Patents

Literature

69results about How to "Exhaust gas recirculation rate increased" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

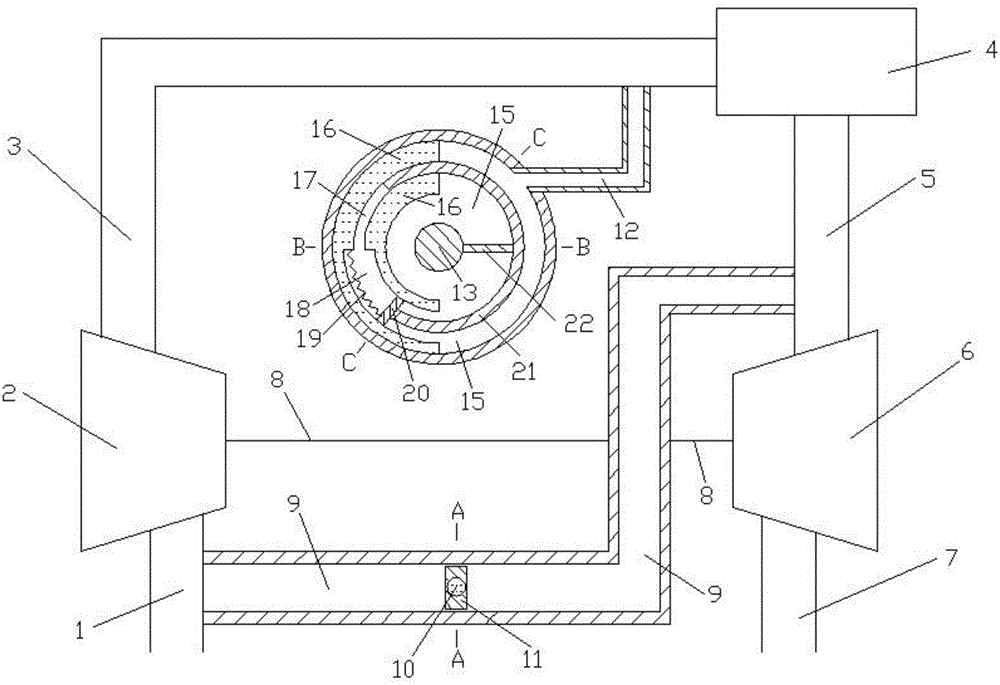

Rotary gas valve control mechanism

ActiveCN103291469ATaking into account low and medium speed conditionsReasonable designEngine controllersMachines/enginesElastic componentGas compressor

