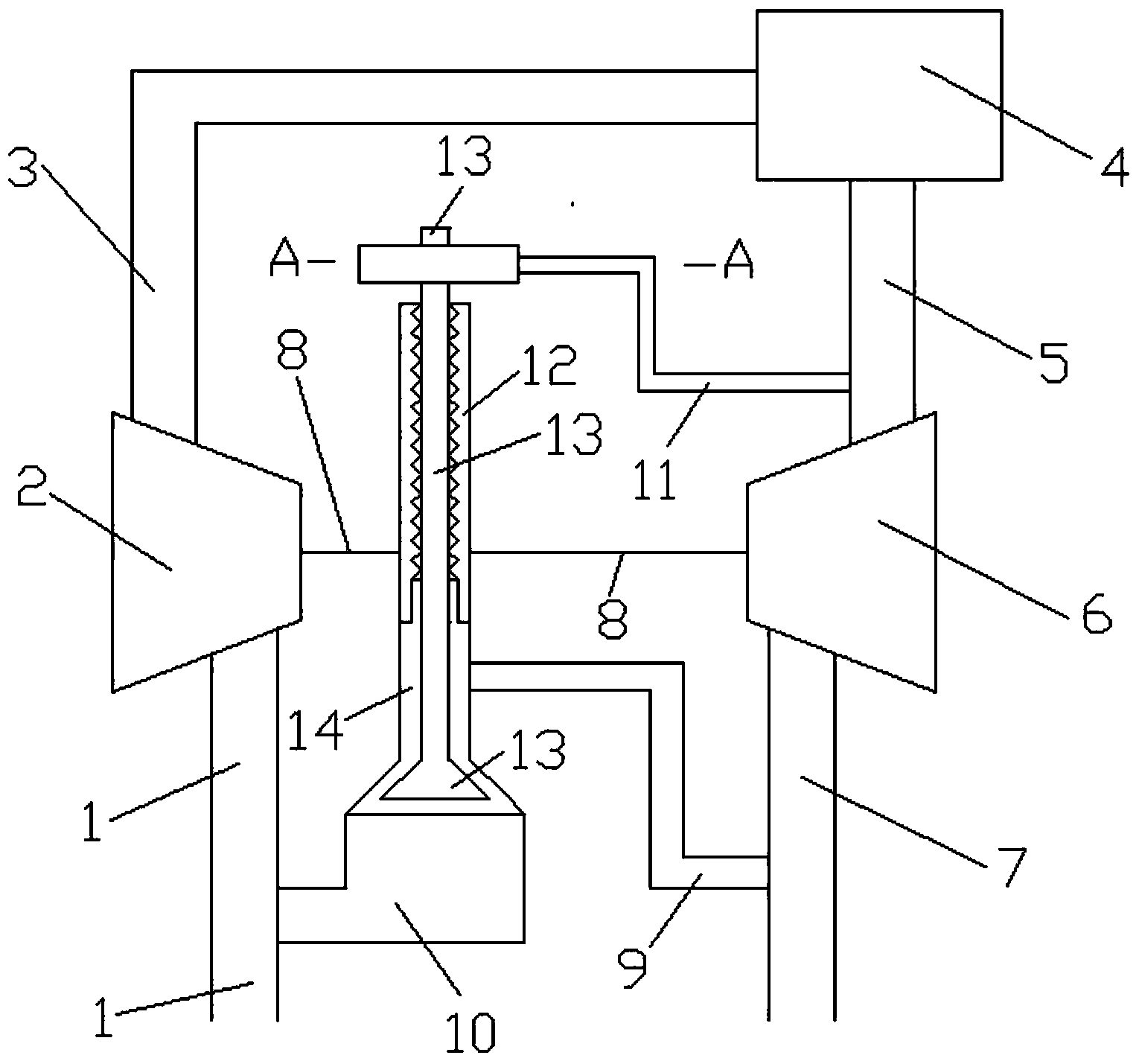

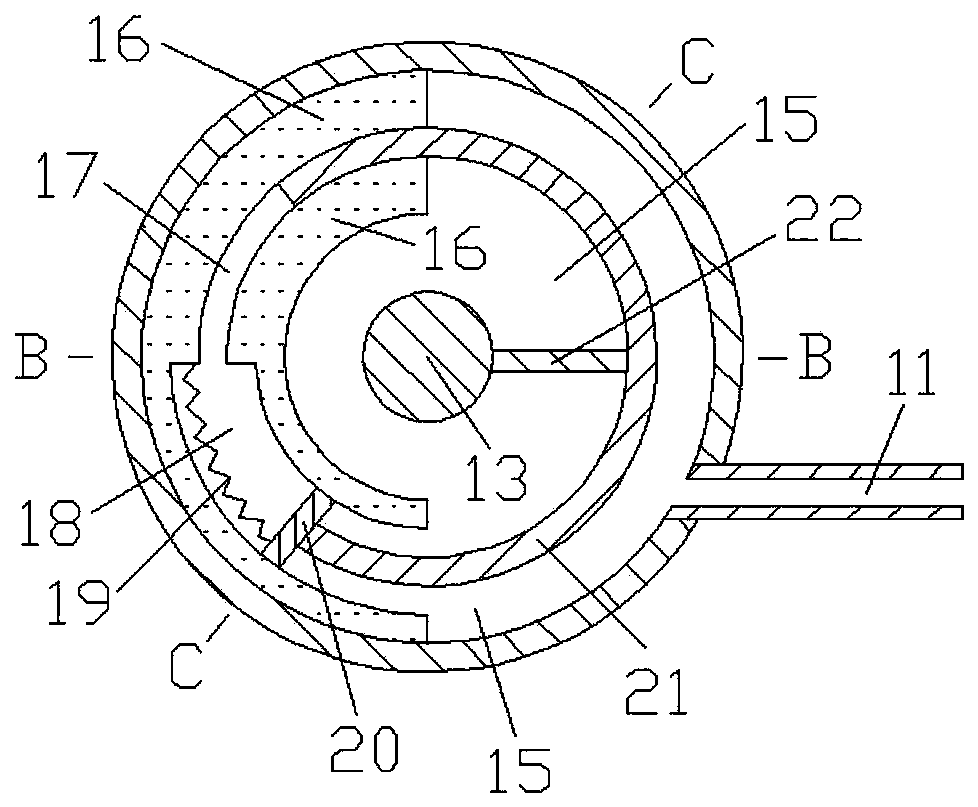

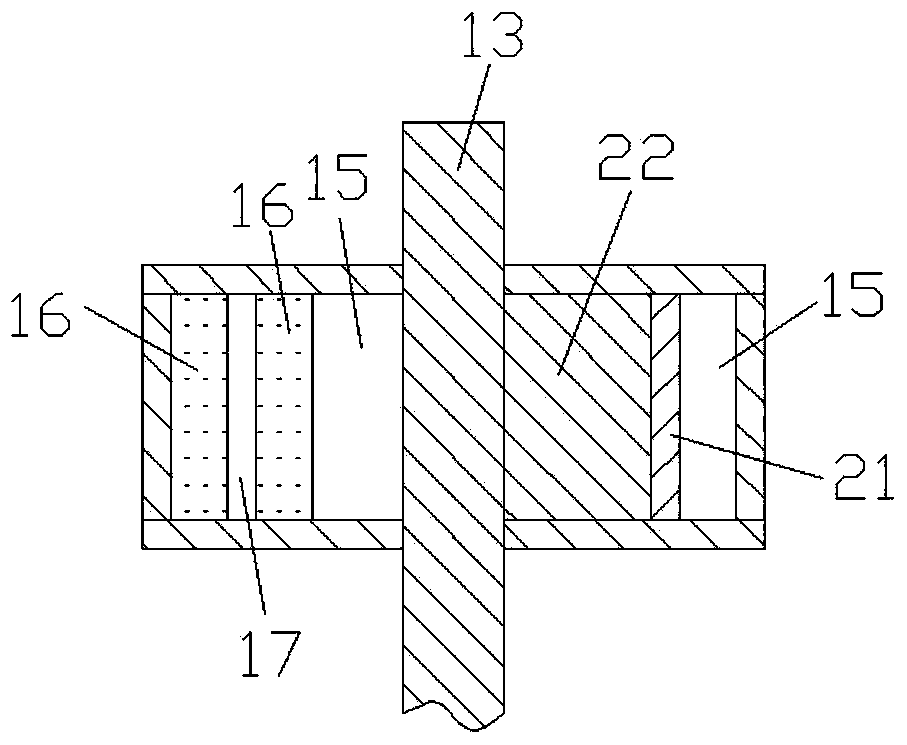

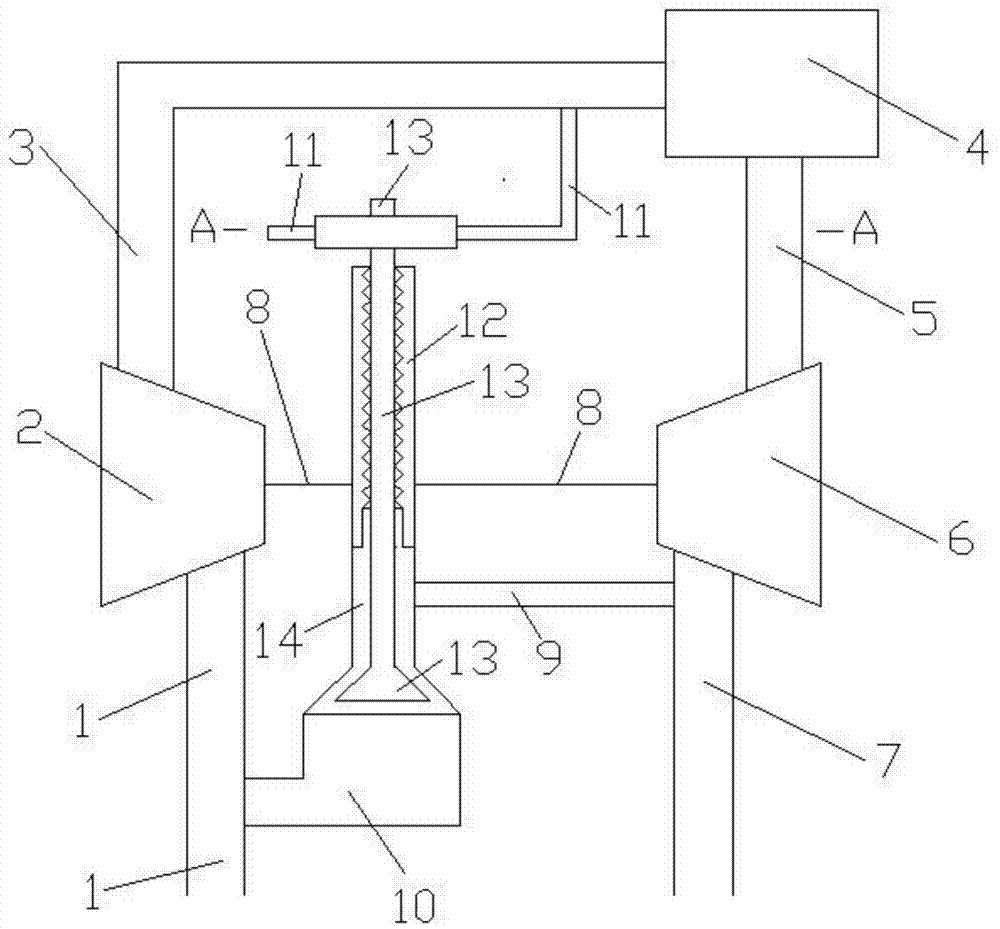

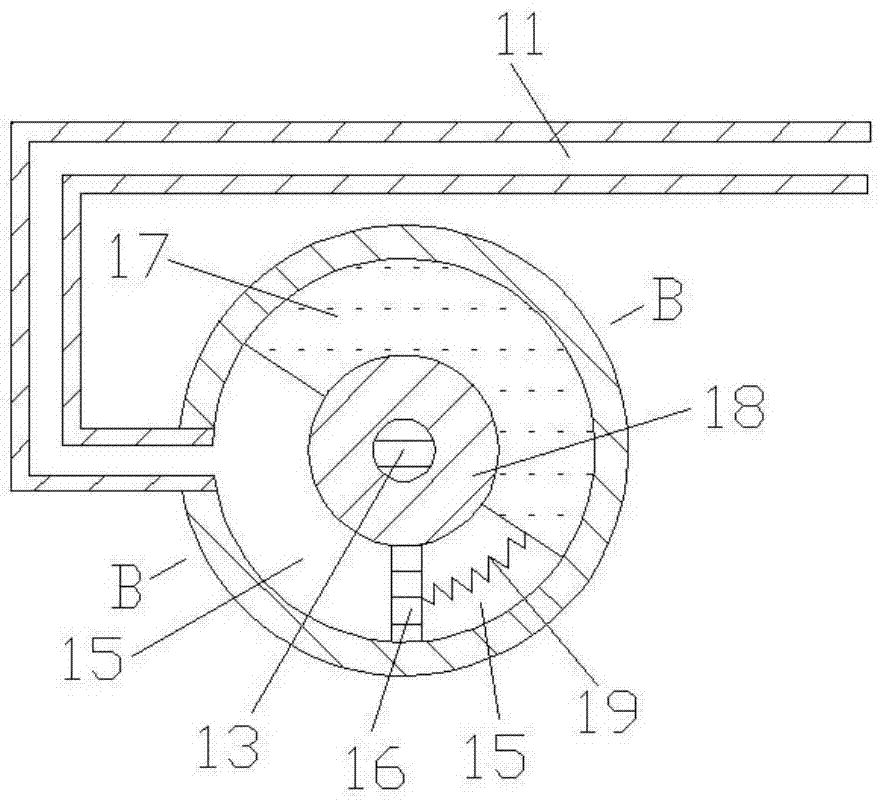

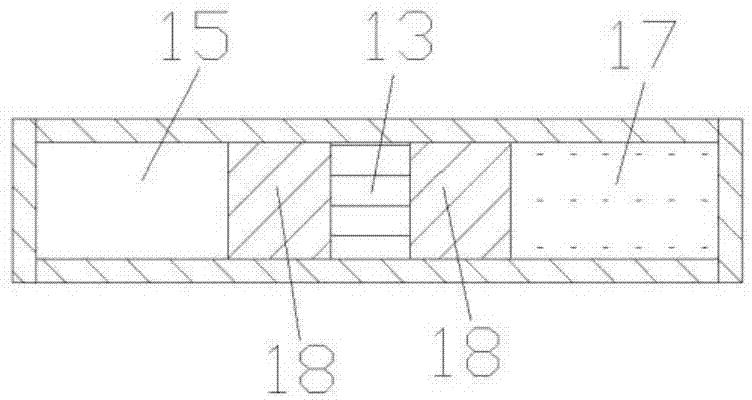

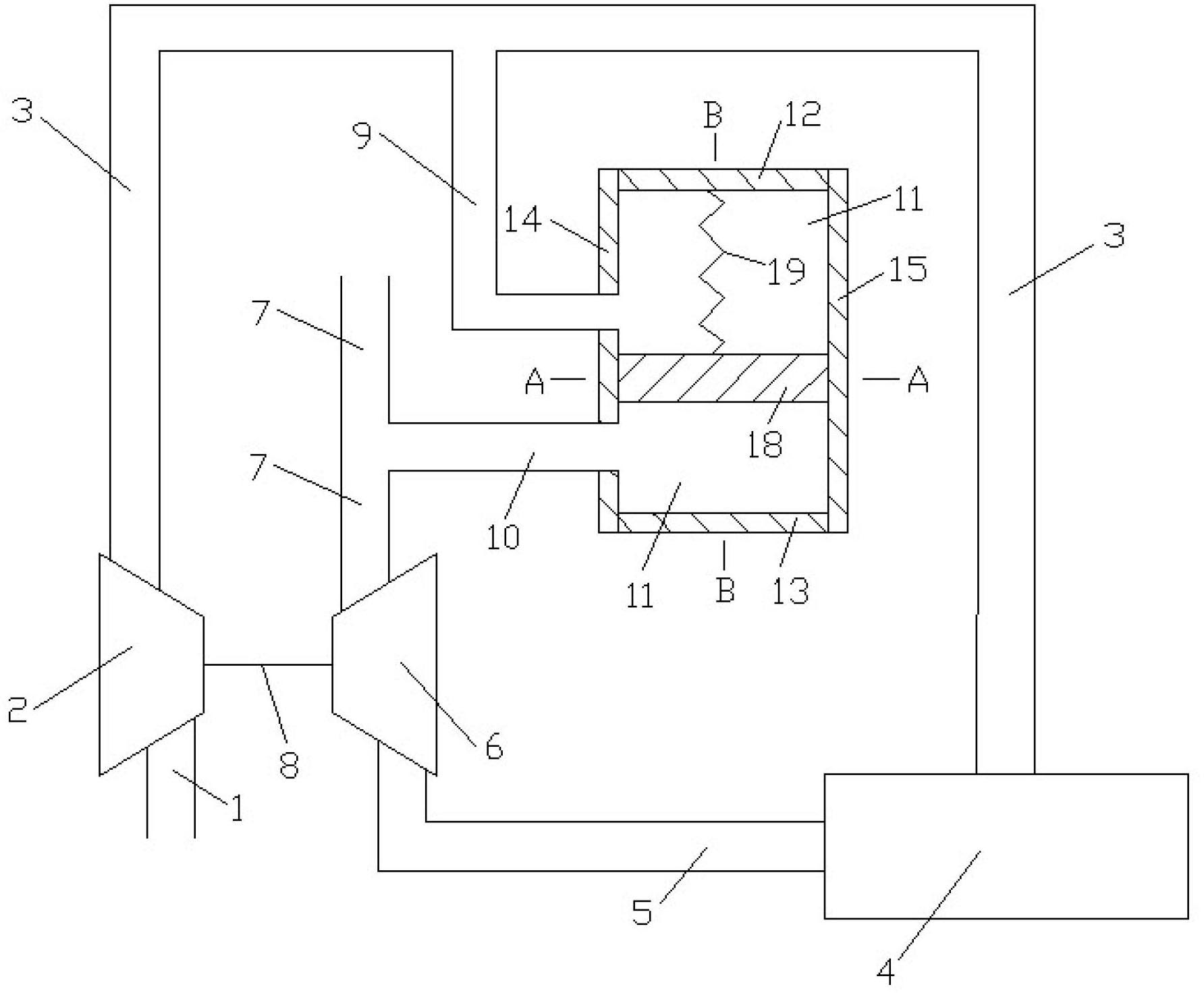

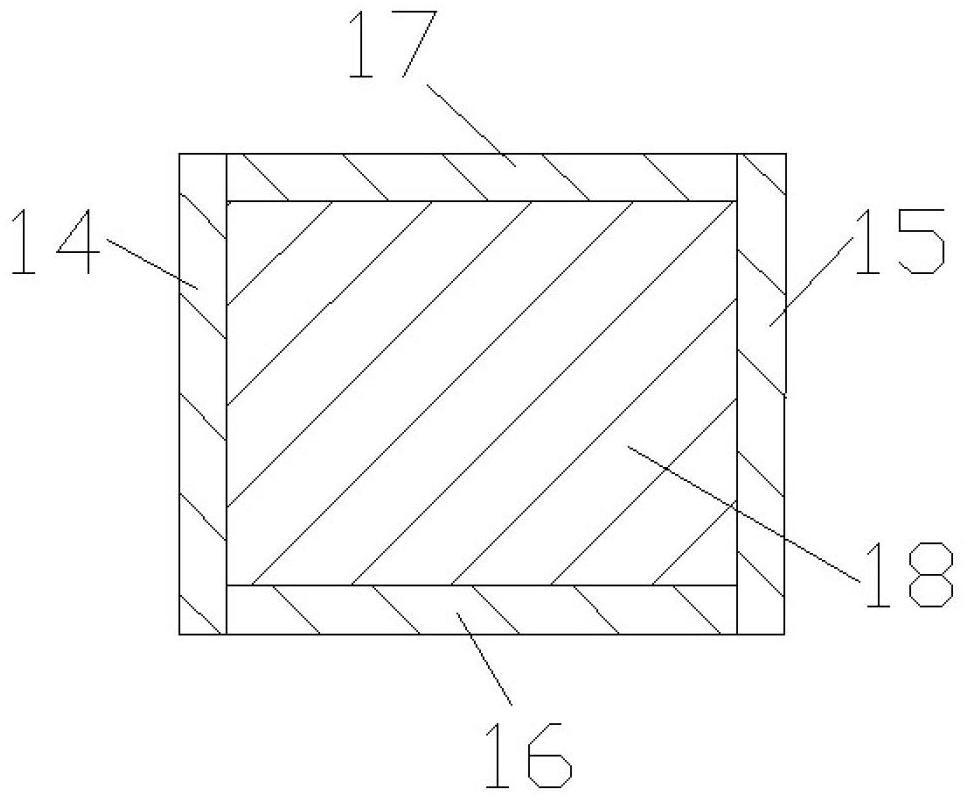

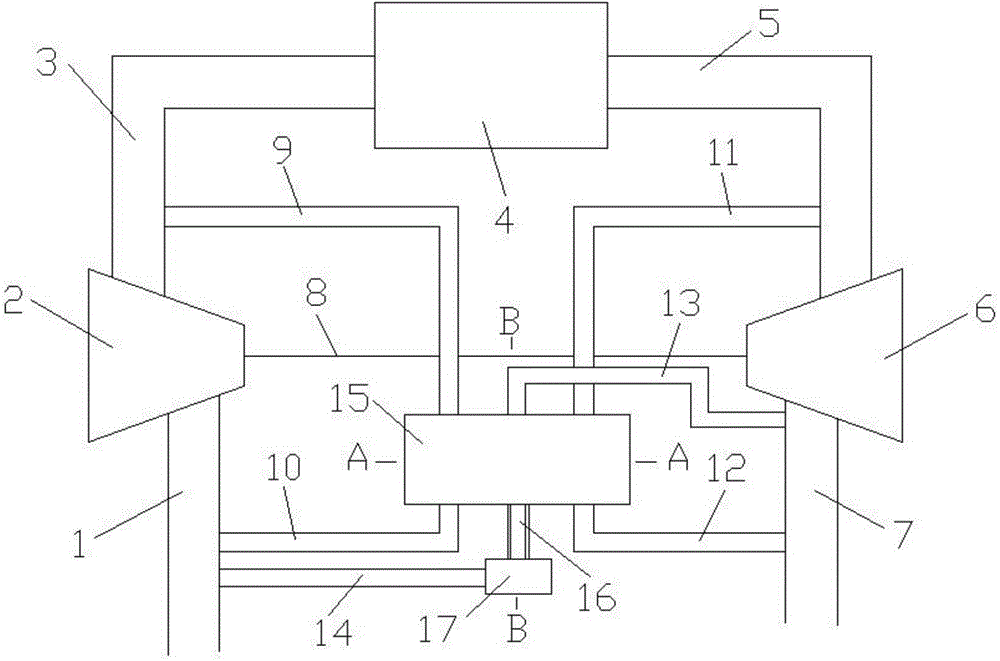

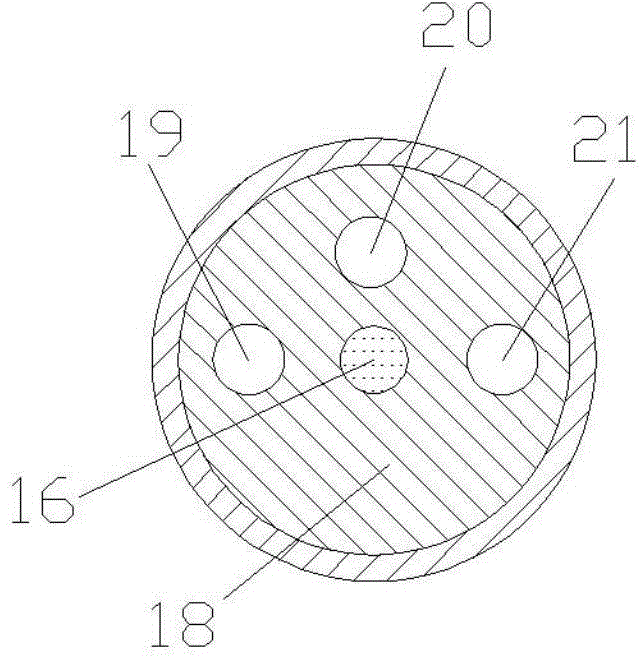

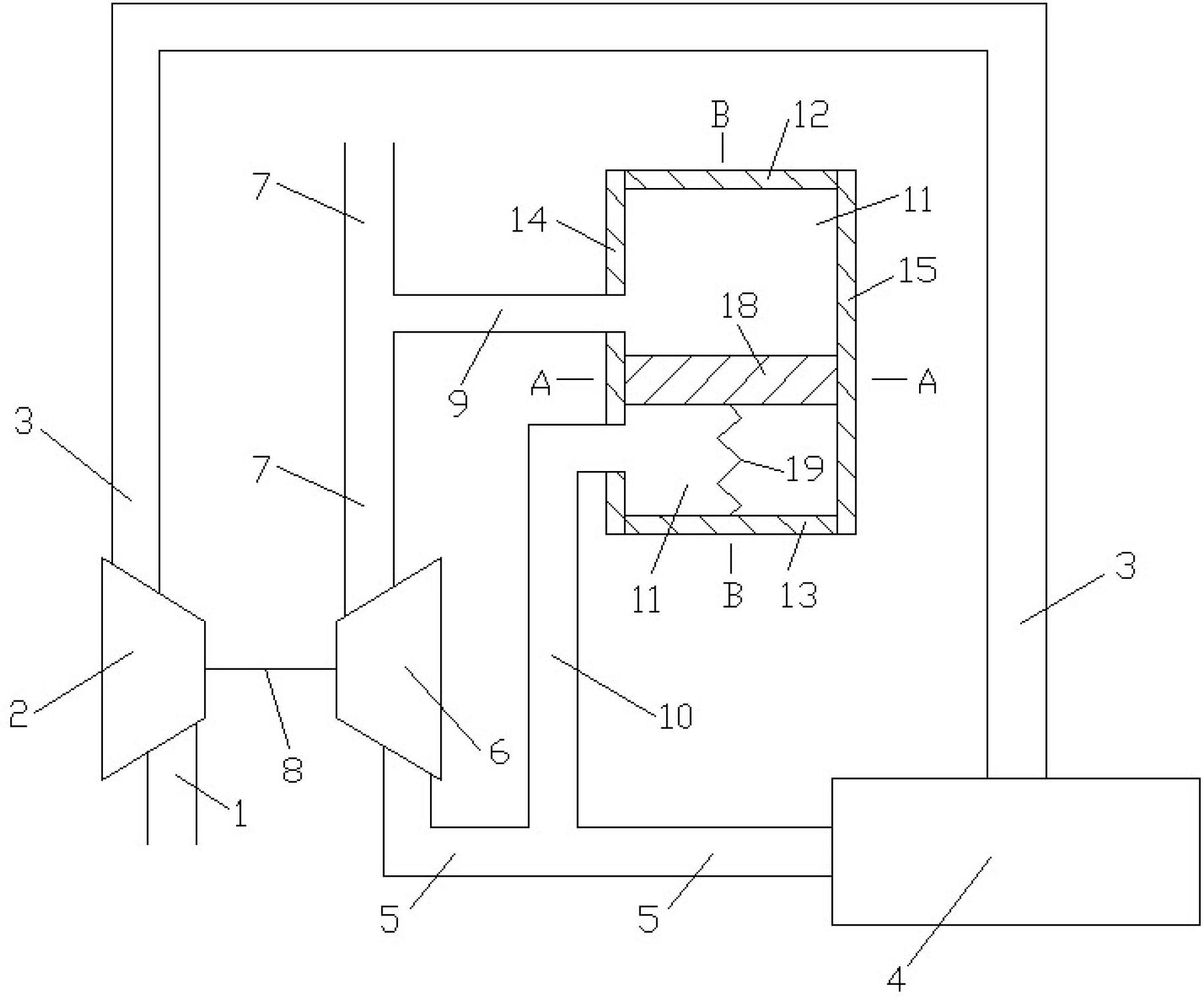

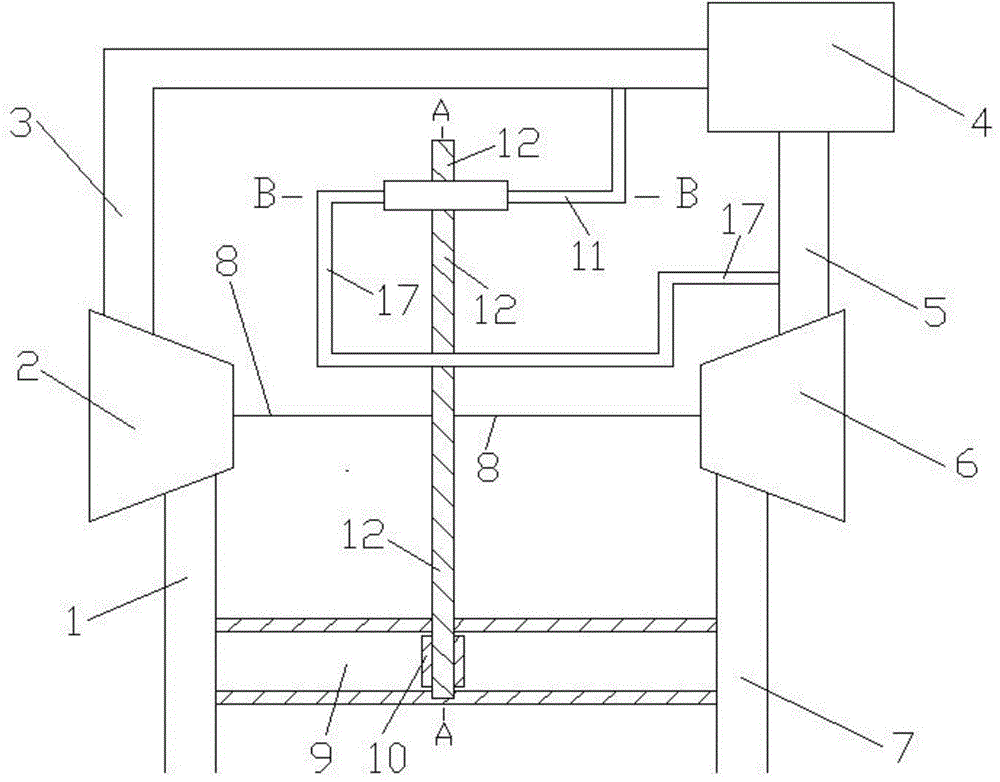

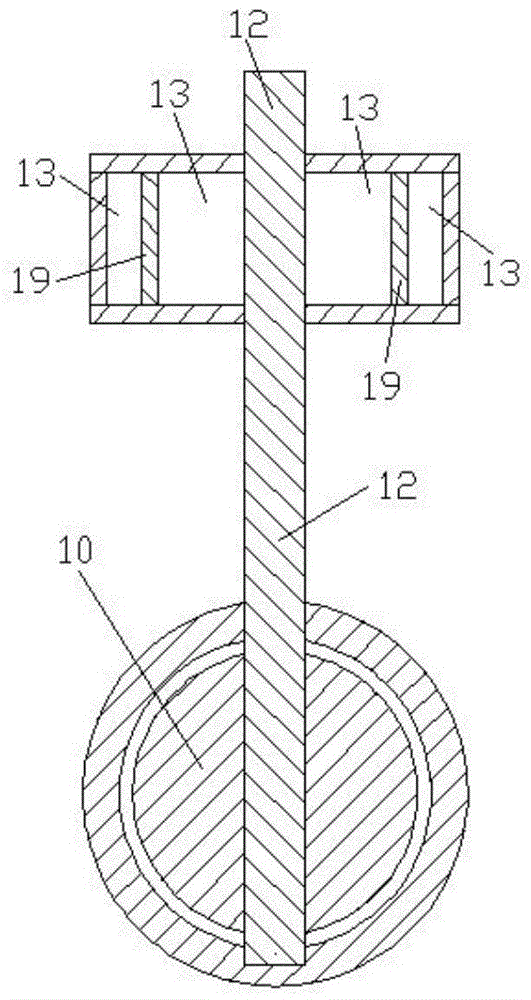

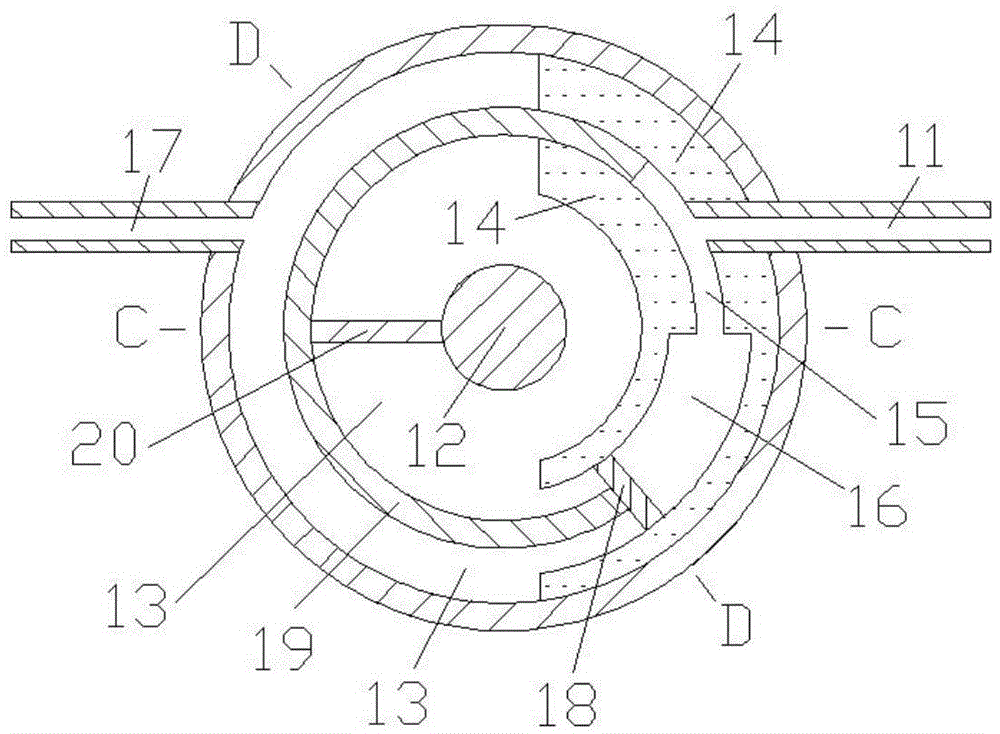

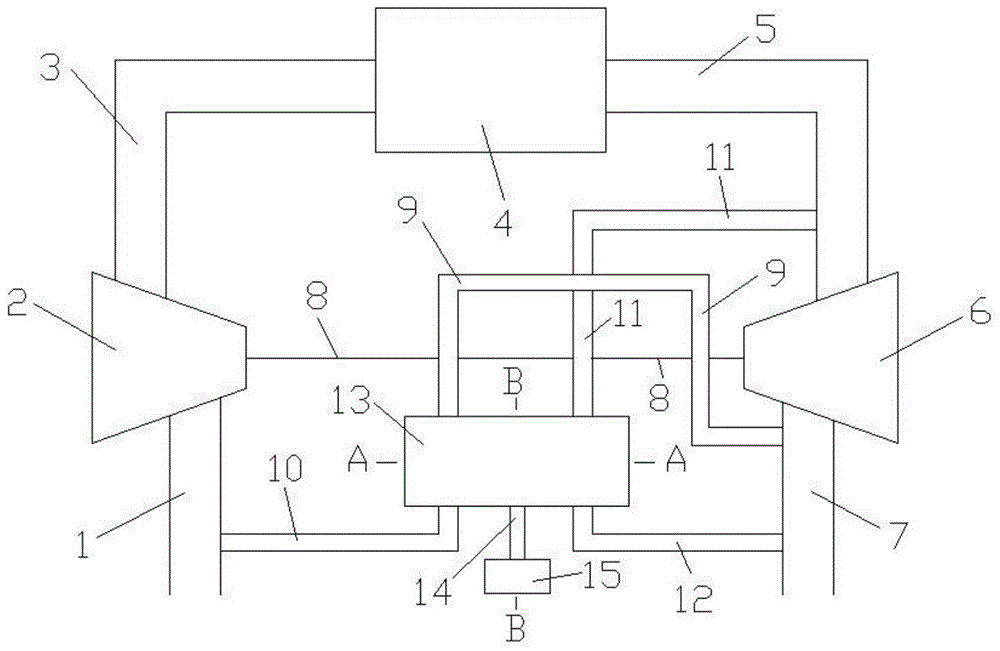

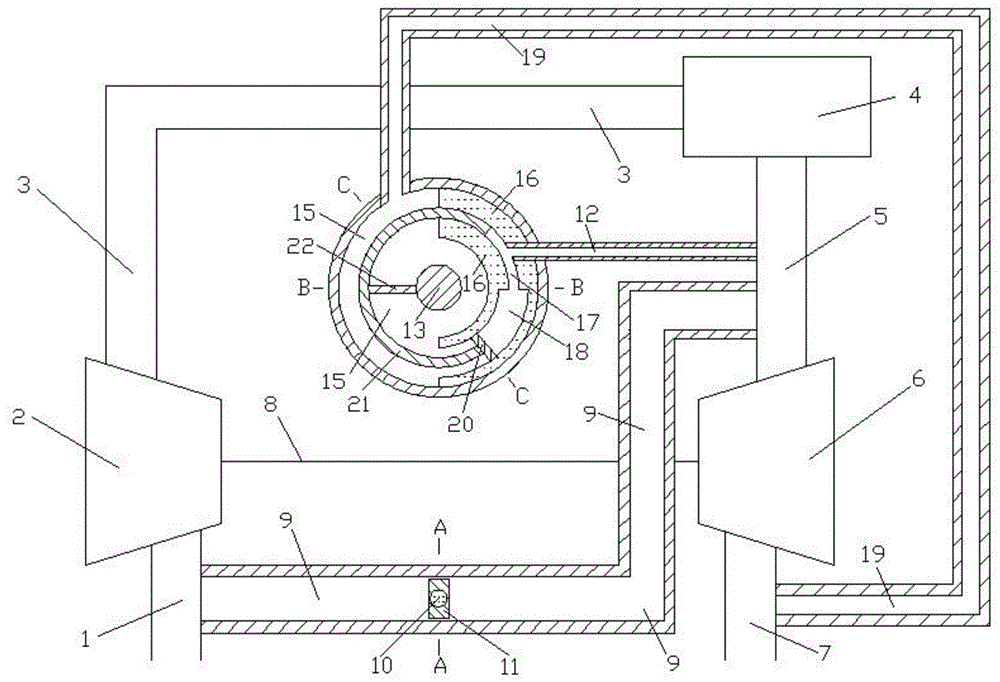

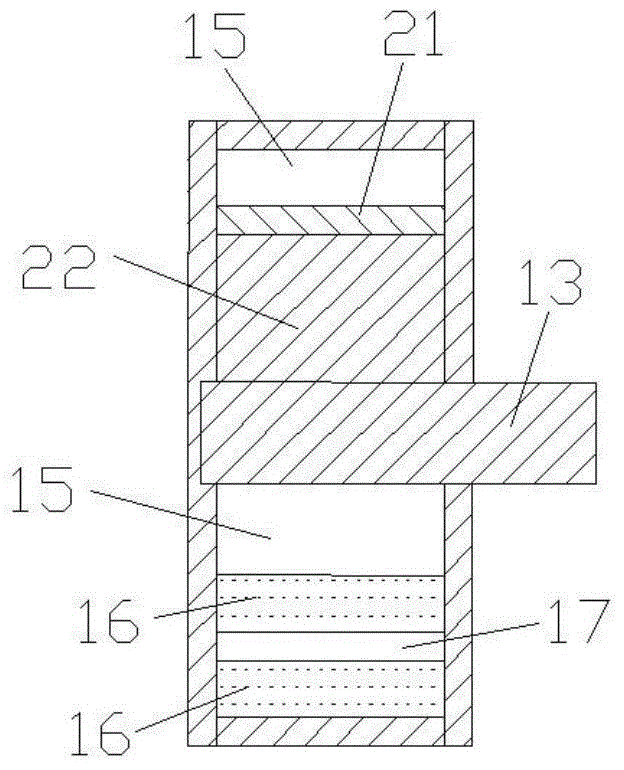

The invention discloses a rotary gas valve control mechanism and belongs to the technical field of mechanical design. The rotary gas valve control mechanism comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, an accommodating cavity, a rotator and an elastic component, wherein the rotator is mounted in the accommodating cavity and is in sealed contact with the inner wall face of the accommodating cavity, the lower wall face of the rotator is connected with the lower wall face of the accommodating cavity through the elastic component, two ends of a first connecting pipe are communicated with gas inlets of an engine exhaust pipe and an accommodating chamber respectively, and two ends of a third connecting pipe are communicated with the engine exhaust pipe and the upper wall face of the accommodating cavity. When the engine exhaust pipe is high in pressure, the rotator drives the valve body to rotate clockwise, exhaust gas recirculation rate of the engine is large, and the engine is low in explosion pressure; and when the engine exhaust pipe is low in pressure, the rotator drives the valve body to rotate anticlockwise, the exhaust gas recirculation rate of the engine is small, and oil consumption of the engine is low. The rotary gas valve control mechanism is reasonable in design, simple in structure and applicable to an exhaust gas recirculation system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

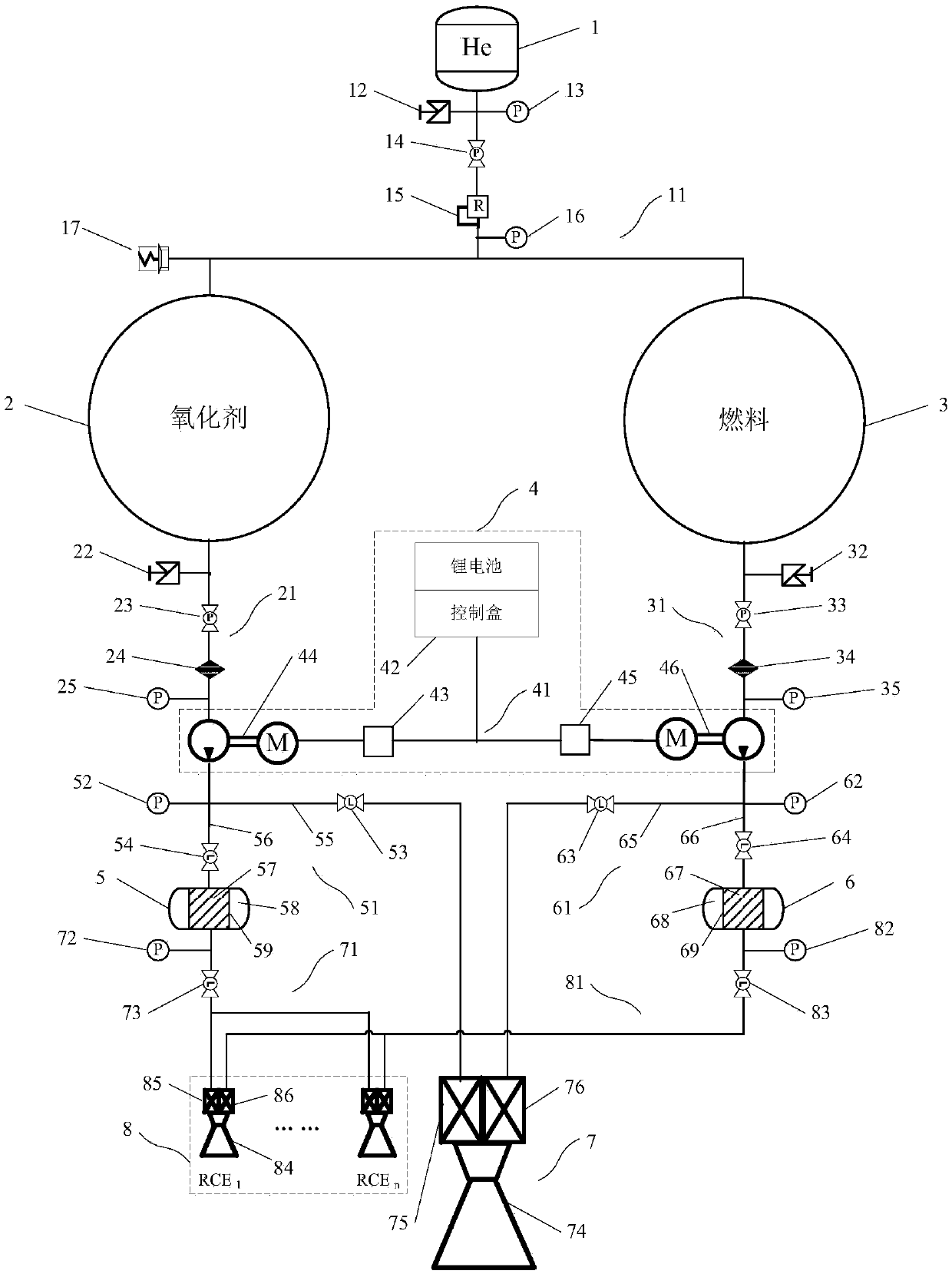

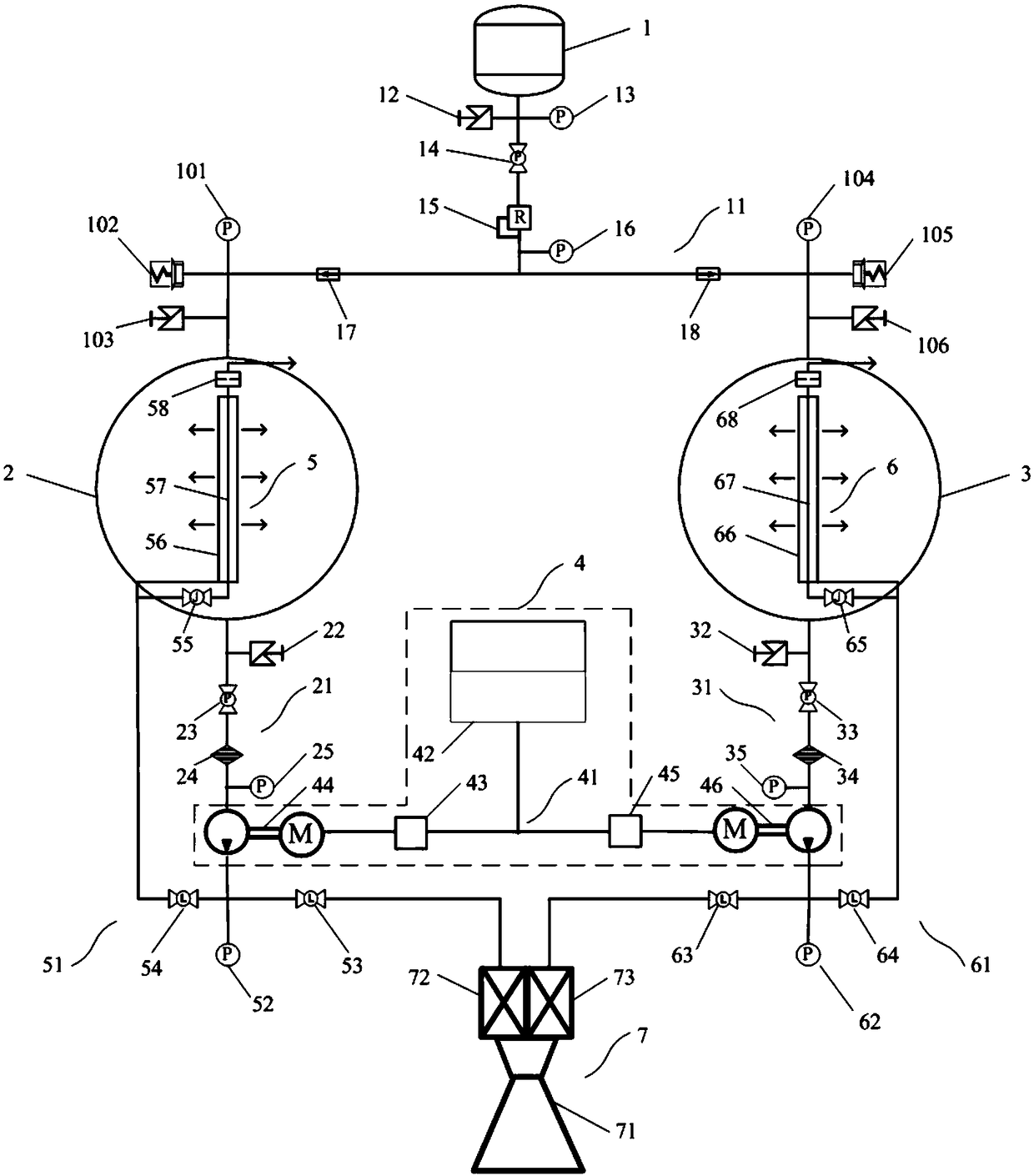

Orbit and attitude control integrated space marching system based on electric pump

ActiveCN109630317AHigh specific impulse performanceReduce carryRocket engine plantsAttitude controlGas cylinder

The invention discloses an orbit and attitude control integrated space marching system based on an electric pump. The orbit and attitude control integrated space marching system comprises a high-pressure air bottle, an oxidizing agent storage tank, a fuel storage tank, an electric pump system, an oxidizing agent pressure accumulator, a fuel pressure accumulator, an orbit-control engine and attitude-control engines; the high-pressure air bottle is connected with the oxidizing agent storage tank and the fuel storage tank through a pipeline I, the oxidizing agent storage tank and the fuel storagetank are connected with the electric pump system through a pipeline II and a pipeline III correspondingly, the electric pump system is connected with the orbit-control engine and the oxidizing agentpressure accumulator and the fuel pressure accumulator through a pipeline V and a pipeline VI correspondingly, and the oxidizing agent pressure accumulator and the fuel pressure accumulator are connected with the attitude-control engines through a pipeline VII and a pipeline VIII correspondingly. The electric pump system controls the rotating speed and the lift of a motor pump through an actuator,the pressure and flow of an oxidizing agent and fuel supplied for the engines are controlled, the adjustment is convenient, and the supplying requirements for a propellant of large-range thrust adjustment and multi-time starting and stopping of the orbit-control engine can be met.