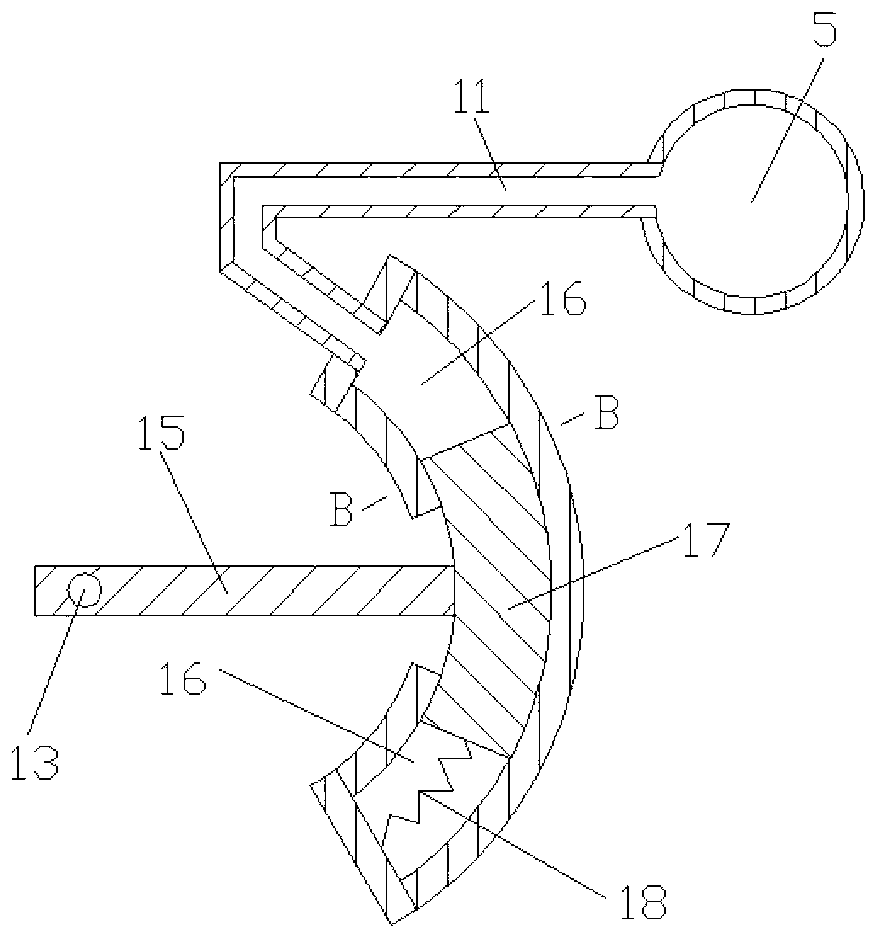

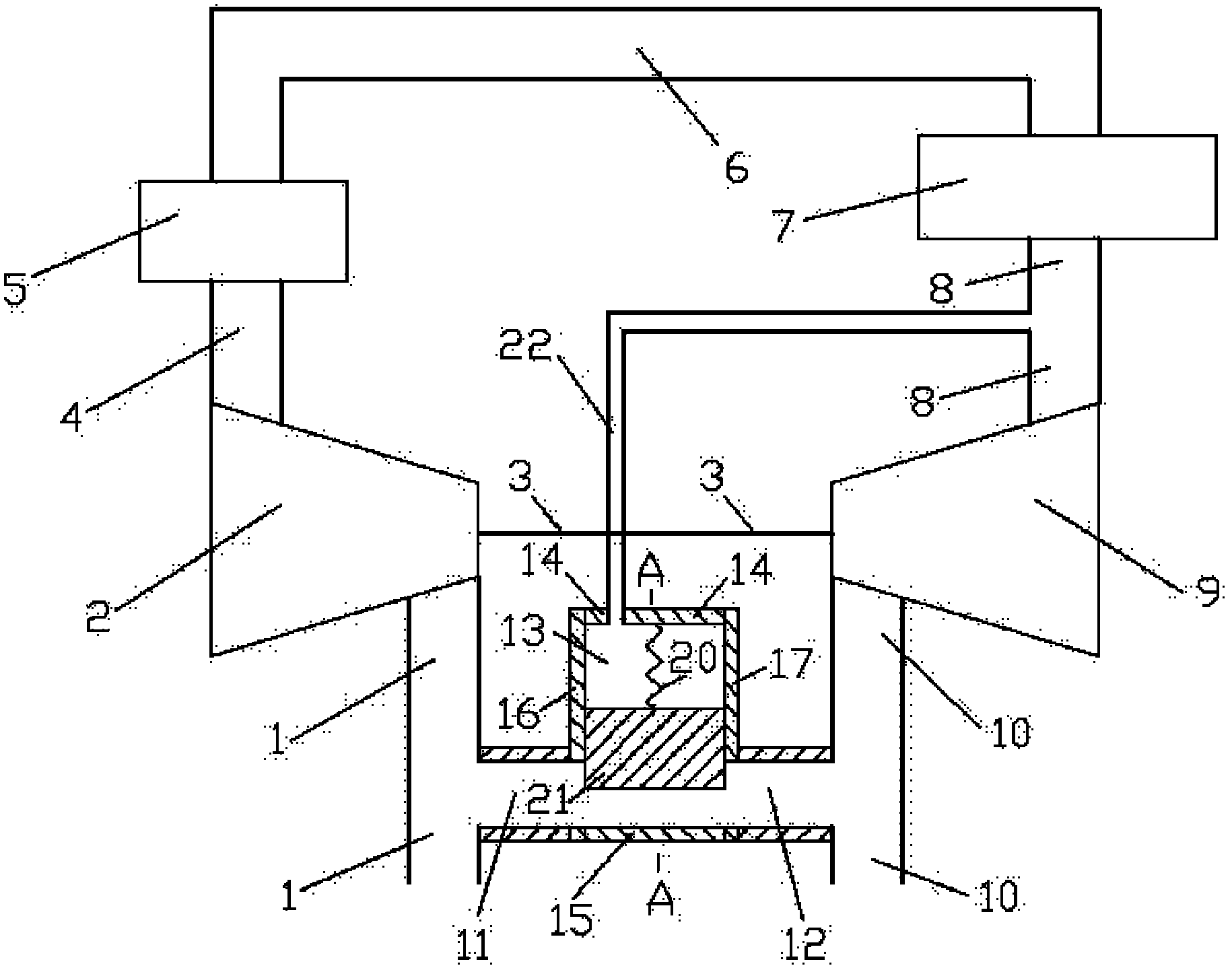

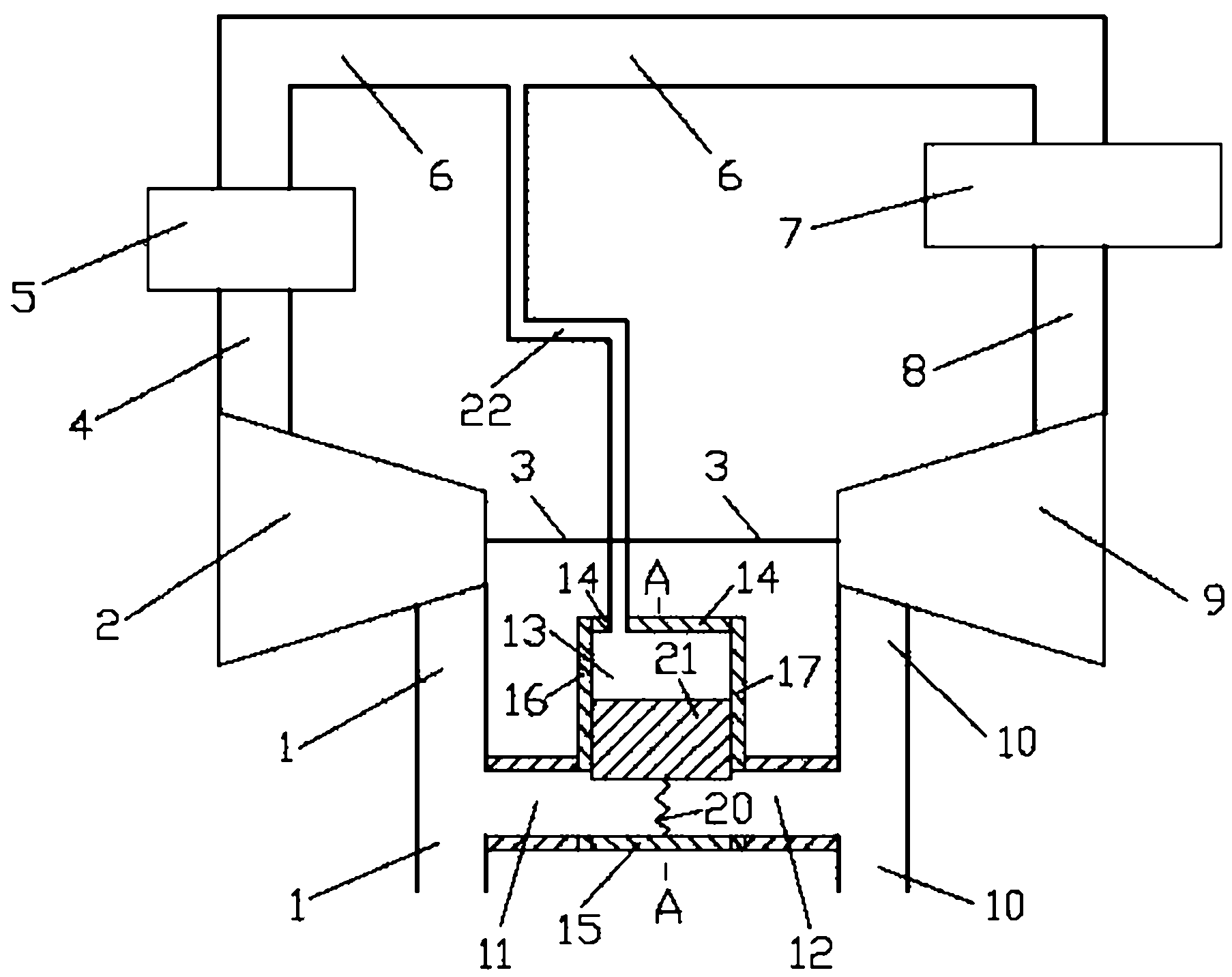

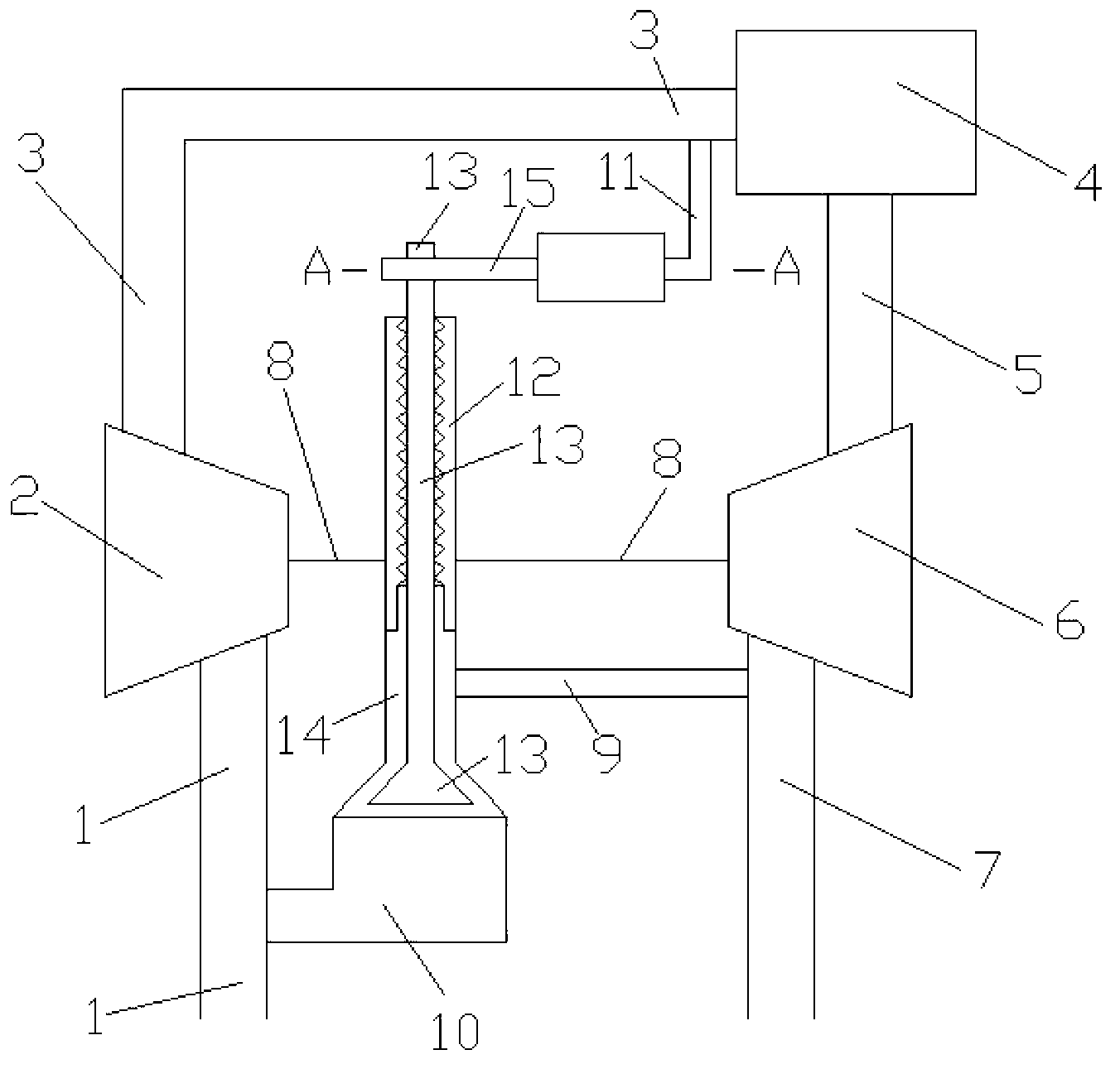

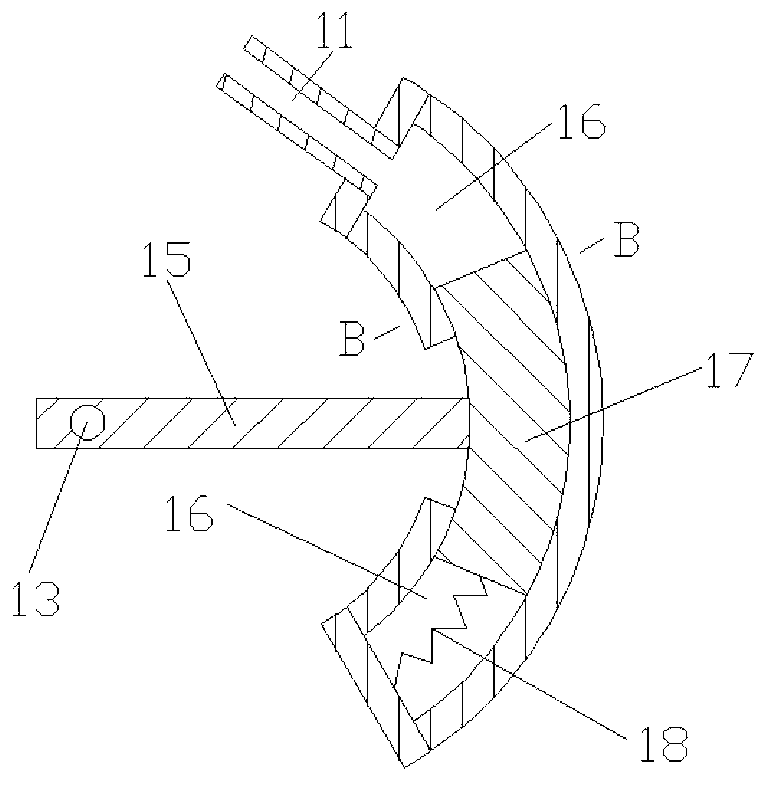

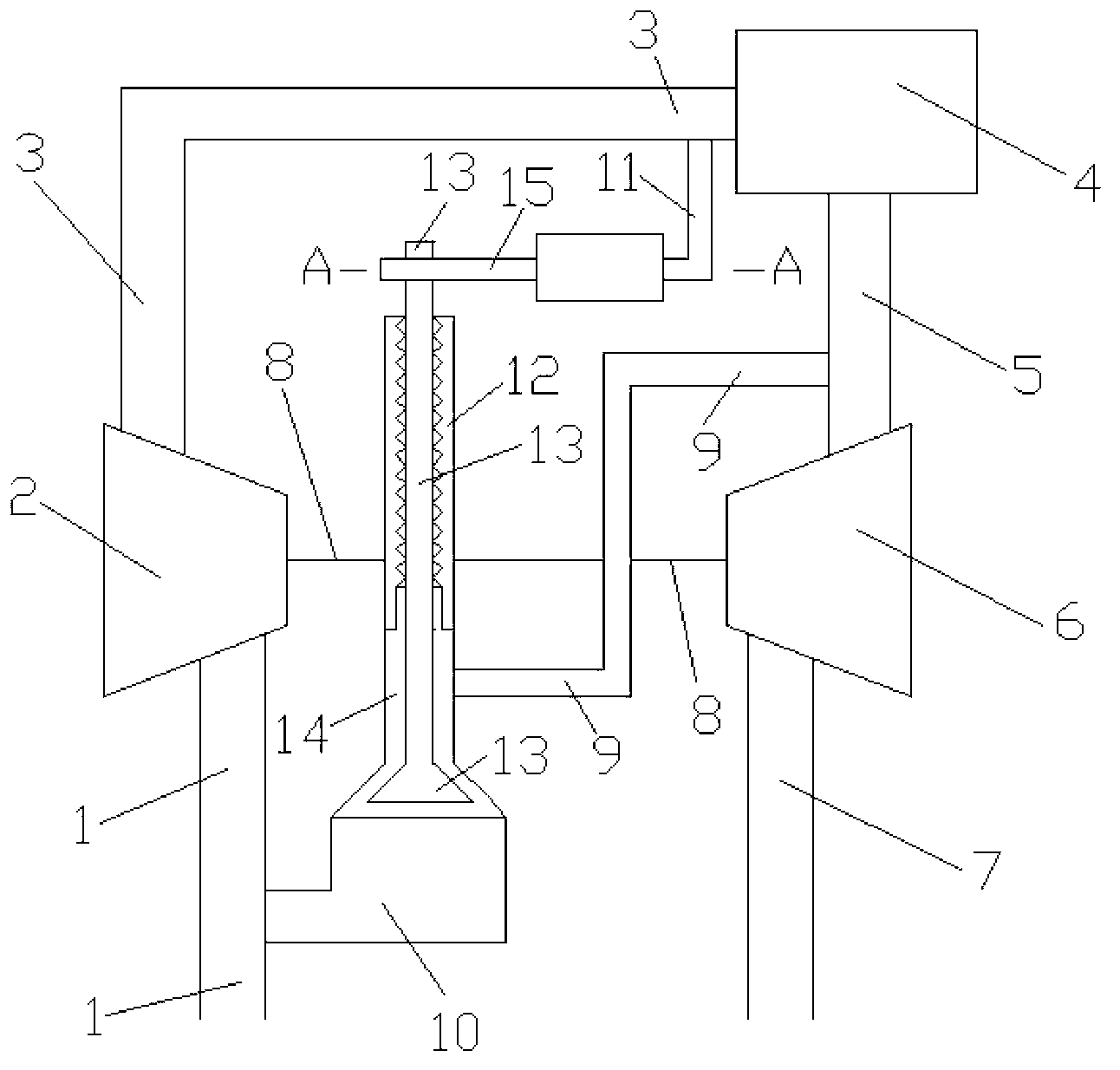

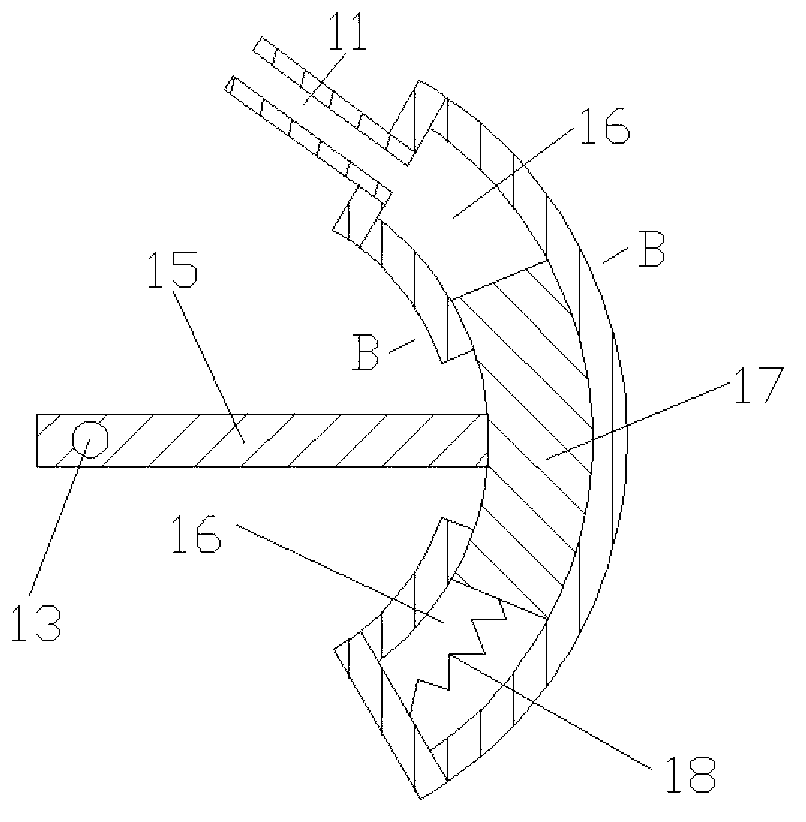

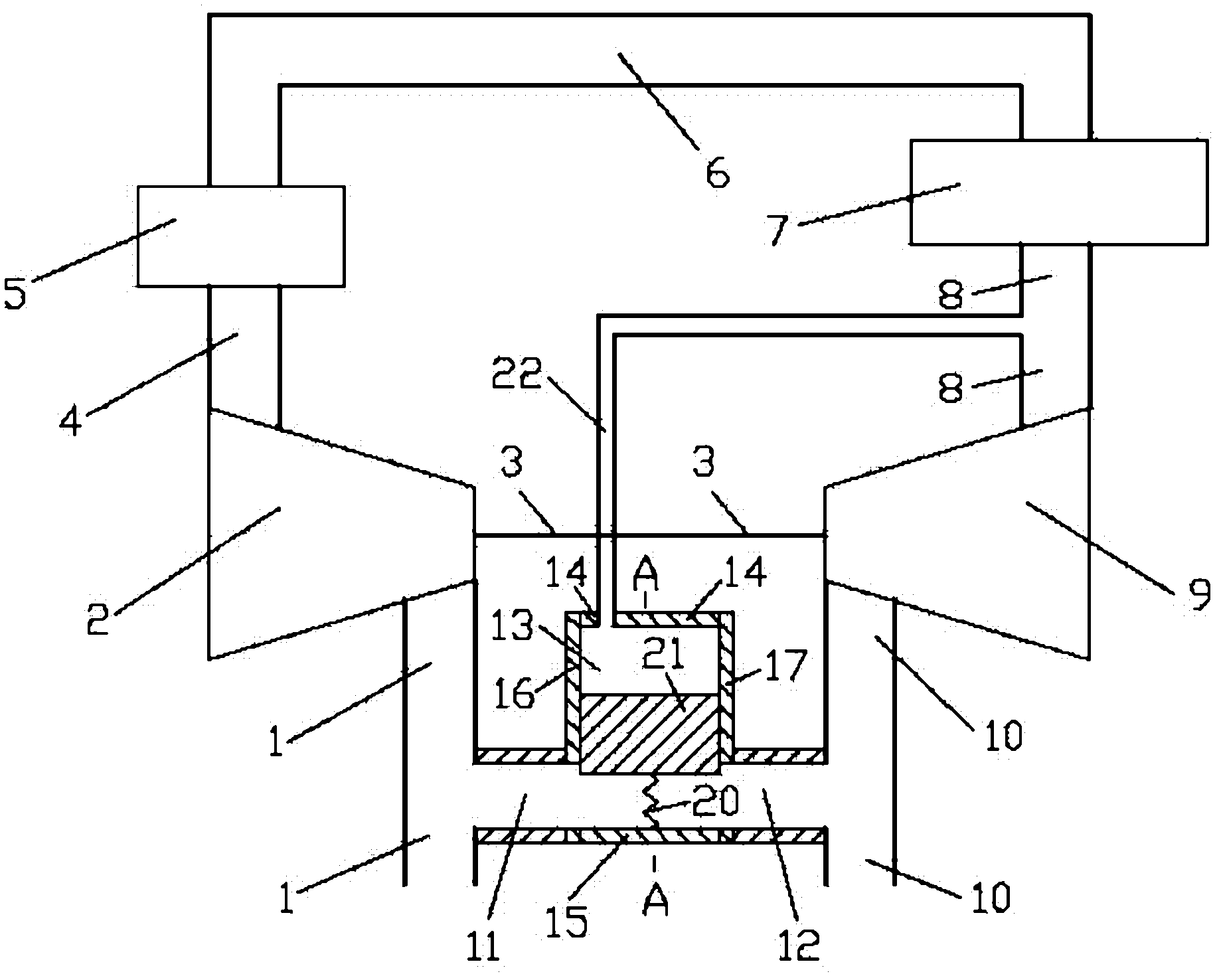

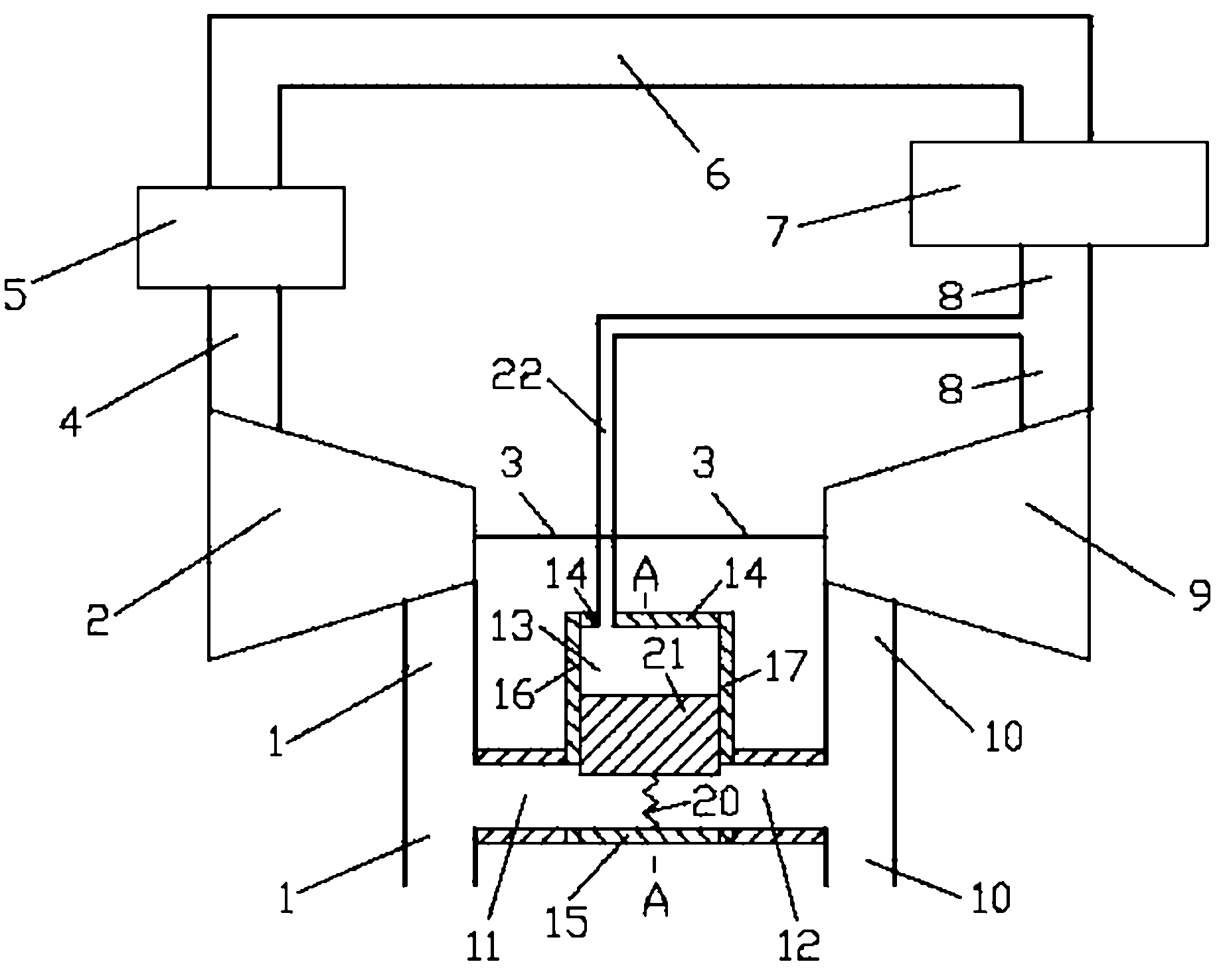

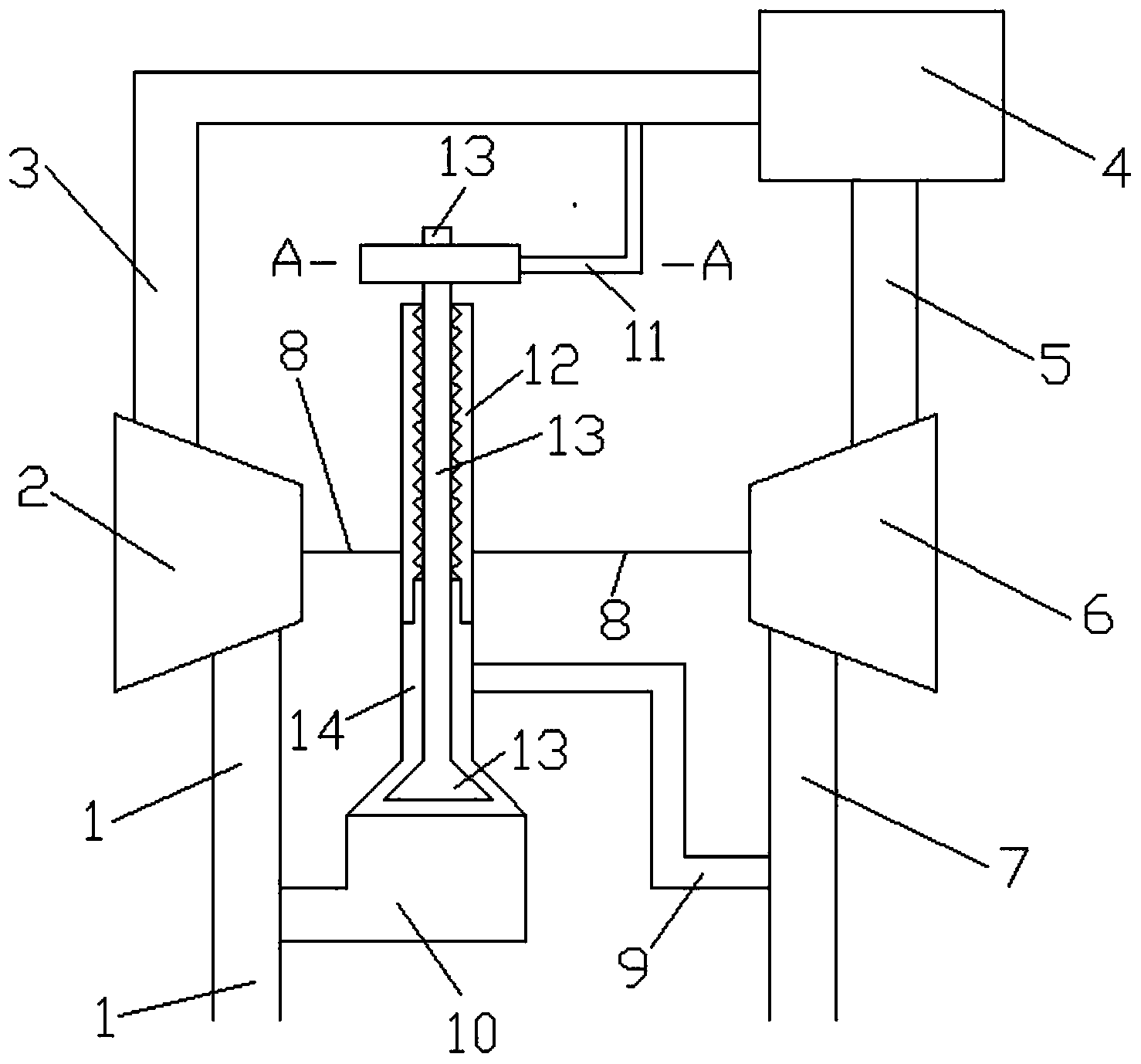

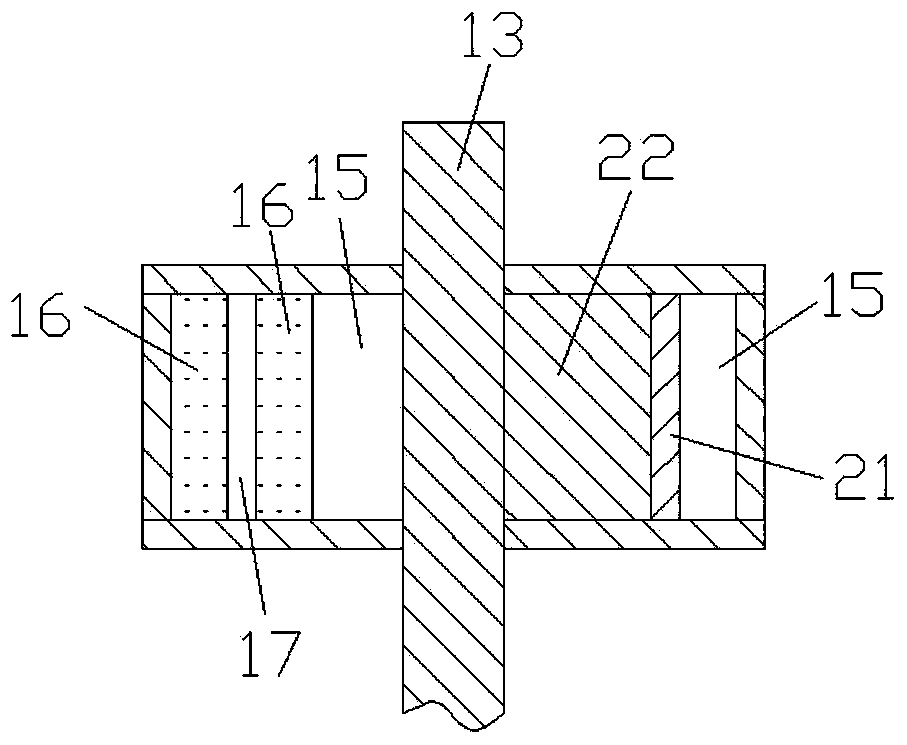

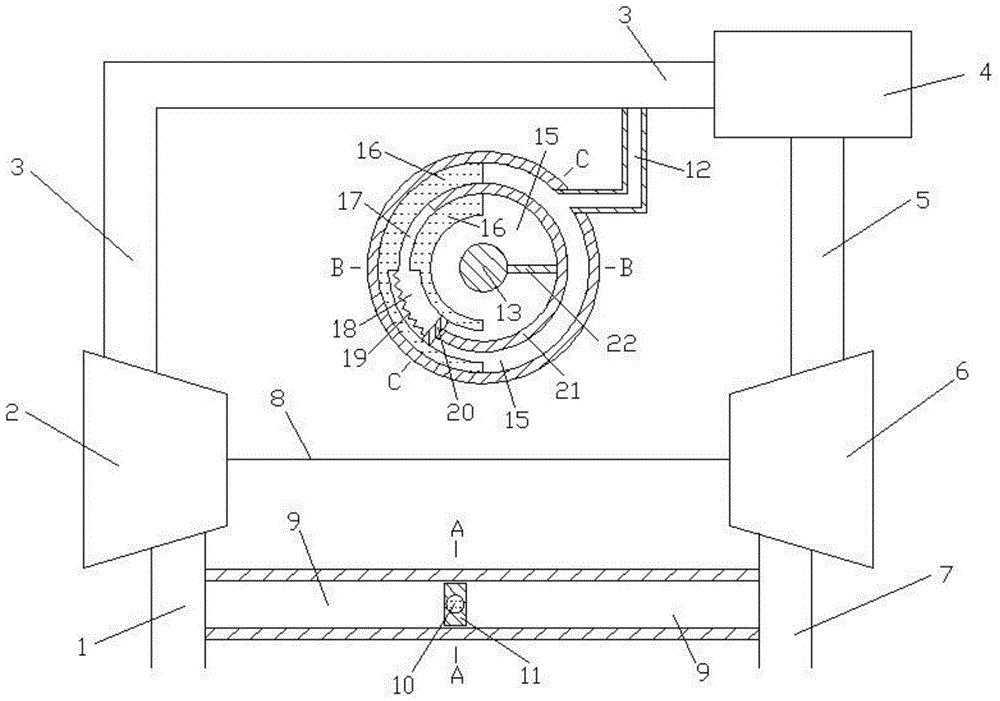

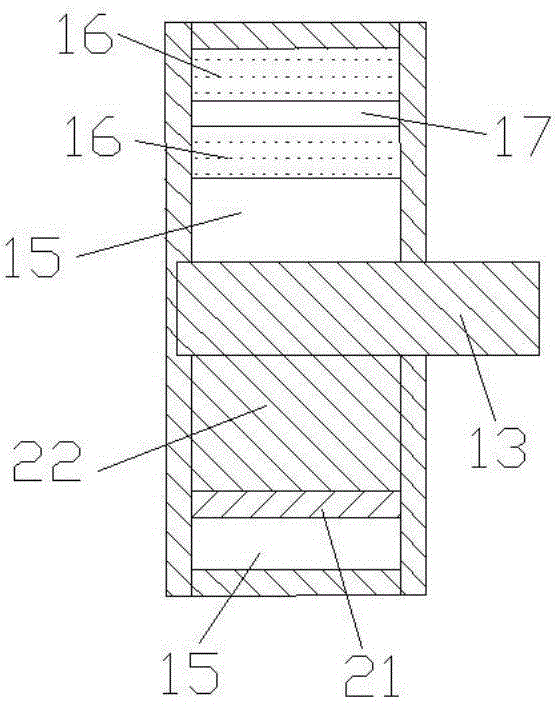

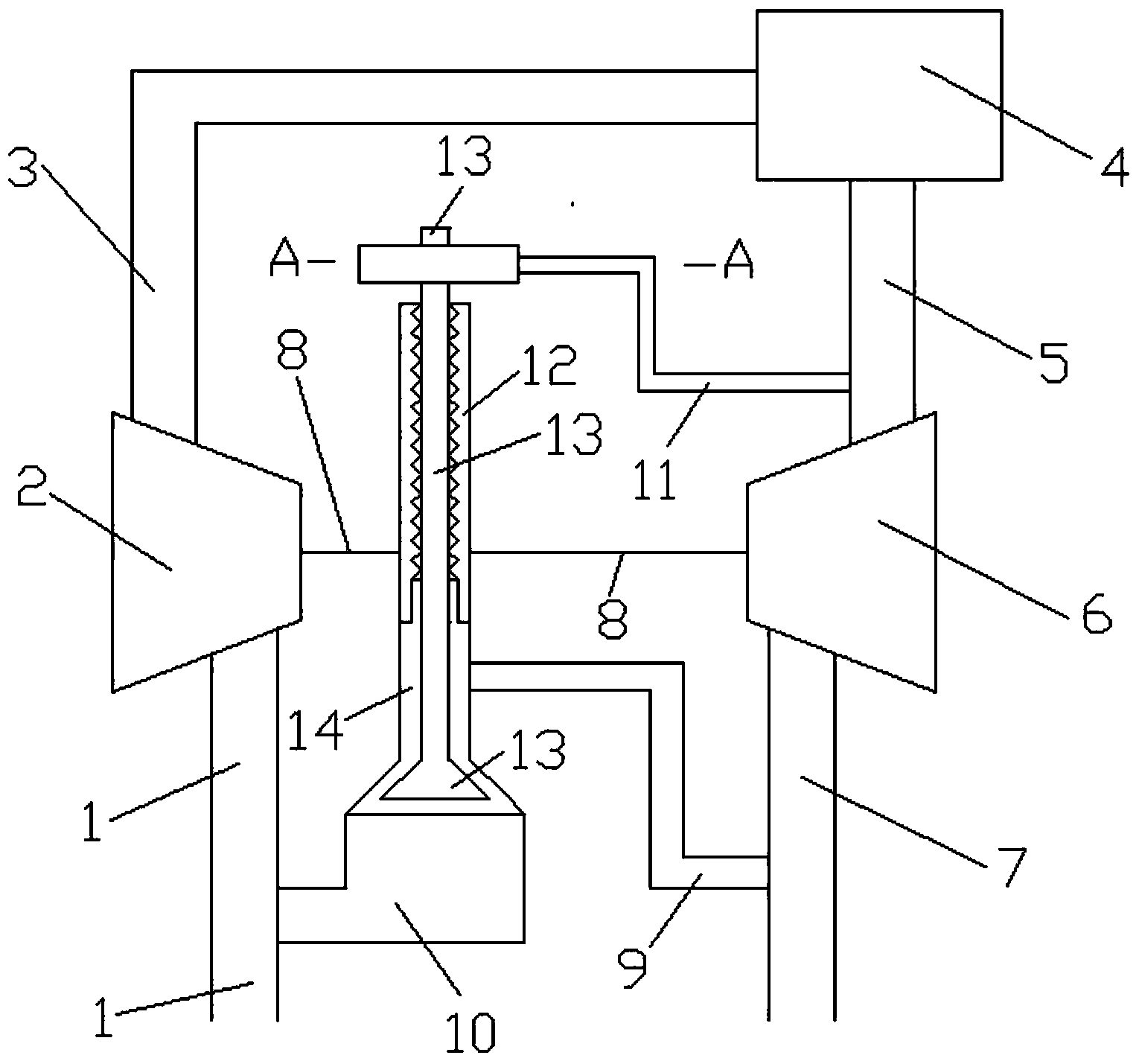

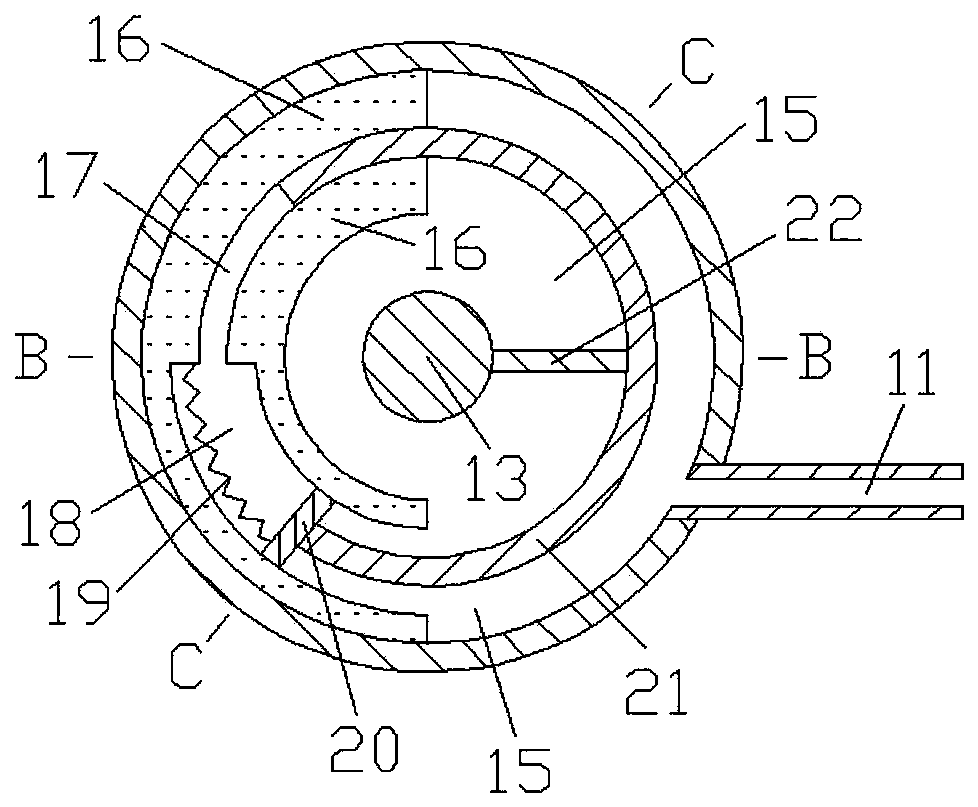

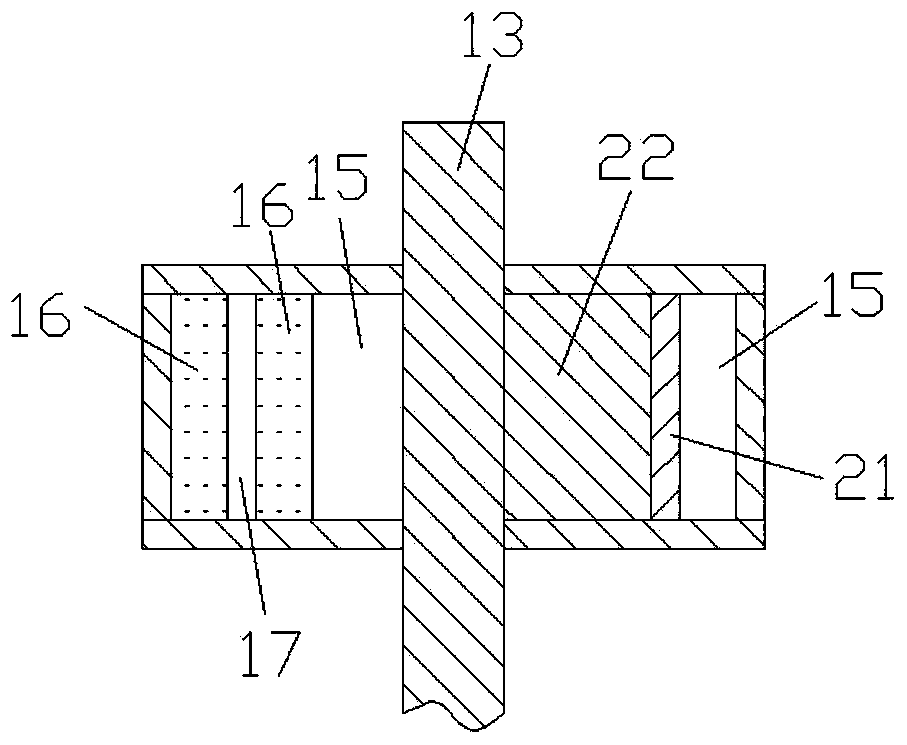

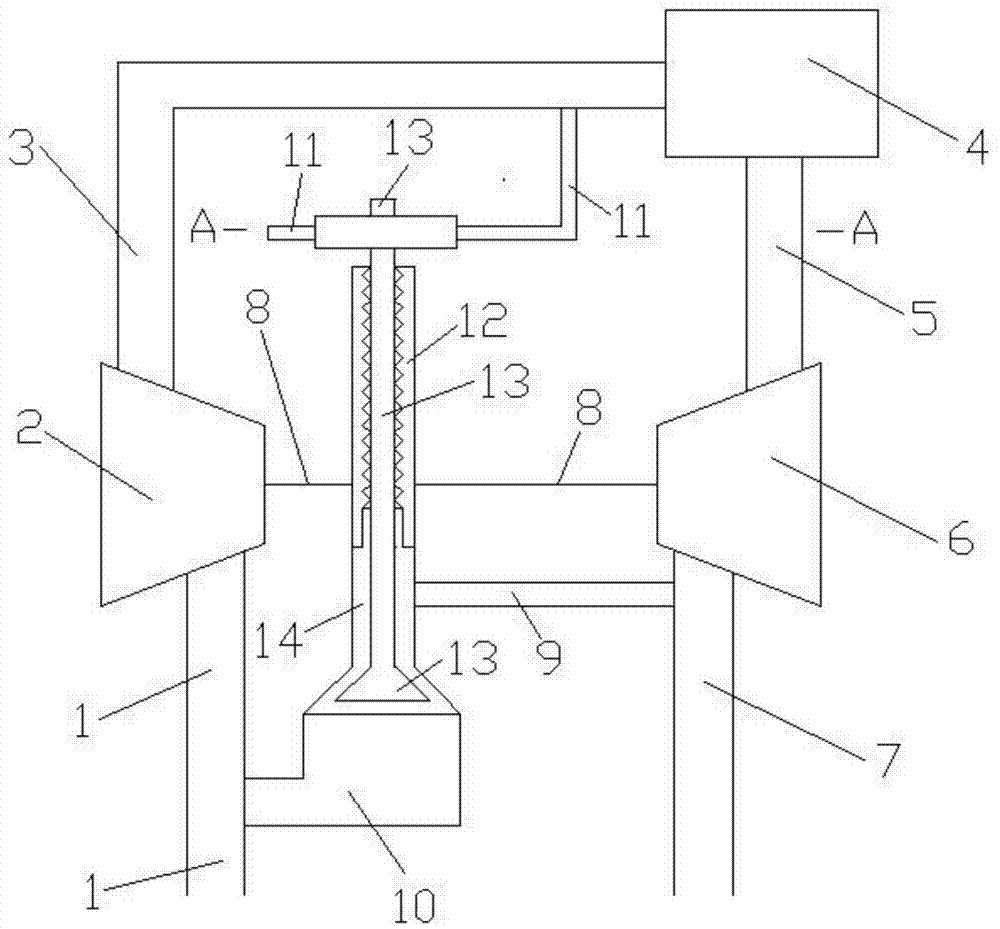

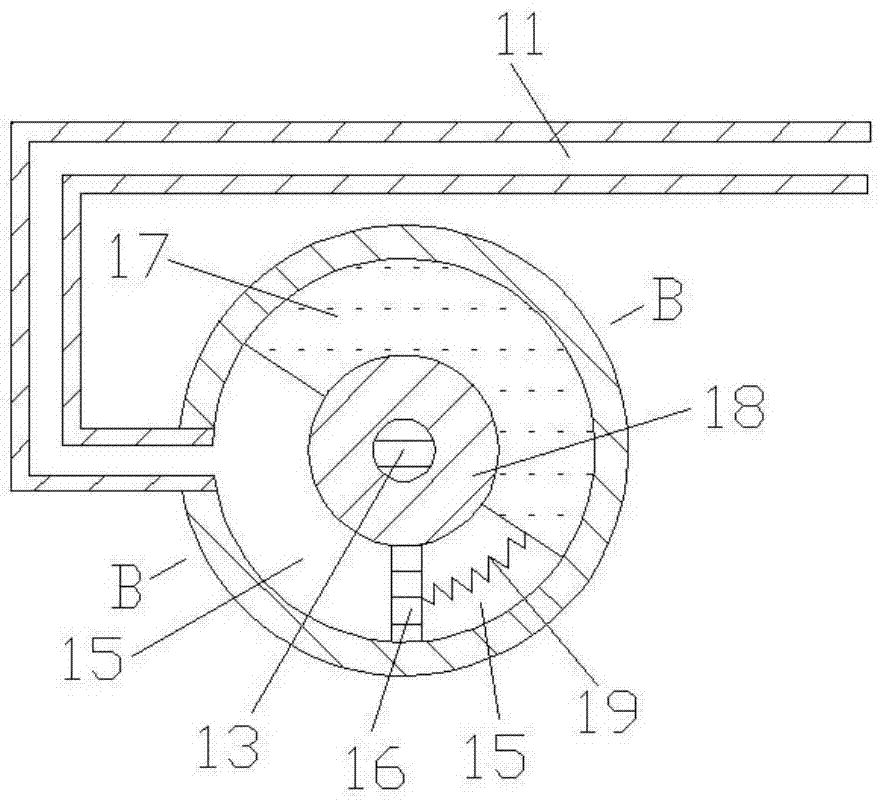

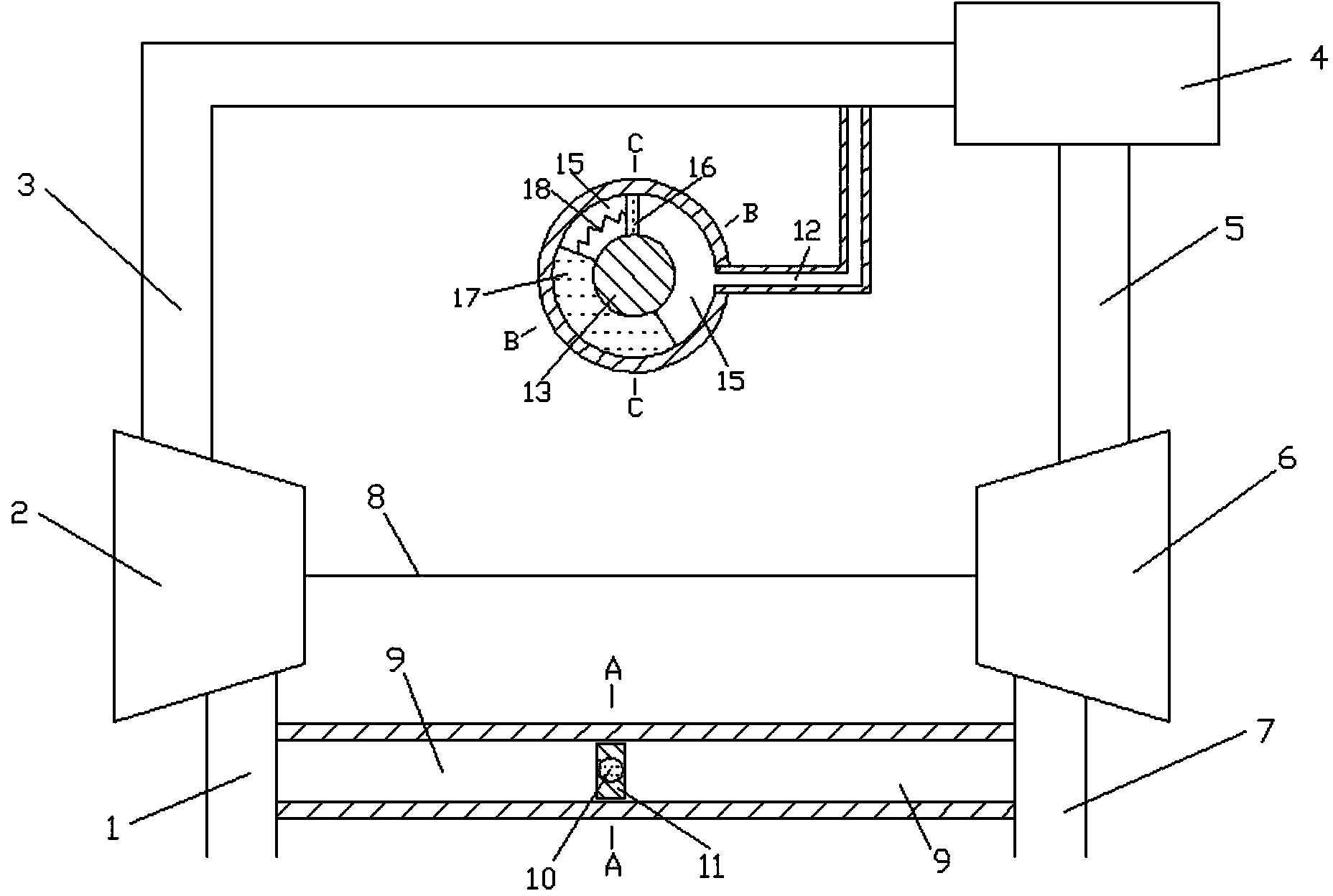

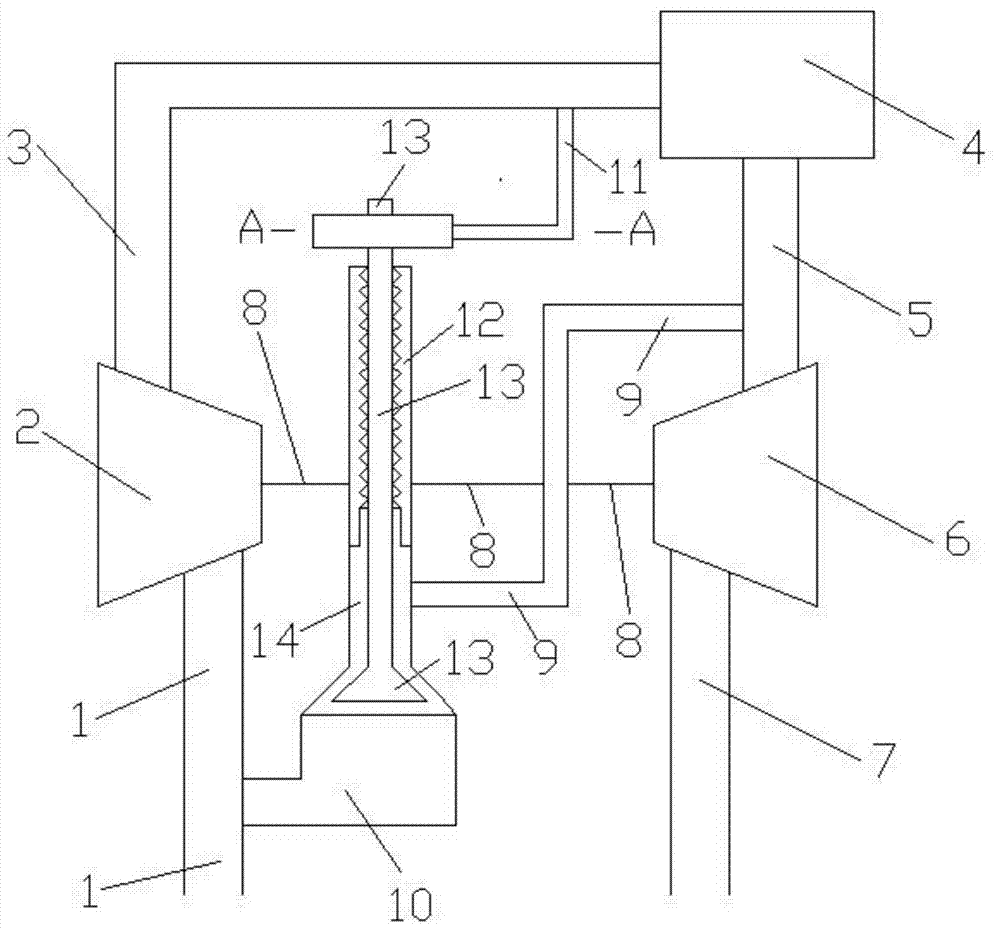

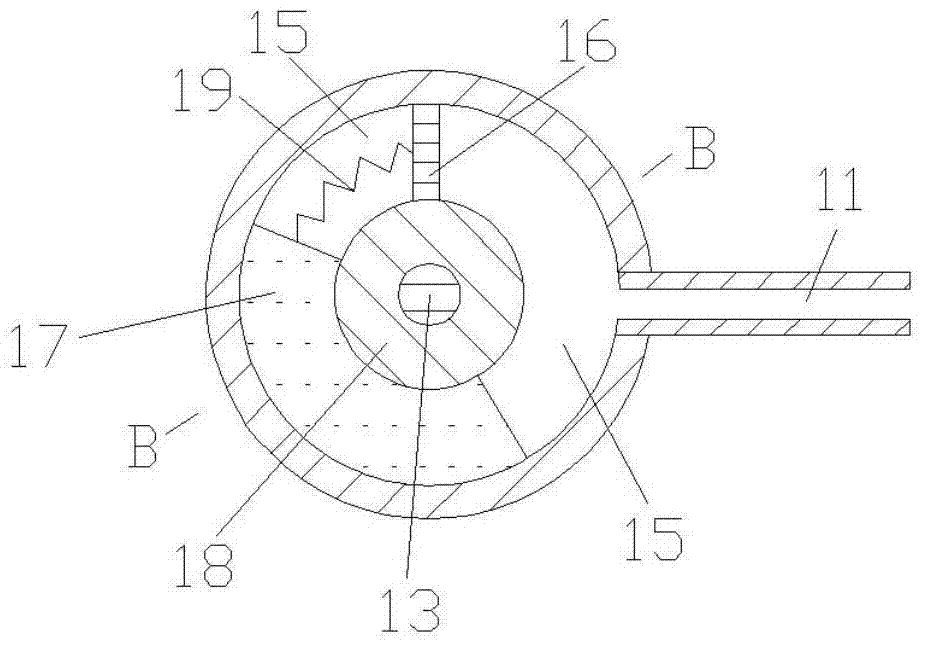

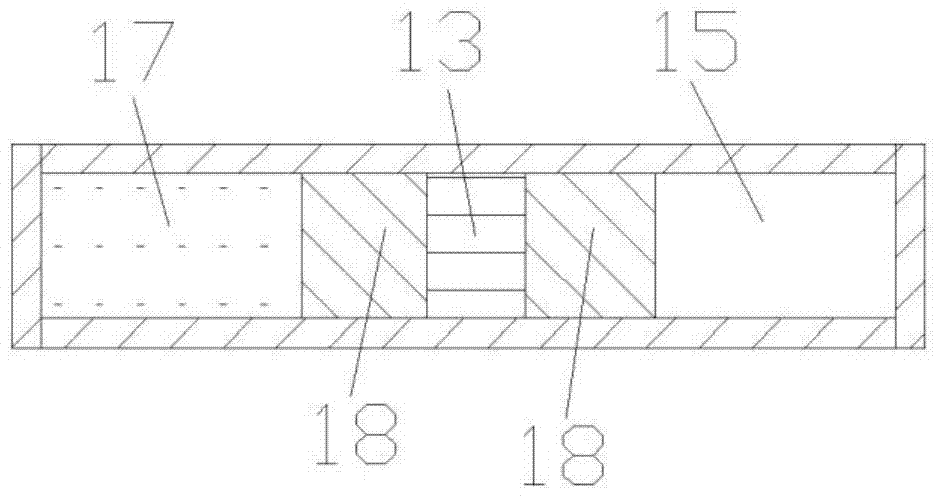

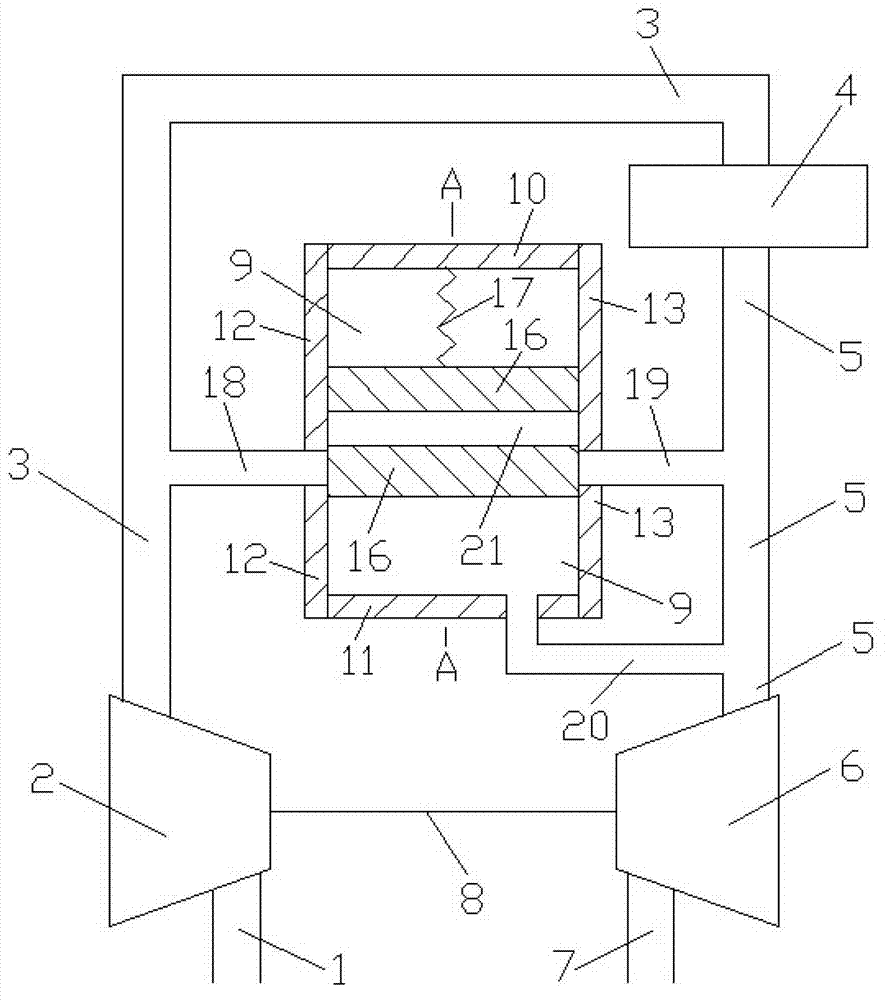

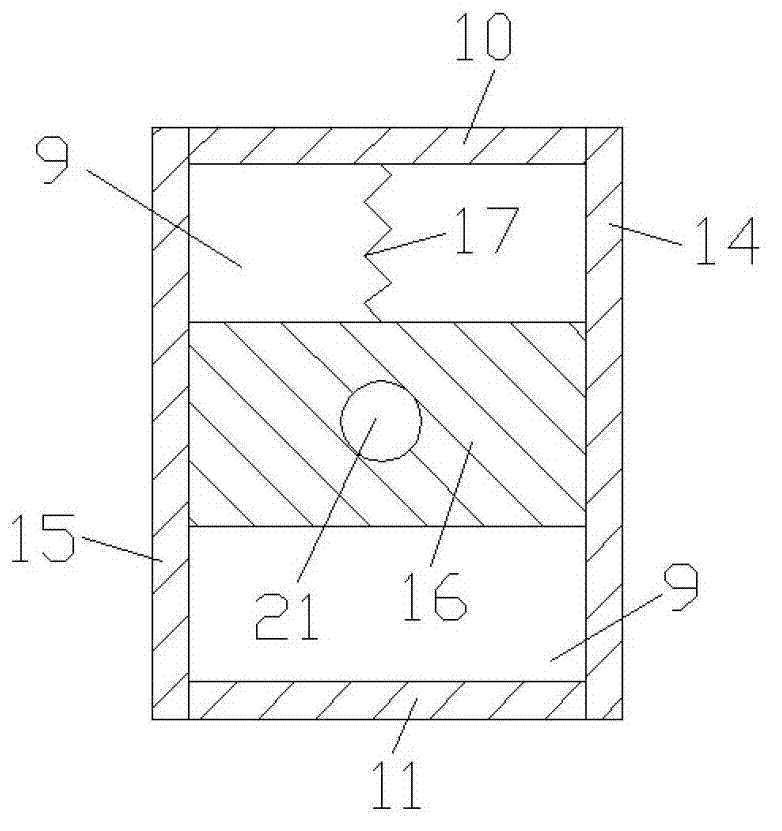

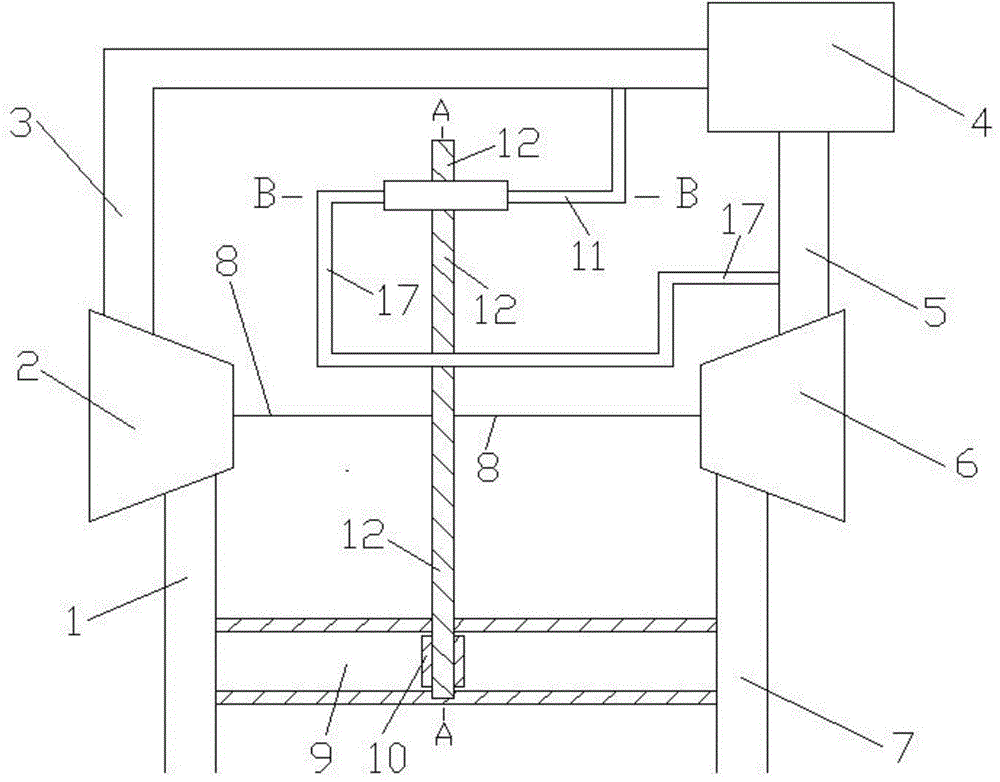

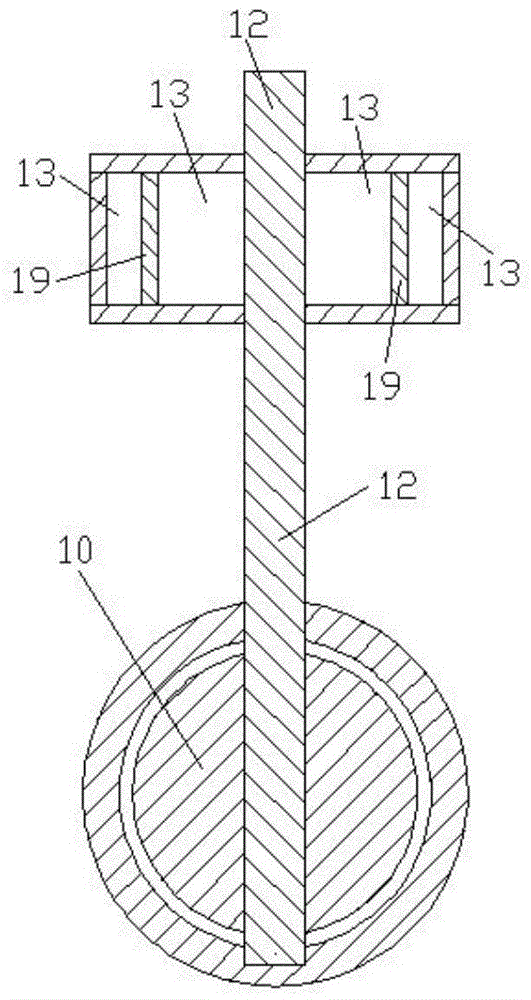

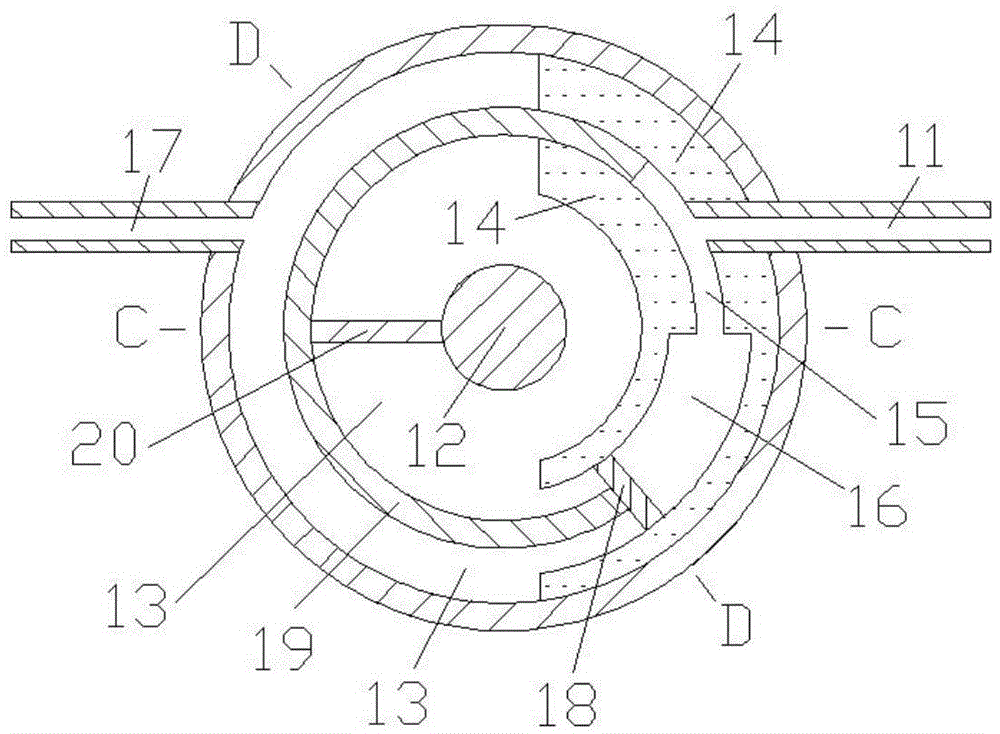

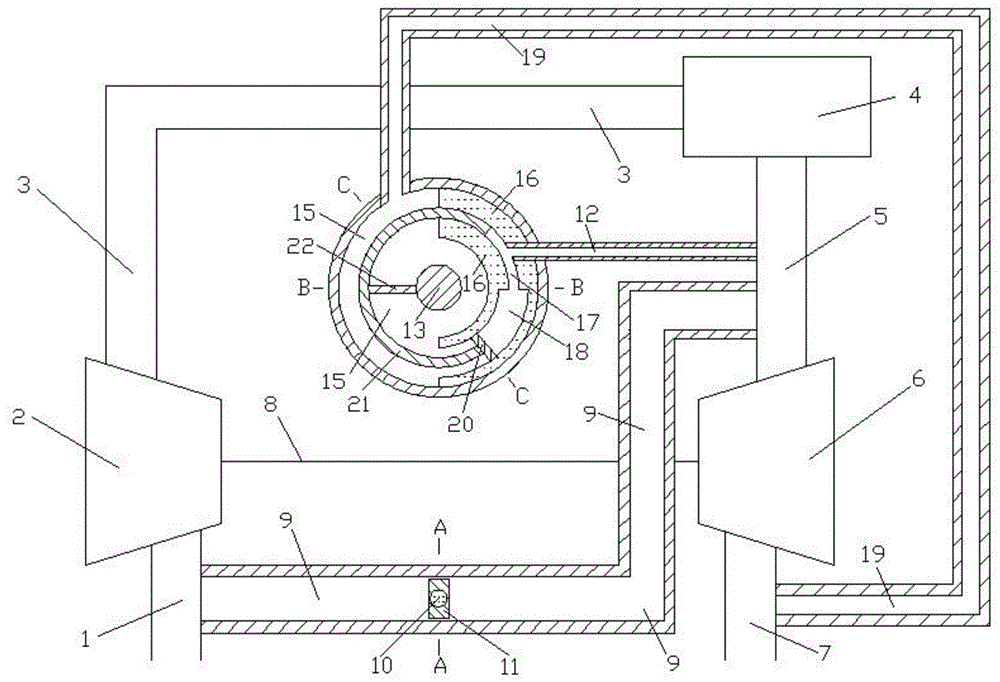

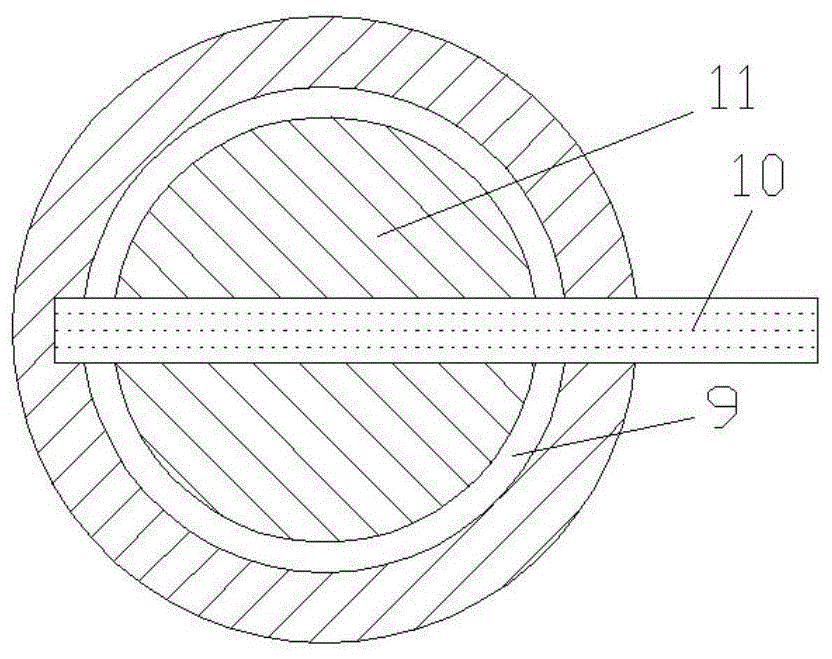

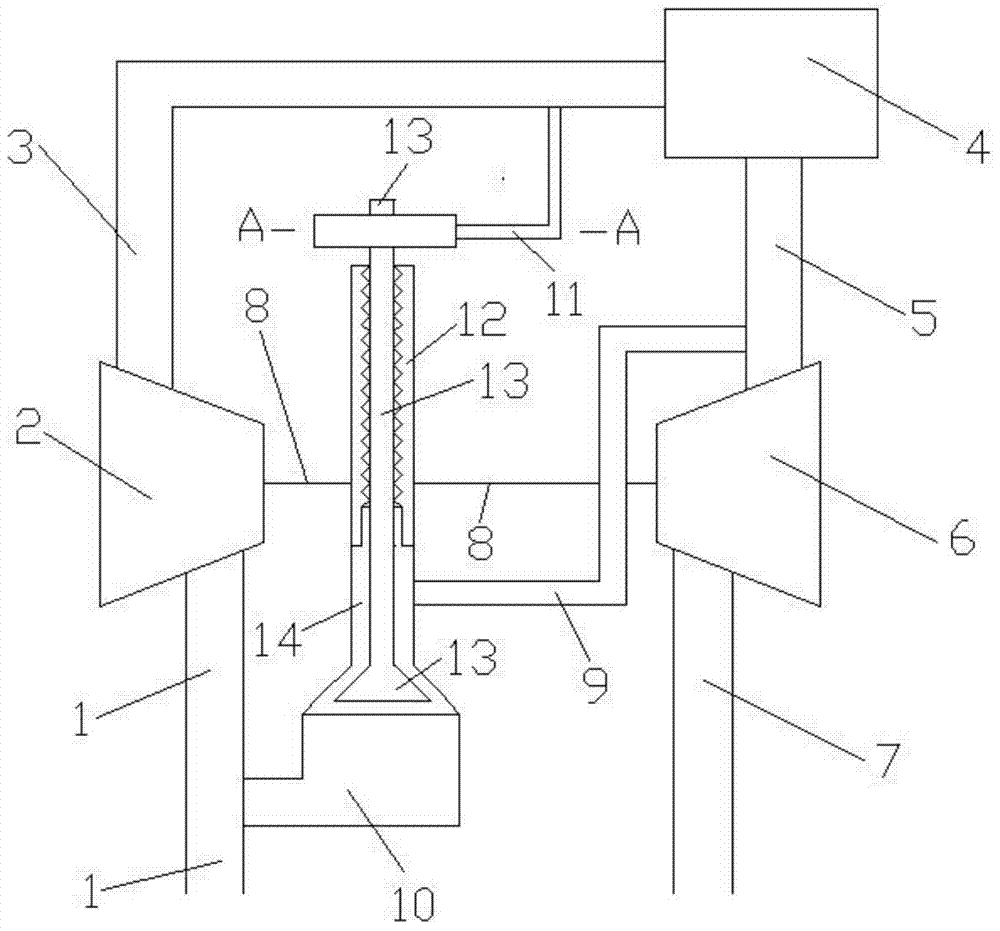

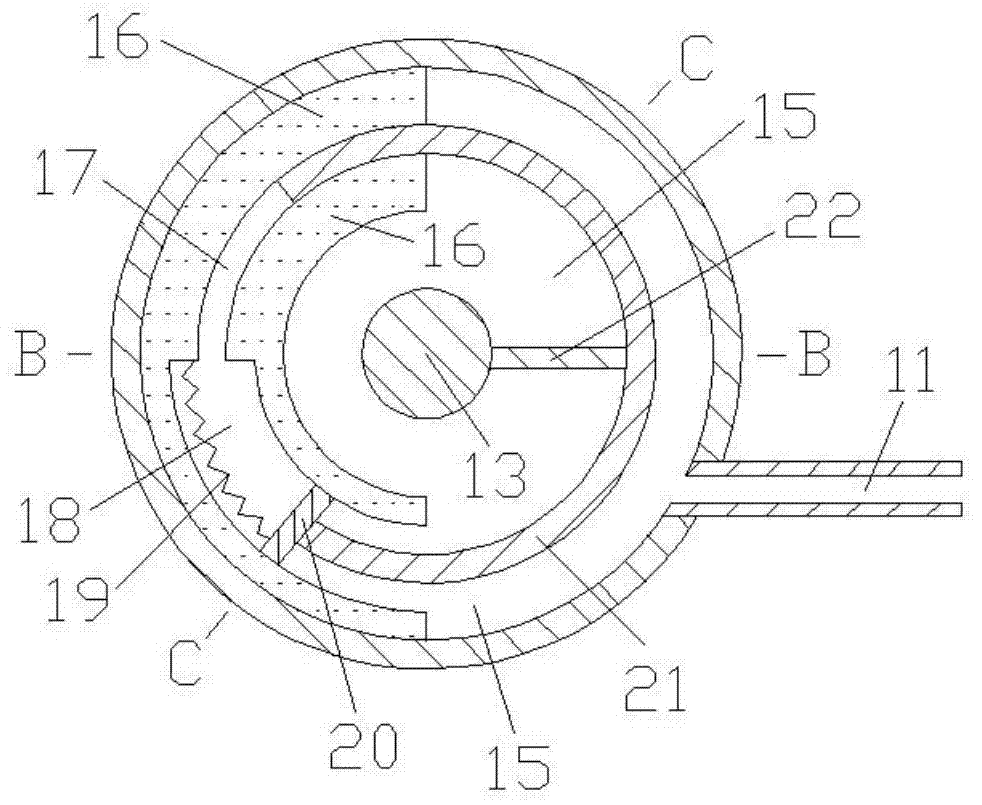

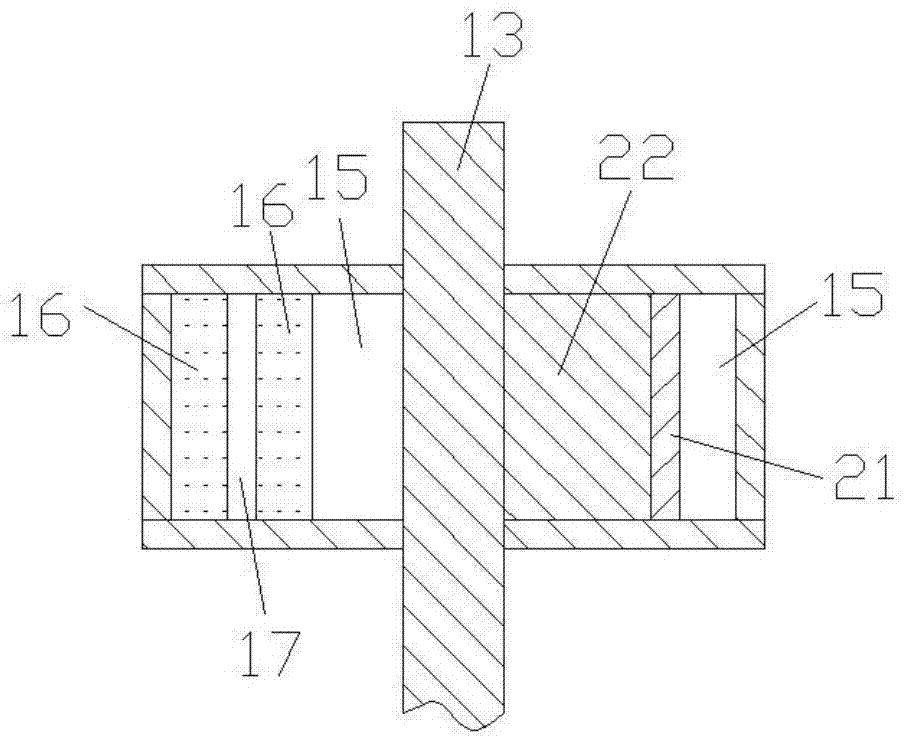

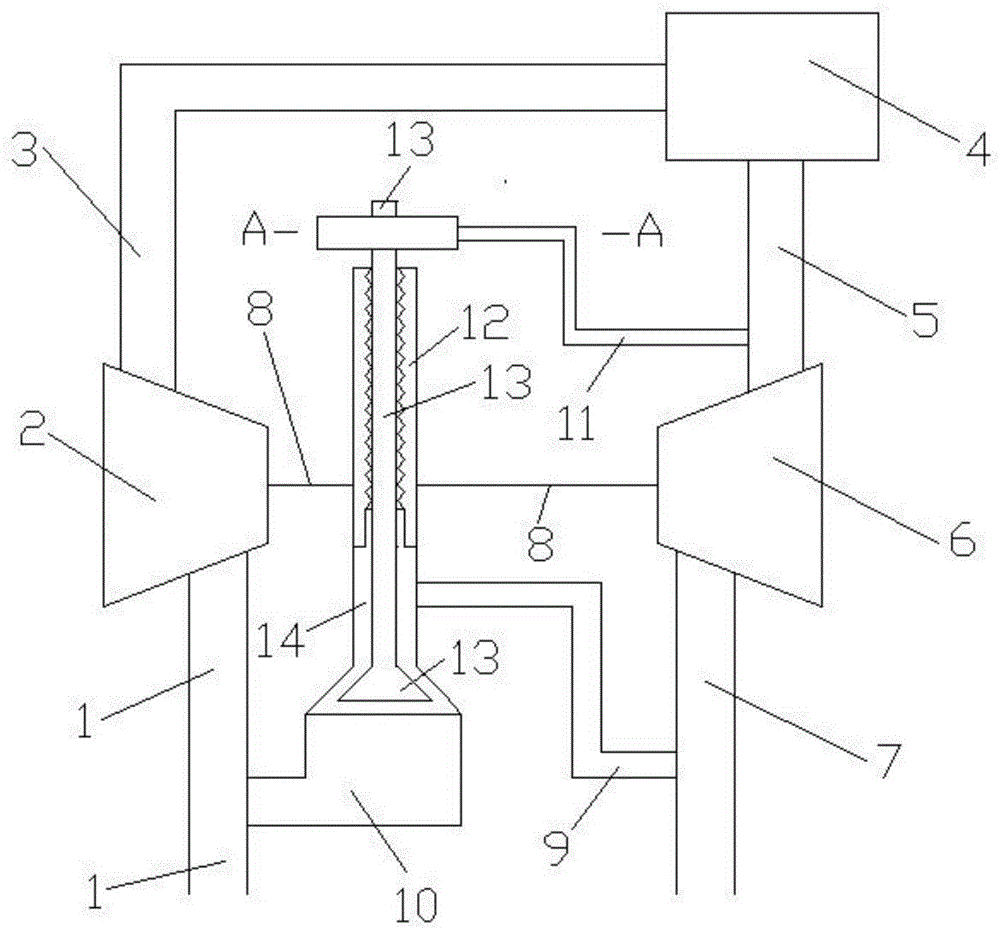

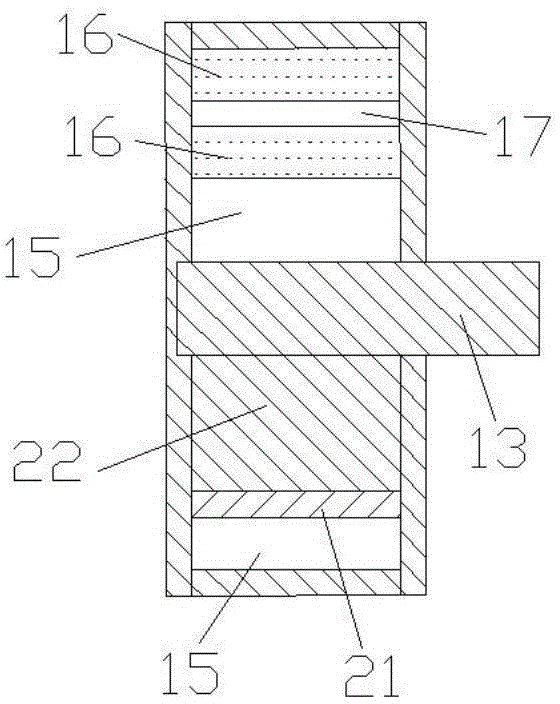

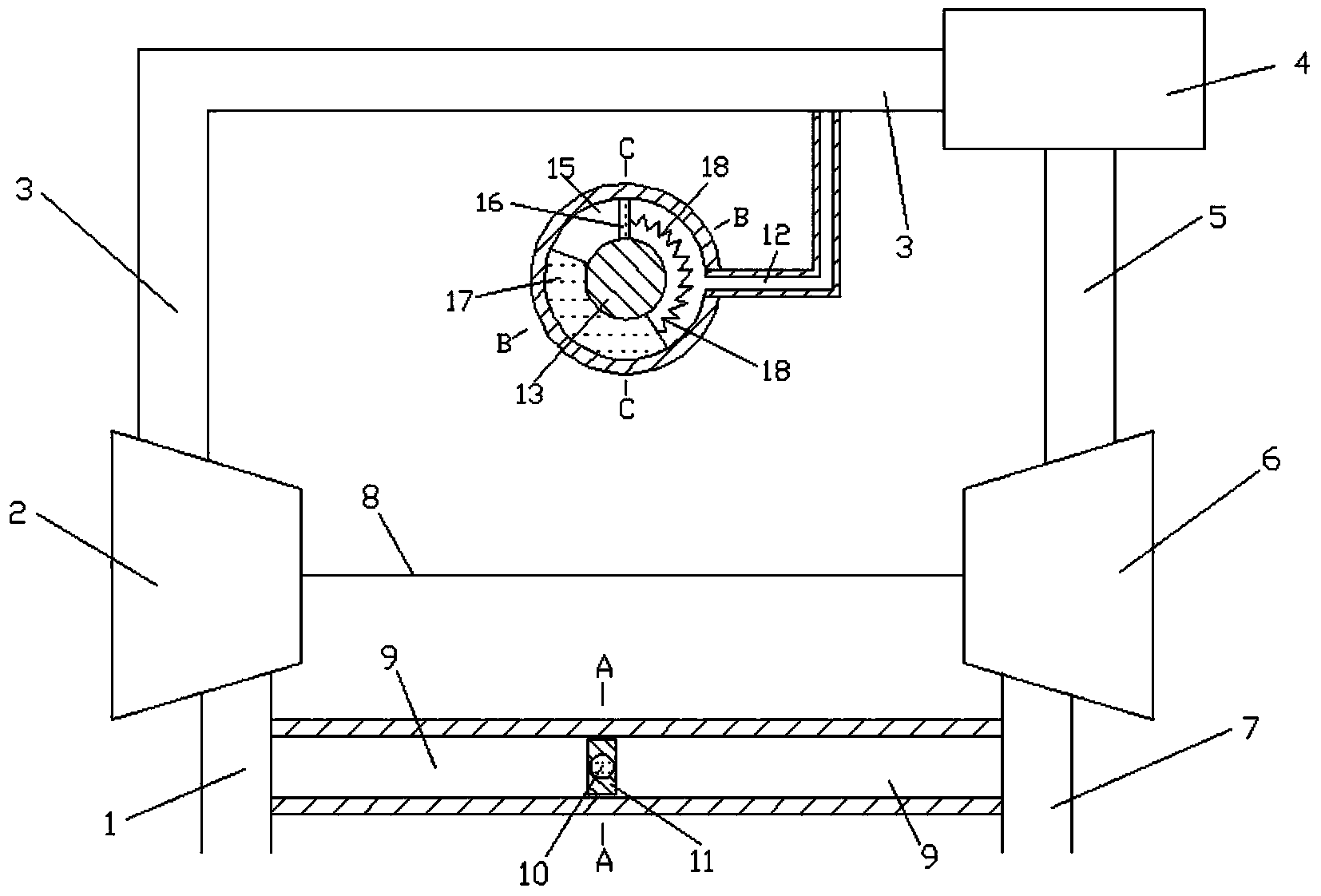

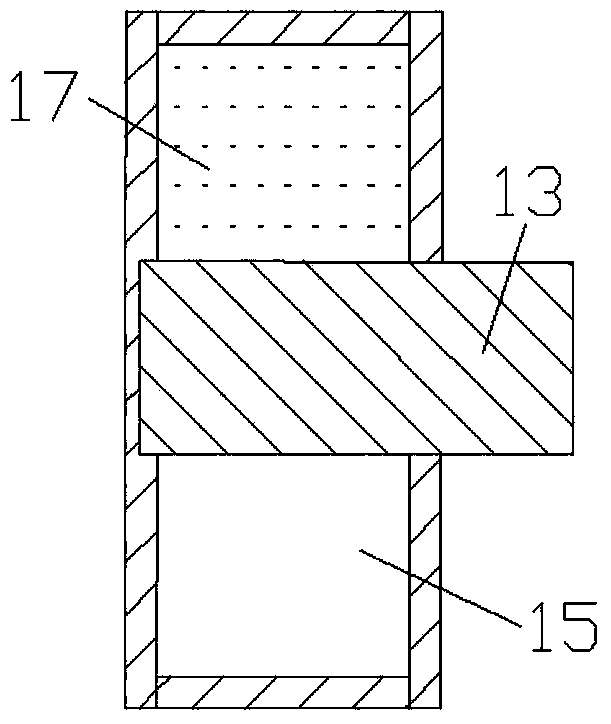

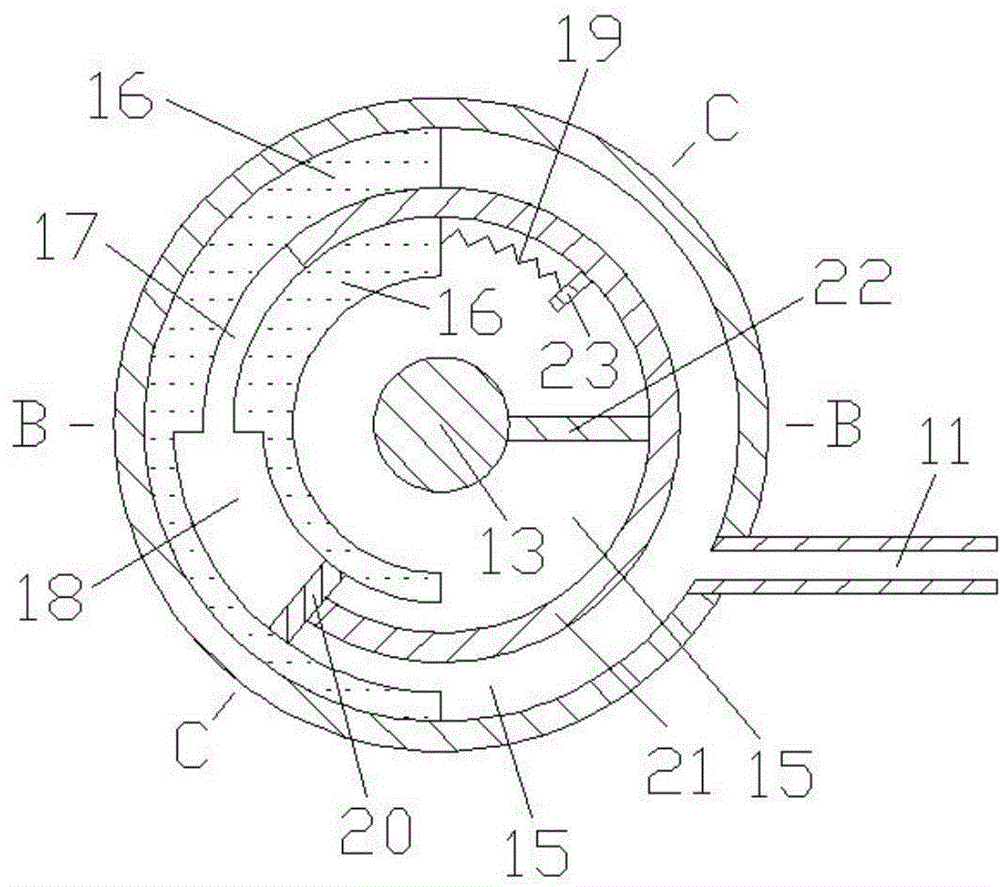

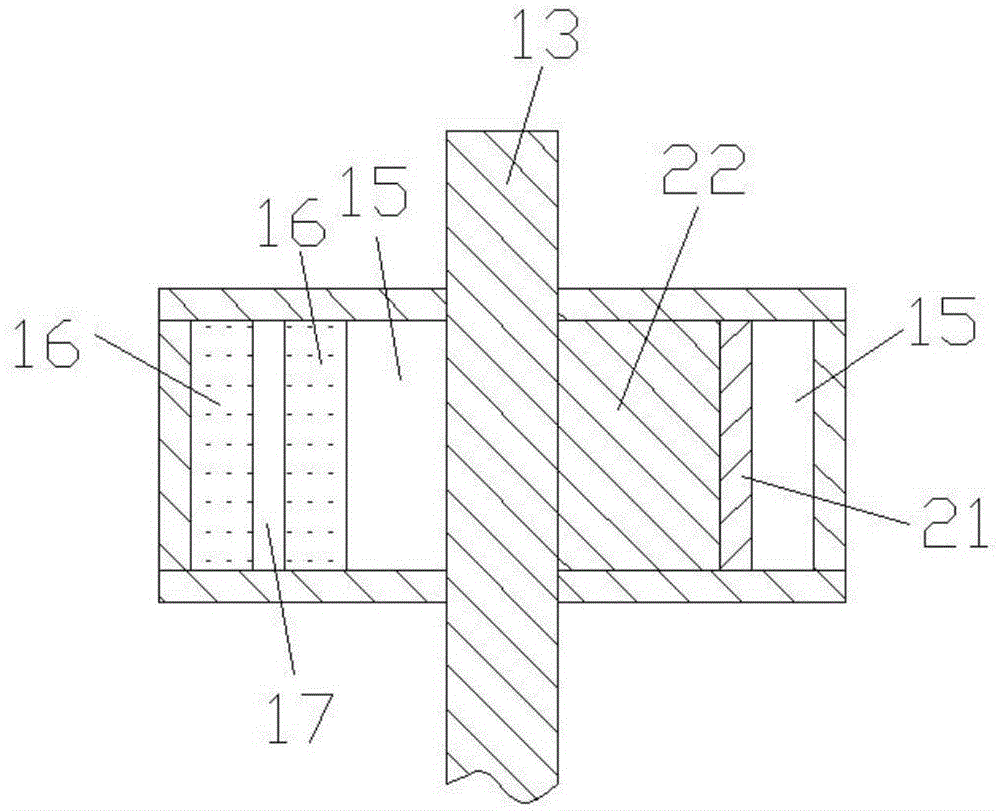

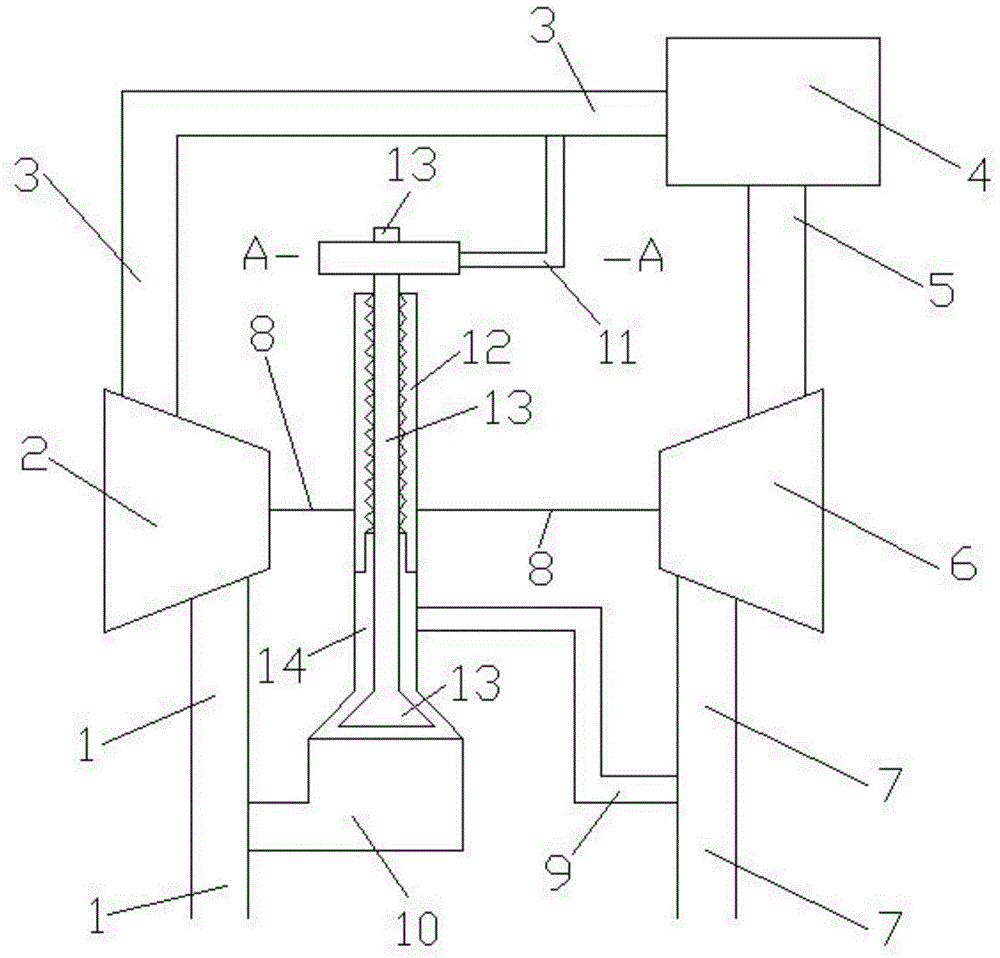

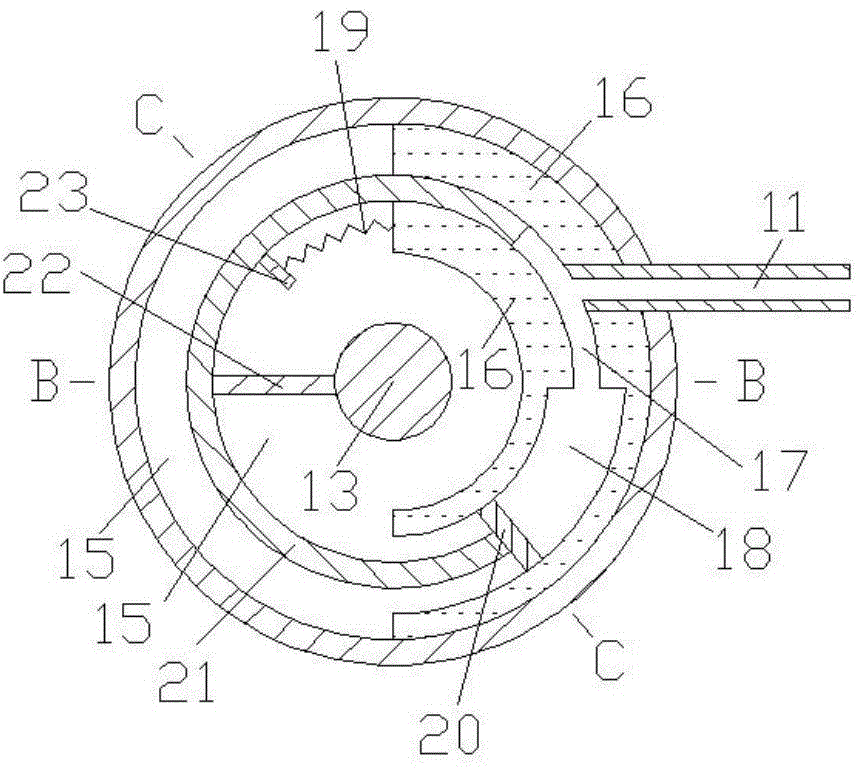

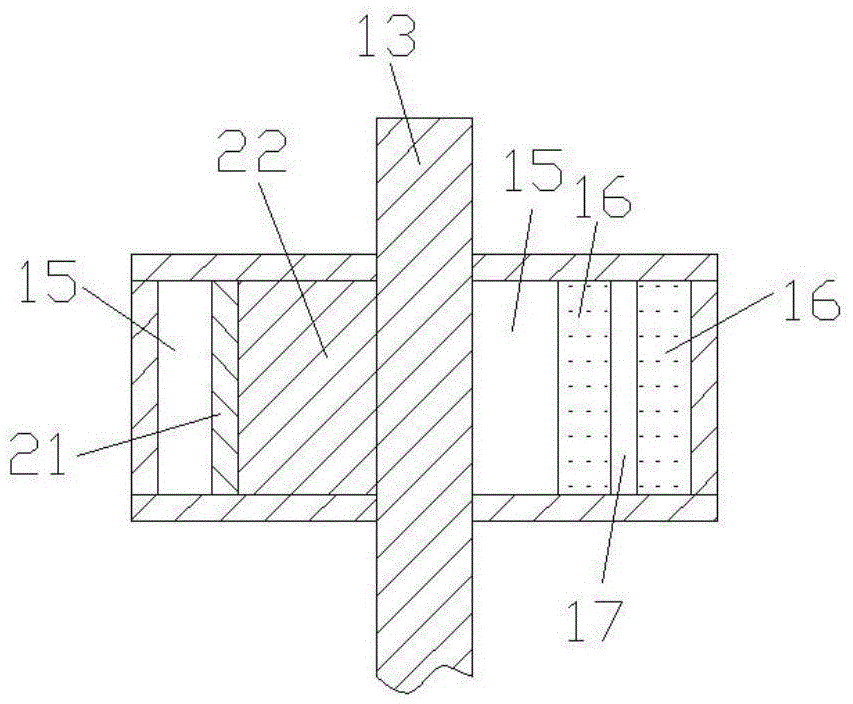

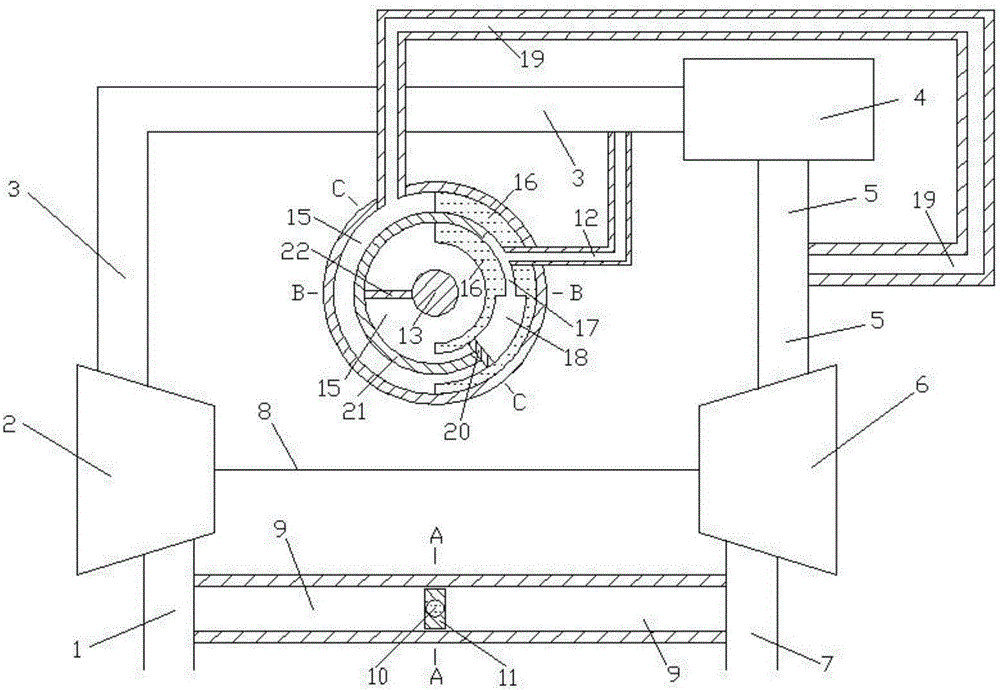

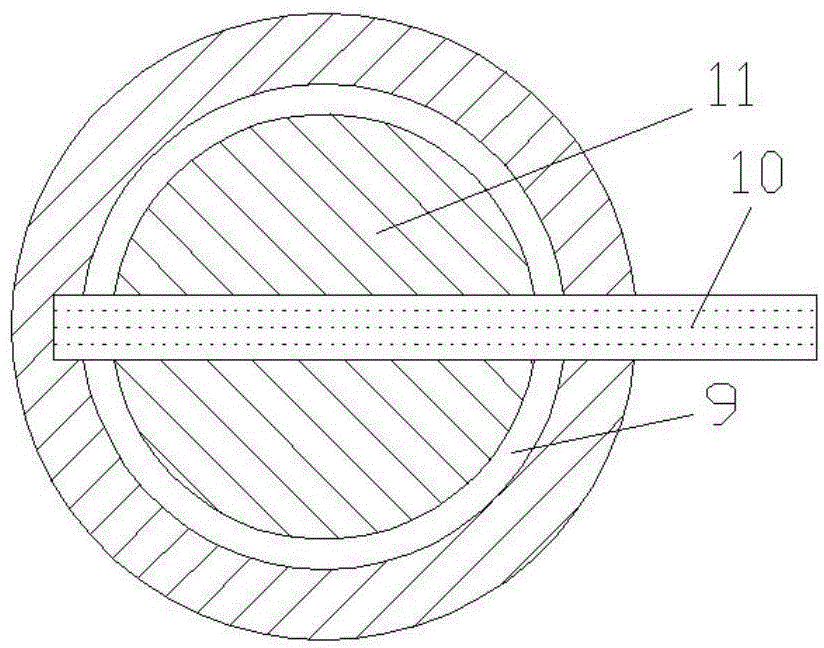

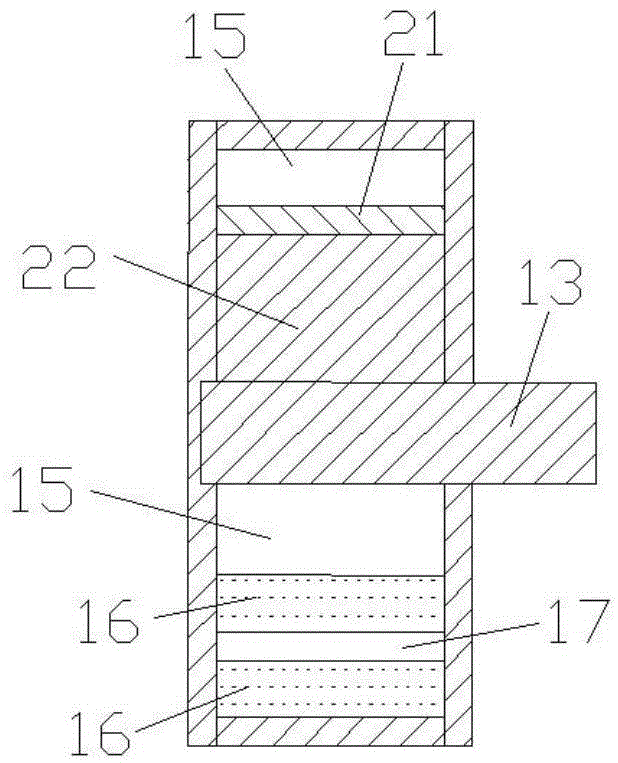

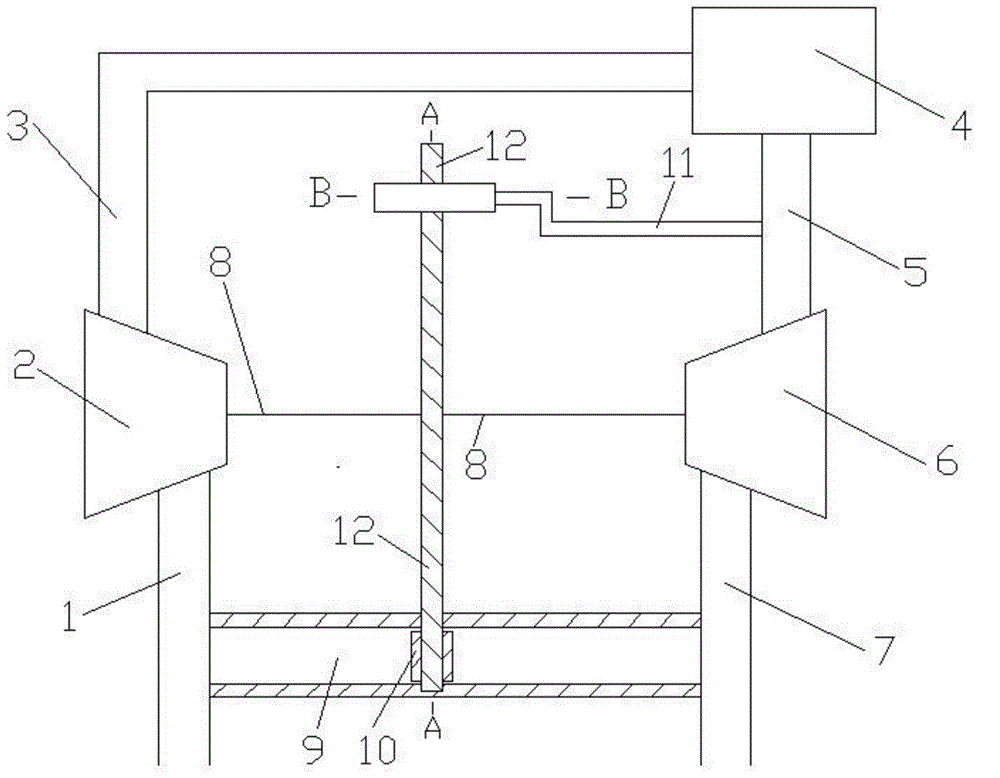

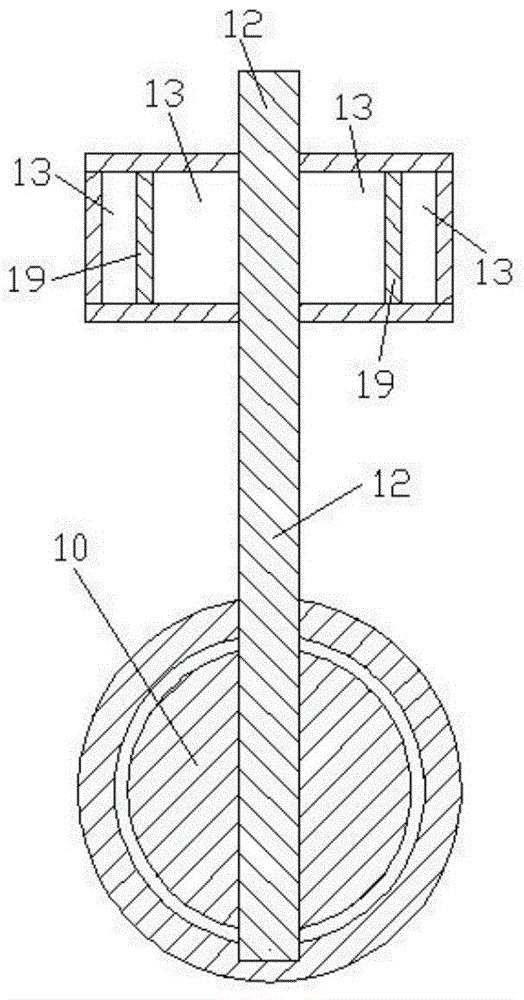

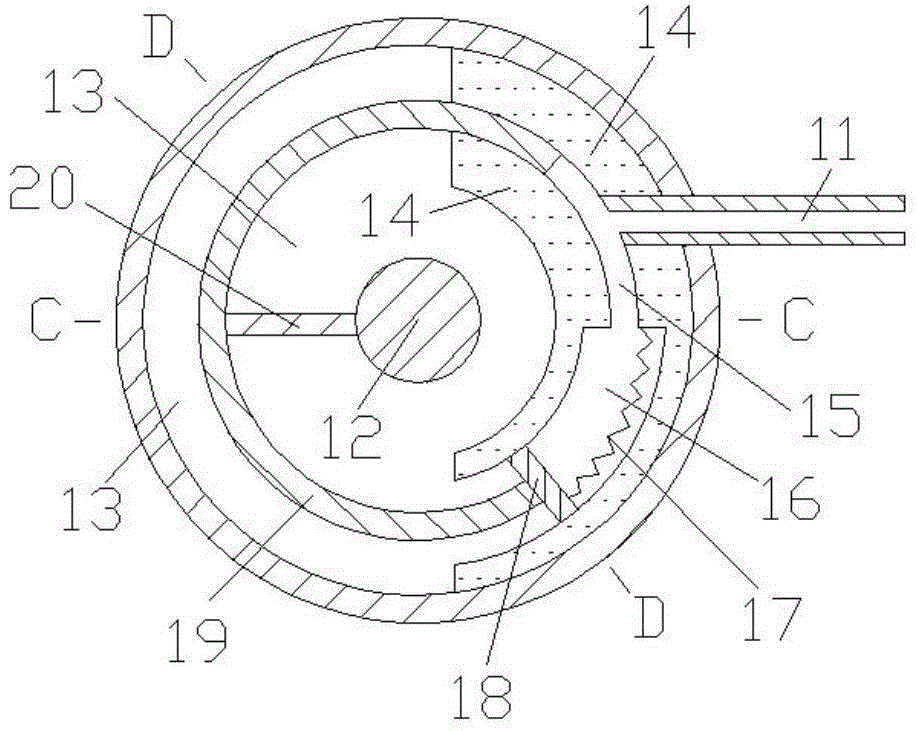