Owner:SHANGHAI INST OF SPACE PROPULSION

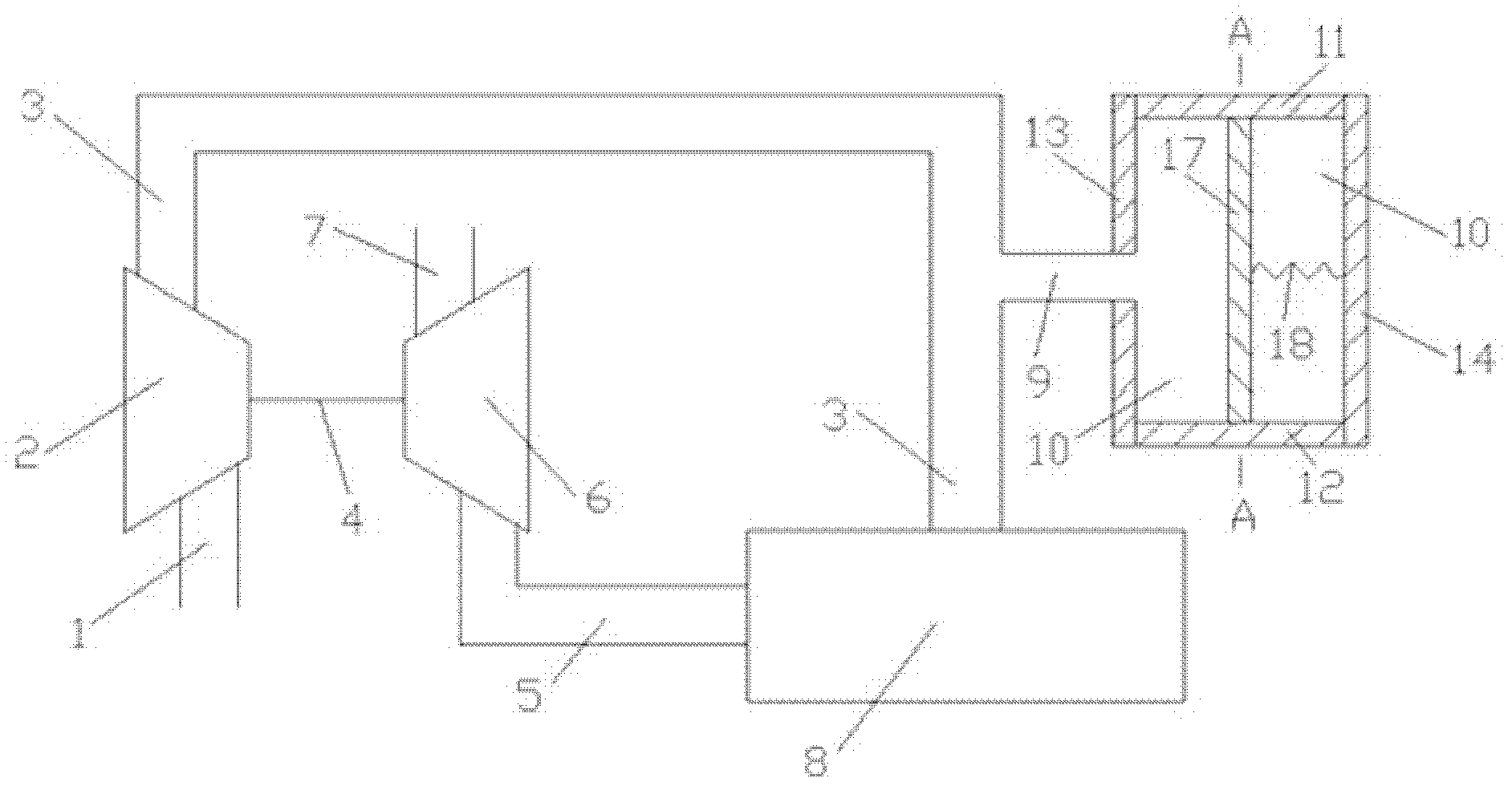

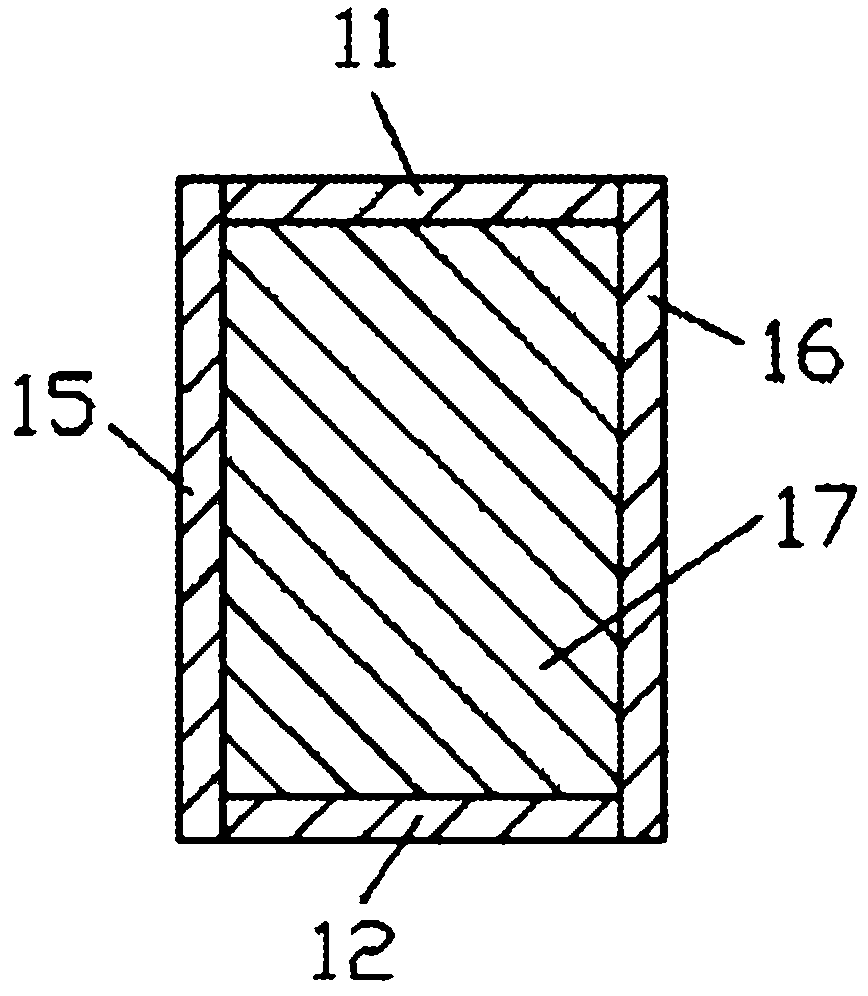

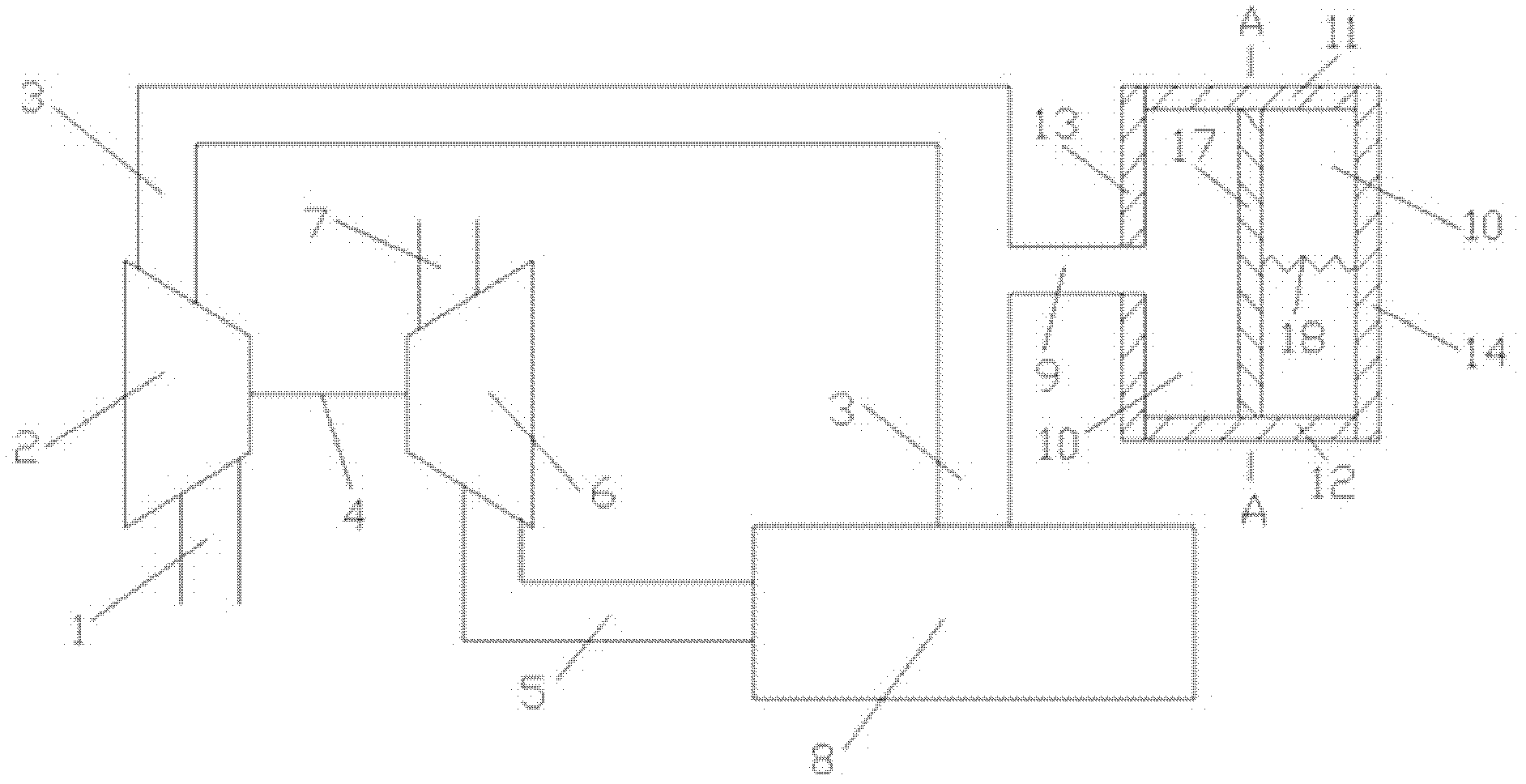

Electric pump pressure type liquid oxygen methane space propelling system

ActiveCN109281774AHigh specific impulse performanceReduce carryCosmonautic vehiclesCosmonautic propulsion system apparatusLiquid oxygenEngineering

The invention provides an electric pump pressure type liquid oxygen methane space propelling system. The electric pump pressure type liquid oxygen methane space propelling system comprises a high-pressure gas cylinder, a liquid oxygen storage tank, a methane storage tank, an electric pump system, an oxygen heat exchange injection rod, a methane heat exchange injection rod and a track control engine; the high-pressure gas cylinder is connected with the liquid oxygen storage tank and the methane storage tank through a first pipeline; the liquid oxygen storage tank and the methane storage tank are connected with an electric pump system through a second pipeline and a third pipeline; the oxygen heat exchange injection rod is arranged in the liquid oxygen storage tank; the methane heat exchangeinjection rod is arranged in the methane storage tank; the electric pump system is connected with the oxygen heat exchange injection rod and the track control engine through a fourth pipeline; and the electric pump system is connected with the methane heat exchange injection rod and the track control engine through a fifth pipeline. The electric pump pressure type liquid oxygen methane space propelling system is suitable for a space aircraft propulsion system, and particularly has obvious application advantages on a space propelling system which has large propellant filling amount and whose track control engine needs to be started for a plurality of times..

Owner:SHANGHAI INST OF SPACE PROPULSION

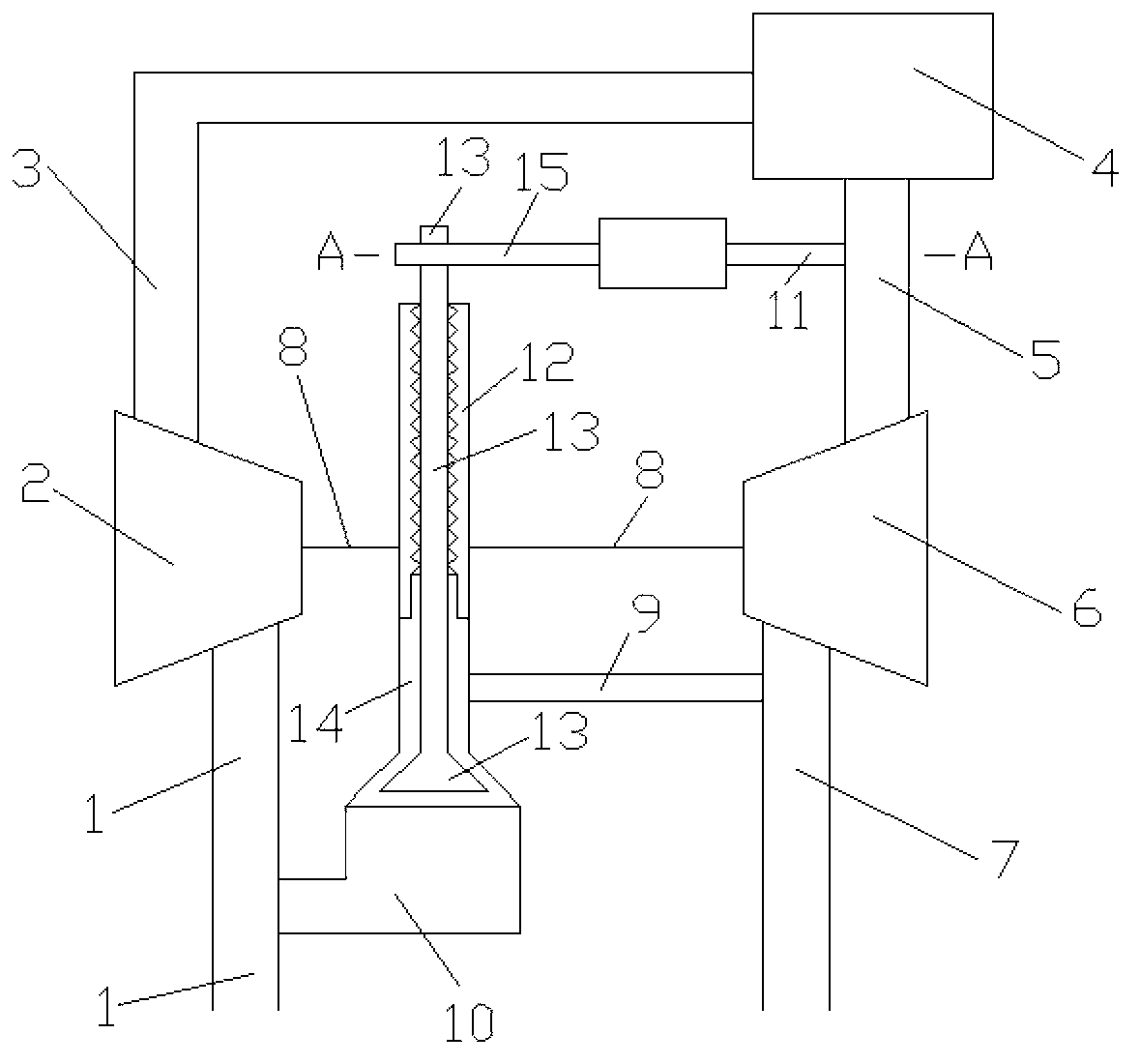

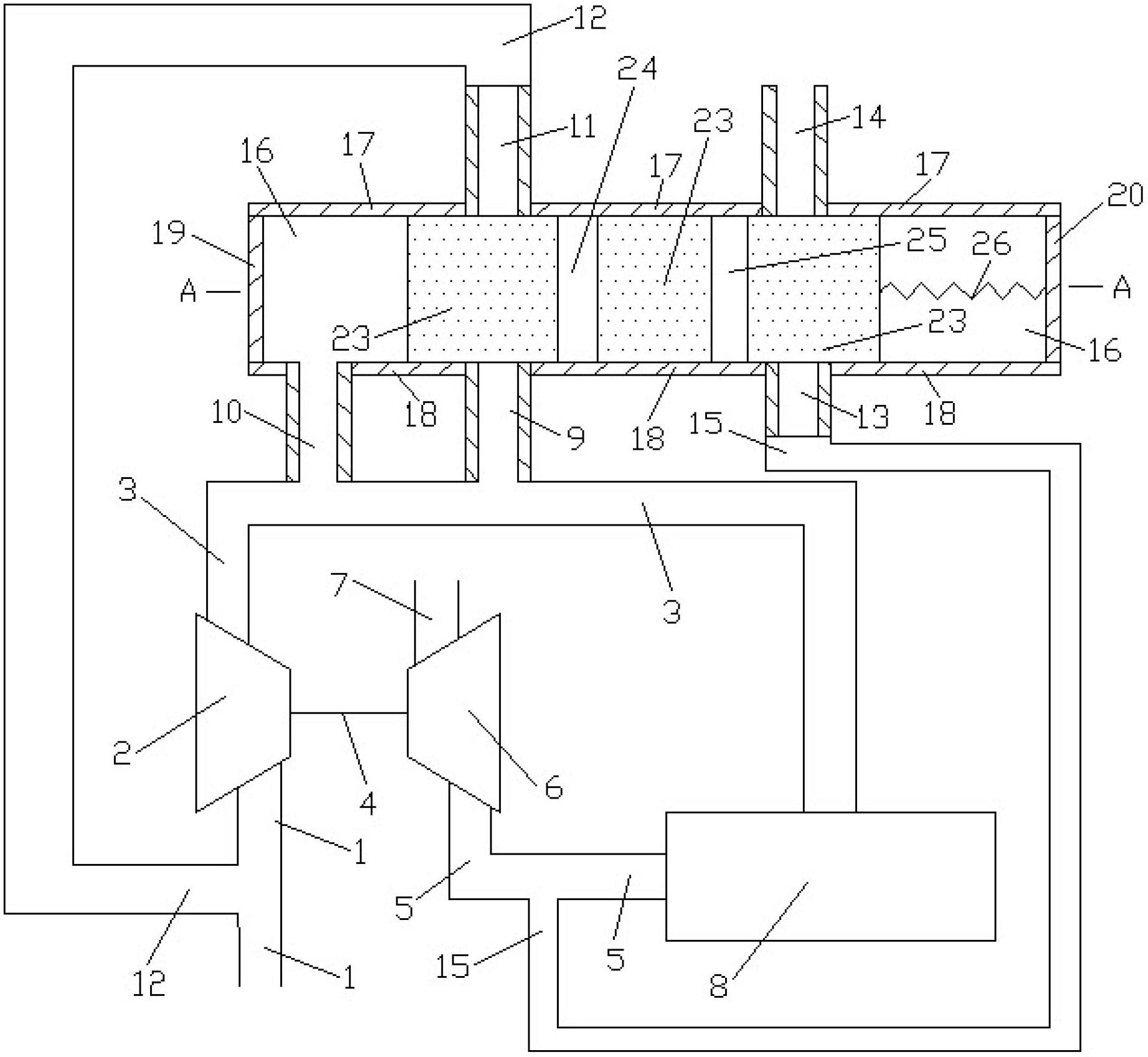

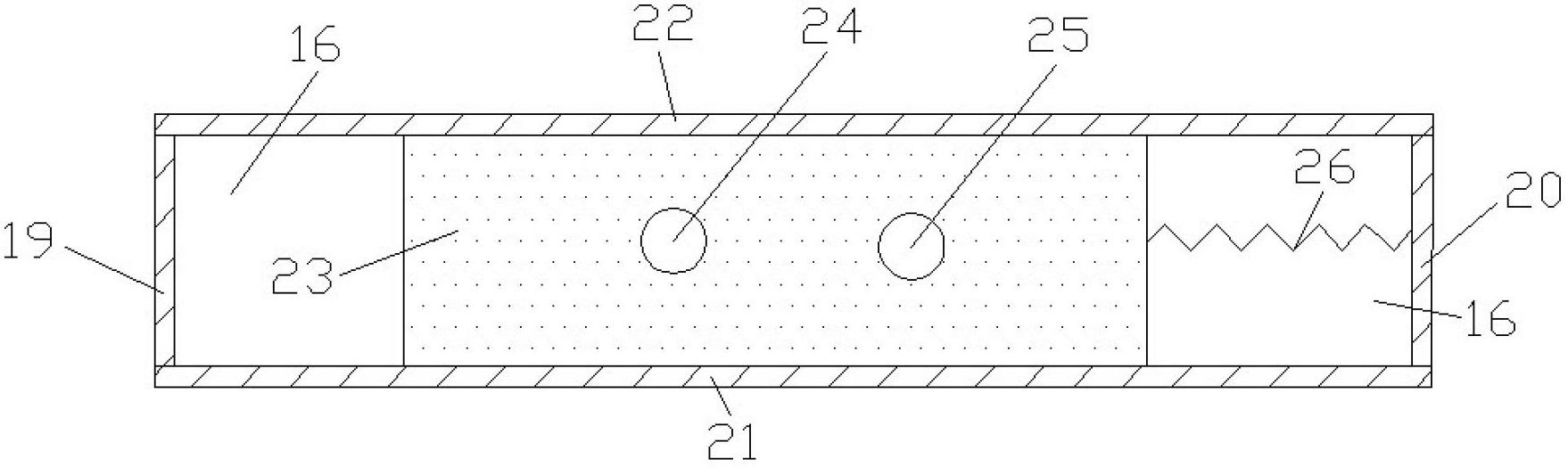

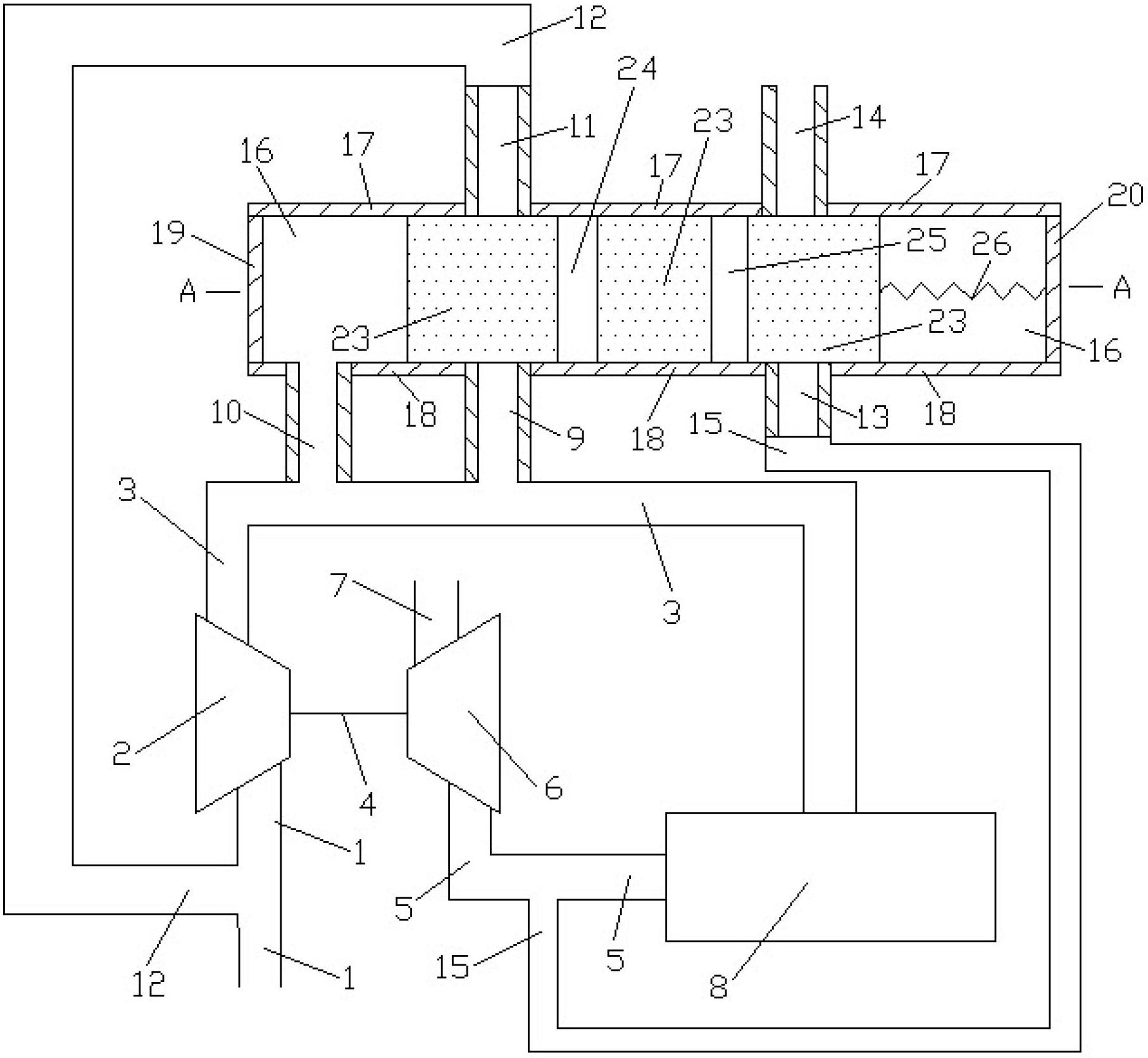

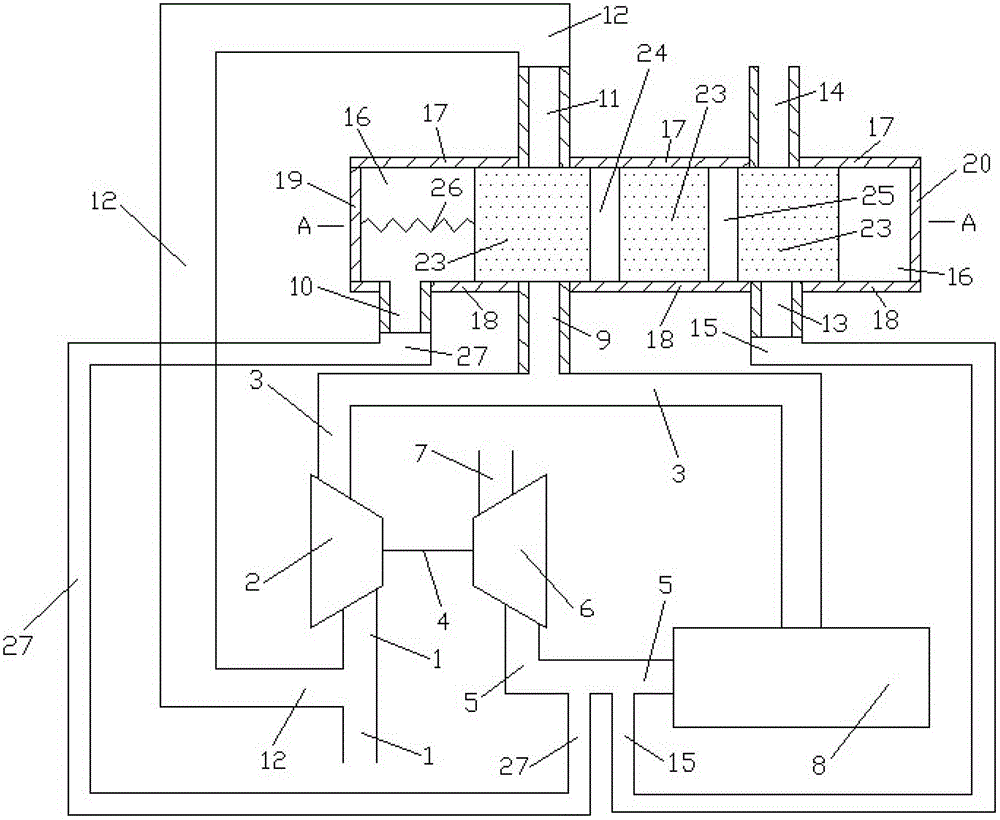

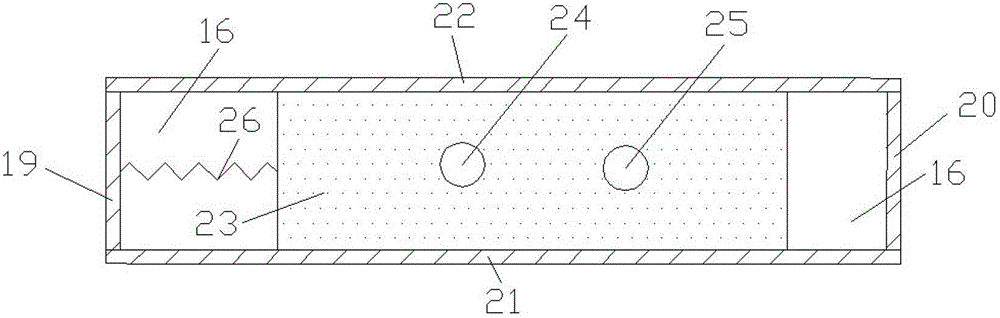

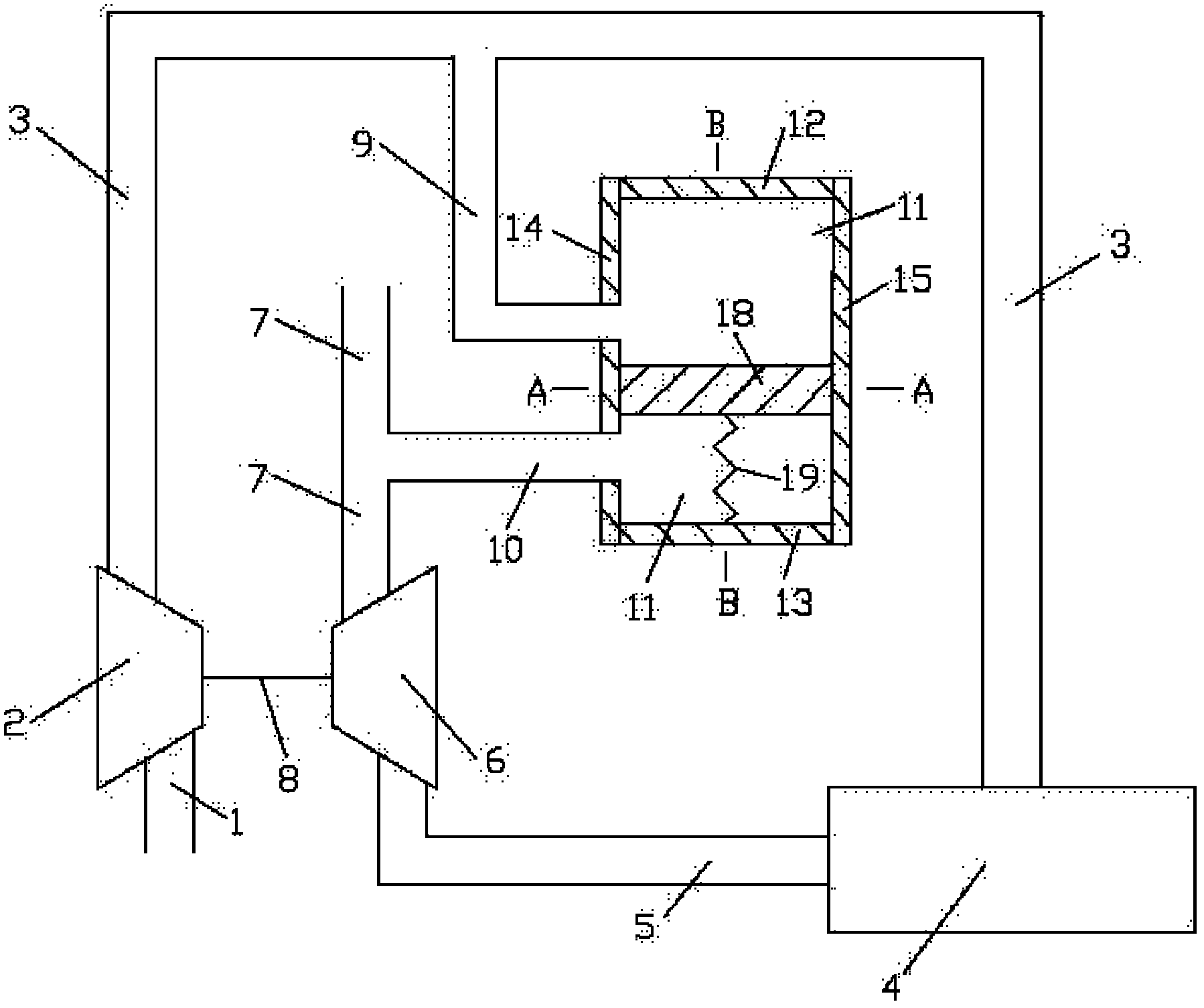

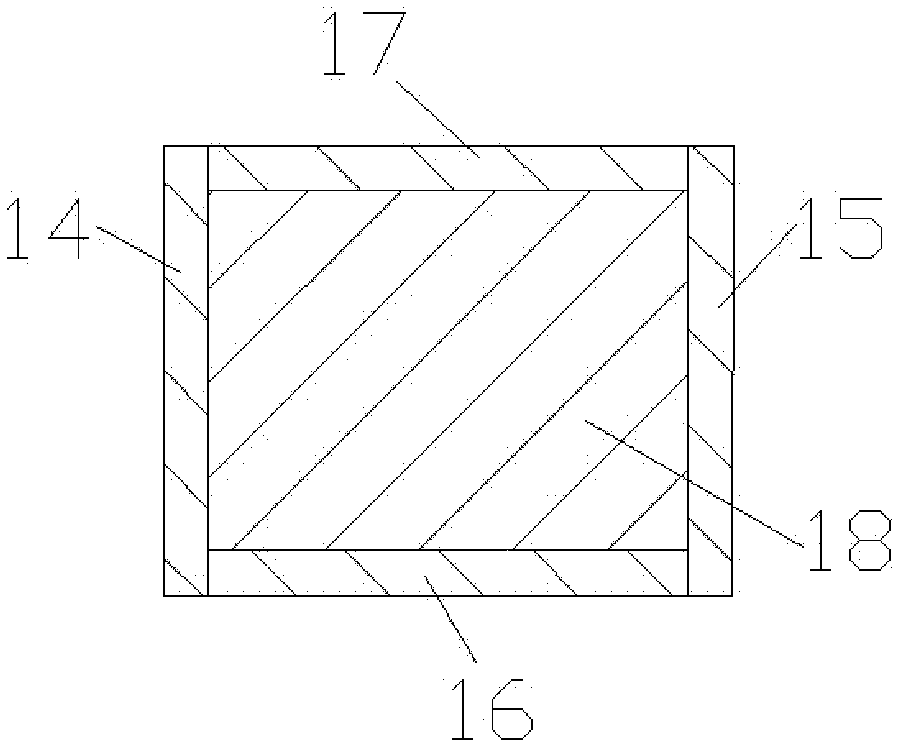

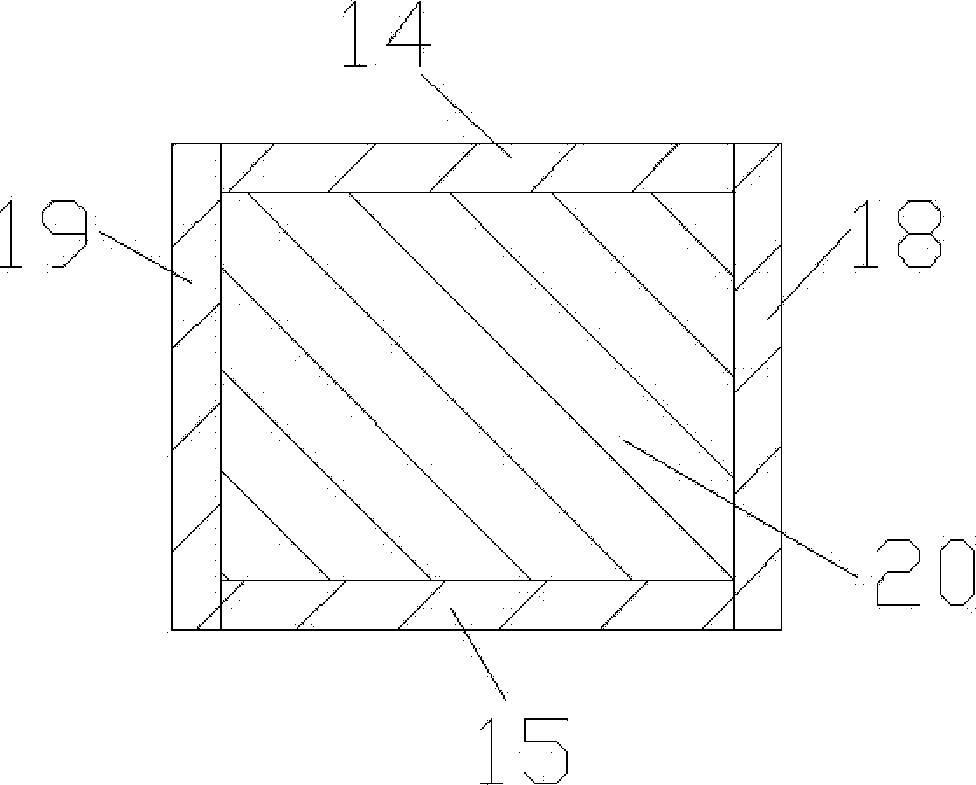

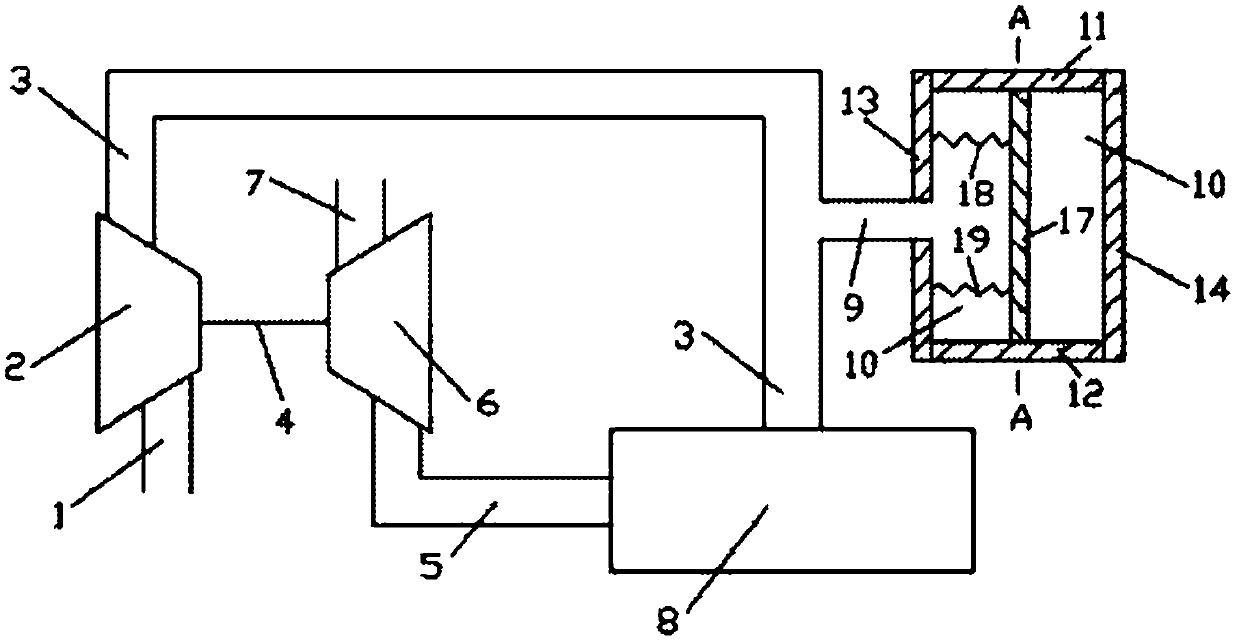

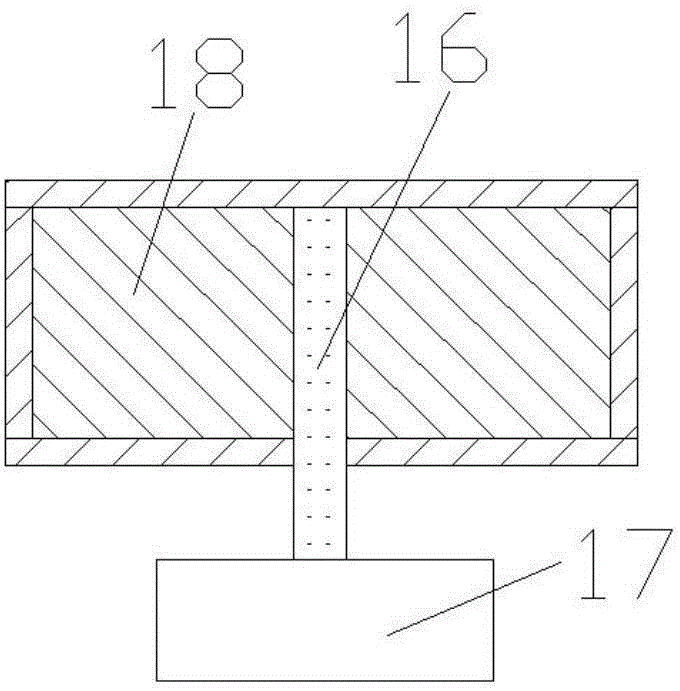

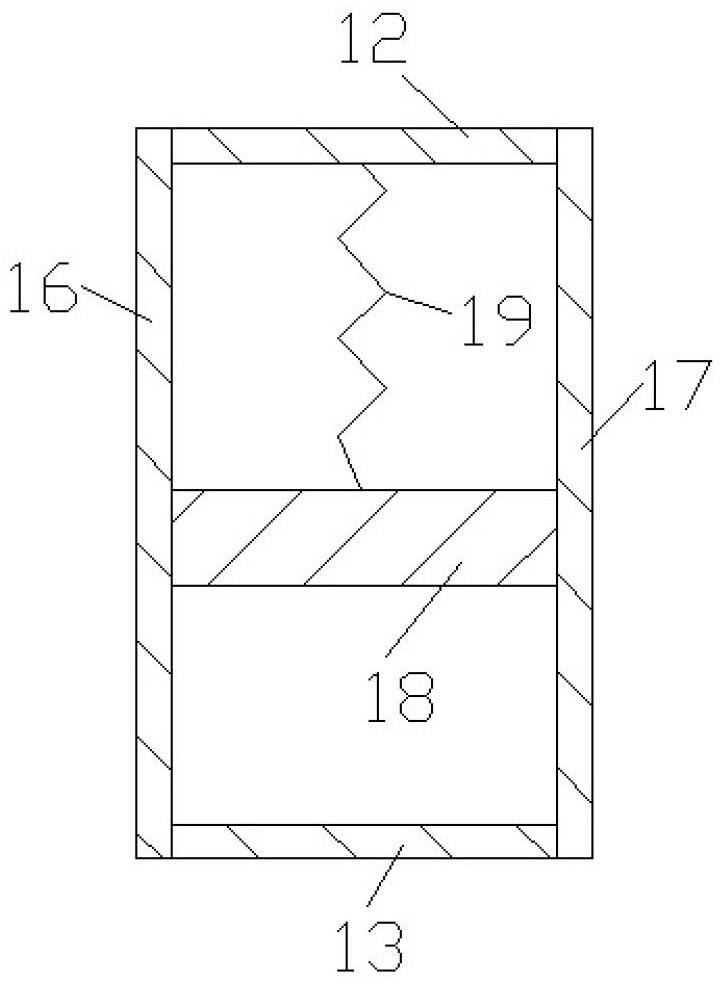

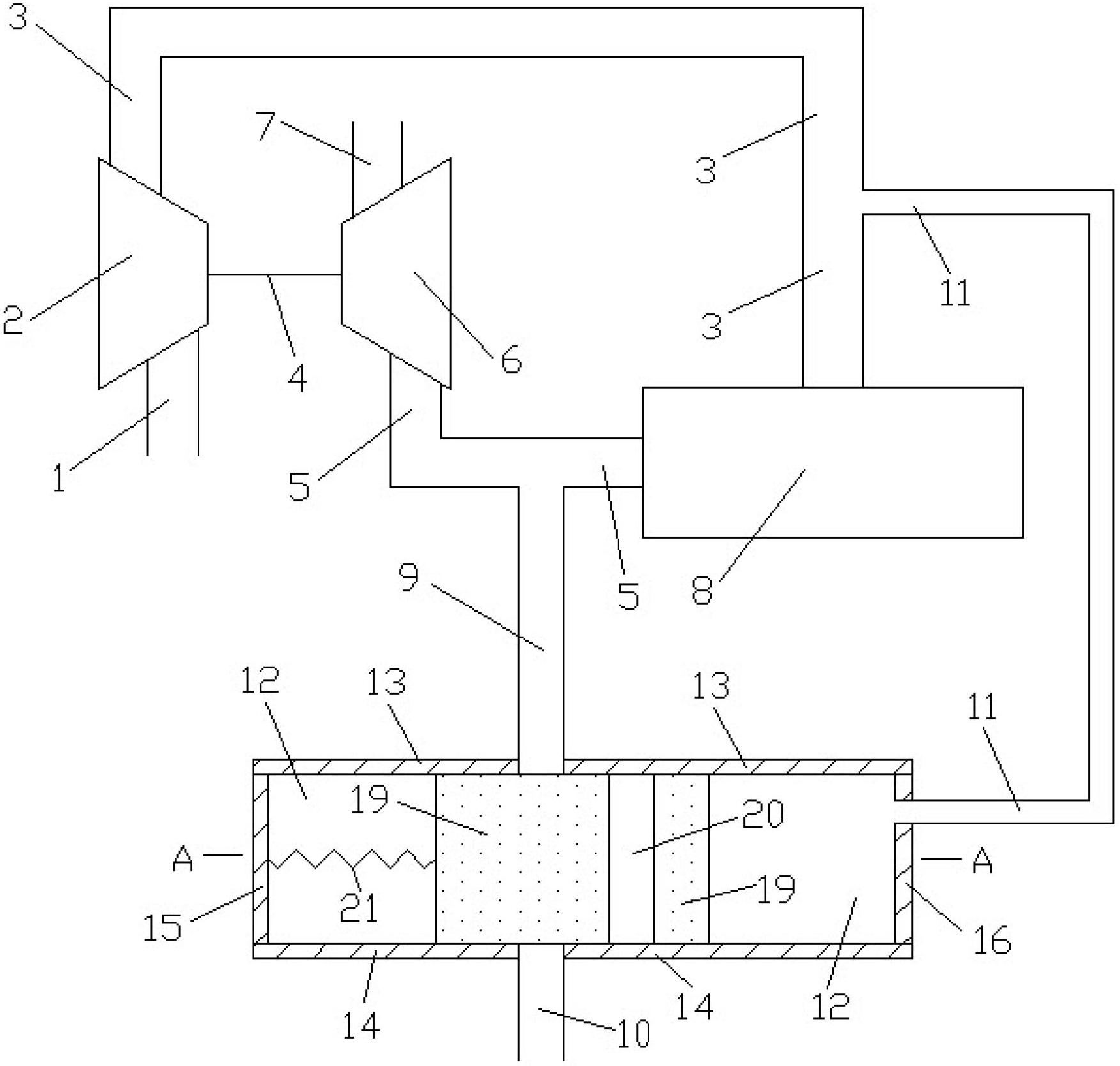

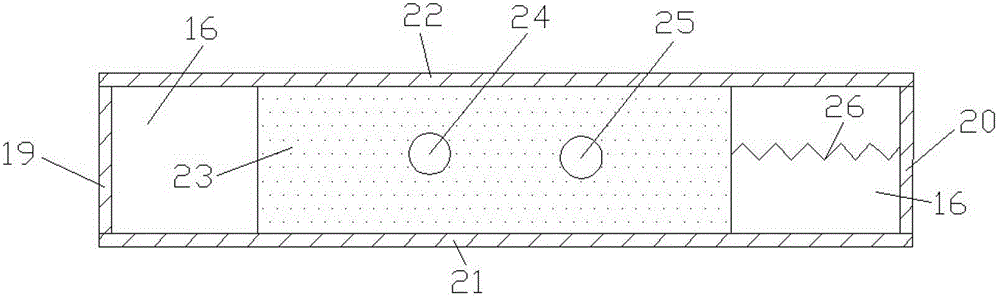

Volume cavity regulating intake device

InactiveCN102588076APromote combustionReduce fuel consumptionInternal combustion piston enginesElastic componentCombustion