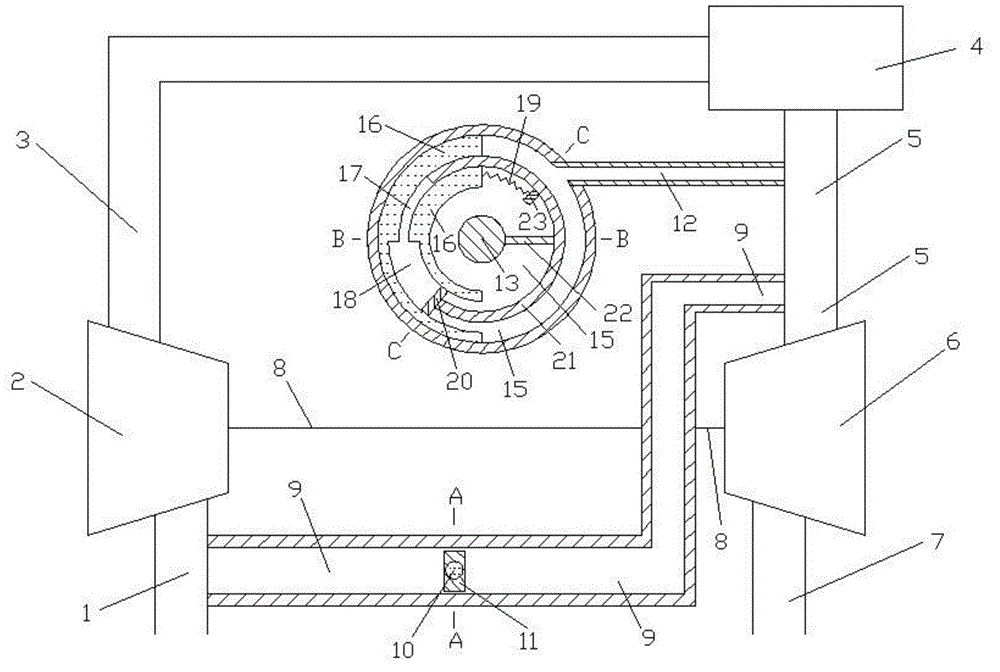

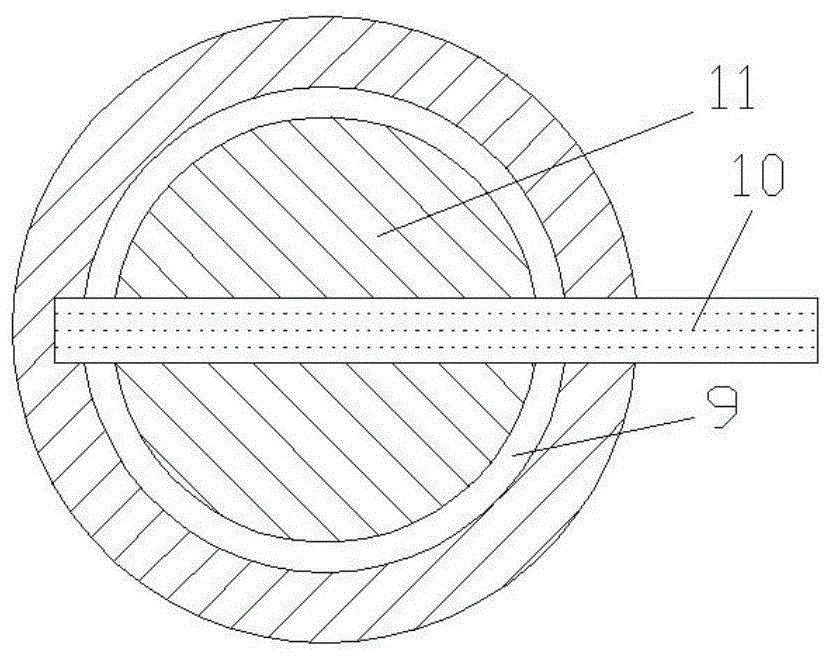

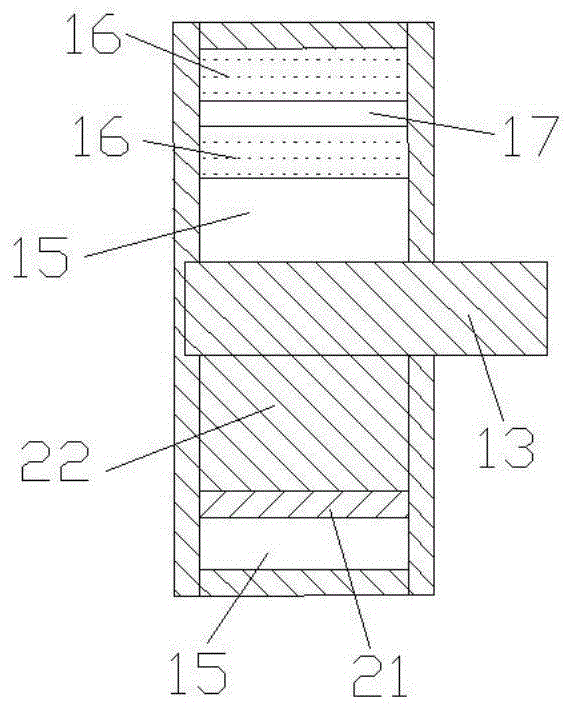

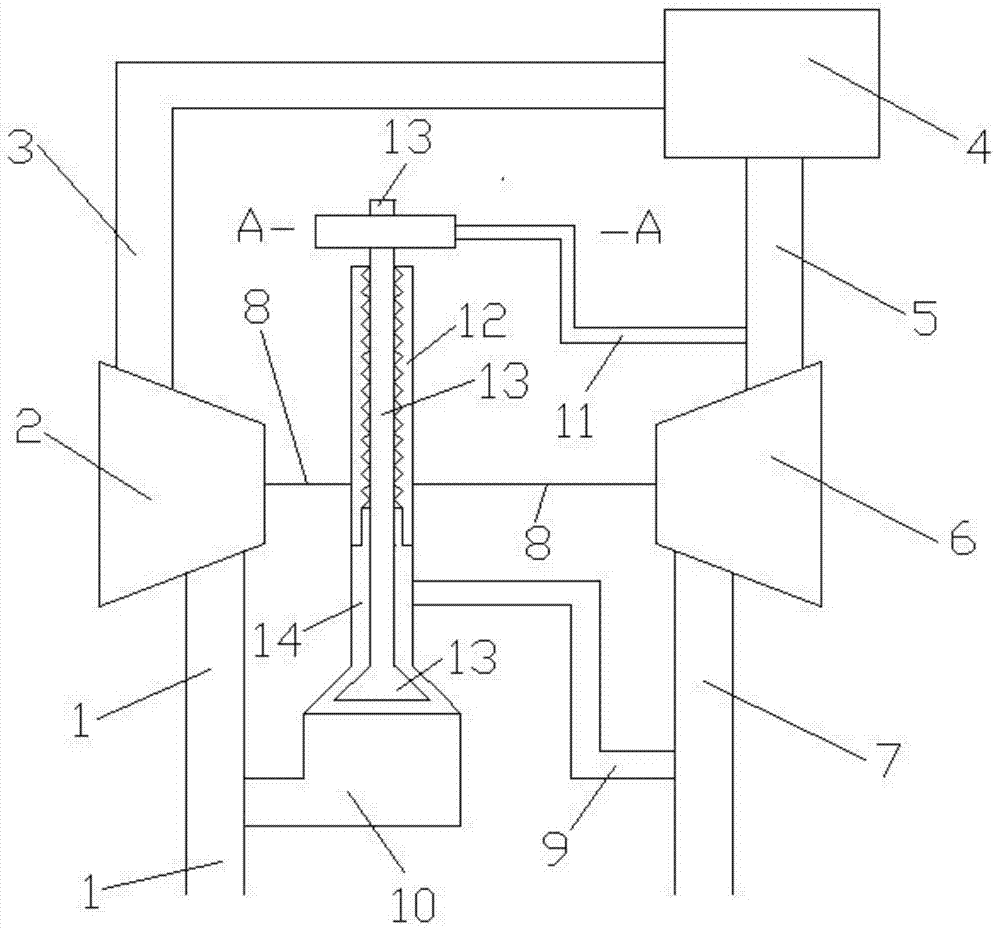

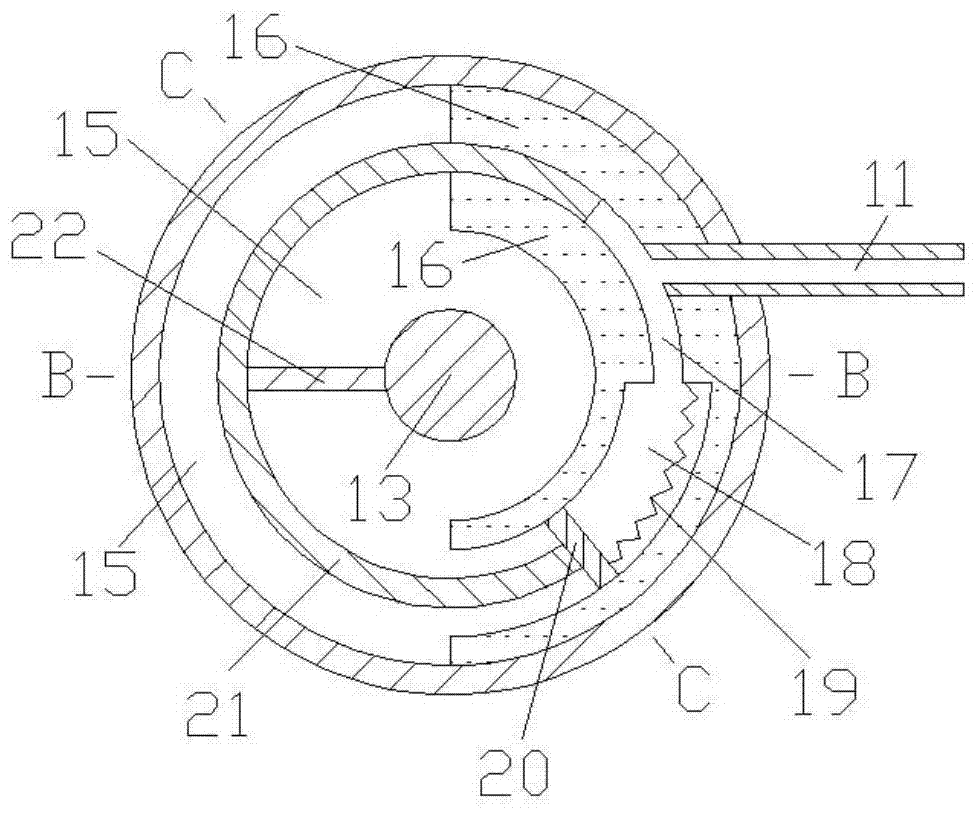

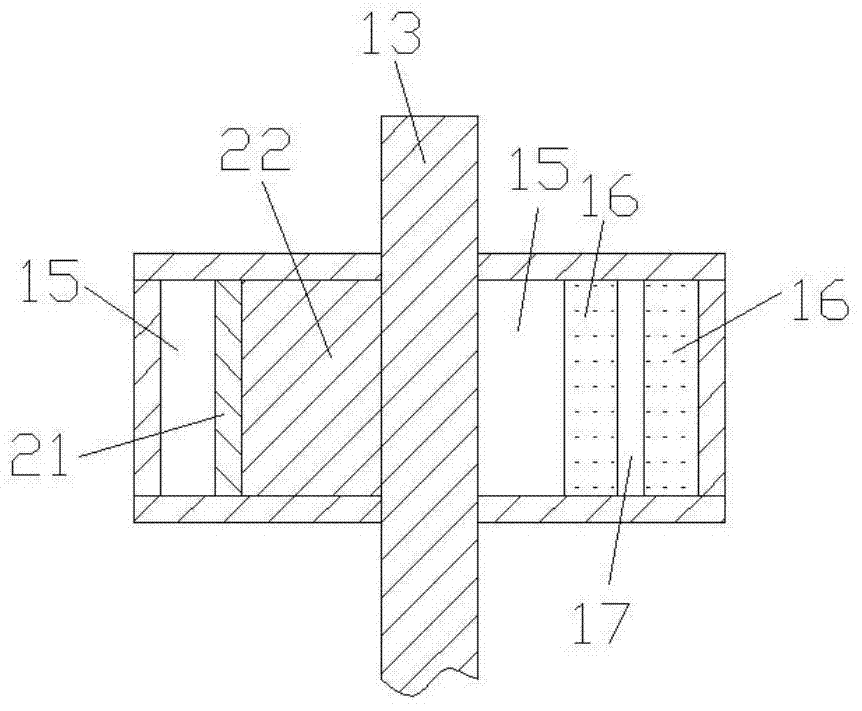

The invention discloses a rotary gas valve control mechanism and belongs to the technical field of mechanical design. The rotary gas valve control mechanism comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, an accommodating cavity, a rotator and an elastic component, wherein the rotator is mounted in the accommodating cavity and is in sealed contact with the inner wall face of the accommodating cavity, the lower wall face of the rotator is connected with the lower wall face of the accommodating cavity through the elastic component, two ends of a first connecting pipe are communicated with gas inlets of an engine exhaust pipe and an accommodating chamber respectively, and two ends of a third connecting pipe are communicated with the engine