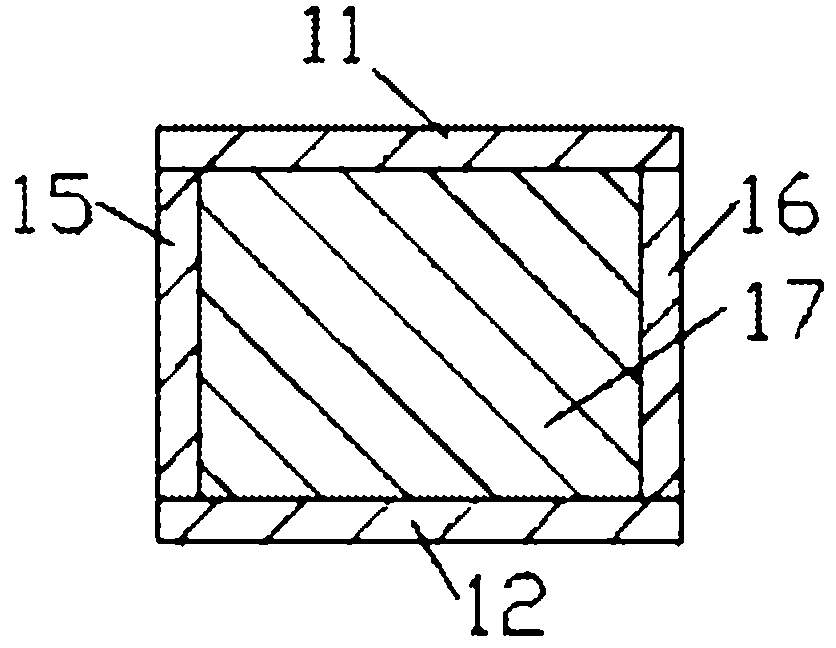

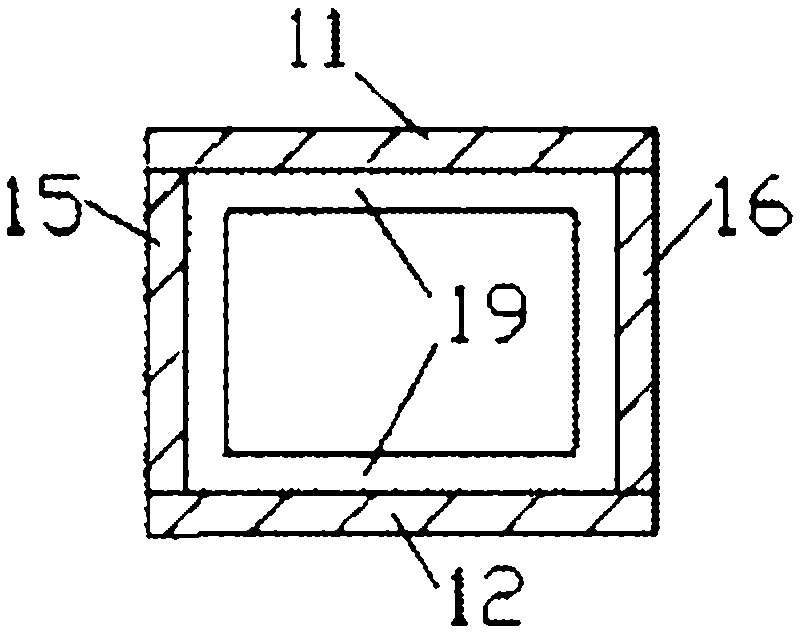

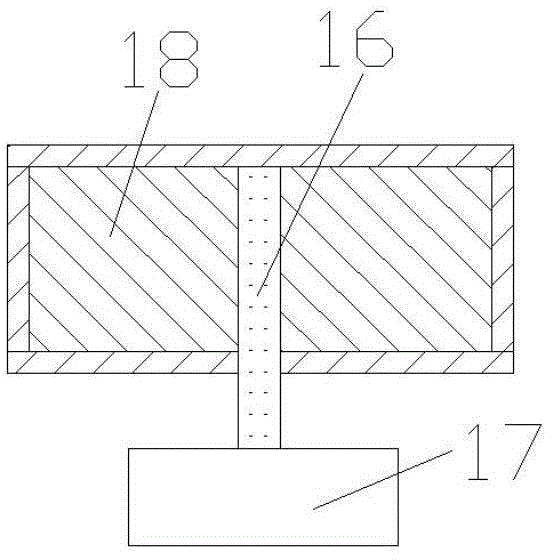

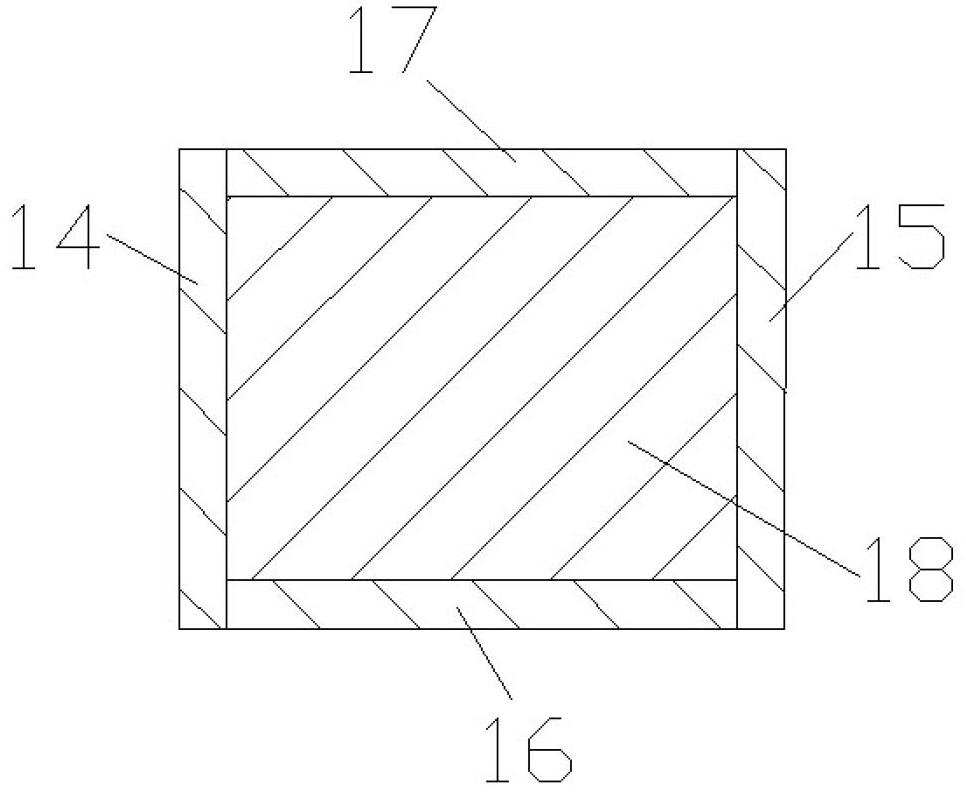

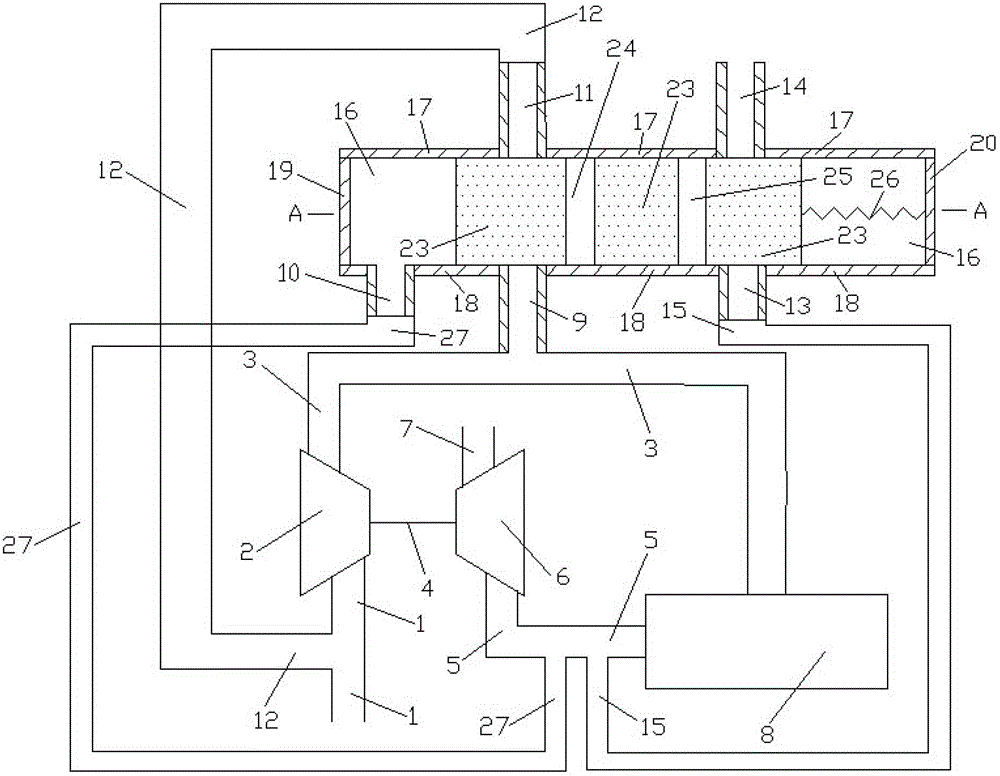

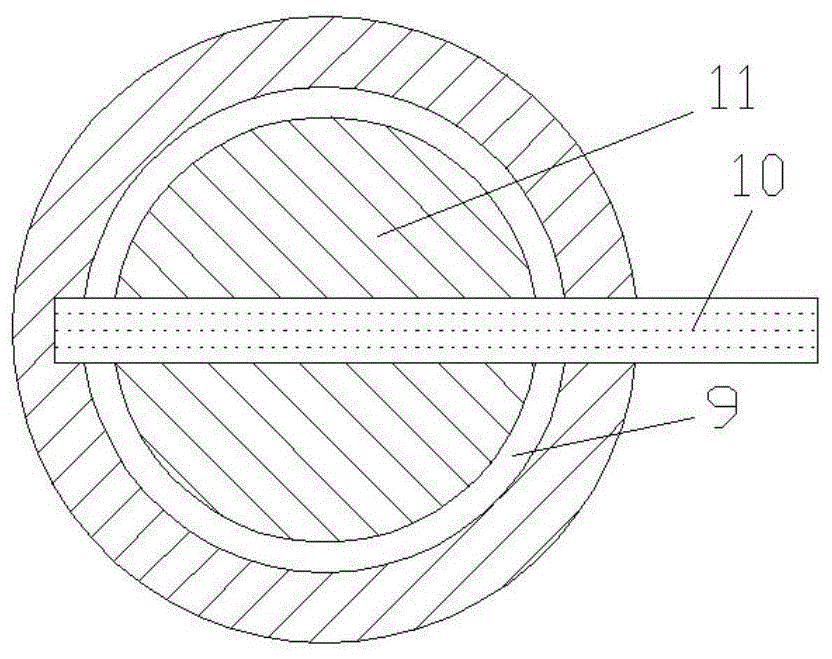

A volume cavity regulating intake device in the technical field of internal-combustion engines comprises an air compressor, a turbine, an engine, a connecting pipe, a volume cavity, a movable plate and an elastic component. The cross section of the volume cavity is rectangular, two ends of the connecting pipe are connected with an intake pipe of the engine and the left wall surface of the volume cavity respectively, the movable plate mounted in the volume cavity hermetically contacts with the inner wall surface of the volume cavity, and the movable plate is connected with the right wall surface of the volume cavity through the elastic component. During operation of the engine, the movable plate is capable of moving left and right in the volume cavity. Under a low-speed working condition, the overall volume of a rear intake pipe of the air compressor is decreased, intake pressure is increased, and the charge efficiency of the engine is high. Under a high-speed working condition, the overall volume of the rear intake pipe of the air compressor is increased, the intake pressure is decreased, and the blasting pressure of the engine is reduced. The volume cavity regulating intake device is reasonable in design, simple in structure and applicable to turbocharging systems for engines.

Owner:SHANGHAI JIAO TONG UNIV

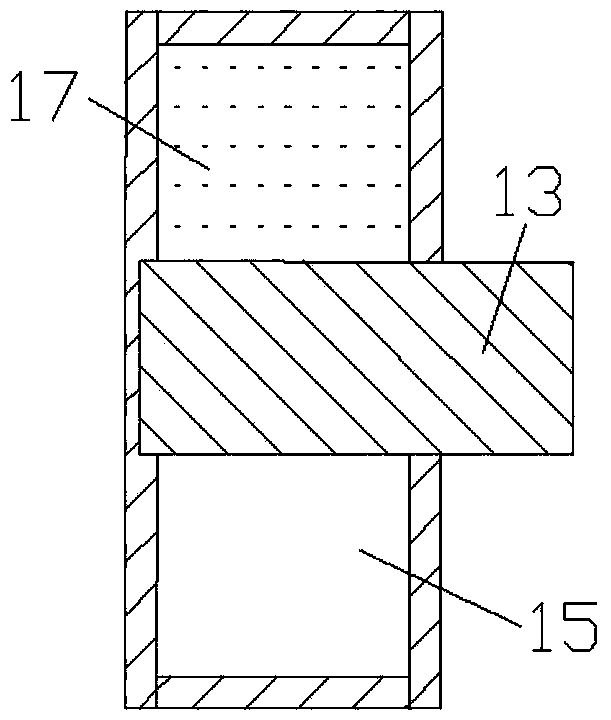

Air valve throat area control system

InactiveCN103291471ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelThroatControl system

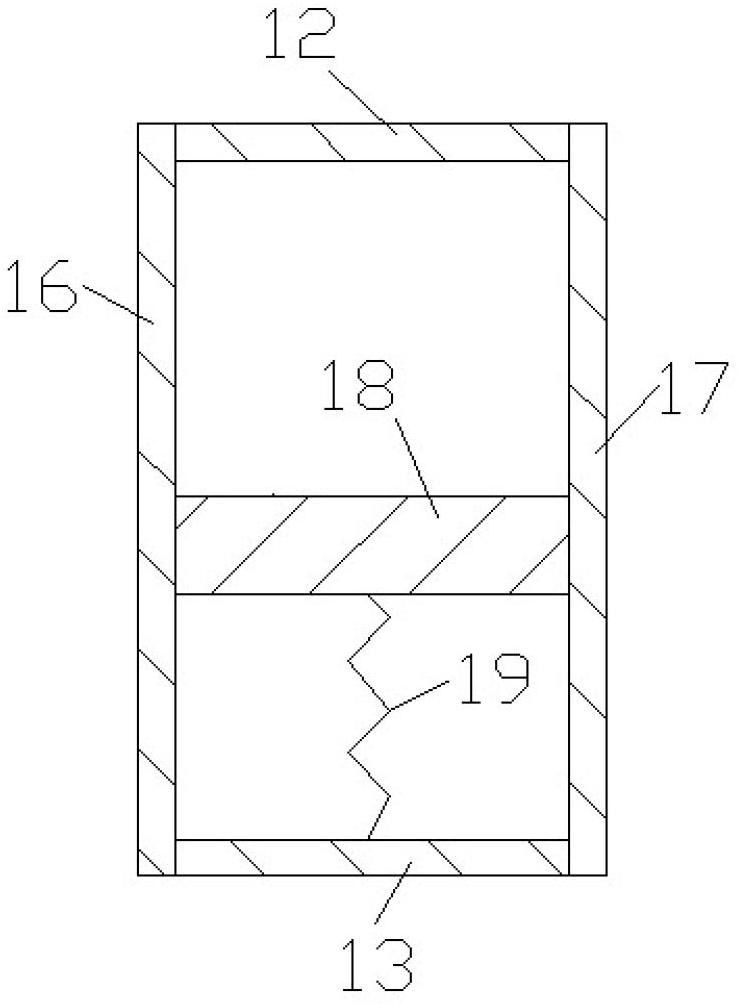

The invention relates to an air valve throat area control system and relates to the technical field of mechanical design. The air valve throat area control system comprises an air compressor, an engine, a turbine, connecting pipes, a valve seat, a valve block, a rotary shaft, a volumetric cavity, a rotor and an elastic part. The rotor is mounted in the volumetric cavity and is in hermetic contact with the inner wall of the volumetric cavity. The lower wall of the rotor is connected with the lower wall of the volumetric cavity through the elastic part. Two ends of the first connecting pipe are communicated with an air inlet of a turbine exhaust pipe and an air inlet of the volumetric cavity respectively. Two ends of the third connecting pipe are communicated with the upper wall of an engine exhaust pipe and the upper wall of the volumetric cavity respectively. When the pressure of the engine exhaust pipe is high, the rotor drives the valve block to rotate clockwise, emission recirculation rate of the engine is high, and denotation pressure of the engine is low; when the pressure of the engine exhaust pipe is low, the rotor drives the valve block to rotate anticlockwise, emission recirculation rate of the engine is low, and oil consumption of the engine is low. The air valve throat area control system is reasonable in design, simple in structure, and applicable to exhaust recirculation systems for supercharged engines.

Owner:SHANGHAI JIAO TONG UNIV

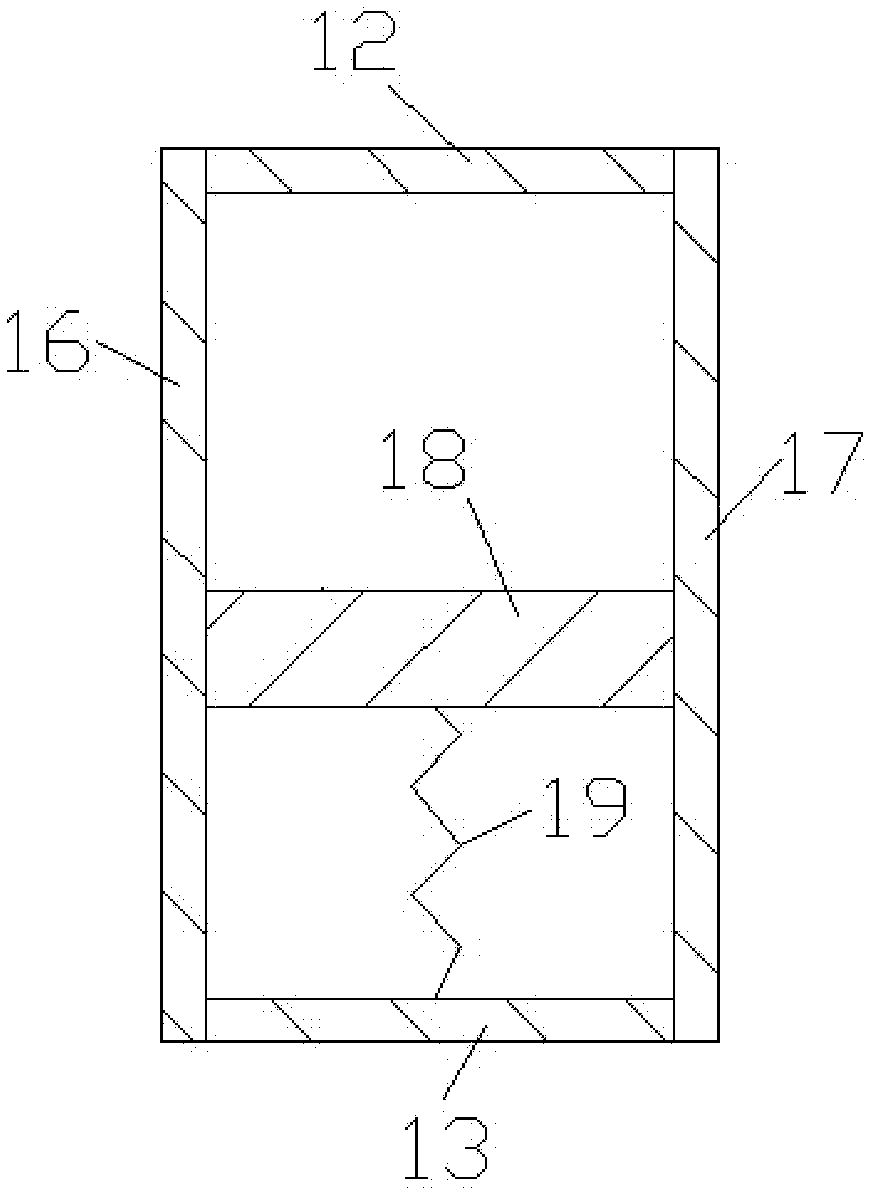

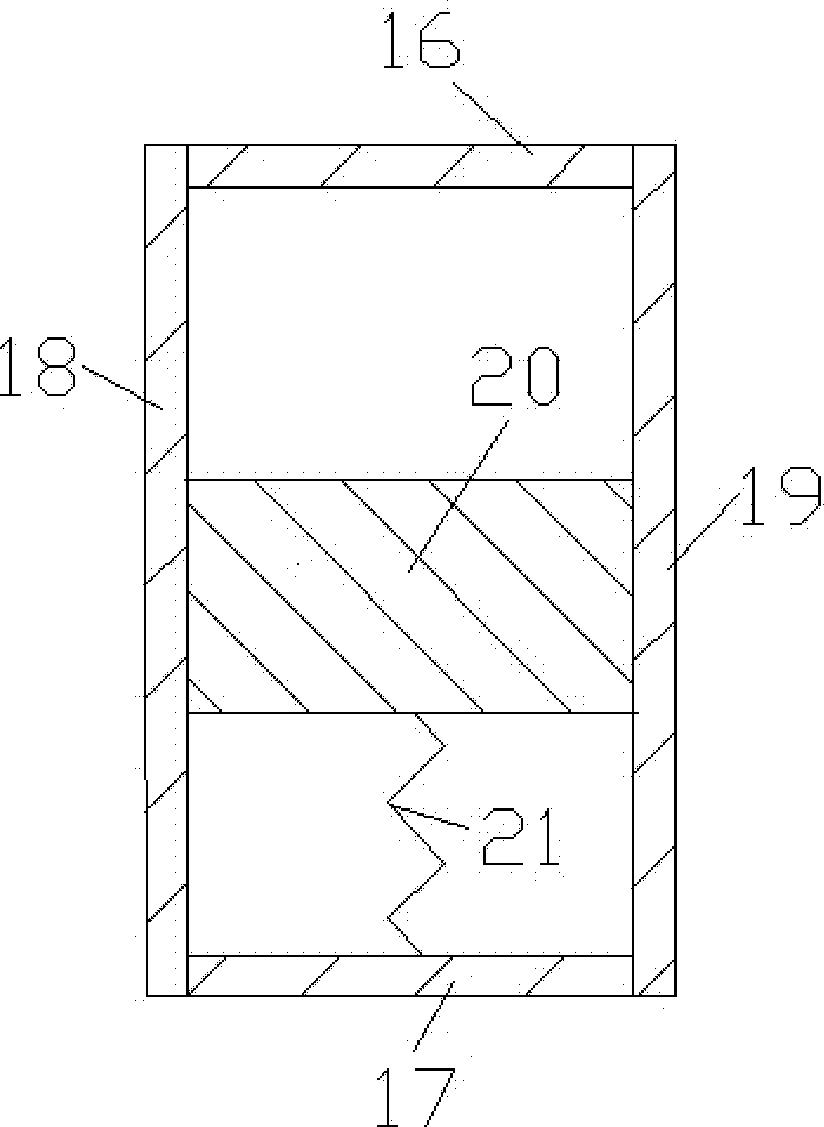

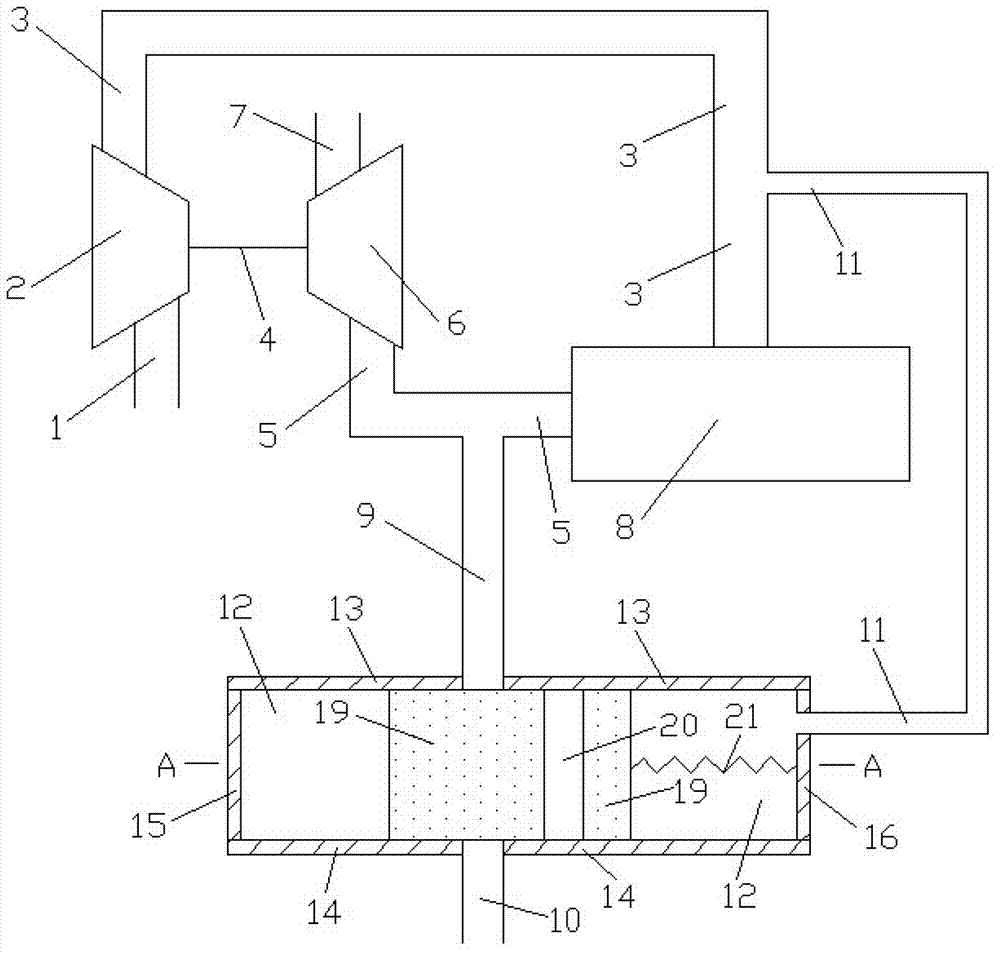

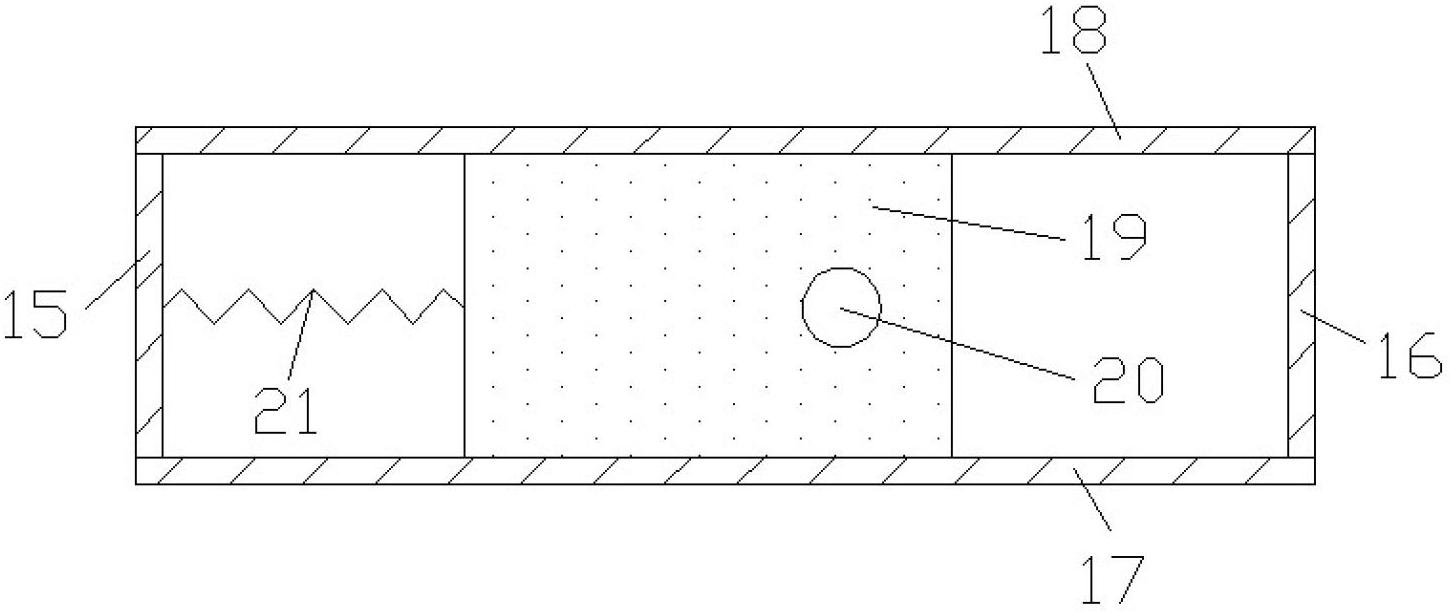

Engine intake system with variable-volume intake pipe

InactiveCN102588077APromote combustionReduce fuel consumptionInternal combustion piston enginesElastic componentCombustion

An engine intake system with a variable-volume intake pipe belongs to the technical field of internal-combustion engines and comprises an air compressor, a turbine, an engine, a volume cavity, a movable plate, retaining rings and an elastic component. The cross section of the volume cavity is rectangular, an air outlet of an escape pipe of the air compressor is communicated with the upper wall surface of the volume cavity, an air inlet of an intake pipe of the engine is communicated with the lower wall surface of the volume cavity, all the retaining rings are mounted in the volume cavity, the movable plate is mounted among the retaining rings and the wall surface of the volume cavity and hermetically contacts with the inner wall surface of the volume cavity, and the movable plate is connected with the wall surface of the volume cavity through the elastic component. During operation of the engine, the movable plate is capable of moving left and right in the volume cavity. Under a low-speed working condition, the overall volume of a rear intake pipe of the air compressor is decreased, intake pressure is increased, and the charge efficiency of the engine is high. Under a high-speed working condition, the overall volume of the rear intake pipe of the air compressor is increased, the intake pressure is decreased, and the blasting pressure of the engine is reduced. The engine intake system is reasonable in design, simple in structure and applicable to turbocharging systems for engines.

Owner:SHANGHAI JIAO TONG UNIV

Pneumatic-control valve lift regulating mechanism

InactiveCN103291470ATaking into account low and medium speed conditionsReasonable designEngine controllersMachines/enginesEngineeringExhaust gas recirculation

The invention relates to a pneumatic-control valve lift regulating mechanism and relates to the technical field of mechanical design. The pneumatic-control valve lift regulating mechanism comprises an air compressor, an engine, a turbine, connecting pipes, a valve seat, a valve block, a rotary shaft, a volumetric cavity, a rotor and an elastic part. The rotor is mounted in the volumetric cavity and hermetically contacts with the inner wall of the volumetric cavity. The lower wall of the rotor is connected with the lower wall of the volumetric cavity through the elastic part. Two ends of the first connecting pipe are communicated with an air inlet of a turbine exhaust pipe and an air inlet of the volumetric cavity. Two ends of the third connecting pipe are communicated with the upper wall of an engine exhaust pipe and the upper wall of the volumetric cavity. When the pressure of an engine intake pipe is high, the rotor drives the valve block to rotate clockwise, emission recirculation rate of the engine is high, and denotation pressure of the engine is low; when the pressure of the engine intake pipe is low, the rotor drives the valve block to rotate anticlockwise, emission recirculation rate of the engine is low, and oil consumption of the engine is low. The pneumatic-control valve lift regulating mechanism is reasonable in design, simple in structure, and applicable to exhaust recirculation systems for supercharged engines.