exhaust pipe and the upper wall face of the accommodating cavity. When the engine exhaust pipe is high in pressure, the rotator drives the valve body to rotate clockwise, exhaust gas recirculation rate of the engine is large, and the engine is low in explosion pressure; and when the engine exhaust pipe is low in pressure, the rotator drives the valve body to rotate anticlockwise, the exhaust gas recirculation rate of the engine is small, and oil consumption of the engine is low. The rotary gas valve control mechanism is reasonable in design, simple in structure and applicable to an exhaust gas recirculation system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

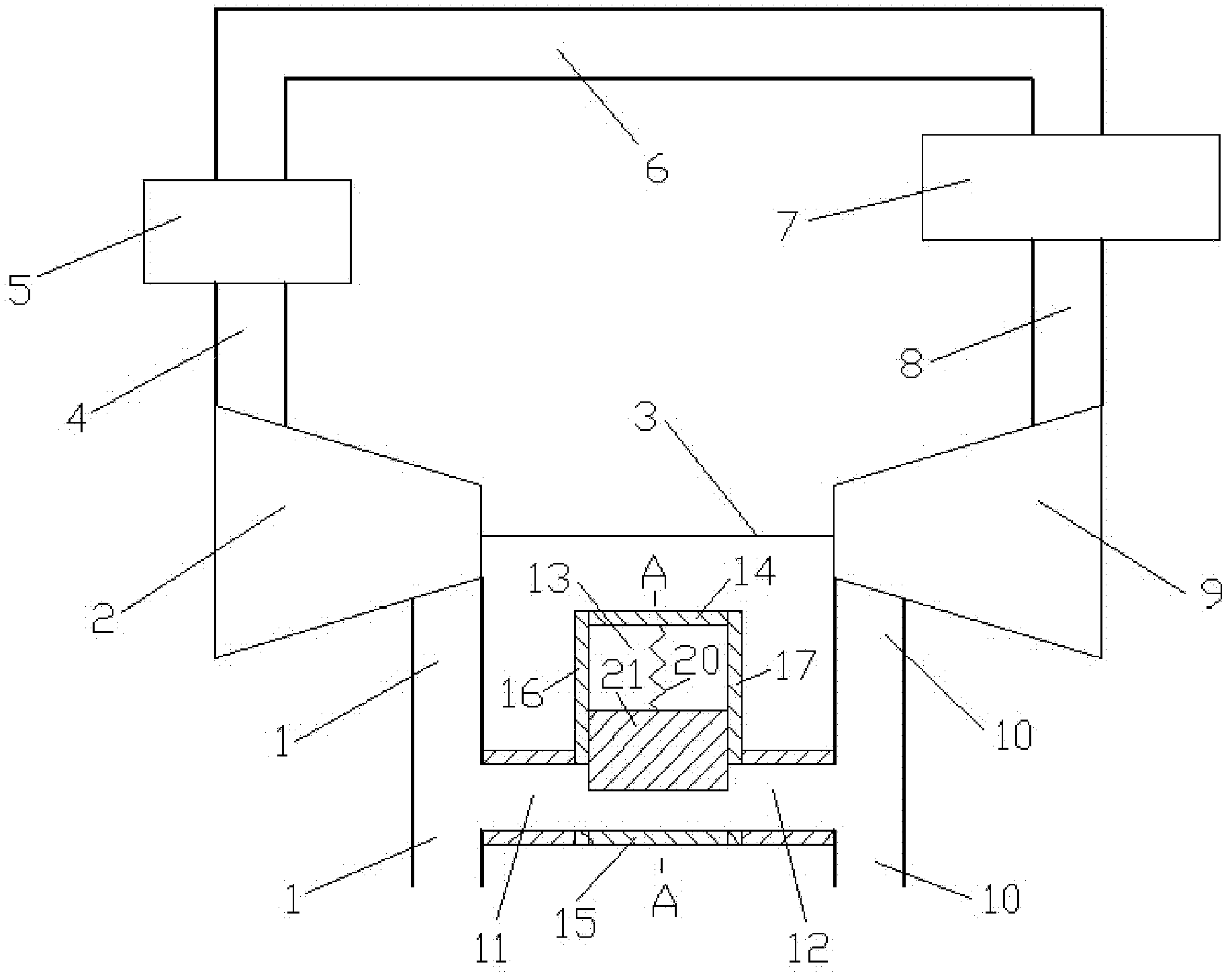

Exhaust-pressure regulated exhaust-gas recirculating system

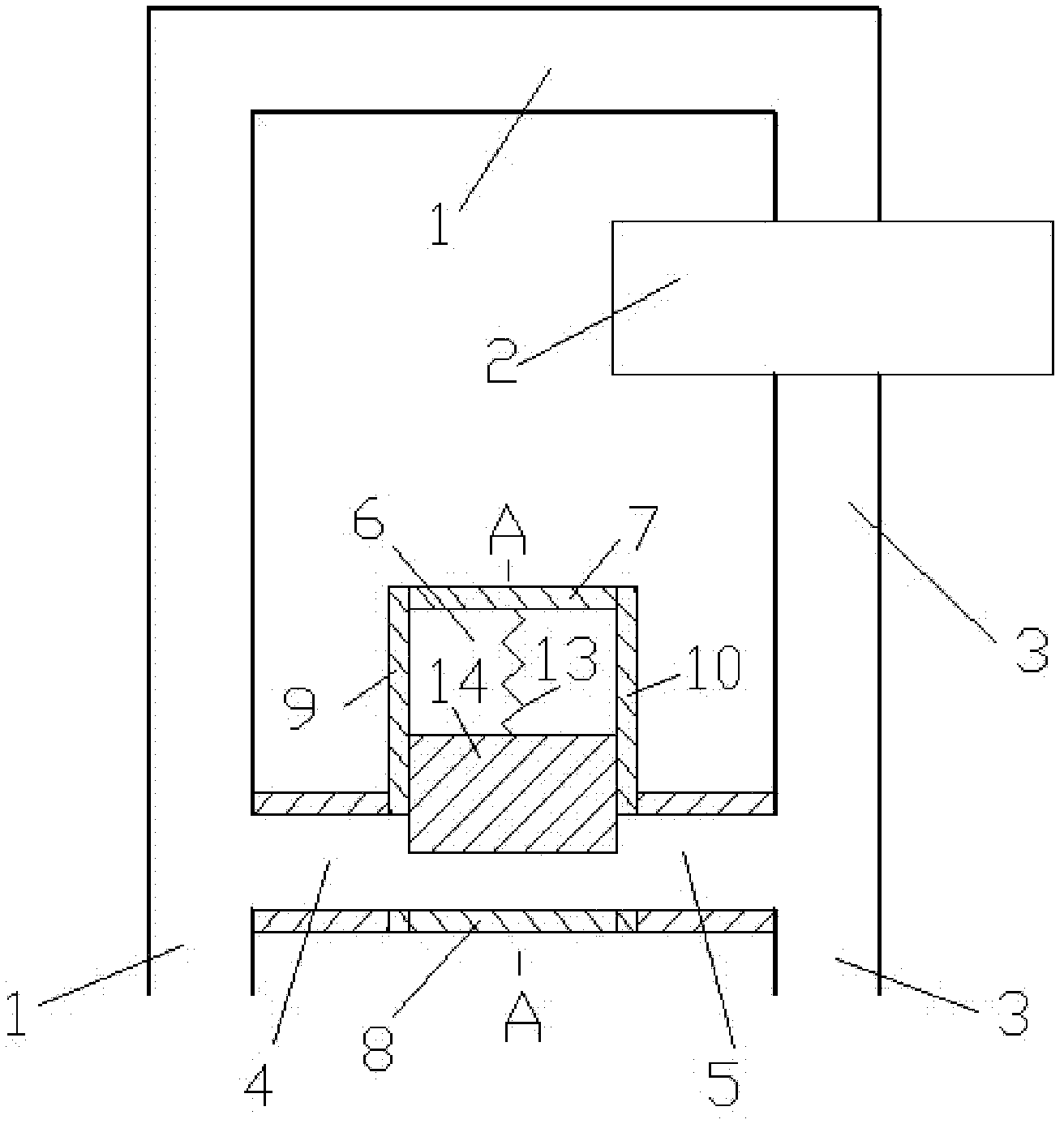

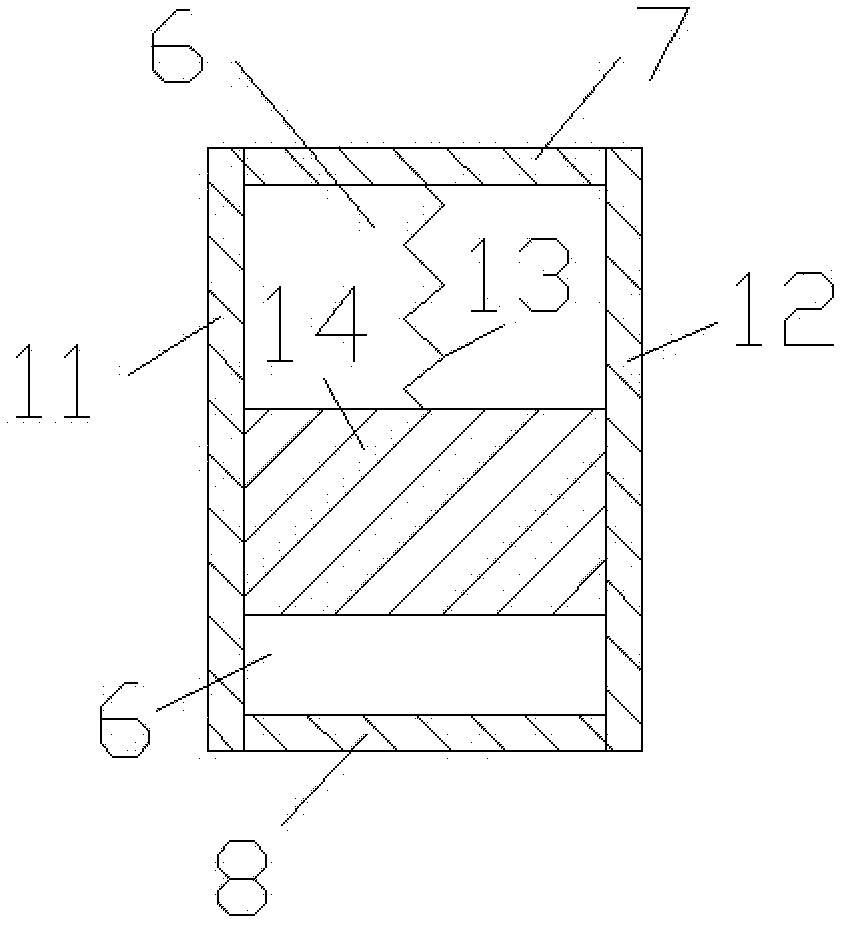

InactiveCN102536524ATaking into account the medium and high speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerEngineering

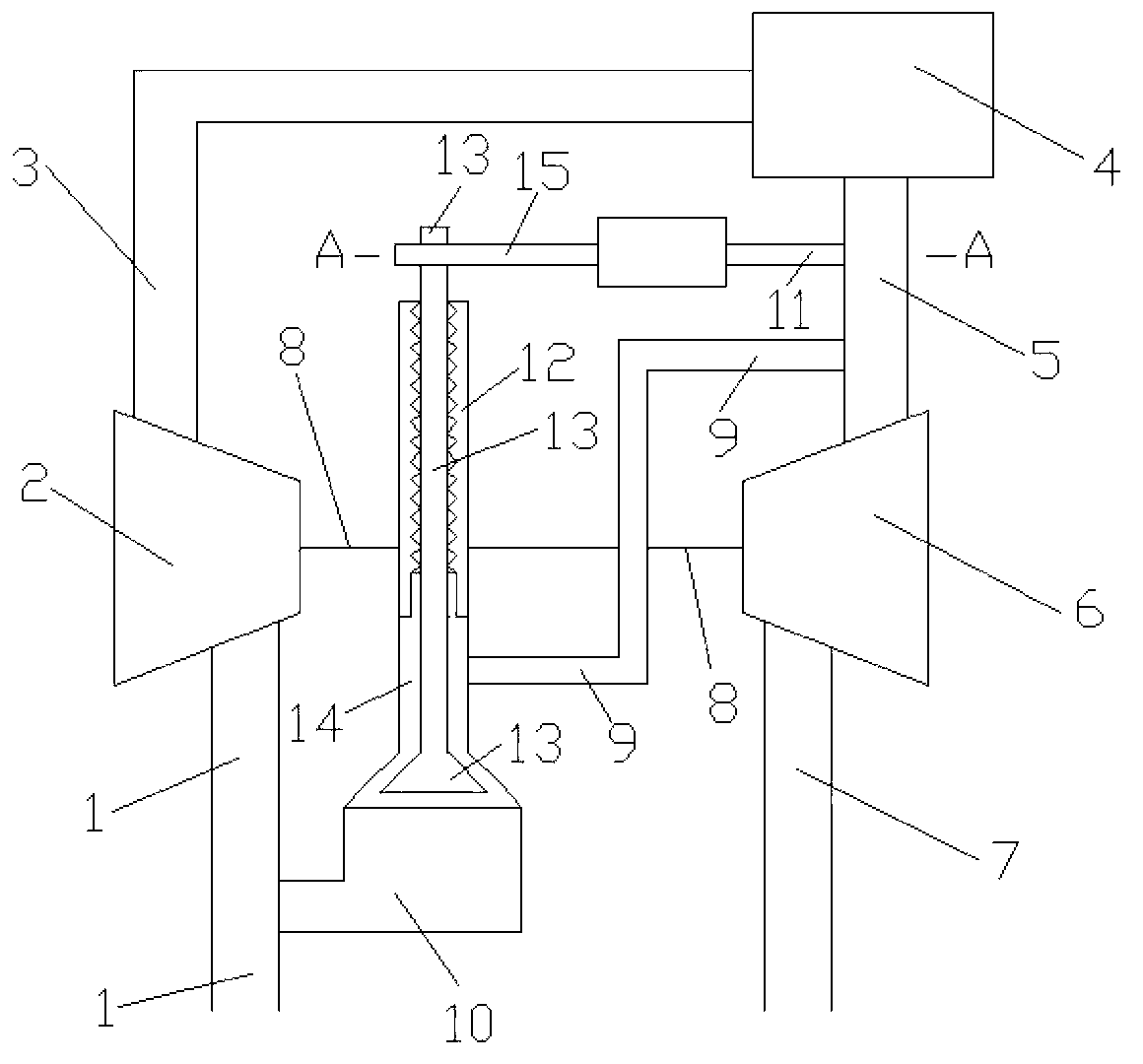

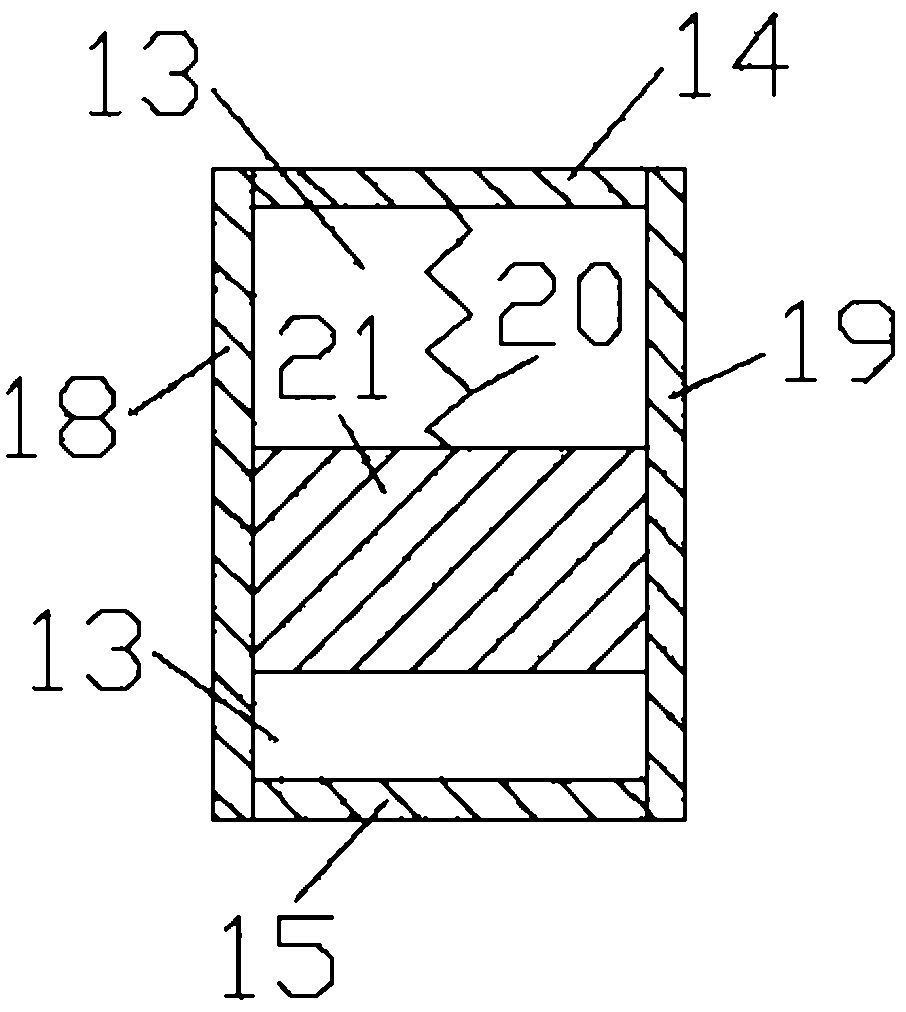

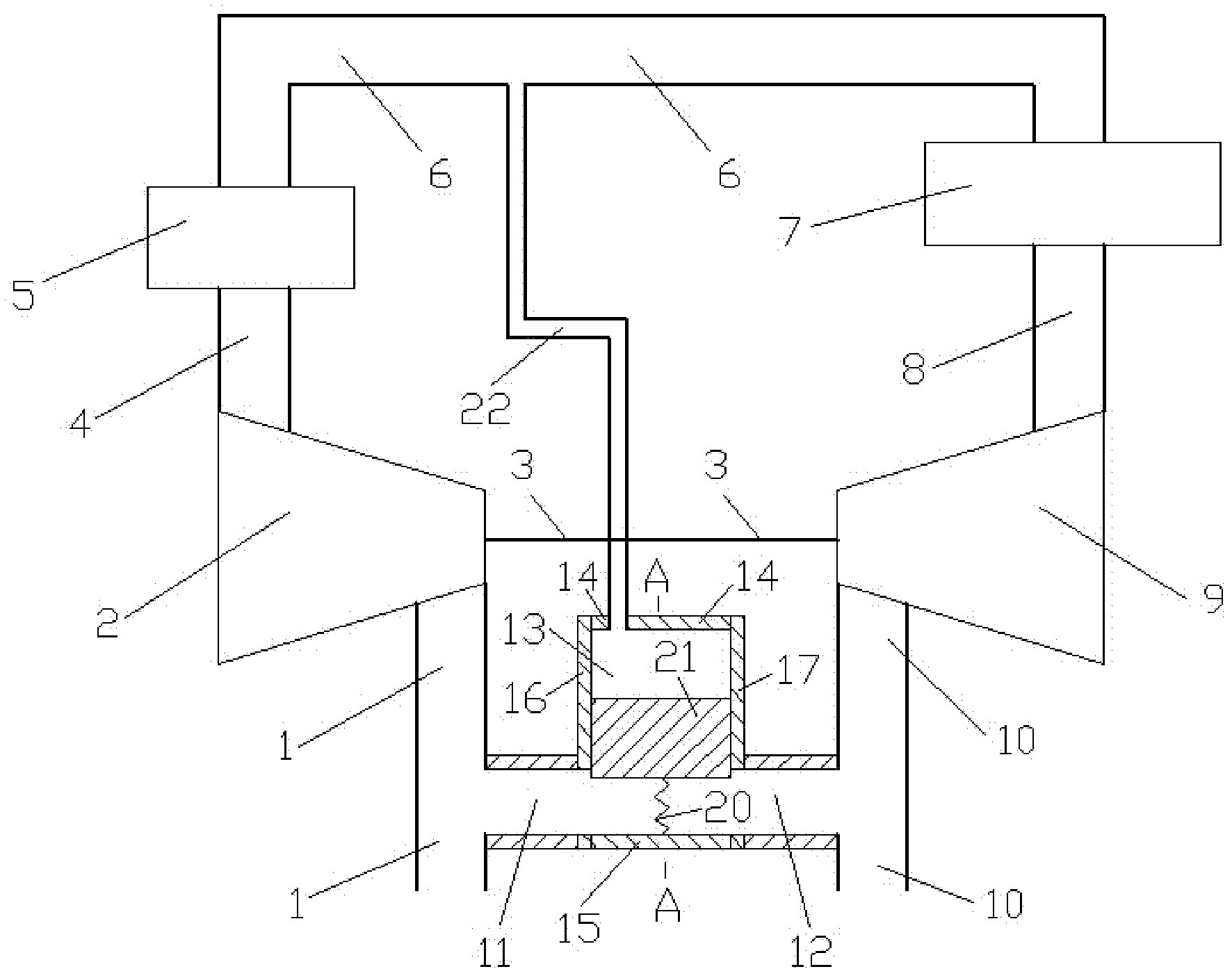

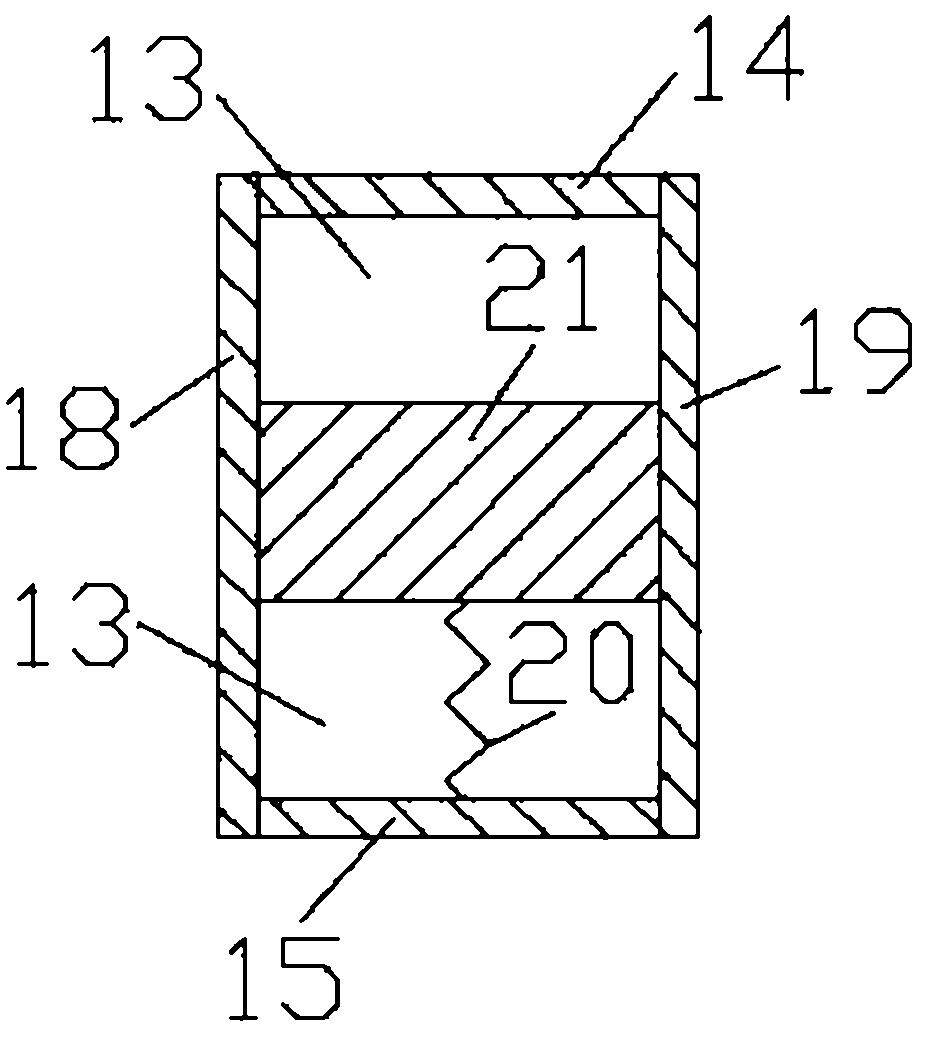

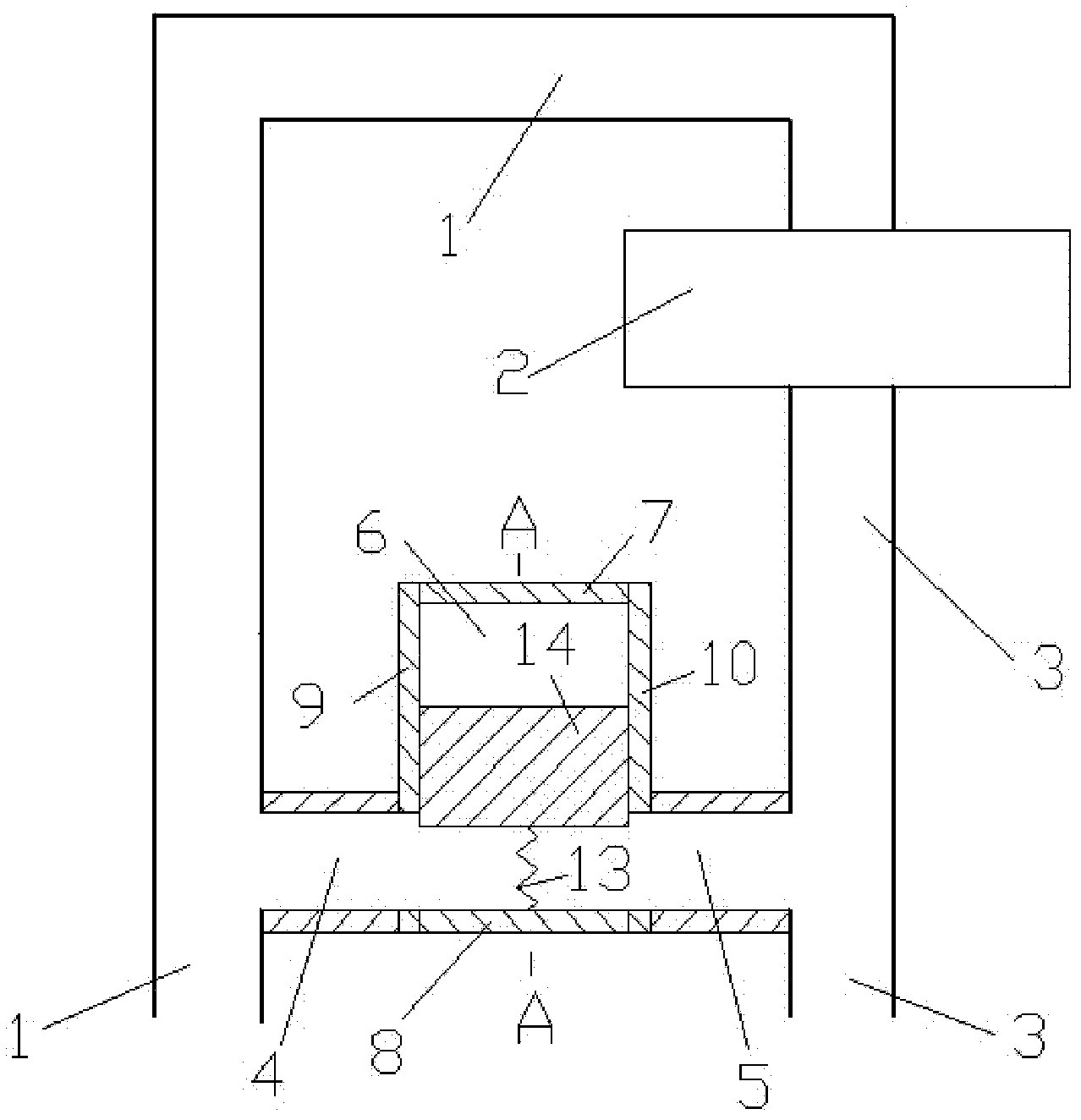

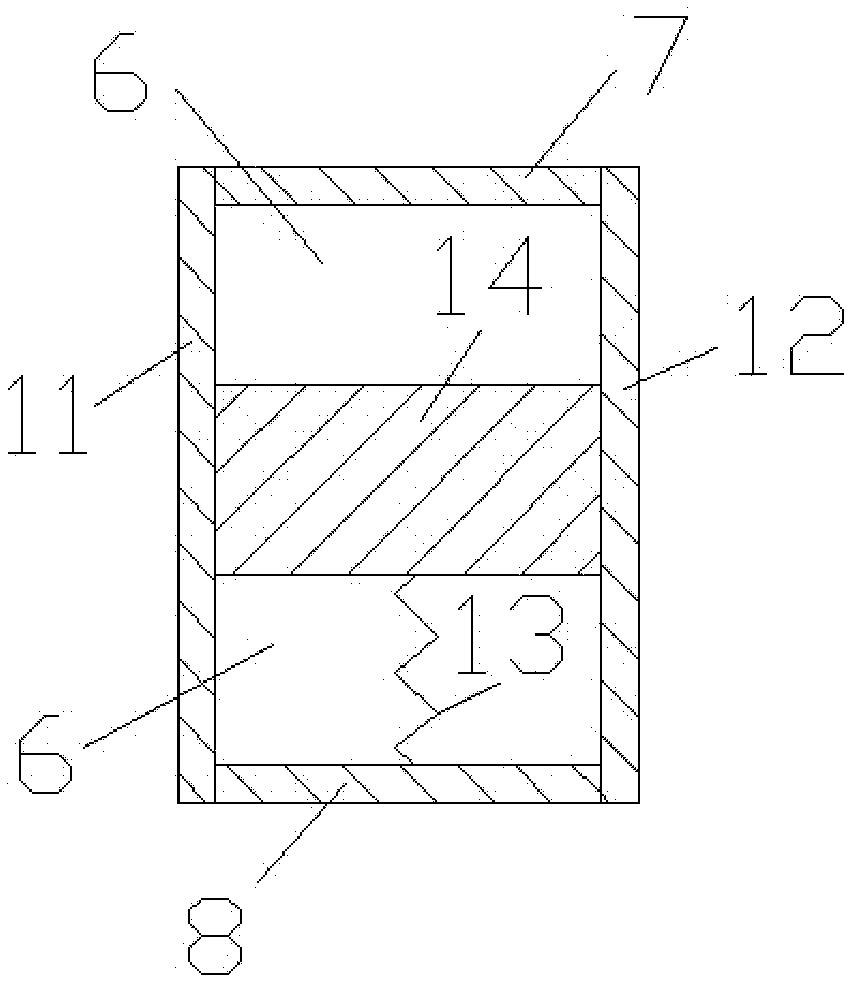

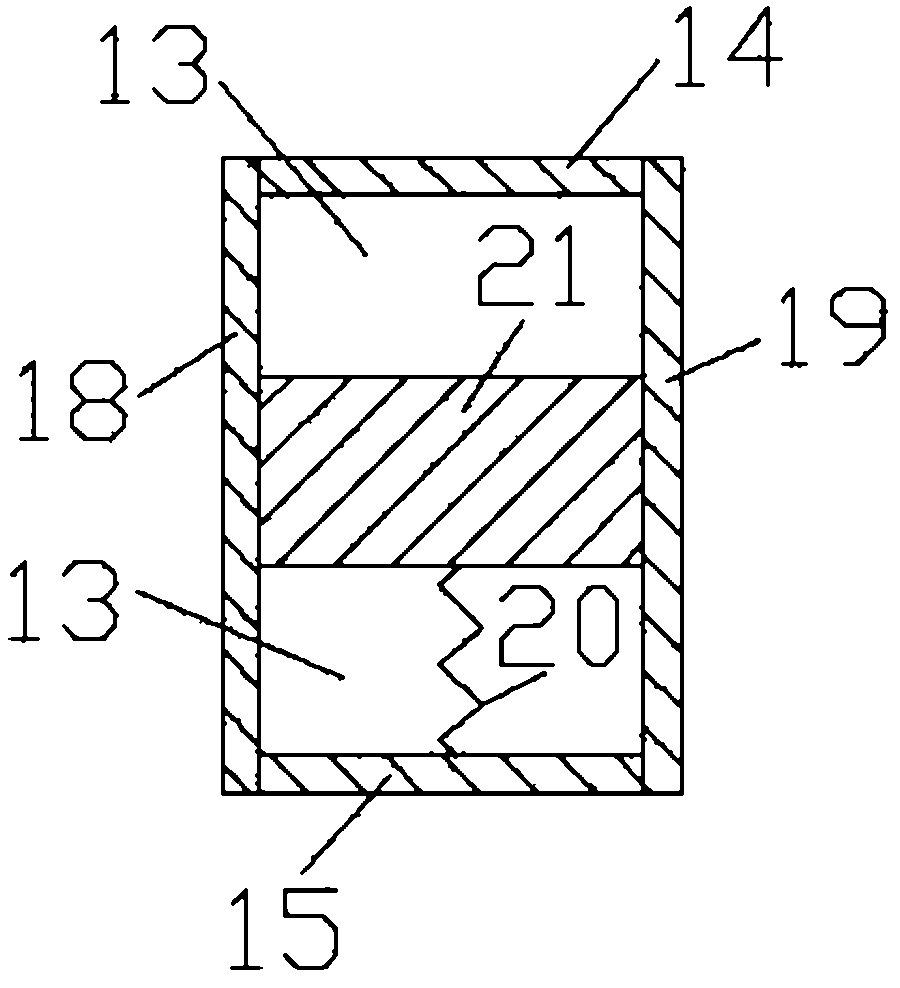

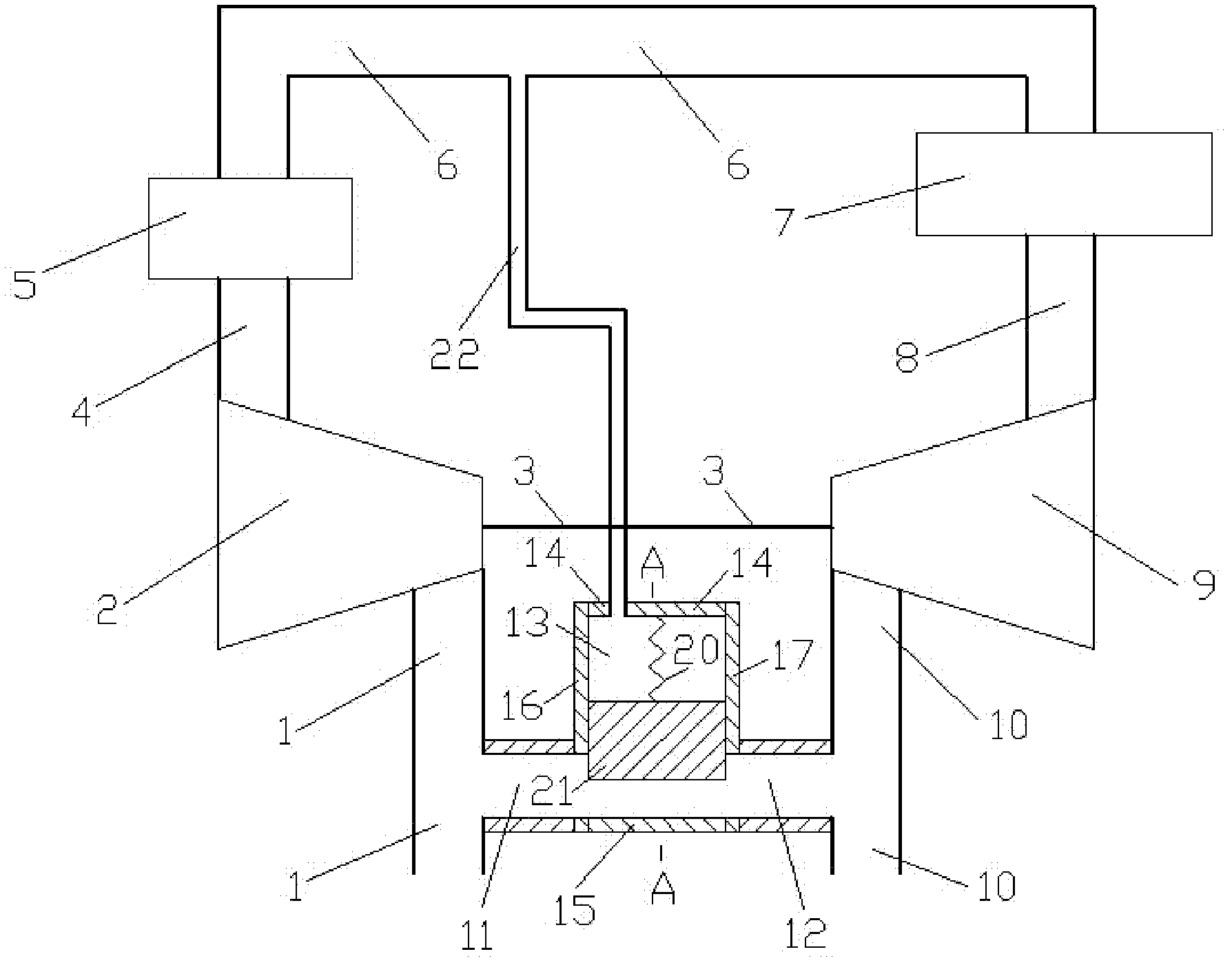

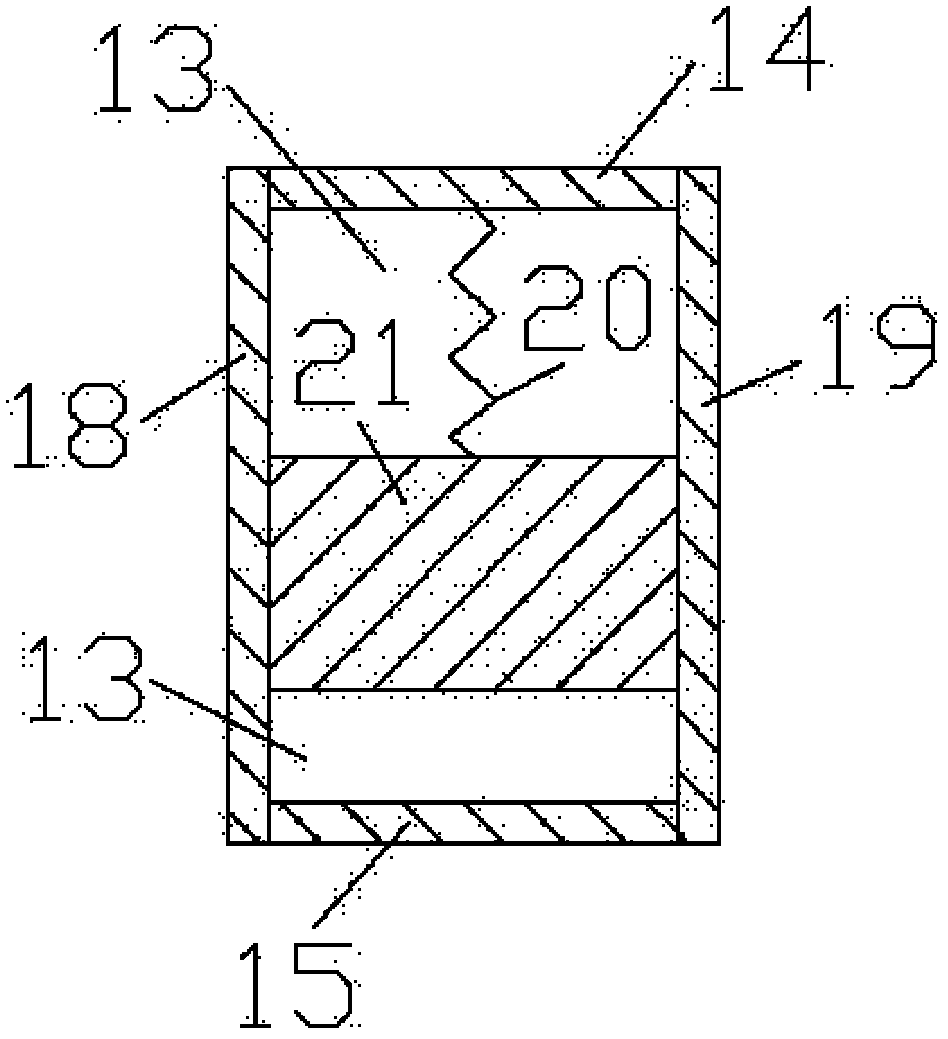

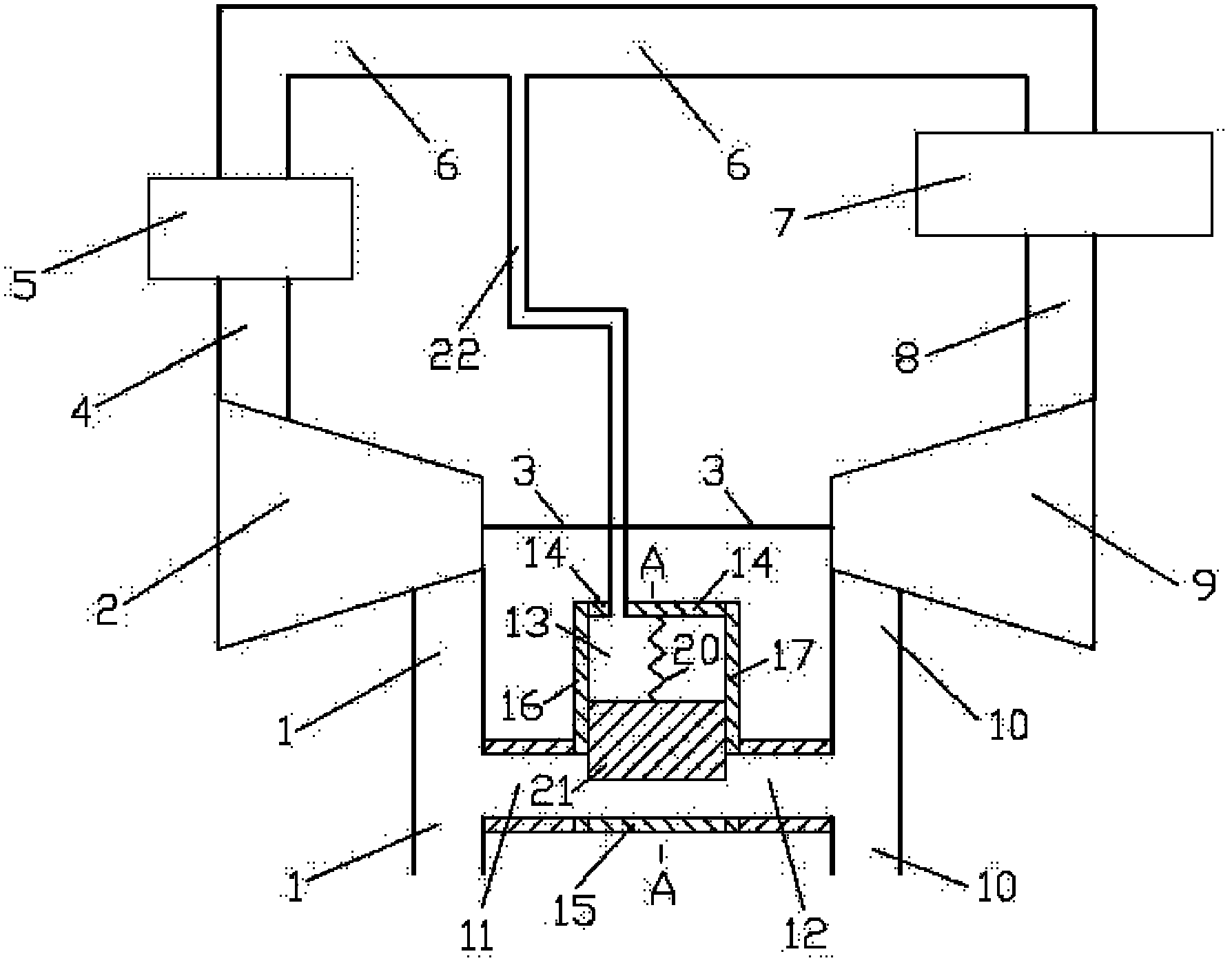

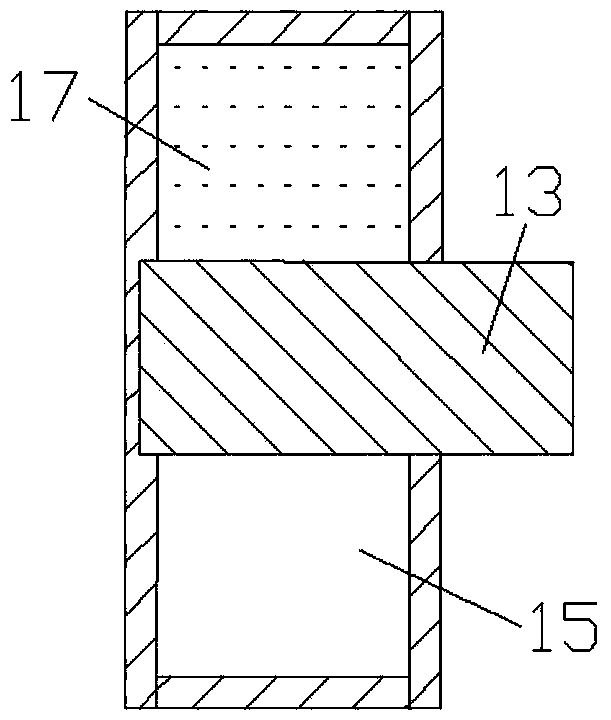

The invention relates to an exhaust-pressure regulated exhaust-gas recirculating system in the technical field of internal-combustion engines, which comprises an air-inlet pipe, an engine, a general exhaust pipe, an air compressor, a turbine, connecting pipes, a volume cavity, a moving body and an elastic part, wherein a third connecting pipe is installed between the general exhaust pipe and the upper wall surface of the volume cavity, the cross section of the volume cavity is rectangular, the moving body is installed in the volume cavity and is hermetically contacted with the inner wall surface of the volume cavity, and the moving body is connected with the upper wall surface of the volume cavity through the elastic part. When the engine is under a medium-speed working condition, the moving body upwards moves in the volume cavity, the exhaust-gas recirculating rate is larger, the exhaust temperature is lower, and the overall performance of the engine is more excellent; and when the engine is under a high-speed working condition, the moving body downwards moves in the volume cavity, the exhaust-gas recirculating rate is smaller, the dynamic property of the engine is better, and the overall performance of the engine is more excellent. The exhaust-pressure regulated exhaust-gas recirculating system has a reasonable design and a simple structure and is applicable to the exhaust-gas recirculating system with a turbocharger.