Owner:SHANGHAI JIAO TONG UNIV

Rotary exhaust gas flow rate regulating system

ActiveCN103291503ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelExhaust gas recirculationElastic componentGas compressor

The invention relates to a rotary exhaust gas flow rate regulating system and belongs to the technical field of mechanical design. The rotary exhaust gas flow rate regulating system comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, an accommodating cavity, a rotator and an elastic component, wherein the rotator is mounted in the accommodating cavity and is in sealed contact with the inner wall face of the accommodating cavity, the lower wall face of the rotator is connected with the lower wall face of the accommodating cavity through the elastic component, two ends of a first connecting pipe are communicated with gas inlets of an engine exhaust pipe and an accommodating chamber respectively, and two ends of a third connecting pipe are communicated with an engine intake pipe and the upper wall face of the accommodating cavity respectively. When the engine intake pipe is high in pressure, the rotator drives the valve body to rotate clockwise, exhaust gas recirculation rate of the engine is large, and the engine is low in explosion pressure; and when the engine intake pipe is low in pressure, the rotator drives the valve body to rotate anticlockwise, the exhaust gas recirculation rate of the engine is small, and oil consumption of the engine is low. The rotary exhaust gas flow rate regulating system is reasonable in design, simple in structure and applicable to an exhaust gas recirculation system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

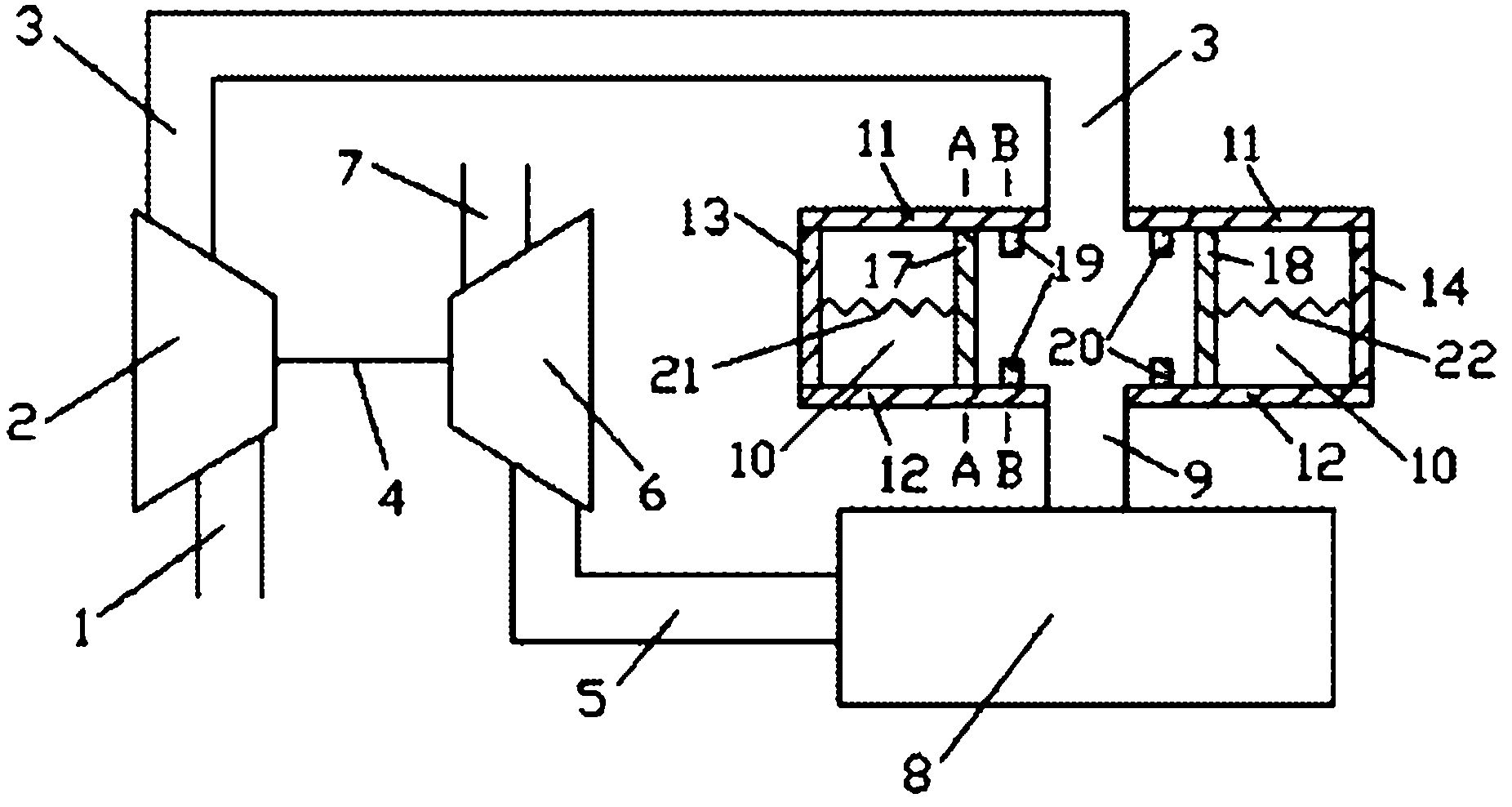

Air feeding and discharging adjustment system with multiple connection pipes

InactiveCN102678275AReduce the temperatureIncrease air intakeInternal combustion piston enginesAir intakes for fuelLow speedCombustion

The invention discloses an air feeding and discharging adjustment system with multiple connection pipes in the technical field of internal combustion engines. The air feeding and discharging adjustment system comprises an air compressor, a turbine, an engine, the connection pipes, a volumetric cavity, a moving body, penetration pipes and an elastic part, wherein the first penetration pipe and the second penetration pipe penetrate through the upper wall surface and the lower wall surface of the moving body; and the right wall surface of the moving body is connected with the right wall surface of the volumetric cavity through the elastic part. In the working process of the engine, the moving body can move in the volumetric cavity left and right; under a working condition of low speed, the pressure of the left side of the moving body is relatively low, so that the moving body moves towards the left, the first connection pipe and the third connection pipe are communicated with each other, the air feeding amount of the air compressor is relatively increased, and the air compressor does not surge; and under a working condition of high speed, the pressure of the left side of the moving body is relatively high, so that the moving body moves towards the right, the fifth connection pipe and the sixth connection pipe are communicated with each other, the air feeding amount of the engine is relatively reduced, and the detonation pressure of each cylinder is reduced. The air feeding and discharging adjustment system is rational in design and suitable for turbine pressurization systems of engines and has a simple structure.

Owner:SHANGHAI JIAO TONG UNIV

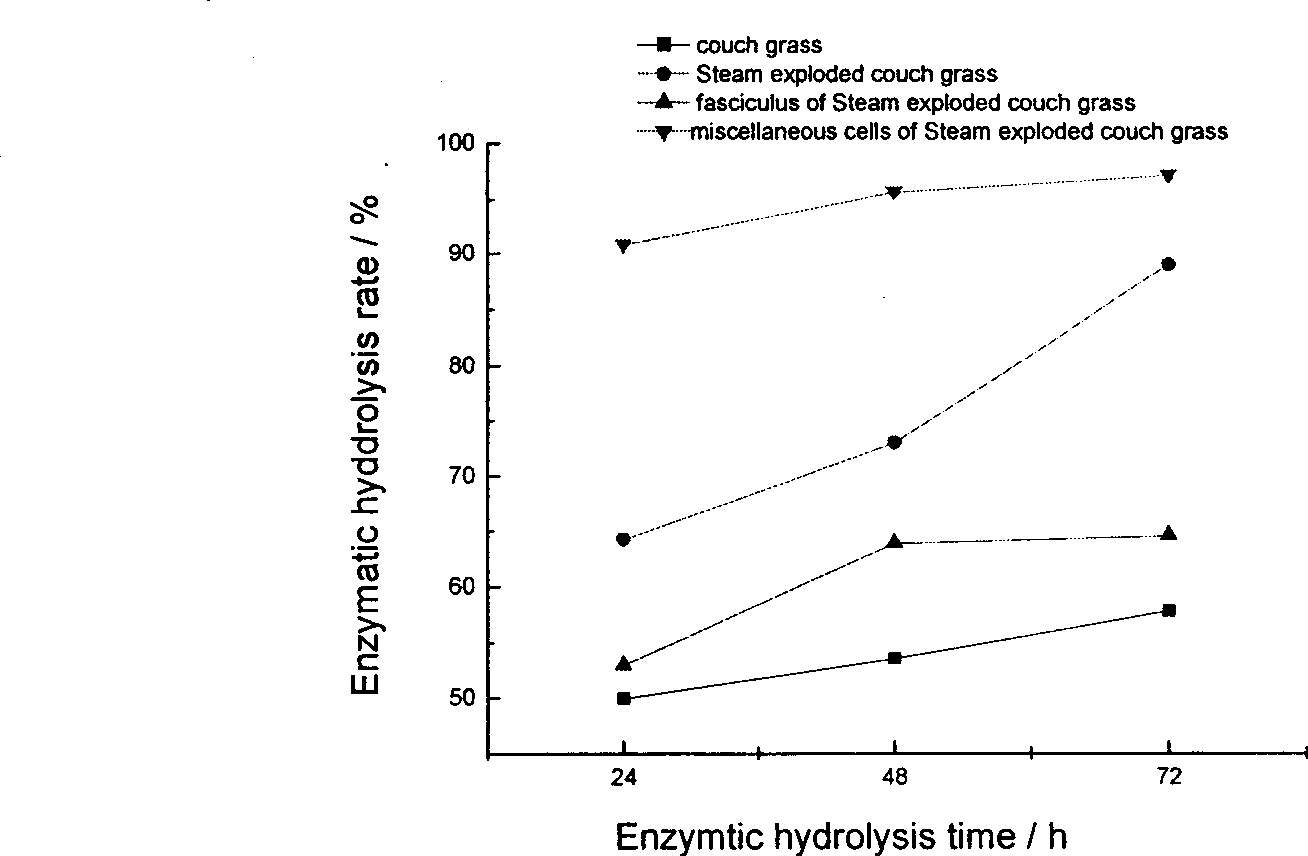

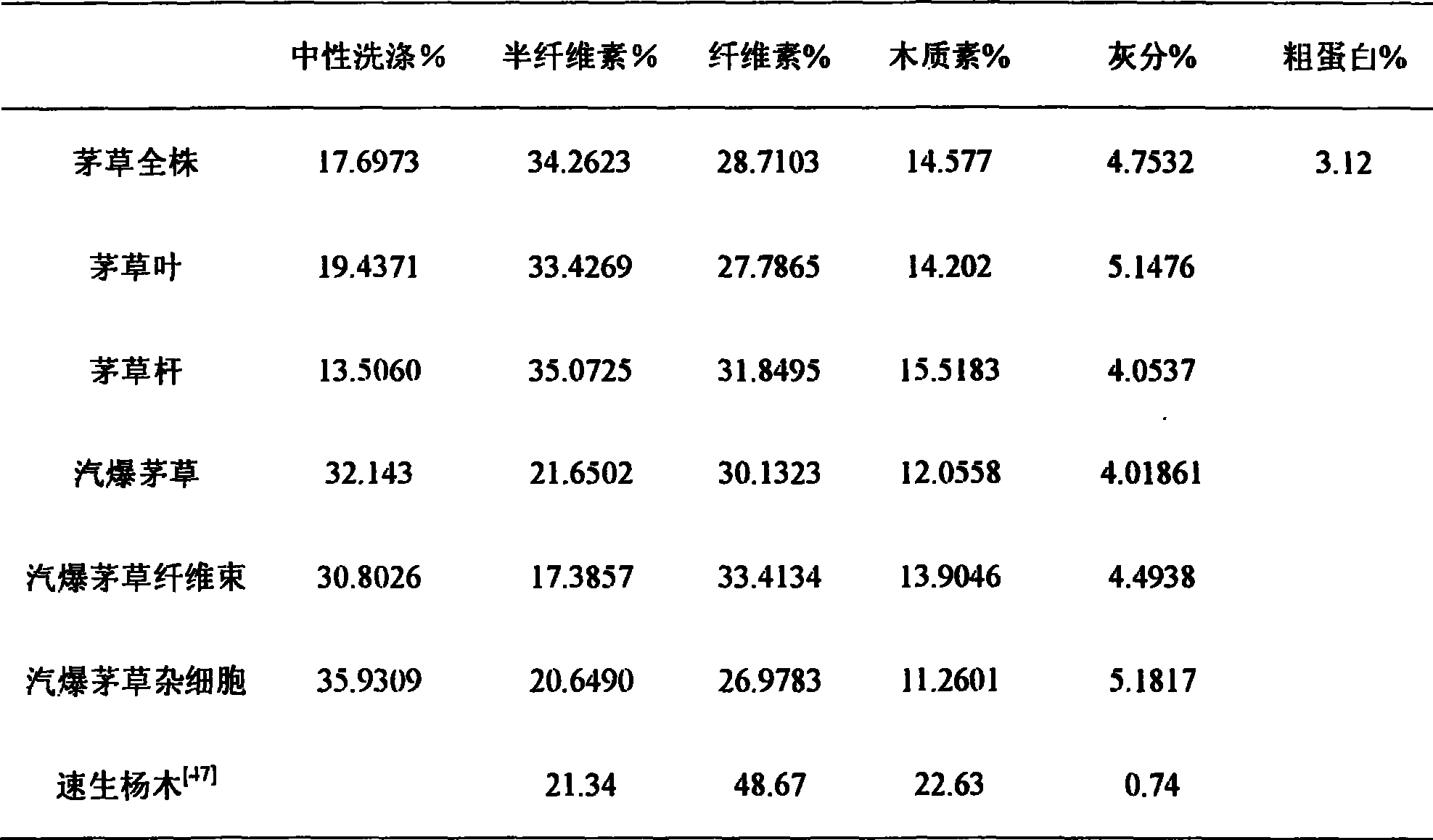

Method for co-producing paper pulp and fuel ethanol by wild grass on forest land

InactiveCN101381970ATo achieve hierarchical utilizationRealize clean high-value full utilizationWashing/displacing pulp-treating liquorsDigestersFiberOligosaccharide

The invention provides a method for co-producing paper pulp and fuel ethanol by waste grass in woodland. In the method, each link is clean and environment friendly ; the steam explosion pretreatment and a mechanical carding tissue are coupled in classification and are separated to obtain a high-quality fibre tissue, a miscellaneous cell tissue and a fine fibre tissue; a high-quality long fibre bundle tissue adopts the steam explosion pretreatment and an ethanol self-catalysis method which are coupled with each other to prepare high-grade paper pulp cleanly; a short fibre consisting of a thin-wall cell and the like ferments to produce the fuel ethanol; at the same time, xylo-oligosaccharides, lignin and nano-silica as byproducts are reclaimed and prepared, thereby realizing the fractionated separation, cleaning and high-value utilization of the waste grass resources in the woodland.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

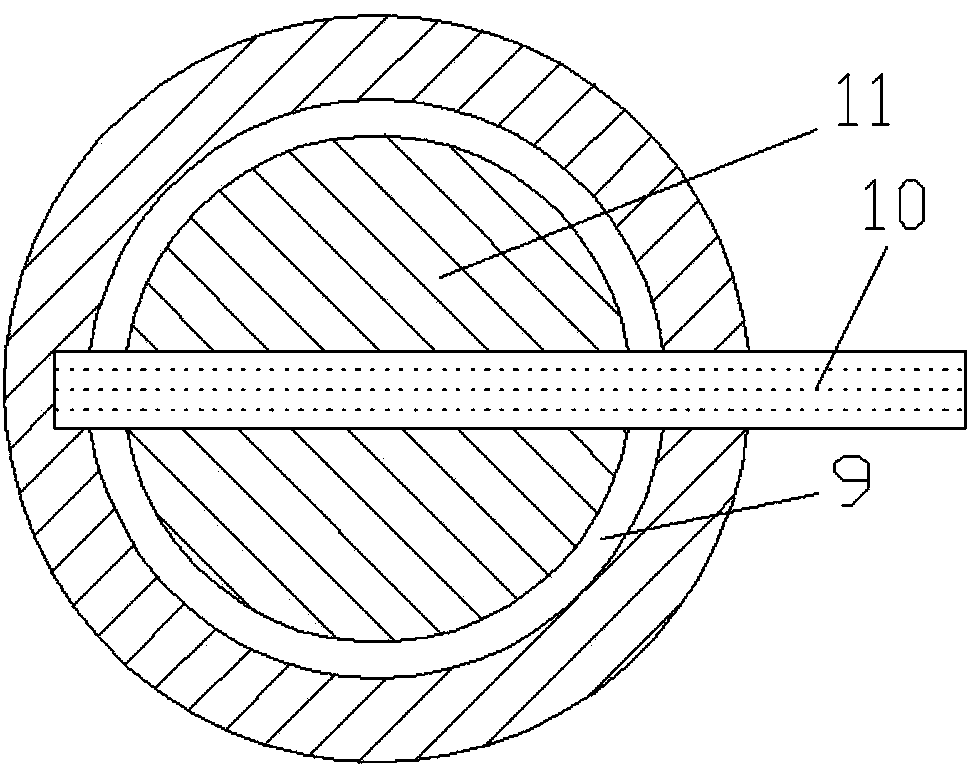

Compressor and turbine homo-mechanism regulating mechanism

InactiveCN102720582AReduce the temperatureIncrease air intakeInternal combustion piston enginesDetonationCombustion

A compressor and turbine homo-mechanism regulating mechanism in the technical field of internal combustion engines comprises a compressor, a turbine, an engine, connecting pipes, a containing cavity, a moving part, penetrating pipes and an elastic part. Both the first penetrating pipe and the second penetrating pipe penetrate an upper wall and a lower wall of the moving part. A left wall of the moving part is connected with a left wall of the containing cavity through the elastic part. During operation of the engine, the moving part can move left and right in the containing cavity. At low operating speed, left pressure of the moving part is low, the moving part moves to the left, the first connecting pipe and the third connecting pipe are communicated with each other, air intake of the compressor increases relatively, and the compressor barely surges. At high operating speed, left pressure of the moving part is high, the moving part moves to the right, the fifth connecting pipe and the sixth connecting pipe are communicated with each other, air intake of the engine decreases relatively, and detonation pressure of cylinders lowers. The compressor and turbine homo-mechanism regulating mechanism is reasonable in design, simple in structure and applicable to turbocharging systems of engines.

Owner:SHANGHAI JIAO TONG UNIV

Supercharged engine air inlet pipe deflating system

InactiveCN102678269APromote combustionReduce fuel consumptionInternal combustion piston enginesEngine controllersLow speedCombustion

The invention discloses a supercharged engine air inlet pipe deflating system in the technical field of internal combustion engines. The system comprises a compressor, a turbine, an engine, connecting pipes, a volume cavity, a moving body and an elastic part, wherein two ends of a first connecting pipe are respectively communicated with an engine air inlet pipe and a volume cavity left wall surface; two ends of a second connecting pipe are respectively communicated with an engine exhaust pipe and the volume cavity left wall surface; the moving body is arranged in the volume cavity and connected with a volume cavity lower wall surface through the elastic part. In the operating process, the moving body can move up and down in the volume cavity; the moving body moves upwards under low-speed working conditions of the engine, air compressed by the compressor totally enters the engine, the air inlet quantity of the engine is relatively increased, and a relative good combustion effect is achieved in each cylinder; and the moving body moves downwards under high-speed working conditions of the engine, part of air compressed by the compressor enters a turbine air outlet pipe, the air inlet quantity of the engine is relatively reduced, and the detonation pressure of each cylinder is reduced. The supercharged engine air inlet pipe deflating system is reasonable in design, simple in structure and suitable for a turbocharging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Regulating device for air intake and discharge flow of supercharger

InactiveCN102678272AReduce the temperatureHigh trafficInternal combustion piston enginesRam-air intakeElastic component

The invention belongs to the technical field of internal combustion engines and relates to a regulating device for air intake and discharge flow of a supercharger. The regulating device comprises a compressor, a turbine, the engine, a connecting pipe, a volume chamber, a moving member and an elastic component, wherein the moving member is installed in the volume chamber, contacts with the inner wall surface of the volume chamber in a sealing mode and is connected with the right wall surface of the volume chamber through the elastic component. During operation of the engine, the moving member can move left and right in the volume chamber. Under a low-speed working condition of the engine, the moving member moves right, a first connecting pipe is communicated with a second connecting pipe, and the flow of the compressor is relatively large, so that the surge of the compressor can be prevented; and under a high-speed working condition of the engine, the moving member moves left, a third connecting pipe is communicated with a fourth connecting pipe, the performance of the turbine is reduced, the air intake of the engine is relatively reduced, and detonation pressures of the cylinders are reduced. The regulating device for the air intake and discharge flow of the supercharger is reasonable in design, simple in structure and suitable for turbine pressurization systems of engines.

Owner:SHANGHAI JIAO TONG UNIV

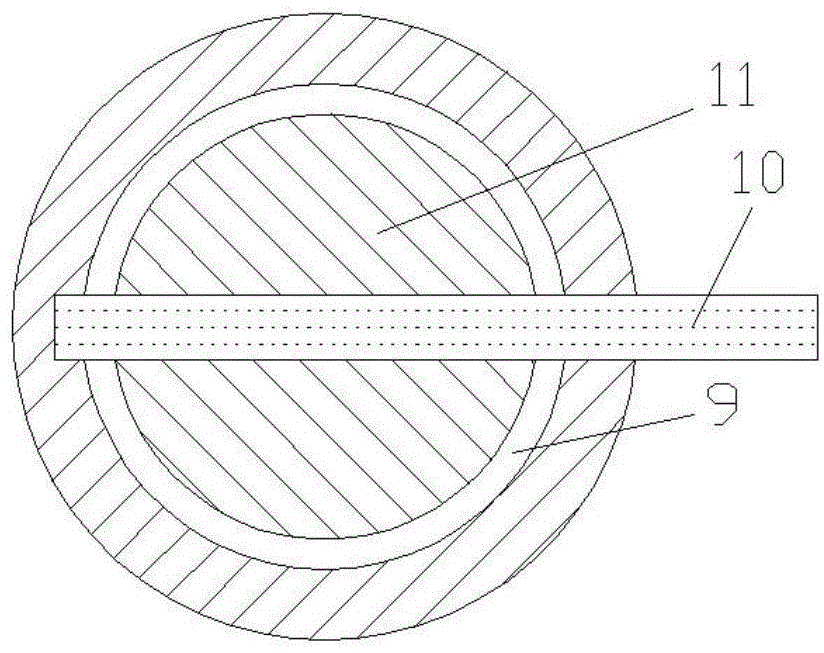

Air inlet device with elastic component

InactiveCN102606278APromote combustionReduce fuel consumptionInternal combustion piston enginesCombustion-air/fuel-air treatmentElastic componentLow speed

An air inlet device with an elastic component relates to the technical field of internal-combustion engines and comprises a compressor, a turbine, an engine, a connecting tube, a volumetric cavity, a movable plate and the elastic component. The cross section of the volumetric cavity is rectangular, two ends of the connecting tube are respectively connected with an air inlet tube of the engine and the left wall surface of the volumetric cavity, and the movable plate is mounted in the volumetric cavity, hermetically contacts with the inner wall surface of the volumetric cavity, and is connected with the left wall surface of the volumetric cavity via the elastic component. When the engine works, the movable plate can move left and right in the volumetric cavity; when in a low-speed working condition, the total volume of the air inlet tube at the rear of the compressor is reduced, air inlet pressure is increased, and air filling efficiency of the engine is high; and when in a high-speed working condition, the total volume of the air inlet tube at the rear of the compressor is increased, the air inlet pressure is reduced, and blasting pressure of the engine is also reduced. The air inlet device is reasonable in design, simple in structure and applicable to a turbocharging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Adjustment system with post-pressure of air compressor as control pressure

InactiveCN102817703AImprove working abilityIncrease air intakeInternal combustion piston enginesLow speedGas compressor

The invention provides an adjustment system with the post-pressure of an air compressor as control pressure in the technical field of an internal combustion engine, comprising an air compressor, a turbo, an engine, connection pipes, a volume chamber, a moving body, a penetration pipe and an elastic part, wherein two ends of the first connection pipe are communicated with an exhaust pipe and the upper wall face of the volume chamber respectively; two ends of the third connection pipe are communicated with the right wall face of the volume chamber and the air inlet pipe of the engine respectively; and the penetration pipe penetrates through the upper wall and the lower wall of the moving body. During the working process of the engine, the moving body can move left and right in the volume chamber; under the low speed working condition, since the pressure on the right side of the moving body is lower, the moving body moves rightward; the first connection pipe and the second connection pipe cannot be communicated; the air inflow of the engine is relatively increased; and the power rises. Under the high speed working condition, since the pressure on the right side of the moving body is higher, the moving body moves leftward; the first connection pipe and the second connection pipe are communicated with each other; the air input of the engine is relatively decreased; and the explosive pressure of each cylinder is decreased. The adjustment system with the post-pressure of the air compressor as the control pressure is rational in design, simple in structure and applicable for a turbo charging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

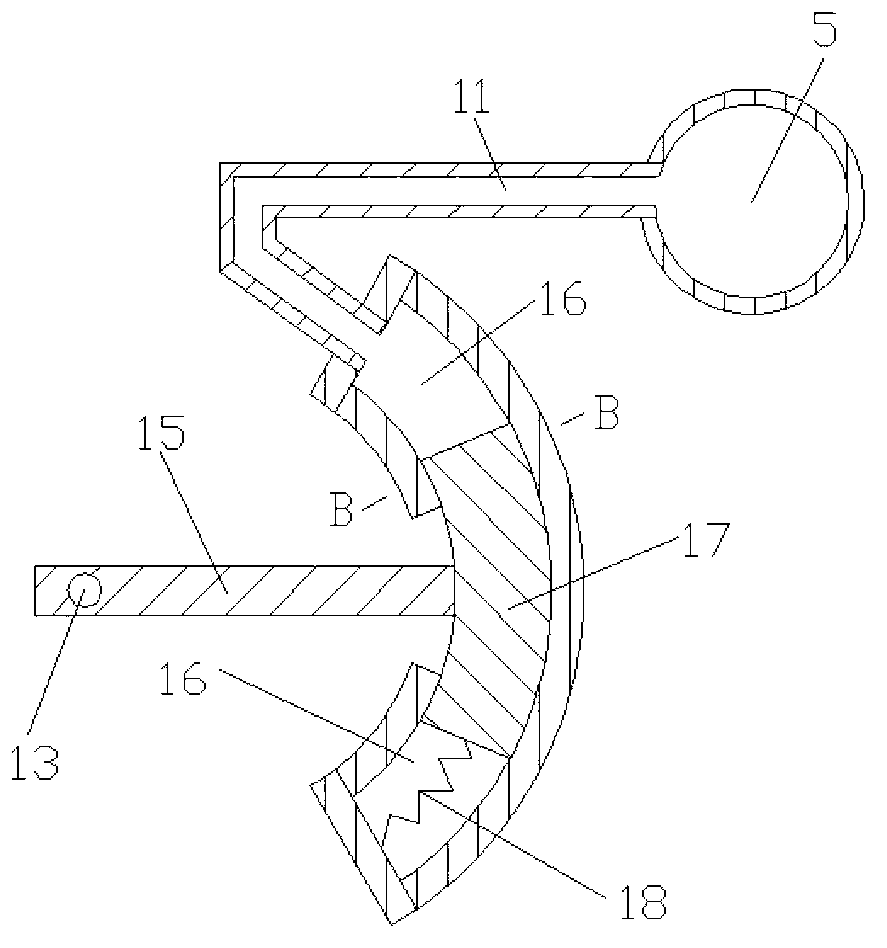

Differential-pressure type gas valve lift adjusting mechanism

InactiveCN103527324ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentDifferential pressure

The invention provides a differential-pressure type gas valve lift adjusting mechanism and belongs to the technical field of mechanical design. The differential-pressure type gas valve lift adjusting mechanism comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, a containing cavity, a fixed body, penetrating pipes, an elastic component, a separating board, a rotary body and a connecting board. One end of the rotary body extends into the first penetrating pipe and makes sealing contact with the wall face of the first penetrating pipe, the other end of the rotary body is fixedly connected with the separating board, one end of the third connecting pipe is communicated with an engine gas inlet pipe, and the other end of the third connecting pipe penetrates through the outer wall face of the containing cavity and then is communicated with the containing cavity. When the pressure of the engine gas inlet pipe is high, the valve body is driven by the rotary body to rotate in the clockwise direction, the exhaust gas recirculation rate of the engine is high, and the detonation pressure of the engine is low; when the pressure of the engine gas inlet pipe is low, the valve body is driven by the rotary body to rotate in the anticlockwise direction, the exhaust gas recirculation rate of the engine is low, and the fuel consumption of the engine is low. The differential-pressure type gas valve lift adjusting mechanism is reasonable in design, simple in structure and suitable for an exhaust gas recirculation system of a supercharged engine.

Owner:刘飞

Intake and exhaust adjusting system with two spray pipes

InactiveCN104061062AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelMotor driveLow speed

An intake and exhaust adjusting system with two spray pipes belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, connecting pipes, an adjusting mechanism, a rotator, penetrating pipes, a stepping motor and a rotating shaft, wherein the gas inlet and the gas outlet of the engine are respectively connected with the gas outlet of an engine gas inlet pipe and the gas inlet of an engine gas outlet pipe; the rotator is arranged in the adjusting mechanism; the penetrating pipes are arranged on the rotator; one end of the rotating shaft is connected with the stepping motor, and the other end of the rotating shaft is fixedly connected with the rotator after penetrating the lower wall surface of the adjusting mechanism. When the engine is under the low-speed working condition, the stepping motor drives the rotator to rotate so as to enable the first connecting pipe and the second connecting pipe to be communicated with each other, and the air compressor is prevented from surge; when the engine is in the high-speed working condition, the stepping motor drives the rotator to rotate so as to enable the third connecting pipe and the fourth connecting pipe to be communicated, and the fifth connecting pipe and the sixth connecting pipe can be communicated to enable the detonation pressure of the engine to be relatively low. The intake and exhaust adjusting system is reasonable in design, simple in structure and suitable for the design of an intake and exhaust system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

Pneumatic type rotary body rotary device

InactiveCN104675534ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelGas compressorExhaust gas recirculation

The invention discloses a pneumatic type rotary body rotary device in the technical field of mechanical design. The pneumatic type rotary body rotary device comprises a gas compressor, an engine, a turbine, a connecting tube, a valve base, a valve body, a rotary shaft, an accommodating chamber, a fixed tube, a penetrating tube, an elastic part, a partition plate, a rotary body and a connecting plate, wherein one end of the rotary body extends into the first penetrating tube and is in sealing contact with the wall surface of the first penetrating tube; the other end of the rotary body is fixedly connected with the partition plate; one end of the second connecting tube is communicated with a gas inlet tube of the engine; the other end of the second connecting tube is communicated with the accommodating chamber. When the pressure of the gas inlet tube of the engine is relatively high, the rotary body drives a butterfly valve to clockwise rotate, so that the larger the gas-exhausting and re-circulating efficiency of the engine, the lower detonation pressure of the engine; when the pressure of the gas inlet tube of the engine is relatively low, the rotary body drives the butterfly valve to anticlockwise rotate, so that the smaller gas-exhausting and re-circulating efficiency of the engine, the lower the oil consumption of the engine. The pneumatic type rotary body rotary device is reasonable in design, simple in structure and suitable for a gas-exhausting and re-circulating system of a booster engine.