Owner:SHANGHAI JIAO TONG UNIV

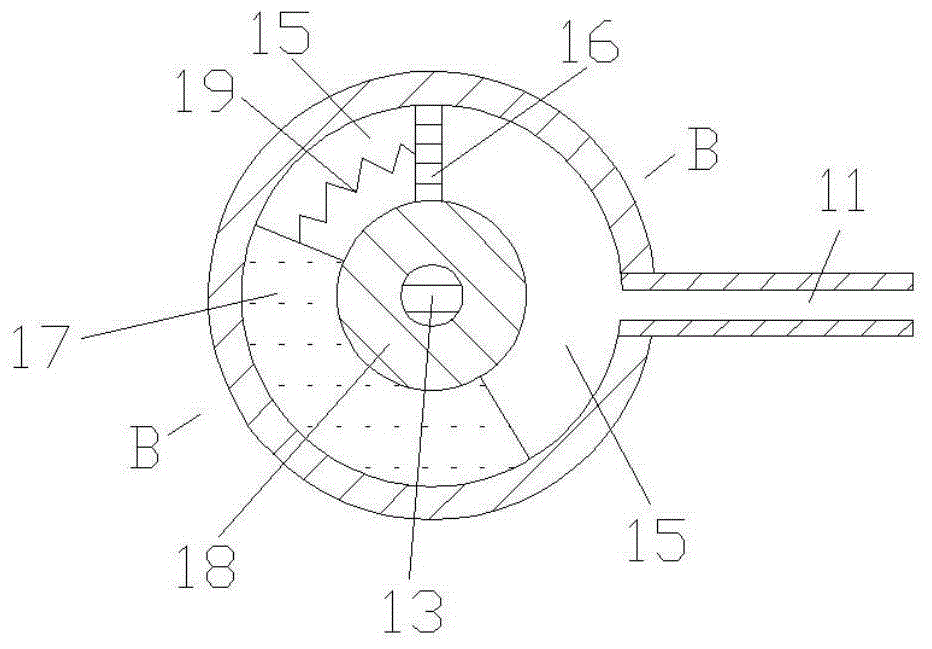

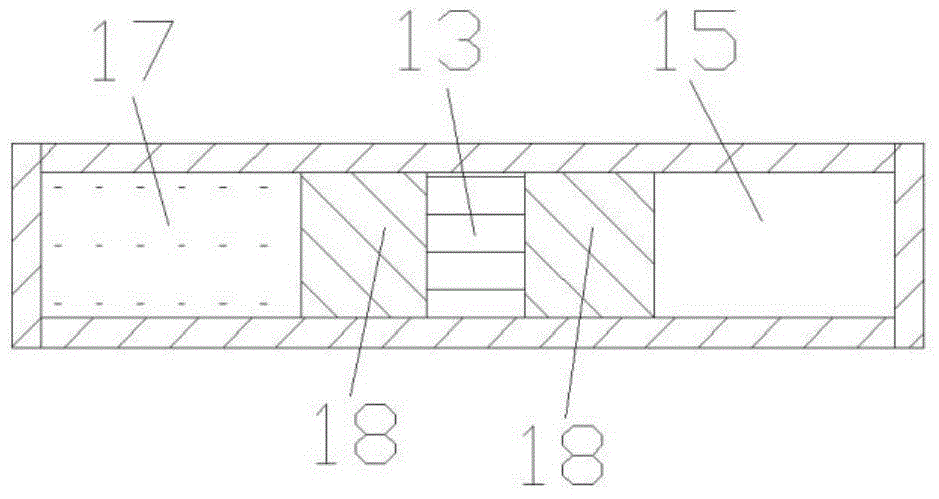

Air valve throat area control system

InactiveCN103291471ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelThroatControl system

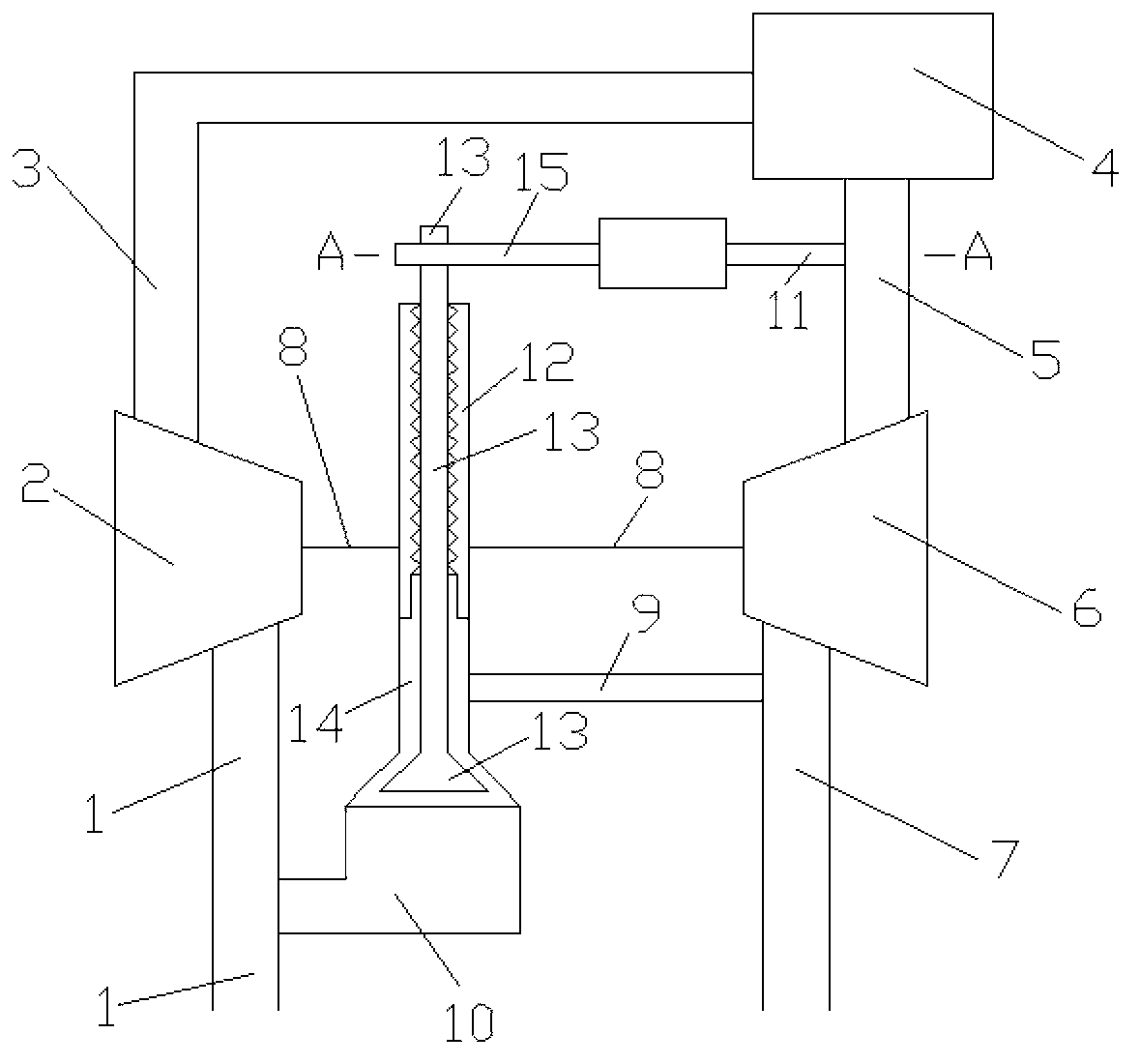

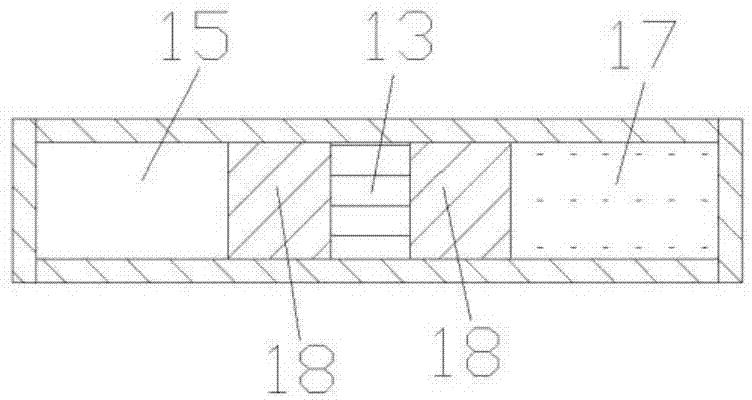

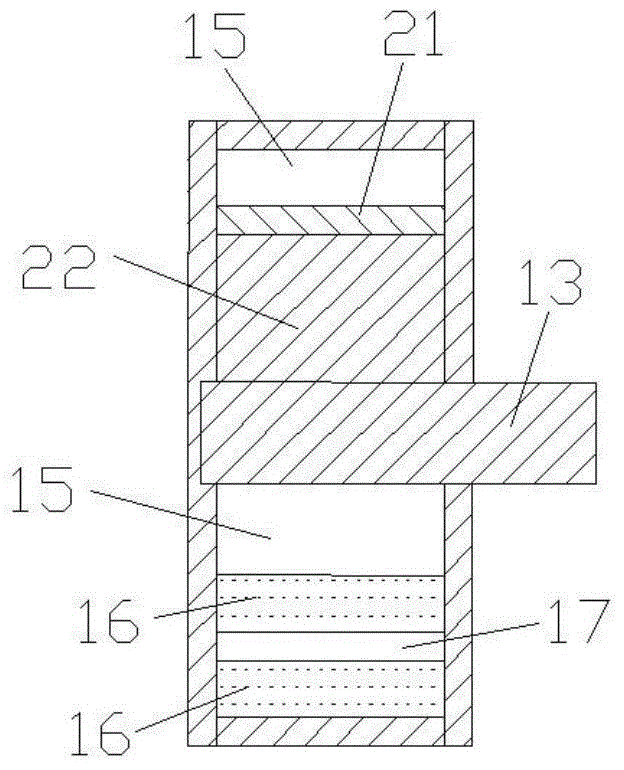

The invention relates to an air valve throat area control system and relates to the technical field of mechanical design. The air valve throat area control system comprises an air compressor, an engine, a turbine, connecting pipes, a valve seat, a valve block, a rotary shaft, a volumetric cavity, a rotor and an elastic part. The rotor is mounted in the volumetric cavity and is in hermetic contact with the inner wall of the volumetric cavity. The lower wall of the rotor is connected with the lower wall of the volumetric cavity through the elastic part. Two ends of the first connecting pipe are communicated with an air inlet of a turbine exhaust pipe and an air inlet of the volumetric cavity respectively. Two ends of the third connecting pipe are communicated with the upper wall of an engine exhaust pipe and the upper wall of the volumetric cavity respectively. When the pressure of the engine exhaust pipe is high, the rotor drives the valve block to rotate clockwise, emission recirculation rate of the engine is high, and denotation pressure of the engine is low; when the pressure of the engine exhaust pipe is low, the rotor drives the valve block to rotate anticlockwise, emission recirculation rate of the engine is low, and oil consumption of the engine is low. The air valve throat area control system is reasonable in design, simple in structure, and applicable to exhaust recirculation systems for supercharged engines.

Owner:SHANGHAI JIAO TONG UNIV

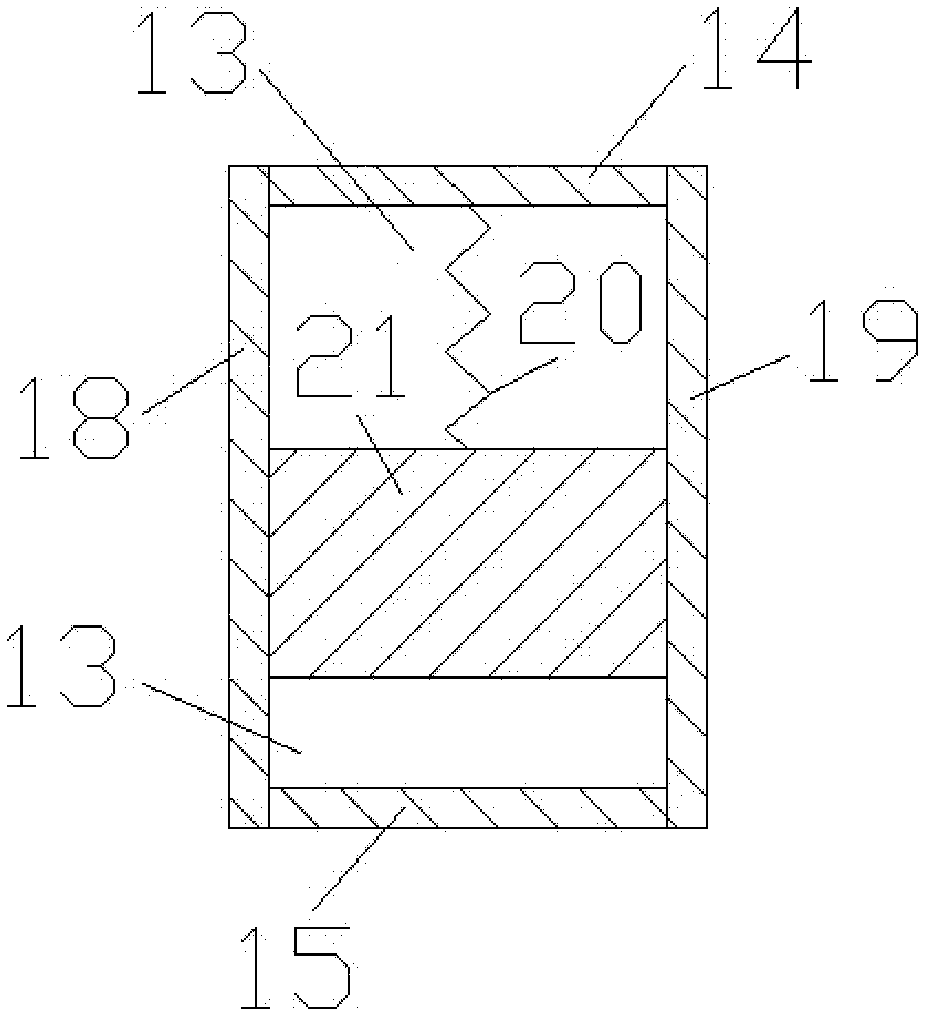

Exhaust recirculating system controlled by aid of air inlet pressure

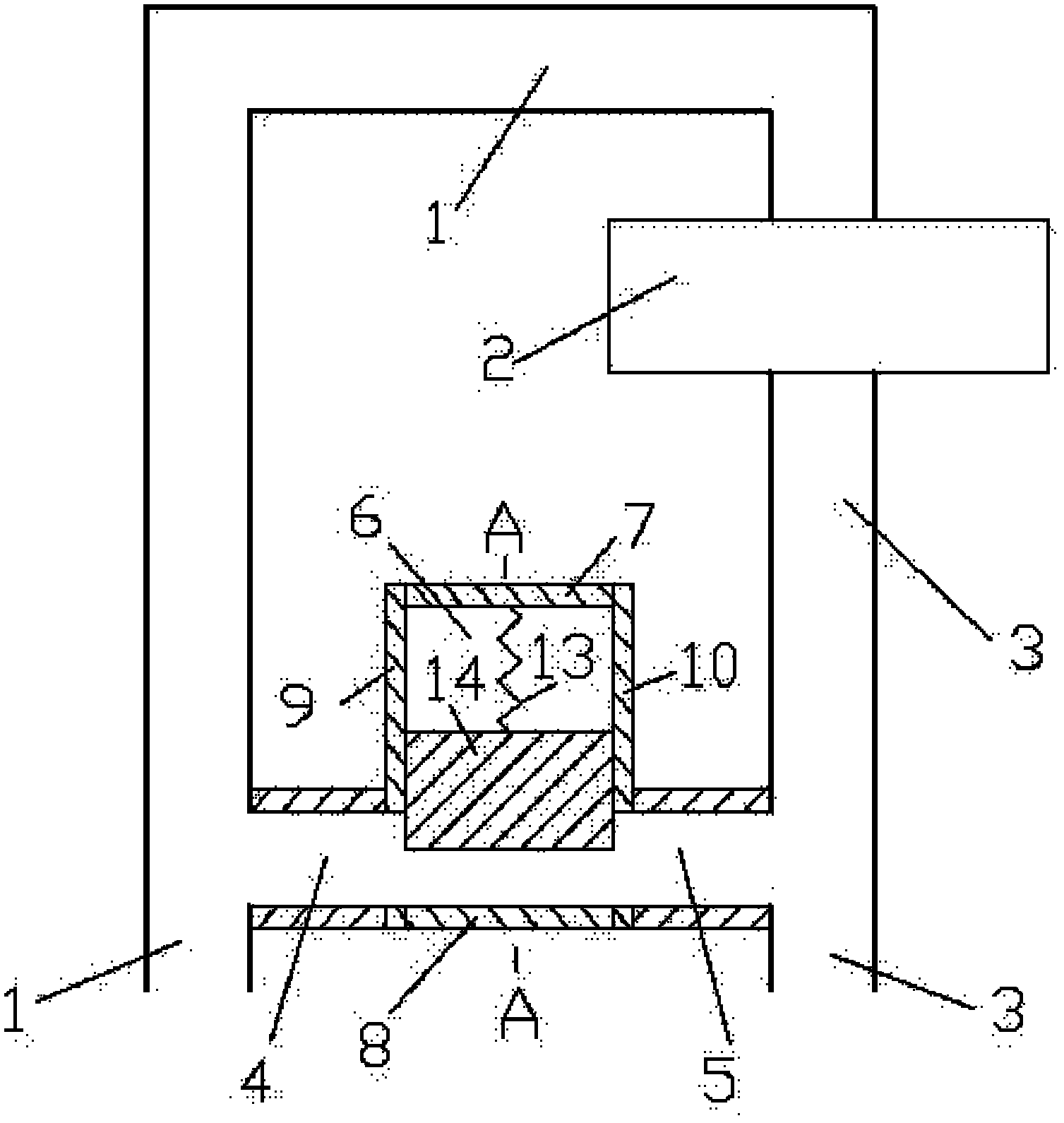

InactiveCN102562369ATaking into account the medium and high speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentTurbocharger

An exhaust recirculating system controlled by the aid of air inlet pressure relates to the technical field of internal combustion engines and comprises an air inlet tube, an engine, an exhaust tube, a compressor, a turbine, connecting tubes, a volumetric cavity, a mover and an elastic component. A third connecting tube is mounted between an air inlet main tube and an upper wall surface of the volumetric cavity, the cross section of the volumetric cavity is rectangular, the mover is mounted in the volumetric cavity and hermetically contacts with an inner wall surface of the volumetric cavity, and the mover is connected with a lower wall surface of the volumetric cavity via the elastic component. When the engine is in a middle-speed working condition, the mover upwards moves in the volumetric cavity, exhaust recirculating rate is high, exhaust temperature is low, and performances of the total engine are excellent; and when the engine is in a high-speed working condition, the mover downwards moves in the volumetric cavity, exhaust recirculating rate is low, dynamic property of the engine is good, and performances of the total engine are excellent. The exhaust recirculating system is reasonable in design and simple in structure. The invention is applicable to exhaust recirculating systems with turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Pneumatic-control valve lift regulating mechanism

InactiveCN103291470ATaking into account low and medium speed conditionsReasonable designEngine controllersMachines/enginesEngineeringExhaust gas recirculation

The invention relates to a pneumatic-control valve lift regulating mechanism and relates to the technical field of mechanical design. The pneumatic-control valve lift regulating mechanism comprises an air compressor, an engine, a turbine, connecting pipes, a valve seat, a valve block, a rotary shaft, a volumetric cavity, a rotor and an elastic part. The rotor is mounted in the volumetric cavity and hermetically contacts with the inner wall of the volumetric cavity. The lower wall of the rotor is connected with the lower wall of the volumetric cavity through the elastic part. Two ends of the first connecting pipe are communicated with an air inlet of a turbine exhaust pipe and an air inlet of the volumetric cavity. Two ends of the third connecting pipe are communicated with the upper wall of an engine exhaust pipe and the upper wall of the volumetric cavity. When the pressure of an engine intake pipe is high, the rotor drives the valve block to rotate clockwise, emission recirculation rate of the engine is high, and denotation pressure of the engine is low; when the pressure of the engine intake pipe is low, the rotor drives the valve block to rotate anticlockwise, emission recirculation rate of the engine is low, and oil consumption of the engine is low. The pneumatic-control valve lift regulating mechanism is reasonable in design, simple in structure, and applicable to exhaust recirculation systems for supercharged engines.

Owner:SHANGHAI JIAO TONG UNIV

Rotary exhaust gas flow rate regulating system

ActiveCN103291503ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelExhaust gas recirculationElastic componentGas compressor

The invention relates to a rotary exhaust gas flow rate regulating system and belongs to the technical field of mechanical design. The rotary exhaust gas flow rate regulating system comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, an accommodating cavity, a rotator and an elastic component, wherein the rotator is mounted in the accommodating cavity and is in sealed contact with the inner wall face of the accommodating cavity, the lower wall face of the rotator is connected with the lower wall face of the accommodating cavity through the elastic component, two ends of a first connecting pipe are communicated with gas inlets of an engine exhaust pipe and an accommodating chamber respectively, and two ends of a third connecting pipe are communicated with an engine intake pipe and the upper wall face of the accommodating cavity respectively. When the engine intake pipe is high in pressure, the rotator drives the valve body to rotate clockwise, exhaust gas recirculation rate of the engine is large, and the engine is low in explosion pressure; and when the engine intake pipe is low in pressure, the rotator drives the valve body to rotate anticlockwise, the exhaust gas recirculation rate of the engine is small, and oil consumption of the engine is low. The rotary exhaust gas flow rate regulating system is reasonable in design, simple in structure and applicable to an exhaust gas recirculation system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

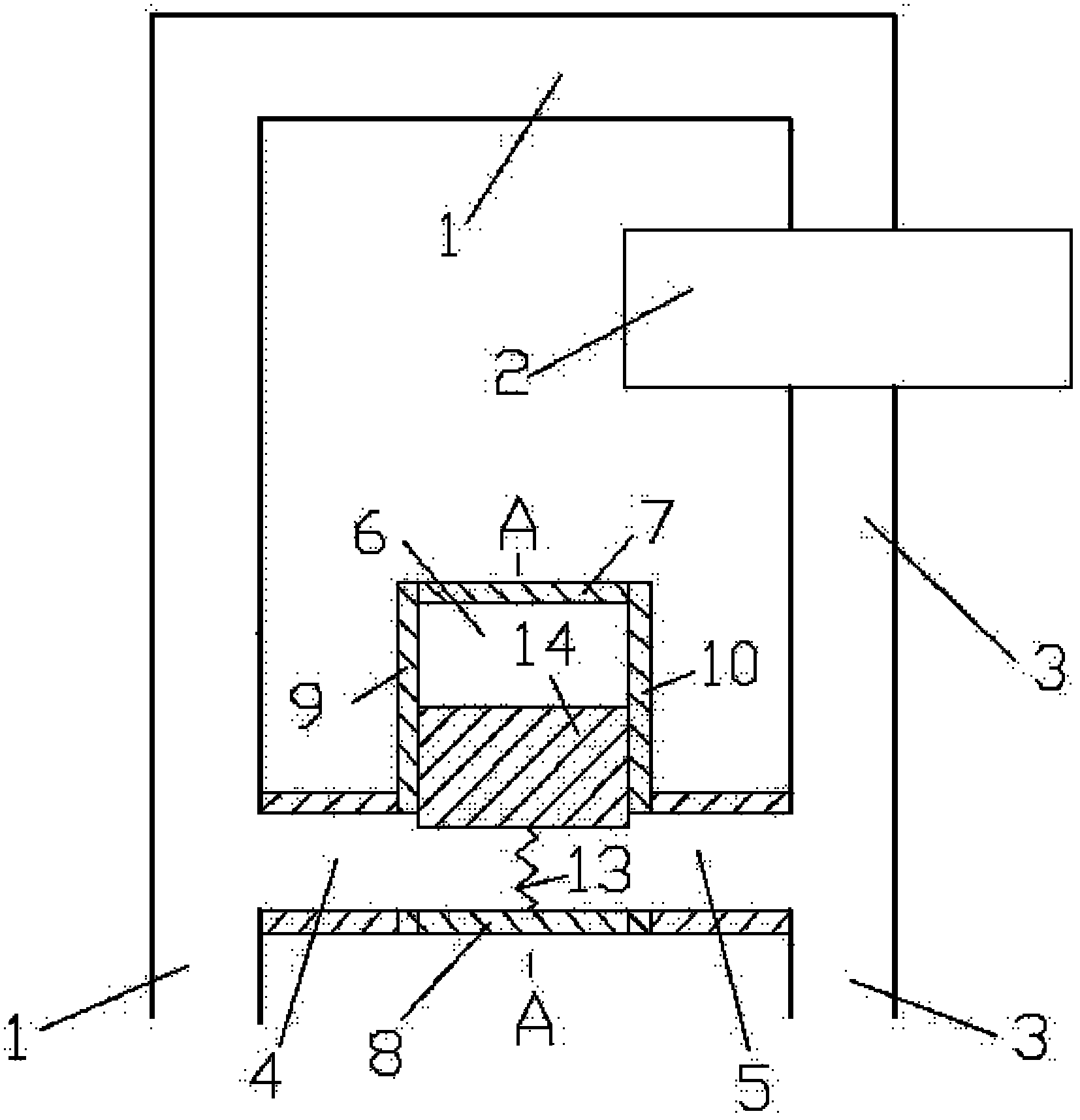

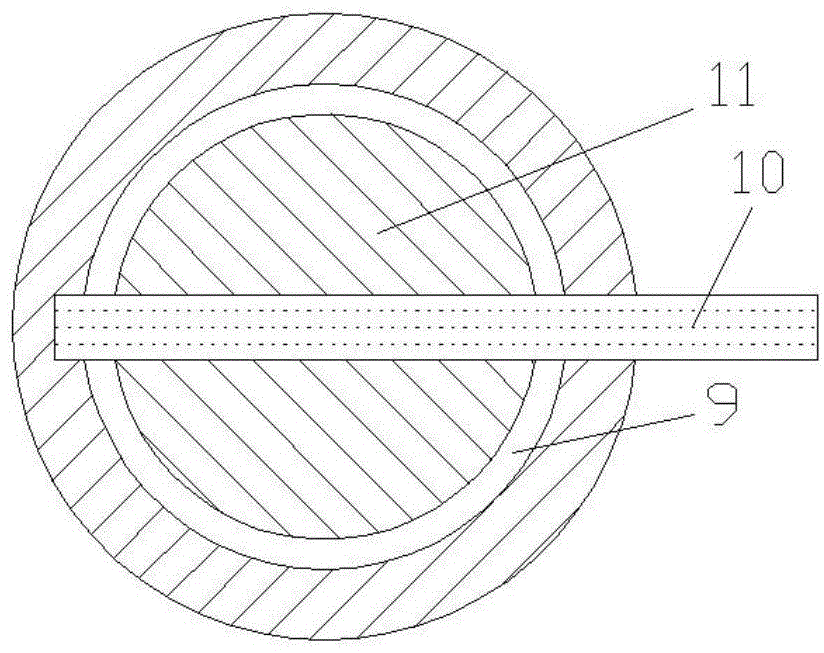

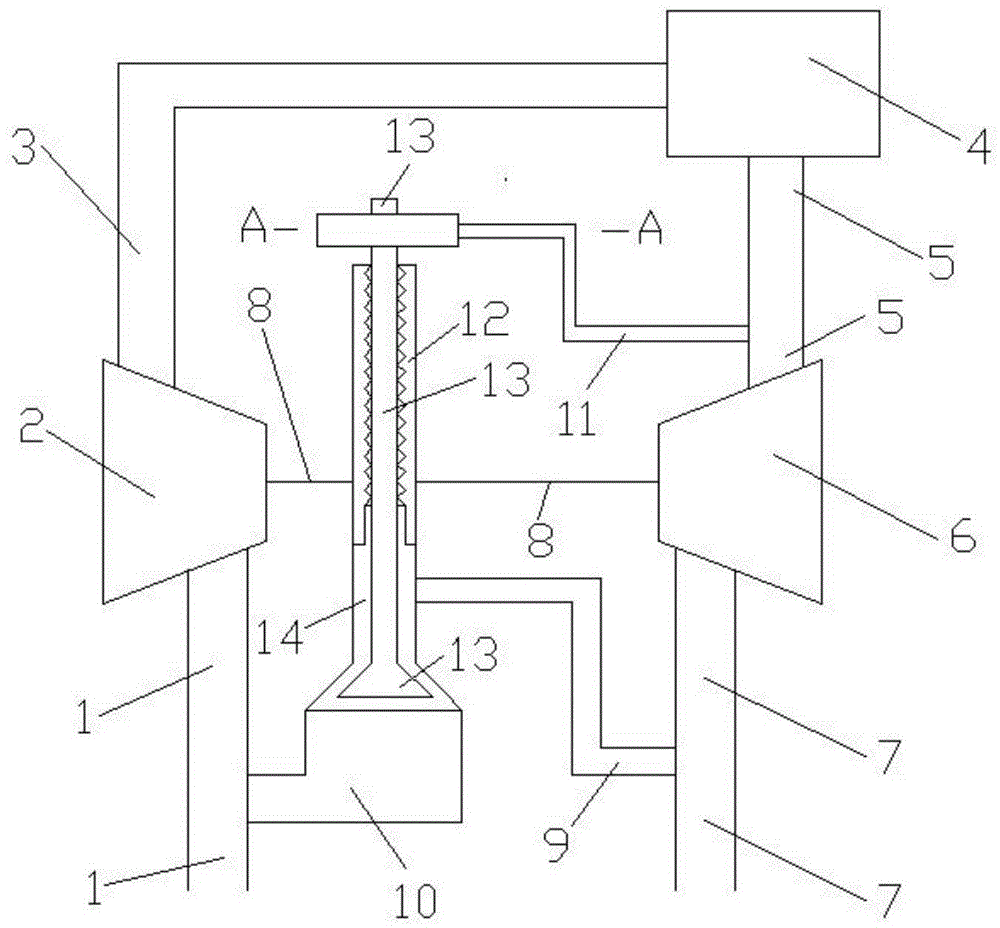

Exhaust recirculation system with elastic component

InactiveCN102536444AConsidering both high and low speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesElastic componentExternal combustion engine