Owner:李华雷

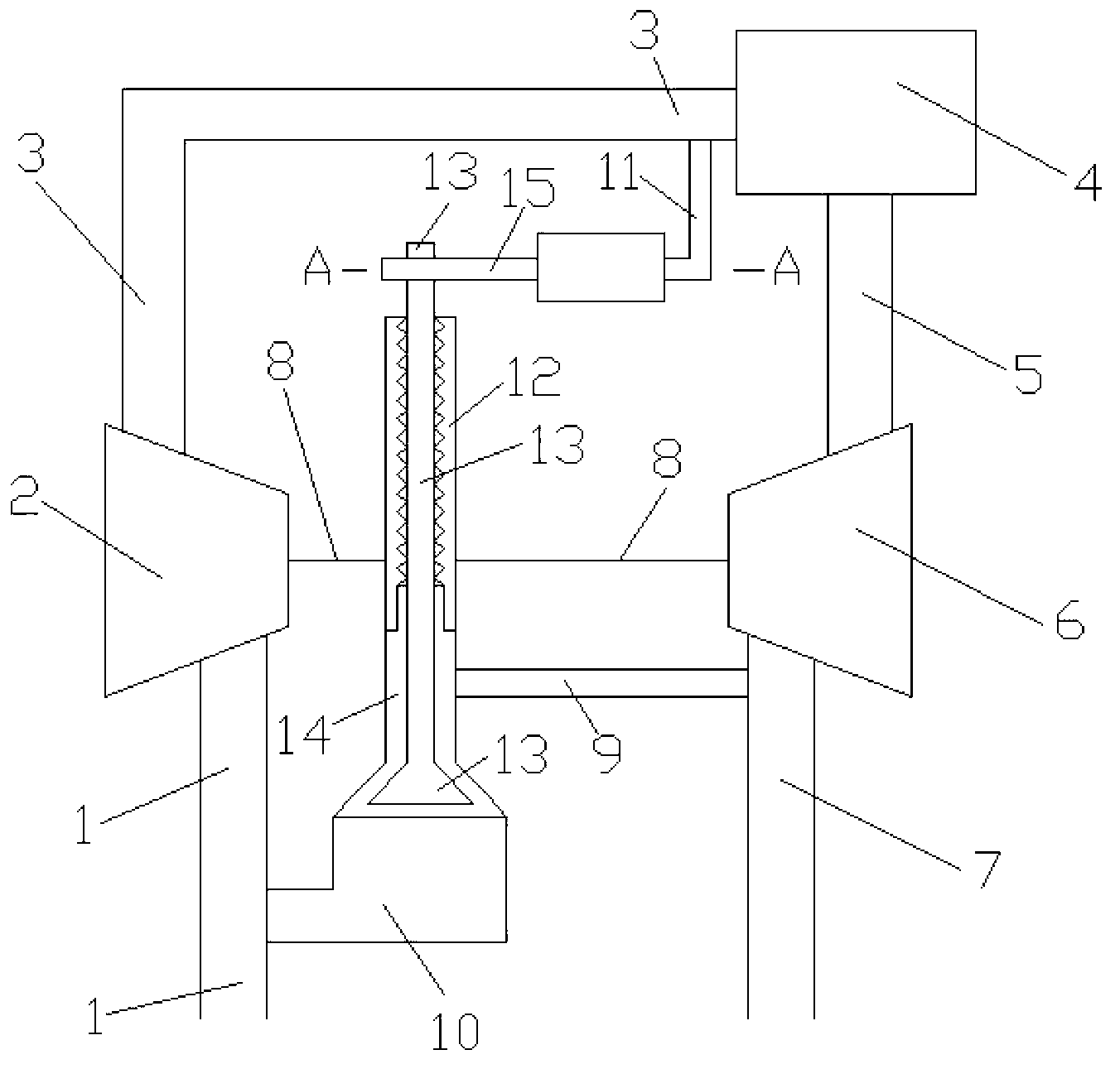

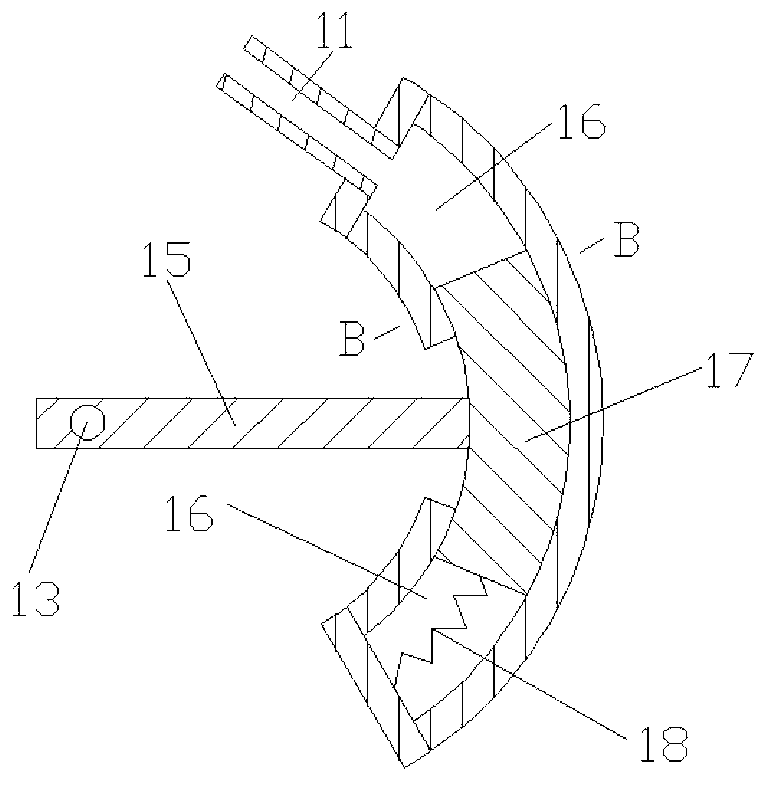

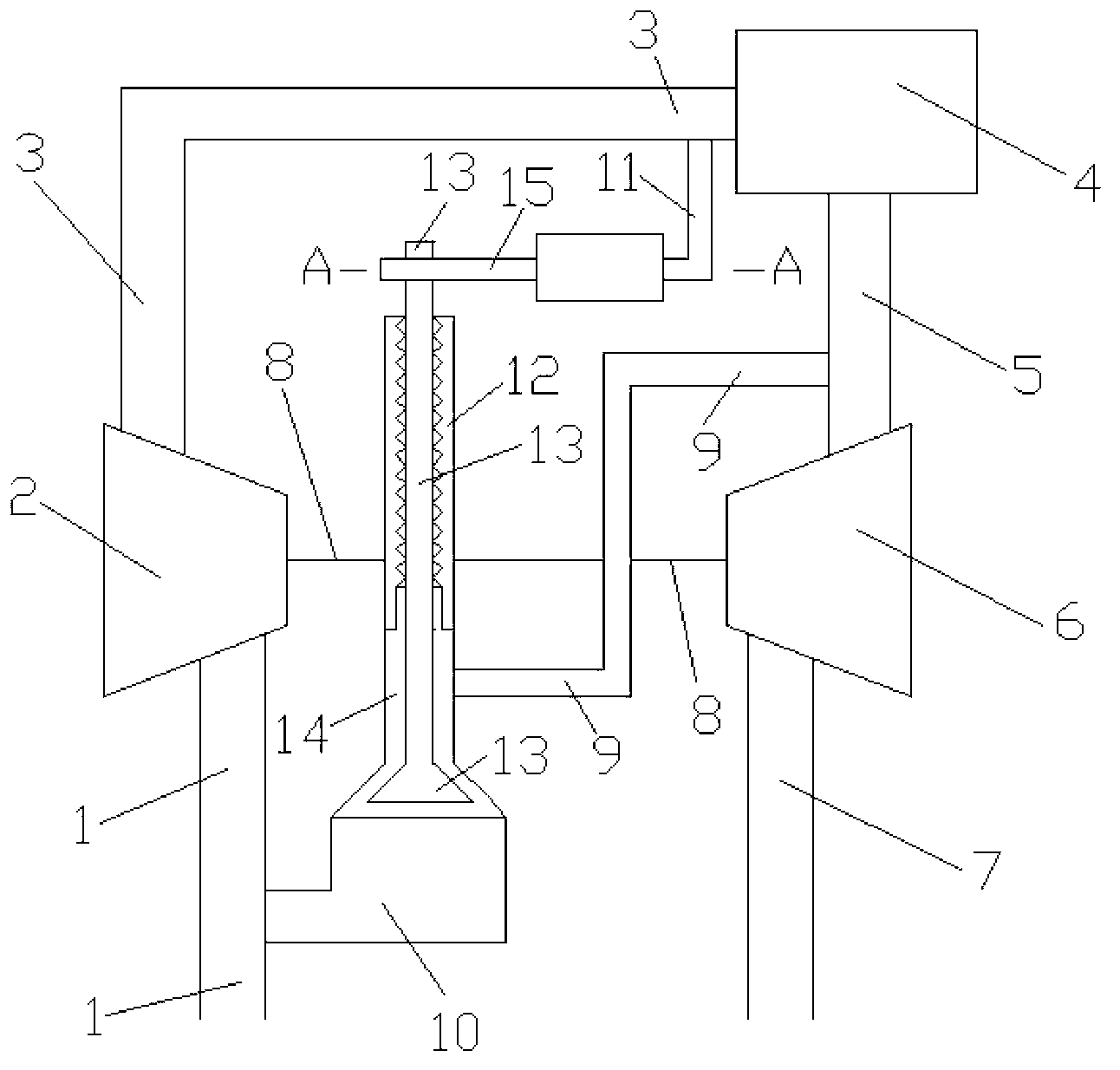

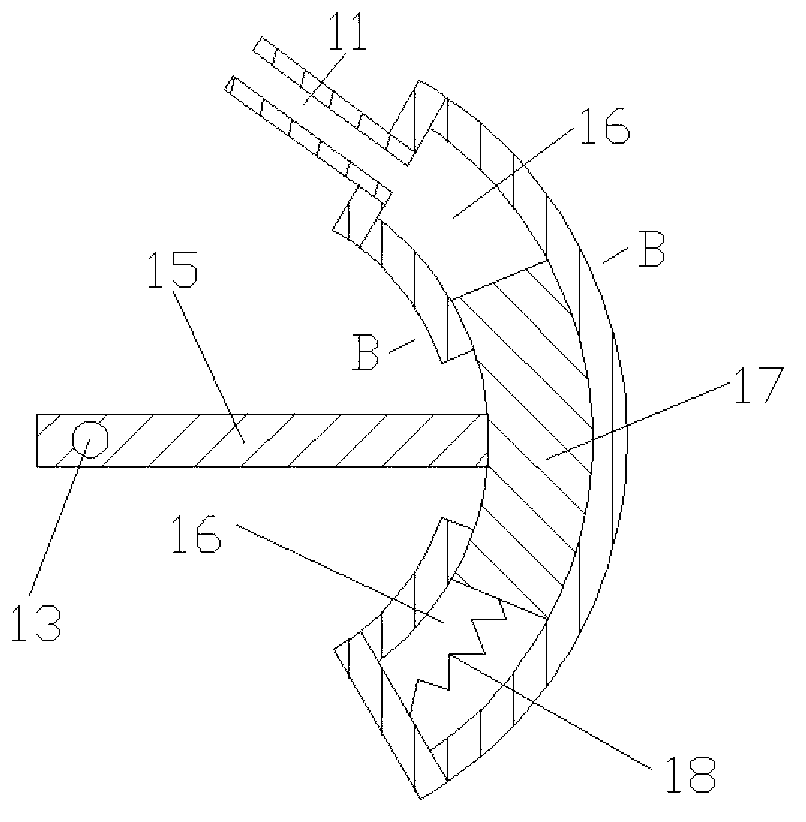

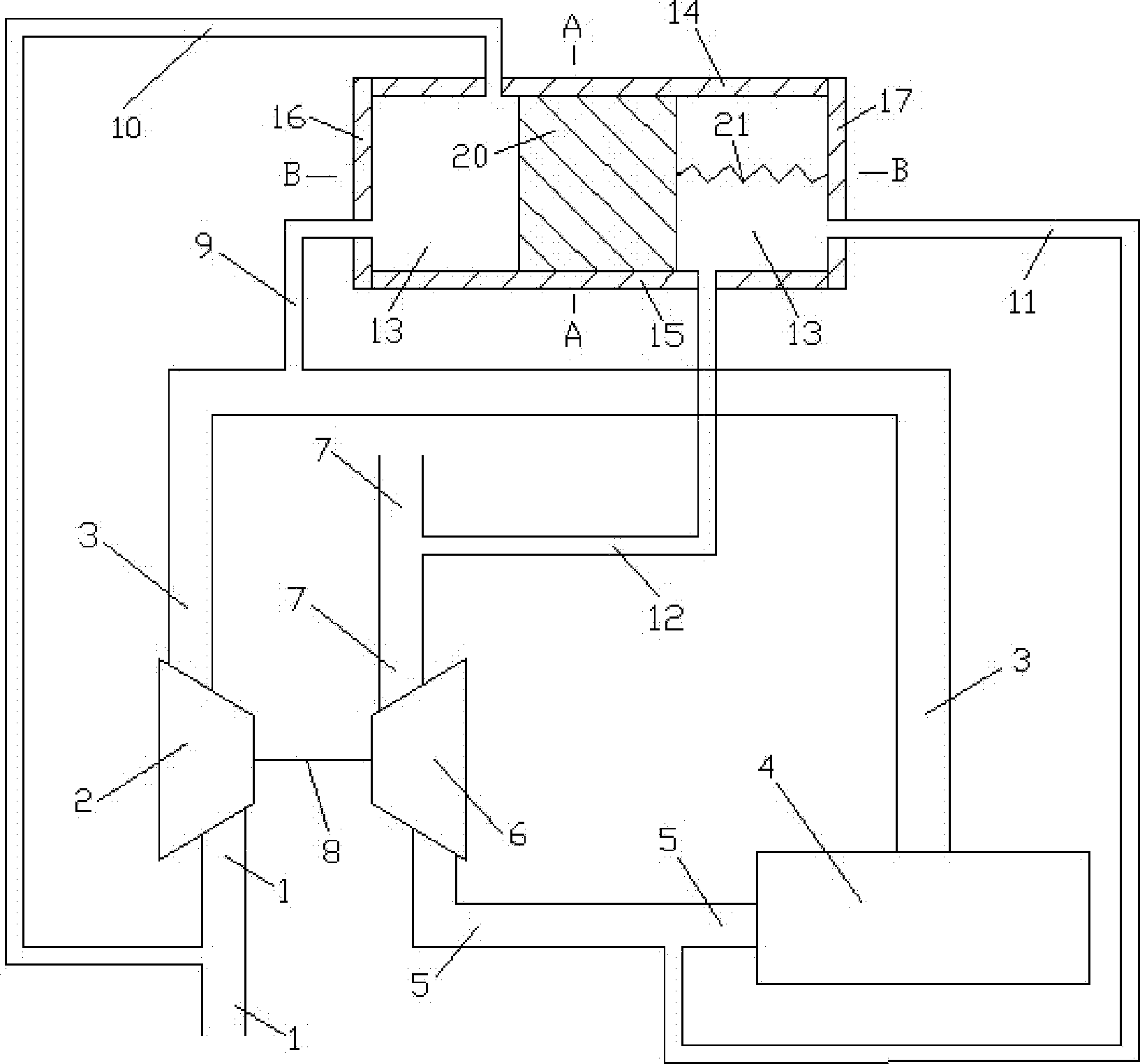

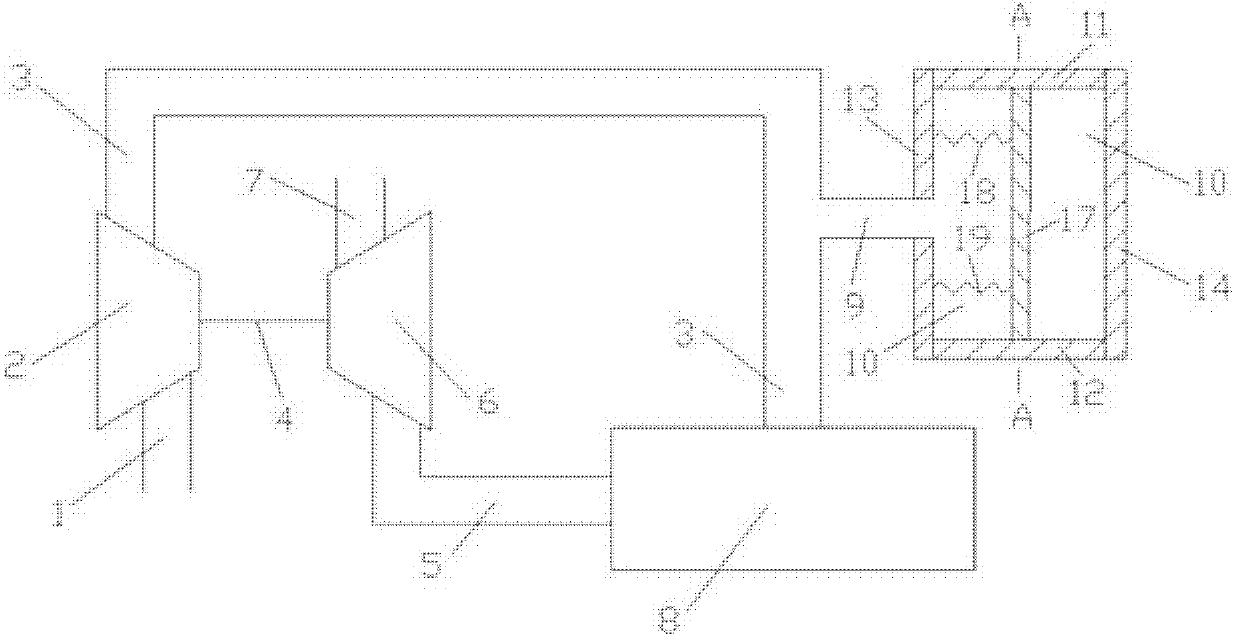

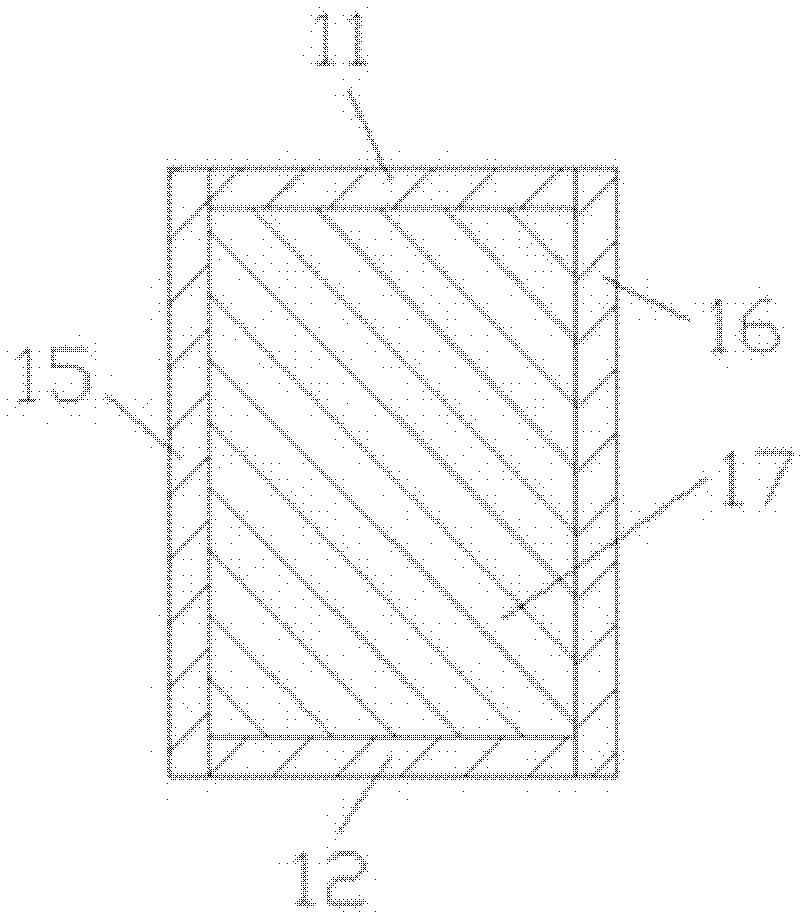

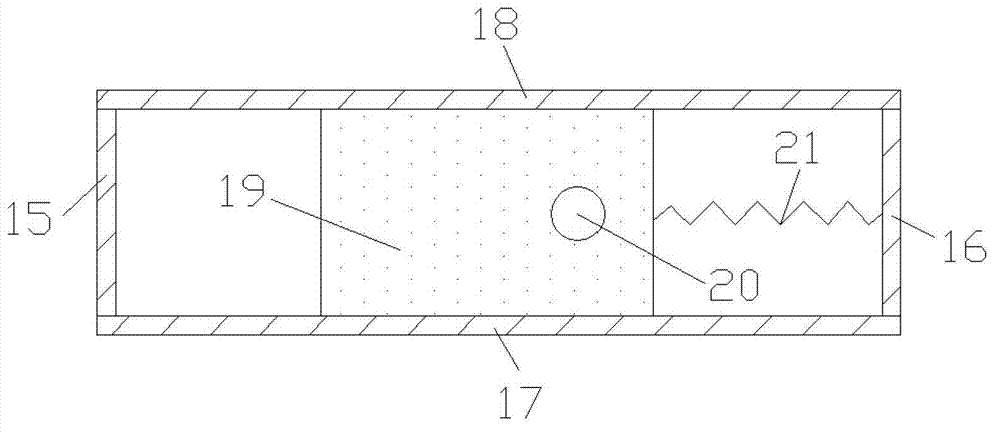

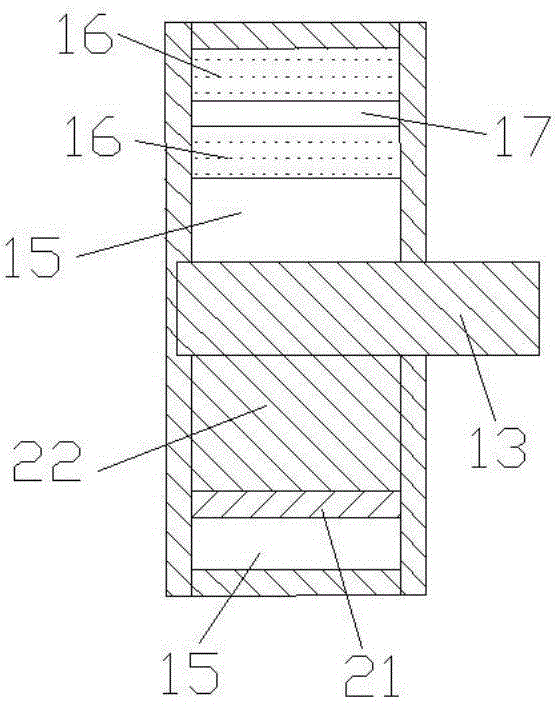

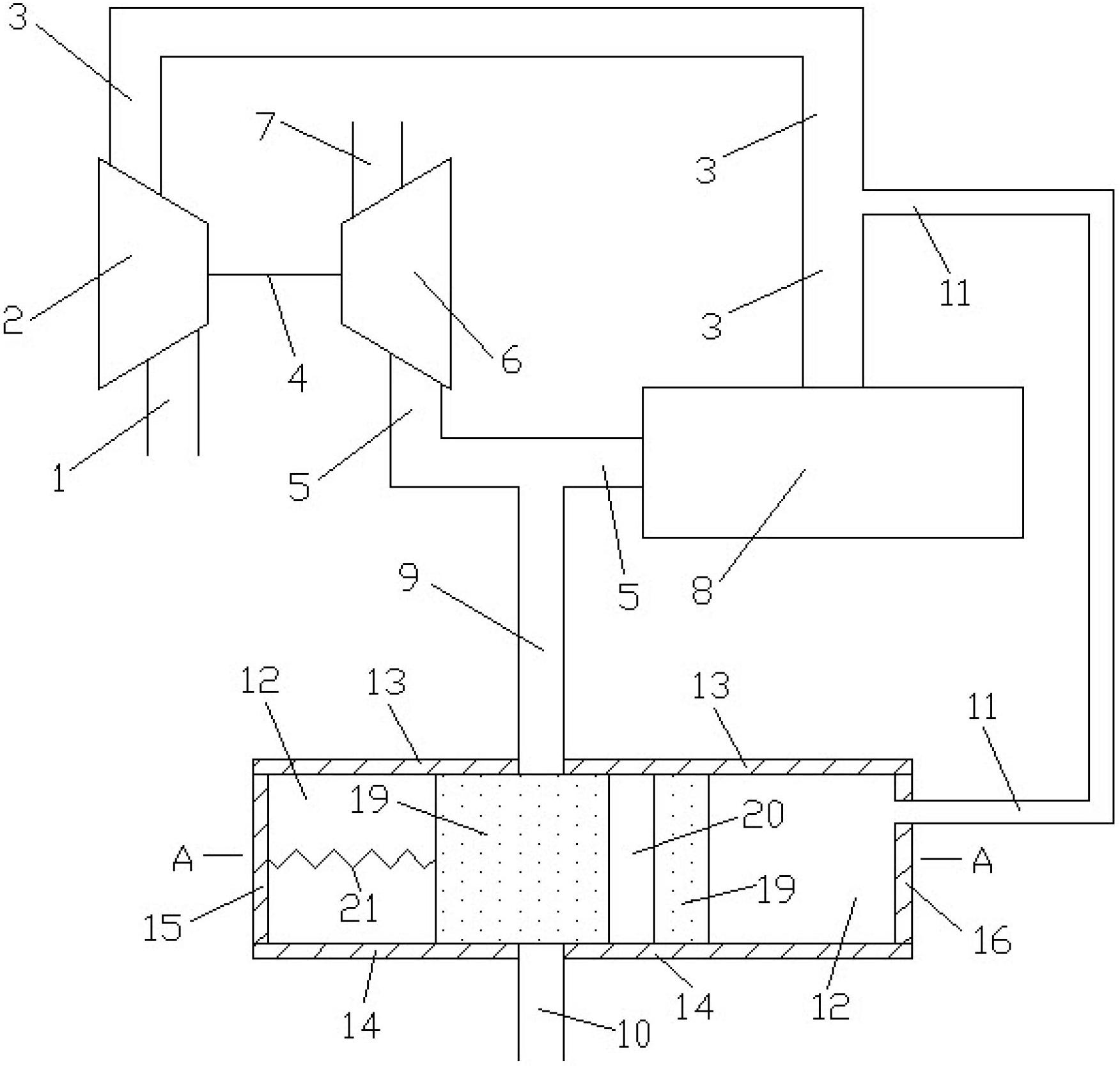

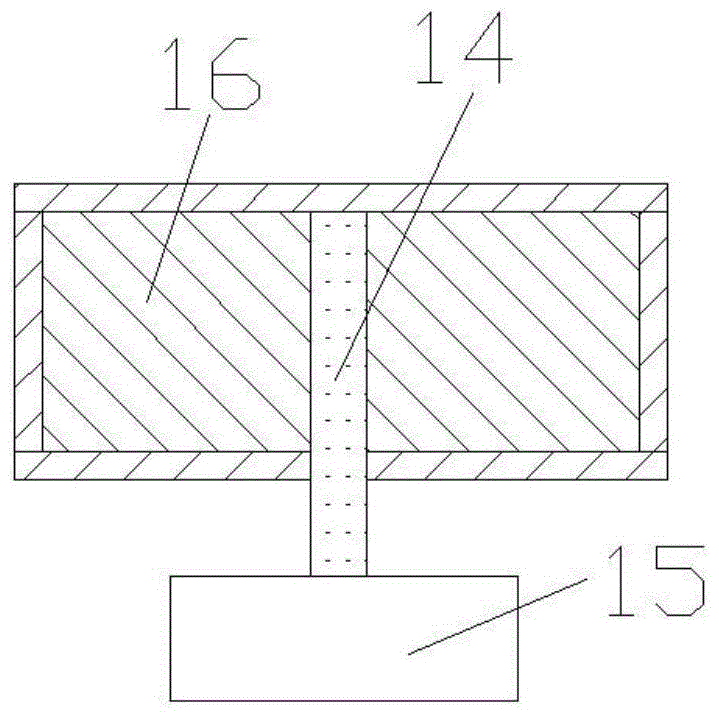

Rotary distance adjustment system for valve body and valve seat

InactiveCN103527325AExhaust gas recirculation rate increasedLow burst pressureNon-fuel substance addition to fuelInternal combustion piston enginesExhaust gas recirculationTurbine

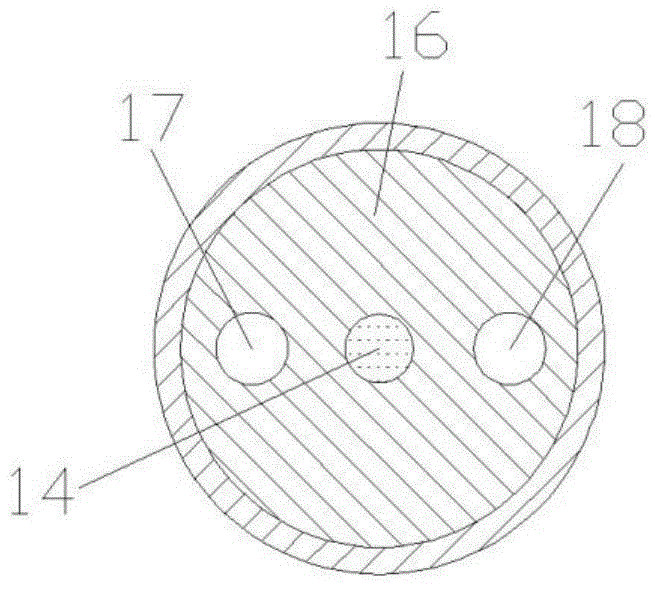

The invention belongs to the technical field of machine design, and provides a rotary distance adjustment system for a valve body and a valve seat. The rotary distance adjustment system comprises a compressor, an engine, a turbine, connecting pipes, the valve seat, the valve body, a rotating shaft, a volume cavity, a fixed body, penetrating pipes, a flexible component, a partition plate, a rotating body and a connecting plate, wherein one end of the rotating body stretches into the first penetrating pipe and makes sealing contact with the wall surface of the first penetrating pipe, the other end of the rotating body is fixedly combined with the partition plate together, one end of the third connecting pipe is communicated with an engine exhaust pipe, and the other end of the third connecting pipe is communicated with the volume cavity after penetrating through the outer wall surface of the volume cavity. When the pressure of the engine exhaust pipe is quite high, the rotating body drives the valve body to rotate clockwise, the exhaust recirculation rate of the engine is quite high, and the detonation pressure of the engine is quite low; when the pressure of the engine exhaust pipe is quite low, the rotating body drives the valve body to rotate counterclockwise, the exhaust recirculation rate of the engine is quite low, and the fuel consumption of the engine is quite low. The rotary distance adjustment system for the valve body and the valve seat is reasonable in design, simple in structure, and applicable to an exhaust recirculation system of a supercharged engine.

Owner:刘飞

Flow control system with area-adjustable throat part

InactiveCN103573477ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesControl systemEngineering

A flow control system with area-adjustable throat part in the technical field of mechanical design comprises a compressor, a motor, a turbine, a connecting pipe, a valve holder, a valve body, a rotary shaft, a volume cavity, a rotary body and an elastic part; the rotary body is mounted in the volume cavity and is hermetically connected with the inner wall surface of the volume cavity; the right wall surface of a partition plate is connected with the rotary body by the elastic part; two ends of a first connecting pipe are respectively communicated with a turbine exhausting pipe and the gas inlet of a volume chamber; two ends of a third connecting pipe are respectively communicated with the gas inlet pipe of the motor and the volume cavity at the left side of the partition plate; when the gas inlet pipe of the motor has higher pressure, the rotary body drives the valve body to rotate clockwise, the exhausting recirculation rate of the motor is larger, and the blasting pressure of the motor is lower; when the gas inlet pipe of the motor has lower pressure, the rotary body drives the valve body to rotate counterclockwise, the motor is smaller in exhausting recirculation rate and lower in oil consumption. The flow control system with the area-adjustable throat part is reasonable in design, simpler in structure, and suitable for the exhausting recirculation systems of boosting motors.

Owner:SHANGHAI JIAO TONG UNIV

Air inlet bypass device in compressor rear air inlet pipe

InactiveCN102678277ABurn wellReduce fuel consumptionInternal combustion piston enginesEngineeringLow speed

The invention discloses an air inlet bypass device in a compressor rear air inlet pipe in the technical field of internal combustion engines. The system comprises a compressor, a turbine, an engine, connecting pipes, a volume cavity, a moving body and an elastic part, wherein two ends of a first connecting pipe are respectively communicated with an engine air inlet pipe and a volume cavity left wall surface; two ends of a second connecting pipe are respectively communicated with an engine exhaust pipe and the volume cavity left wall surface; the moving body is arranged in the volume cavity and connected with a volume cavity upper wall surface through the elastic part. In the operating process, the moving body can move up and down in the volume cavity; the moving body moves upwards under low-speed working conditions of the engine, air compressed by the compressor totally enters the engine, the air inlet quantity of the engine is relatively increased, and a relatively good combustion effect is achieved in each cylinder; and the moving body moves downwards under high-speed working conditions of the engine, part of air compressed by the compressor enters a turbine air outlet pipe, the air inlet quantity of the engine is relatively reduced, and the detonation pressure of each cylinder is reduced. The supercharged engine air inlet pipe deflating system is reasonable in design, simple in structure and suitable for a turbocharging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Intake pressure regulating type valve rotating mechanism

InactiveCN103670812ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelDetonationGas compressor

Disclosed is an intake pressure regulating type valve rotating mechanism in the technical field of mechanical design. The intake pressure regulating type valve rotating mechanism comprises a gas compressor, an engine, a turbine, connecting pipes, a volume cavity, an elastic part and a rotator. The rotator is connected with the left wall surface of a fixing plate through the elastic part, two ends of a first connecting pipe are communicated with a gas compressor intake pipe and a turbine exhaust pipe respectively, one end of a second connecting pipe is communicated with an engine intake pipe, and the other end of the second connecting pipe is communicated with the volume cavity. When the engine intake pipe is high in pressure, the rotator drives a butterfly valve to rotate clockwise, exhaust gas recirculation rate of the engine is high, and detonation pressure of the engine is low; when the engine intake pipe is low in pressure, the rotator drives the butterfly valve to rotate anticlockwise, exhaust gas recirculation rate of the engine is low, and oil consumption of the engine is low. The intake pressure regulating type valve rotating mechanism is reasonable in design, simple in structure and applicable to an exhaust gas recirculation system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

Turbine exhaust device with penetrating pipe

InactiveCN102678281AReduce the temperatureSolve the sealing problemInternal combustion piston enginesCombustionLow speed

The invention discloses a turbine exhaust device with a penetrating pipe in the technical field of internal combustion engines. The device comprises a compressor, a turbine, an engine, a connecting pipe, a volume cavity, a moving body, the penetrating pipe and an elastic part, wherein two ends of a first connecting pipe are respectively communicated with an exhaust pipe of the engine and the upper wall surface of the volume cavity; two ends of a third connecting pipe are respectively communicated with a right wall surface of the volume cavity and an air inlet pipe of the engine; and the penetrating pipe penetrates through the upper and lower walls of the moving body. In the operating process of the engine, the moving body can move left and right in the volume cavity; the pressure on the right side of the moving body is low and the moving body moves to the right side under low-speed working conditions, the first connecting pipe cannot be communicated with a second connecting pipe, the air inlet quantity of the engine is relatively increased, and the power of the engine is raised; and the pressure on the right side of the moving body is high and the moving body moves to the left side under high-speed working conditions, the first connecting pipe is communicated with the second connecting pipe, the air inlet quantity of the engine is relatively reduced, and the detonation pressure of each cylinder is reduced. The turbine exhaust device is reasonable in design, simple in structure and suitable for a turbocharging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Pressure control type mechanical rotating mechanism

InactiveCN103573432ATaking into account low and medium speed conditionsReasonable designEngine controllersMachines/enginesDetonationGas compressor

A pressure control type mechanical rotating mechanism in the technical field of mechanical design comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, a volume cavity, a rotating body, and an elastic part, wherein the rotating body is arranged in the volume cavity and is in sealing contact with the inner wall surface of the volume cavity, the left wall surface of a partition plate is connected with the rotating body by the elastic part, two ends of a first connecting pipe are respectively communicated with the air inlet of the volume cavity and an engine exhaust pipe, and two ends of a third connecting pipe are respectively communicated with an engine admission pipe and the volume cavity at the right side of the partition plate. When the pressure of the engine admission pipe is higher, the valve body is driven by the rotating body to rotate clockwise, the exhaust recycling rate of the engine is relatively large, and the detonation pressure of the engine is less; when the pressure of the engine admission pipe is lower, the valve body is driven by the rotating body to rotate anticlockwise, the exhaust recycling rate of the engine is relatively small, and the oil consumption of the engine is less. The system is reasonable in design, simple in structure and suitable for the exhaust recycling system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

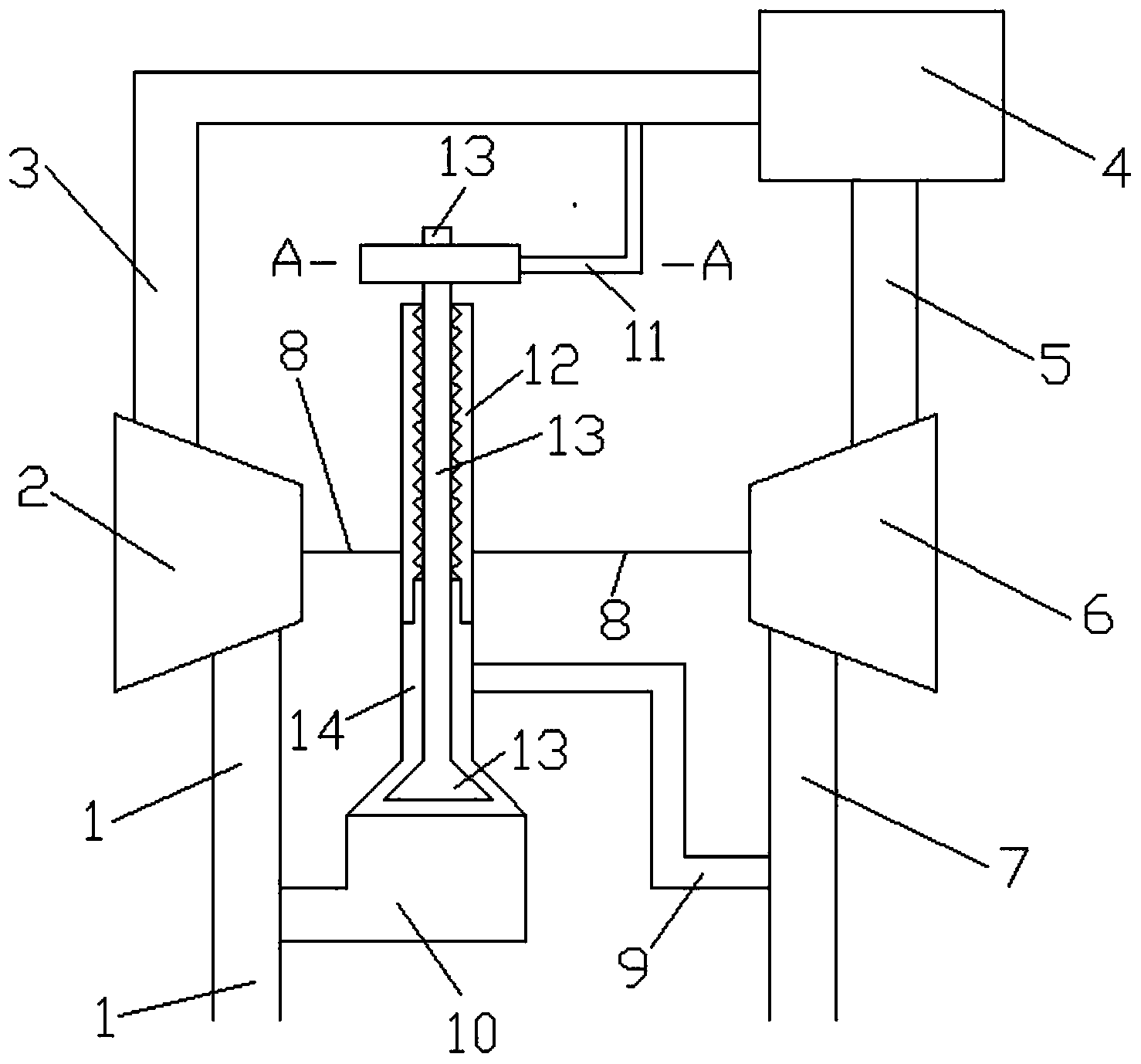

Tri-communicated rotary adjusting device

InactiveCN104061060AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesEngine componentsMotor driveLow speed

The invention relates to a tri-communicated rotary adjusting device, and belongs to the technical field of mechanical design. The device comprises an air compressor, an engine, a turbine, a connecting pipe, an adjusting mechanism, a rotator, a run-through pipe, a step motor, and a rotating shaft, wherein the air inlet and the air outlet of the engine are respectively connected with the air outlet of an air inlet pipe of the engine and the air inlet of an air outlet pipe of the engine; the rotator is arranged inside the adjusting mechanism; the run-through pipe is arranged on the rotator; one end of the rotating shaft is connected with the step motor, and the other end of the rotating shaft penetrates through the lower wall surface of the adjusting mechanism, and then is fixedly connected with the rotator into a whole. When the engine is operated at a low speed, the step motor drives the rotator to rotate to enable a first connecting pipe and a second connecting pipe to be communicated, so that the shaking and vibration of the air compressor can be avoided; when the engine is operated at a high speed, the step motor drives the rotator to rotate to enable a third connecting pipe and a fourth connecting pipe to be communicated and to enable a fifth connecting pipe and a sixth connecting pipe to be communicated, so that the detonation pressure of the engine is relatively lower. The device is reasonable in design, simple in structure, and applicable to the design of the air feeding and discharging system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

Mechanical regulating type turbine bleeding system

InactiveCN102678284ABurn wellReduce fuel consumptionInternal combustion piston enginesLow speedExternal combustion engine

The invention belongs to the technical field of internal combustion engines and relates to a mechanical regulating type turbine bleeding system. The mechanical regulating type turbine bleeding system comprises a compressor, a turbine, the engine, a connecting pipe, a volume chamber, a moving member and an elastic component, wherein two ends of a first connecting pipe are communicated with a discharging pipe of the turbine and the left wall surface of the volume respectively, the two ends of a second connecting pipe are communicated with a discharging pipe of the engine and the left wall surface of the volume respectively, the moving member is installed in the volume chamber and connected with the lower wall surface of the volume chamber through the elastic component. During operation, the moving member can move up and down in the volume chamber. Under a low-speed working condition of the engine, the moving member moves downward, all the discharged air of the engine passes through the turbine, the air intake of the engine is relatively enlarged, and combustion conditions of cylinders are good; and under a high-speed working condition of the engine, the moving member moves upward, part of the discharged air of the engine directly flows into the discharging pipe of the turbine, the air intake of the engine is relatively reduced, and detonation pressures of the cylinders are reduced. The mechanical regulating type turbine bleeding system is reasonable in design, simple in structure and suitable for turbine pressurization systems of engines.

Owner:SHANGHAI JIAO TONG UNIV

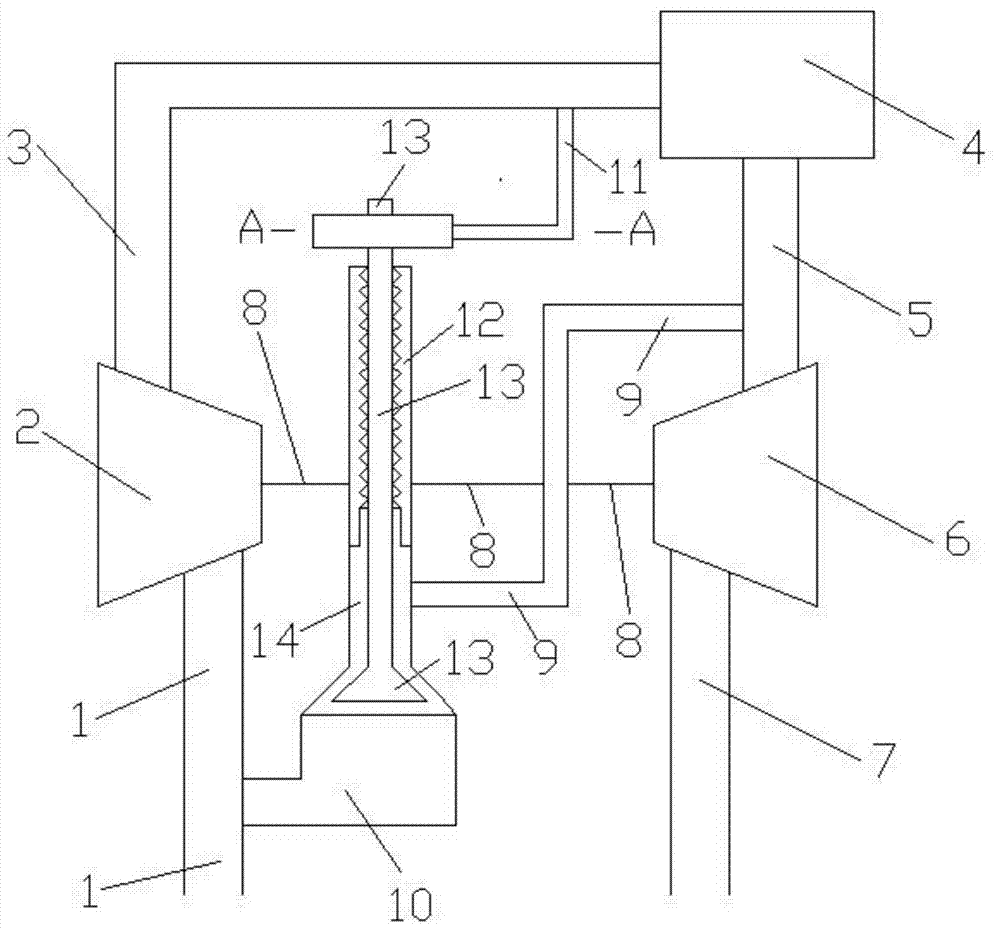

Coaxial connecting device for rotating body and valve

ActiveCN104675576ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringAir compressor

The invention provides a coaxial connecting device for a rotating body and a valve, and belongs to the technical field of mechanism design. The device comprises an air compressor, an engine, a turbine, a connecting pipe, a rotating shaft, a volume cavity, a fixing body, a through pipe, a separating plate, a rotating body and a connecting plate; one end of the rotating body extends into the first through pipe and is in sealing contact with the wall surface of the first through pipe, and while the other end of the rotating body is integrally fixedly connected with the separating plate; two ends of the first connecting pipe are respectively communicated with an air inlet pipe of the air compressor and an exhaust pipe of the turbine; in case of relatively high pressure difference between the previous period and the later period of the turbine, the rotating body drives a valve to clockwise rotate, the exhaust of the engine is high in recycling efficiency, and the detonation pressure of the engine is relatively low. The device is reasonable in design, simple in structure, and suitable for an exhaust gas recycling system of a supercharged engine.

Owner:浙江和夏科技股份有限公司

Displacement cavity type homo-mechanism intake and exhaust regulating device

InactiveCN102720583AIncrease air intakeReduce air intakeInternal combustion piston enginesCombustionEngineering

A displacement cavity type homo-mechanism intake and exhaust regulating device which belongs to the technical field of internal combustion engines comprises a compressor, a turbine, an engine, connecting pipes, a displacement cavity, a moving part, penetrating pipes, and an elastic part. Both the first penetrating pipe and the second penetrating pipe penetrate through an upper wall and a lower wall of the moving part. The right wall of the moving part is connected with a right wall of the displacement cavity through the elastic part. When the engine operates, the moving part can move left and right in the displacement cavity. At the low operating speed, the left pressure of the moving part is low, the moving part moves to the left, the first connecting pipe is communicated with the third connecting pipe, intake of the compressor increases relatively, and the compressor scarcely surges. At high operating speed, the left pressure of the moving part is high, the moving part moves to the right, the fifth connecting pipe is communicated with the sixth connecting pipe, intake of the engine decreases relatively, and detonation pressure of cylinders decreases. The displacement cavity type homo-mechanism intake and exhaust regulating device is reasonable in design, simple in structure and applicable to turbocharging systems of engines.

Owner:SHANGHAI JIAO TONG UNIV

Engine high-speed working condition detonation pressure reducing device

InactiveCN104061064ALow burst pressureReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelSystems designMotor drive

An engine high-speed working condition detonation pressure reducing device in the technical field of machine design comprises an air compressor, an engine, a turbine, connecting pipes, an adjusting mechanism, a rotating body, penetrating pipes, a stepping motor and a rotating shaft, wherein the inlet and the outlet of the engine are respectively connected with the air outlet of an engine air intake pipe and the air inlet of an engine air exhaust pipe; the rotating body is arranged inside the adjusting mechanism; the penetrating pipes are arranged on the rotating body; one end of the rotating shaft is connected with the stepping motor; the other end of the rotating shaft penetrates through the lower wall surface of the adjusting mechanism and is fixedly connected with the rotating body together. In the engine high-speed working condition, the stepping motor drives the rotating body to rotate so as to ensure that a third connecting pipe and a fourth connecting pipe are communicated and a first connecting pipe and a second connecting pipe are communicated, and the detonation pressure of the engine is enabled to be relatively low. The device is reasonable in design, simple in structure, and suitable for air intake and exhaust system design of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

Rotary multi-pipeline connecting system

InactiveCN104653340ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesDifferential pressureEngineering

A rotary multi-pipeline connecting system belongs to the technical field of machinery design and comprises a compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, an accommodating cavity, a fixing body, through pipes, a separation plate, a rotation body and a connection plate. One end of the rotation body extends into a first through pipe and has a sealed contact with the wall surface of the first through pipe; the other end of the rotation body is fixedly connected with the separation plate; one end of a second connecting pipe is communicated with an air exhaust pipe of the engine; and the other end of the second connecting pipe passes through the fixing body to be communicated with the first through pipe. When large differential pressure between the back and front parts of the turbine exists, the rotating body drives a butterfly valve to clockwise rotate; large high pressure exhausting and recirculation efficiency of the engine is achieved. The rotary multi-pipeline connecting system is rationally designed, simply structured and suitable for exhaust recirculation system of the engine.

Owner:张琨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com