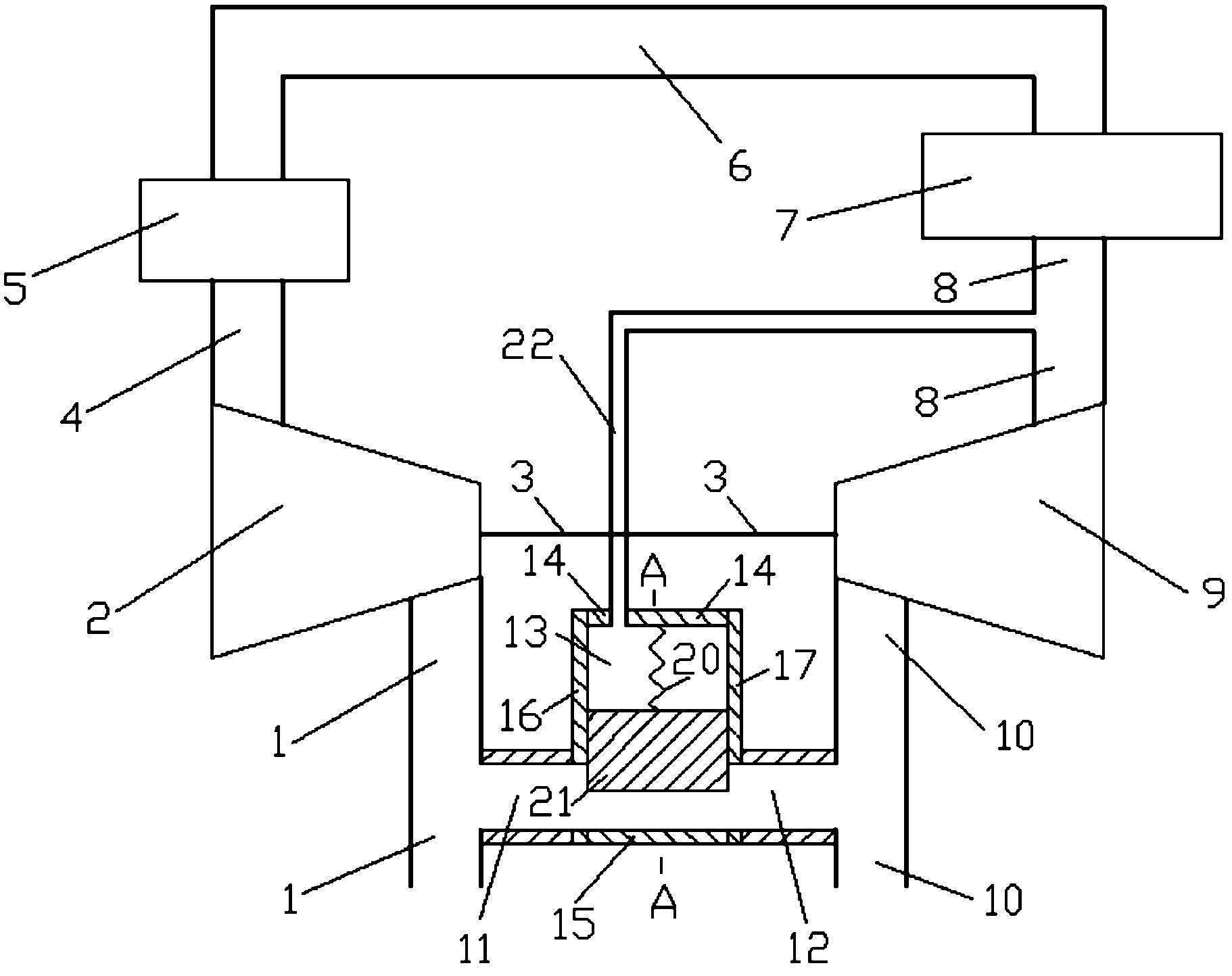

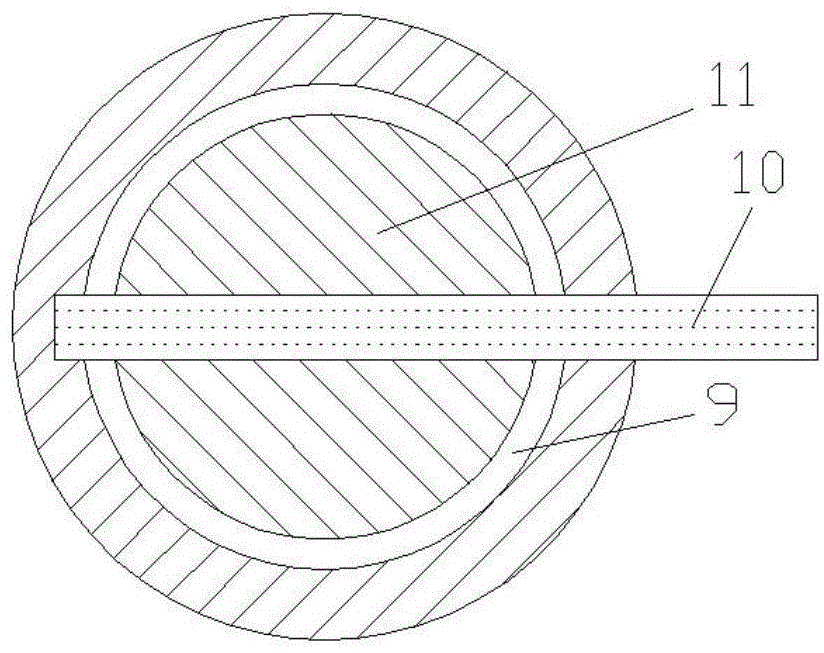

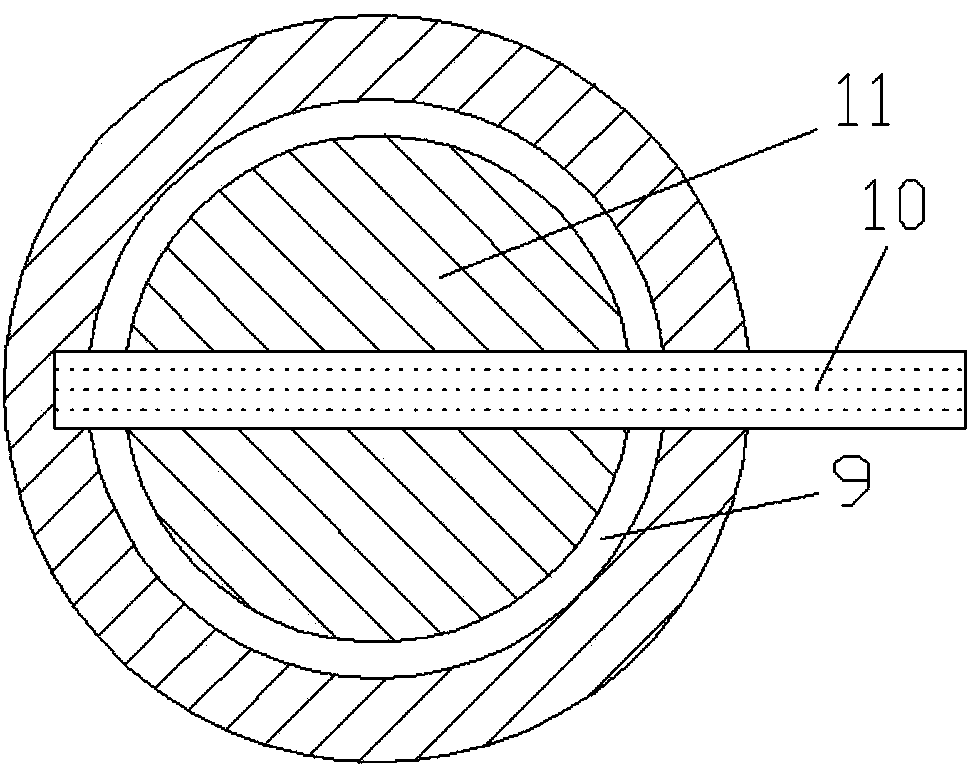

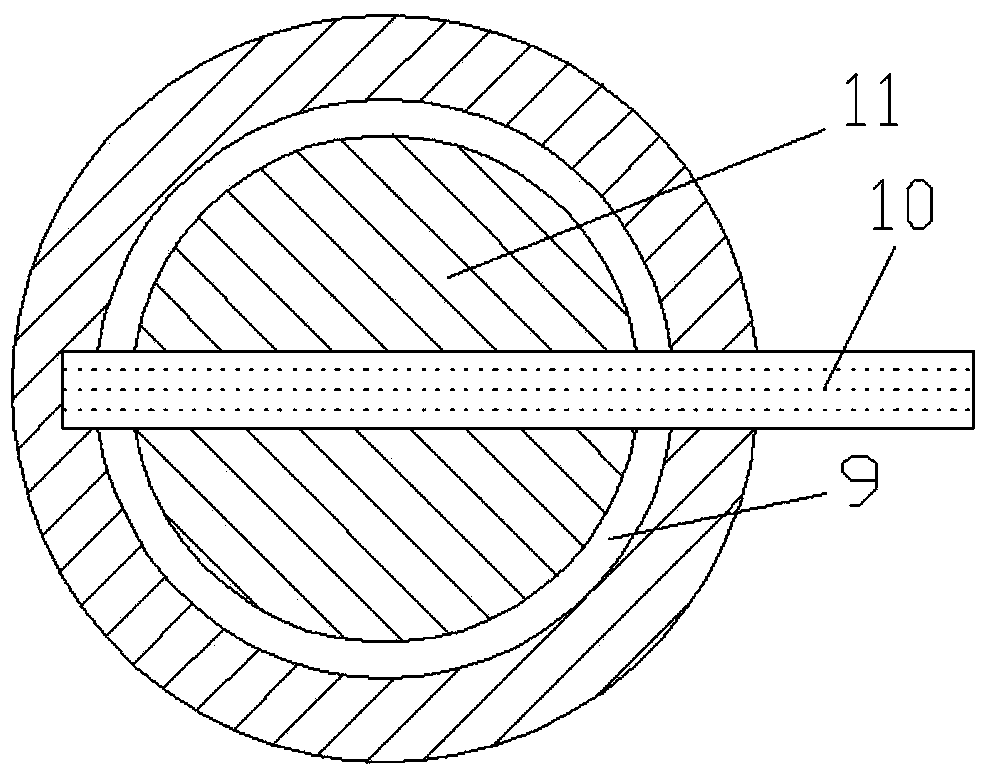

The invention relates to an exhaust recirculation system with an elastic component and belongs to the technical field of internal combustion engines. The exhaust recirculation system comprises a gas inlet pipe, an engine, an exhaust pipe, a connecting pipe, an volume cavity, a moving body and the elastic element, wherein the cross section of the volume cavity is in a rectangular shape, the moving body is arranged in the volume cavity and is in contact with the inner wall surface of the volume cavity in a sealed way, and the moving body is connected with the lower wall surface of the volume cavity through the elastic element. When the engine is in a high-speed work condition, the moving body upwards moves in the volume cavity, the exhaust recirculation rate is higher, the exhaust temperature is lower, and the integral performance of the engine is better. When the engine is in a low-speed work condition, the moving body downwards moves in the volume cavity, the exhaust regeneration rate is lower, the air intake is greater, and the integral performance of the engine is better. The exhaust recirculation system has the advantages that the design is reasonable, the structure is simple, and the exhaust recirculation system is applicable to the exhaust regeneration system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Self-adjusting exhaust gas recycling system

InactiveCN102588152AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentLow speed

The invention discloses a self-adjusting exhaust gas recycling system, belonging to the technical field of combustion engines. The self-adjusting exhaust gas recycling system comprises an air inlet pipe, an engine, an exhaust pipe, a compressor, a turbine, a connecting pipe, a volume chamber, a movable body and an elastic component, wherein the cross section of the volume chamber is of a rectangular shape; the movable body is arranged inside the volume chamber and is tightly contacted with the inner wall surface of the volume chamber; the movable body is connected with the upper wall surface of the volume chamber through the elastic component; when the engine is in a high-speed work condition, the movable body moves upwards in the volume chamber, the exhaust gas recycling rate is larger, the exhaust temperature is lower, and the overall performance of the engine is more excellent; when the engine is in a low-speed work condition, the movable body moves downwards in the volume chamber, the exhaust gas recycling rate is smaller, the air inlet quantity is larger, and the overall performance of the engine is more excellent. The self-adjusting exhaust gas recycling system is reasonable in design, simple in structure and suitable for the exhaust gas recycling system with a turbosupercharger.

Owner:SHANGHAI JIAO TONG UNIV

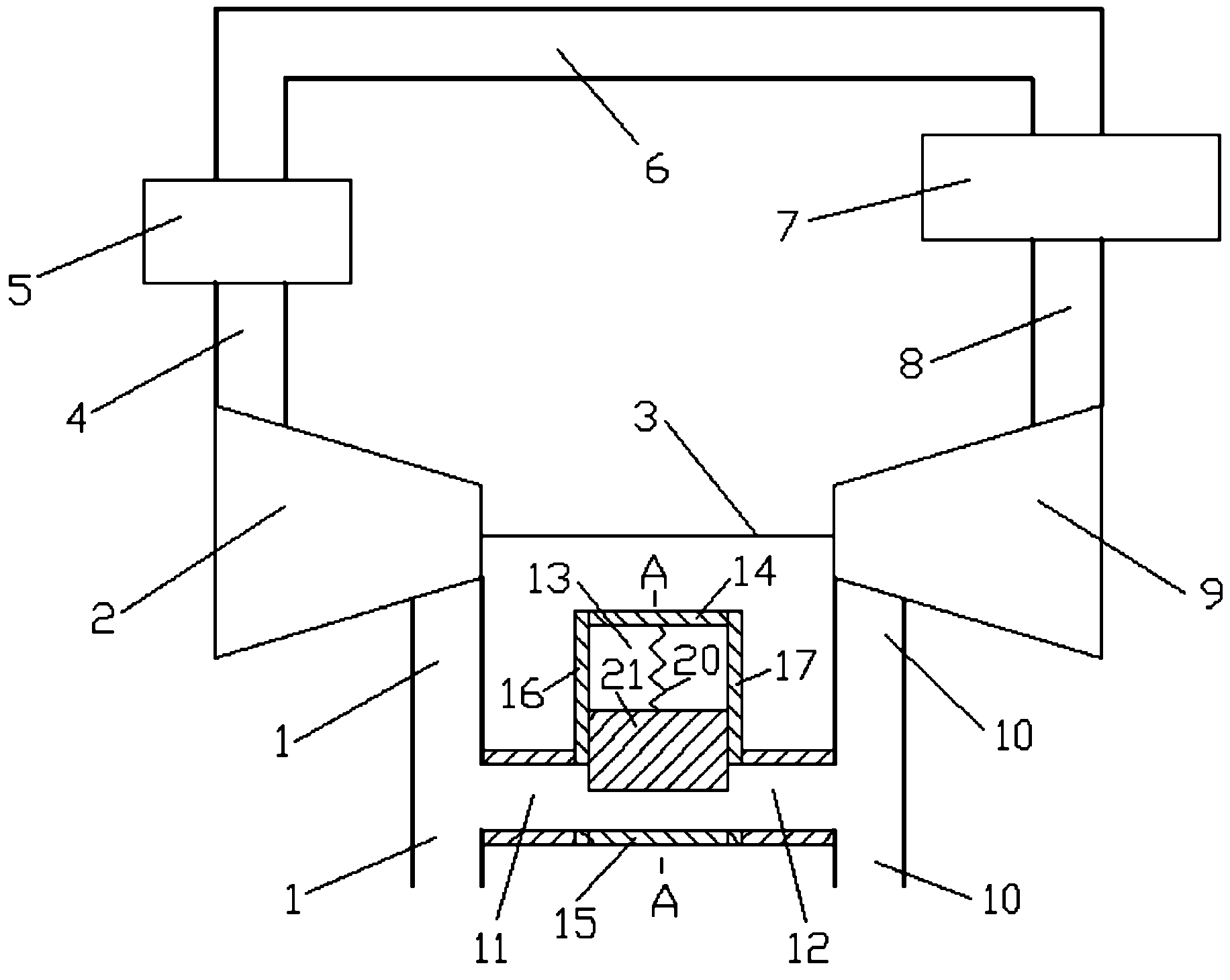

Exhaust recirculating system controlled by exhaust pressure

InactiveCN102562281ATaking into account the medium and high speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentTurbocharger

An exhaust recirculating system controlled by exhaust pressure belongs to the technical field of internal combustion engines and comprises a gas inlet pipe, an engine, an exhaust pipe, a gas compressor, a turbine, a connecting pipe, a cavity, a movable part and an elastic component. A third connecting pipe is mounted between a main exhaust pipe and the upper wall surface of the cavity, the cross section of the cavity is rectangular, and the movable part mounted in the cavity hermetically contacts with the inner wall surface of the cavity and is connected with the lower wall surface of the cavity through the elastic component. When the engine is in a medium-speed running state, the movable part moves upwards in the cavity, the exhaust recirculating rate is higher, exhaust temperature is lower, and the integral performance of the engine is excellent. When the engine is in a high-speed running state, the movable part moves downwards in the cavity, the exhaust recirculating rate is lower, the dynamic property of the engine is better, and the integral performance of the engine is excellent. The exhaust recirculating system controlled by exhaust pressure is reasonable in design and simple in structure and applicable to exhaust recirculating systems with turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Exhaust recirculating system controlled by intake pressure

InactiveCN102562370ATaking into account the medium and high speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesElastic componentTurbocharger

An exhaust recirculating system controlled by intake pressure belongs to the technical field of internal combustion engines and comprises a gas inlet pipe, an engine, an exhaust pipe, a gas compressor, a turbine, a connecting pipe, a cavity, a movable part and an elastic component. A third connecting pipe is mounted between a main exhaust pipe and the upper wall surface of the cavity, the cross section of the cavity is rectangular, and the movable part mounted in the cavity hermetically contacts with the inner wall surface of the cavity and is connected with the upper wall surface of the cavity through the elastic component. When the engine is in a medium-speed running state, the movable part moves upwards in the cavity, the exhaust recirculating rate is higher, exhaust temperature is lower, and the integral performance of the engine is excellent. When the engine is in a high-speed running state, the movable part moves downwards in the cavity, the exhaust recirculating rate is lower, the dynamic property of the engine is better, and the integral performance of the engine is excellent. The exhaust recirculating system controlled by intake pressure is reasonable in design and simple in structure and applicable to exhaust recirculating systems with turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Differential-pressure type gas valve lift adjusting mechanism

InactiveCN103527324ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentDifferential pressure

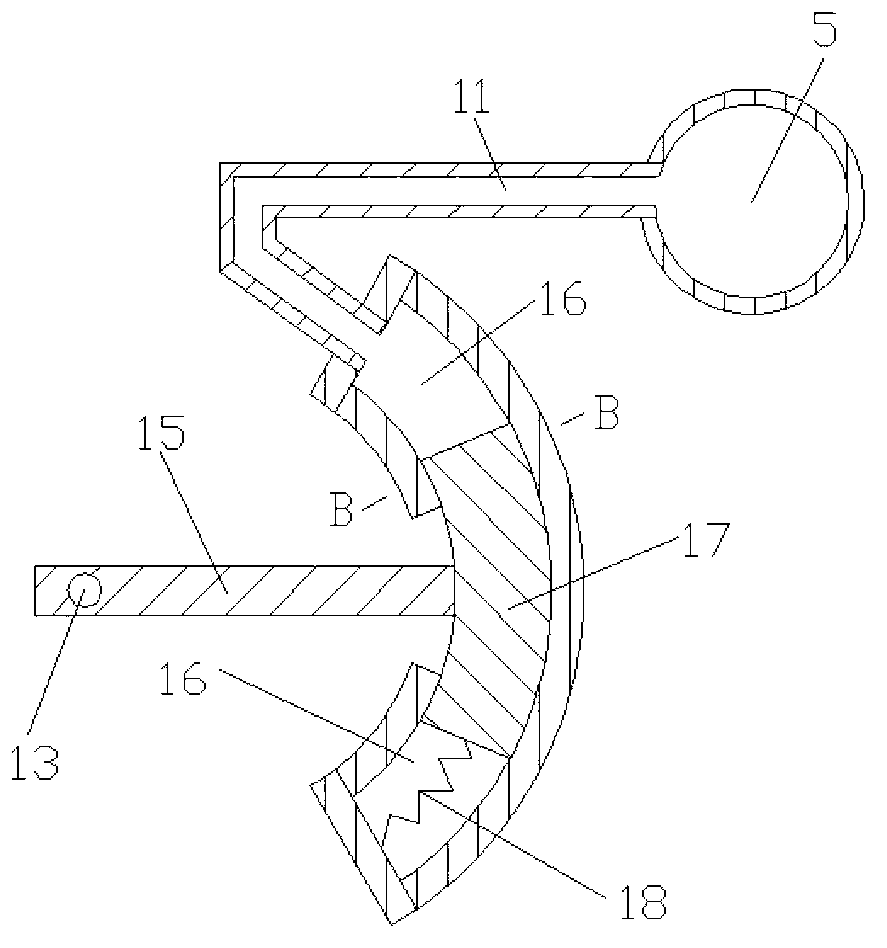

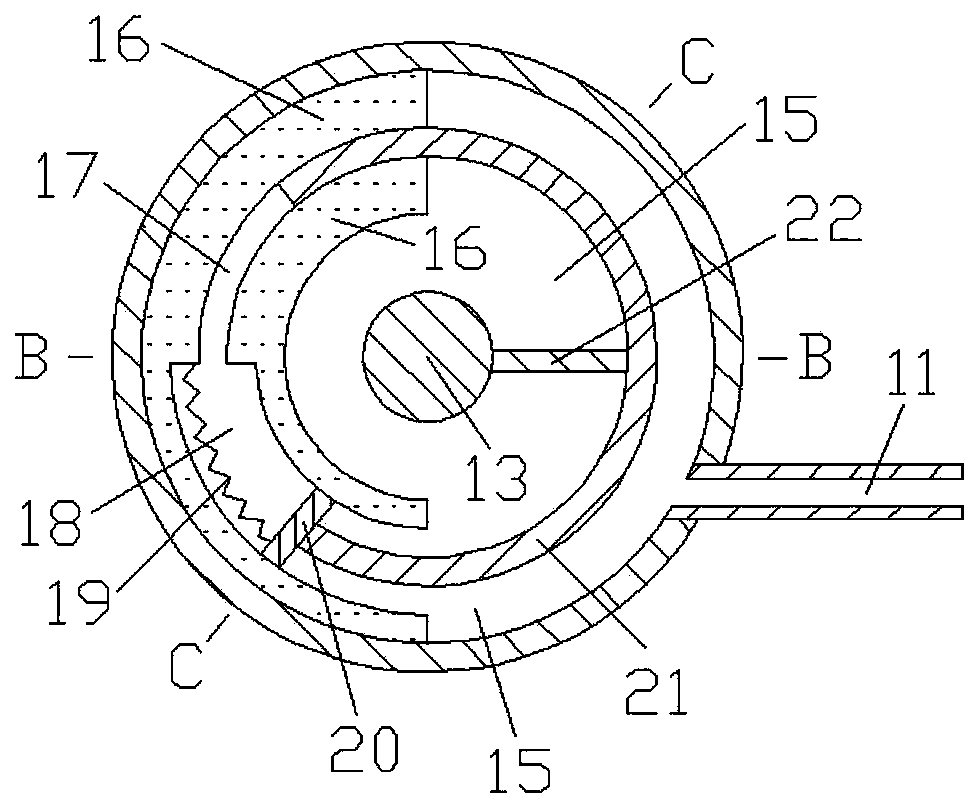

The invention provides a differential-pressure type gas valve lift adjusting mechanism and belongs to the technical field of mechanical design. The differential-pressure type gas valve lift adjusting mechanism comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, a containing cavity, a fixed body, penetrating pipes, an elastic component, a separating board, a rotary body and a connecting board. One end of the rotary body extends into the first penetrating pipe and makes sealing contact with the wall face of the first penetrating pipe, the other end of the rotary body is fixedly connected with the separating board, one end of the third connecting pipe is communicated with an engine gas inlet pipe, and the other end of the third connecting pipe penetrates through the outer wall face of the containing cavity and then is communicated with the containing cavity. When the pressure of the engine gas inlet pipe is high, the valve body is driven by the rotary body to rotate in the clockwise direction, the exhaust gas recirculation rate of the engine is high, and the detonation pressure of the engine is low; when the pressure of the engine gas inlet pipe is low, the valve body is driven by the rotary body to rotate in the anticlockwise direction, the exhaust gas recirculation rate of the engine is low, and the fuel consumption of the engine is low. The differential-pressure type gas valve lift adjusting mechanism is reasonable in design, simple in structure and suitable for an exhaust gas recirculation system of a supercharged engine.

Owner:刘飞

Pneumatic type rotary body rotary device

InactiveCN104675534ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelGas compressorExhaust gas recirculation

The invention discloses a pneumatic type rotary body rotary device in the technical field of mechanical design. The pneumatic type rotary body rotary device comprises a gas compressor, an engine, a turbine, a connecting tube, a valve base, a valve body, a rotary shaft, an accommodating chamber, a fixed tube, a penetrating tube, an elastic part, a partition plate, a rotary body and a connecting plate, wherein one end of the rotary body extends into the first penetrating tube and is in sealing contact with the wall surface of the first penetrating tube; the other end of the rotary body is fixedly connected with the partition plate; one end of the second connecting tube is communicated with a gas inlet tube of the engine; the other end of the second connecting tube is communicated with the accommodating chamber. When the pressure of the gas inlet tube of the engine is relatively high, the rotary body drives a butterfly valve to clockwise rotate, so that the larger the gas-exhausting and re-circulating efficiency of the engine, the lower detonation pressure of the engine; when the pressure of the gas inlet tube of the engine is relatively low, the rotary body drives the butterfly valve to anticlockwise rotate, so that the smaller gas-exhausting and re-circulating efficiency of the engine, the lower the oil consumption of the engine. The pneumatic type rotary body rotary device is reasonable in design, simple in structure and suitable for a gas-exhausting and re-circulating system of a booster engine.

Owner:李华雷

Rotary distance adjustment system for valve body and valve seat

InactiveCN103527325AExhaust gas recirculation rate increasedLow burst pressureNon-fuel substance addition to fuelInternal combustion piston enginesExhaust gas recirculationTurbine

The invention belongs to the technical field of machine design, and provides a rotary distance adjustment system for a valve body and a valve seat. The rotary distance adjustment system comprises a compressor, an engine, a turbine, connecting pipes, the valve seat, the valve body, a rotating shaft, a volume cavity, a fixed body, penetrating pipes, a flexible component, a partition plate, a rotating body and a connecting plate, wherein one end of the rotating body stretches into the first penetrating pipe and makes sealing contact with the wall surface of the first penetrating pipe, the other end of the rotating body is fixedly combined with the partition plate together, one end of the third connecting pipe is communicated with an engine exhaust pipe, and the other end of the third connecting pipe is communicated with the volume cavity after penetrating through the outer wall surface of the volume cavity. When the pressure of the engine exhaust pipe is quite high, the rotating body drives the valve body to rotate clockwise, the exhaust recirculation rate of the engine is quite high, and the detonation pressure of the engine is quite low; when the pressure of the engine exhaust pipe is quite low, the rotating body drives the valve body to rotate counterclockwise, the exhaust recirculation rate of the engine is quite low, and the fuel consumption of the engine is quite low. The rotary distance adjustment system for the valve body and the valve seat is reasonable in design, simple in structure, and applicable to an exhaust recirculation system of a supercharged engine.

Owner:刘飞

Flow control system with area-adjustable throat part

InactiveCN103573477ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesControl systemEngineering

A flow control system with area-adjustable throat part in the technical field of mechanical design comprises a compressor, a motor, a turbine, a connecting pipe, a valve holder, a valve body, a rotary shaft, a volume cavity, a rotary body and an elastic part; the rotary body is mounted in the volume cavity and is hermetically connected with the inner wall surface of the volume cavity; the right wall surface of a partition plate is connected with the rotary body by the elastic part; two ends of a first connecting pipe are respectively communicated with a turbine exhausting pipe and the gas inlet of a volume chamber; two ends of a third connecting pipe are respectively communicated with the gas inlet pipe of the motor and the volume cavity at the left side of the partition plate; when the gas inlet pipe of the motor has higher pressure, the rotary body drives the valve body to rotate clockwise, the exhausting recirculation rate of the motor is larger, and the blasting pressure of the motor is lower; when the gas inlet pipe of the motor has lower pressure, the rotary body drives the valve body to rotate counterclockwise, the motor is smaller in exhausting recirculation rate and lower in oil consumption. The flow control system with the area-adjustable throat part is reasonable in design, simpler in structure, and suitable for the exhausting recirculation systems of boosting motors.

Owner:SHANGHAI JIAO TONG UNIV

Intake pressure regulating type valve rotating mechanism

InactiveCN103670812ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelDetonationGas compressor

Disclosed is an intake pressure regulating type valve rotating mechanism in the technical field of mechanical design. The intake pressure regulating type valve rotating mechanism comprises a gas compressor, an engine, a turbine, connecting pipes, a volume cavity, an elastic part and a rotator. The rotator is connected with the left wall surface of a fixing plate through the elastic part, two ends of a first connecting pipe are communicated with a gas compressor intake pipe and a turbine exhaust pipe respectively, one end of a second connecting pipe is communicated with an engine intake pipe, and the other end of the second connecting pipe is communicated with the volume cavity. When the engine intake pipe is high in pressure, the rotator drives a butterfly valve to rotate clockwise, exhaust gas recirculation rate of the engine is high, and detonation pressure of the engine is low; when the engine intake pipe is low in pressure, the rotator drives the butterfly valve to rotate anticlockwise, exhaust gas recirculation rate of the engine is low, and oil consumption of the engine is low. The intake pressure regulating type valve rotating mechanism is reasonable in design, simple in structure and applicable to an exhaust gas recirculation system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

Pressure control type mechanical rotating mechanism

InactiveCN103573432ATaking into account low and medium speed conditionsReasonable designEngine controllersMachines/enginesDetonationGas compressor

A pressure control type mechanical rotating mechanism in the technical field of mechanical design comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, a volume cavity, a rotating body, and an elastic part, wherein the rotating body is arranged in the volume cavity and is in sealing contact with the inner wall surface of the volume cavity, the left wall surface of a partition plate is connected with the rotating body by the elastic part, two ends of a first connecting pipe are respectively communicated with the air inlet of the volume cavity and an engine exhaust pipe, and two ends of a third connecting pipe are respectively communicated with an engine admission pipe and the volume cavity at the right side of the partition plate. When the pressure of the engine admission pipe is higher, the valve body is driven by the rotating body to rotate clockwise, the exhaust recycling rate of the engine is relatively large, and the detonation pressure of the engine is less; when the pressure of the engine admission pipe is lower, the valve body is driven by the rotating body to rotate anticlockwise, the exhaust recycling rate of the engine is relatively small, and the oil consumption of the engine is less. The system is reasonable in design, simple in structure and suitable for the exhaust recycling system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

High-pressure stage loop device using exhaust gas as gas source

InactiveCN102767438ATaking into account the speed conditionReasonable designInternal combustion piston enginesEngine operationsLow speedElastic component

The invention relates to a high-pressure stage loop device using an exhaust gas as a gas source in the technical field of internal combustion engines. The high-pressure stage loop device comprises a gas inlet pipe, an engine, an exhaust pipe, a gas compressor, a turbine, a connecting pipe, a capacity cavity, a moving body and an elastic component, wherein the connecting pipe is communicated with the wall surface of the capacity cavity; the moving body is arranged in the capacity cavity and is in sealed contact with the inner wall surface of the capacity cavity; a through pipe penetrates through the left wall surface and the right wall surface of the moving body; and two ends of the elastic component are respectively connected with the upper wall surface of the moving body and the upper wall surface of the capacity cavity. When the engine is under a medium-low speed working condition, the moving body moves downwards in the capacity cavity, the exhaust recycling rate is large, the exhaust temperature of each cylinder of the engine is low, and the performance of the entire engine is excellent; and when the engine is under a high-speed working condition, the moving body moves upwards in the capacity cavity, the exhaust recycling rate is small, the dynamic property of the engine is good, and the performance of the entire engine is excellent. The high-pressure stage loop device is reasonable in design and simple in structure, and is suitable for an exhaust recycling system provided with a turbocharger.

Owner:SHANGHAI JIAO TONG UNIV

Coaxial connecting device for rotating body and valve

ActiveCN104675576ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringAir compressor

The invention provides a coaxial connecting device for a rotating body and a valve, and belongs to the technical field of mechanism design. The device comprises an air compressor, an engine, a turbine, a connecting pipe, a rotating shaft, a volume cavity, a fixing body, a through pipe, a separating plate, a rotating body and a connecting plate; one end of the rotating body extends into the first through pipe and is in sealing contact with the wall surface of the first through pipe, and while the other end of the rotating body is integrally fixedly connected with the separating plate; two ends of the first connecting pipe are respectively communicated with an air inlet pipe of the air compressor and an exhaust pipe of the turbine; in case of relatively high pressure difference between the previous period and the later period of the turbine, the rotating body drives a valve to clockwise rotate, the exhaust of the engine is high in recycling efficiency, and the detonation pressure of the engine is relatively low. The device is reasonable in design, simple in structure, and suitable for an exhaust gas recycling system of a supercharged engine.

Owner:浙江和夏科技股份有限公司

Rotary multi-pipeline connecting system

InactiveCN104653340ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesDifferential pressureEngineering

A rotary multi-pipeline connecting system belongs to the technical field of machinery design and comprises a compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, an accommodating cavity, a fixing body, through pipes, a separation plate, a rotation body and a connection plate. One end of the rotation body extends into a first through pipe and has a sealed contact with the wall surface of the first through pipe; the other end of the rotation body is fixedly connected with the separation plate; one end of a second connecting pipe is communicated with an air exhaust pipe of the engine; and the other end of the second connecting pipe passes through the fixing body to be communicated with the first through pipe. When large differential pressure between the back and front parts of the turbine exists, the rotating body drives a butterfly valve to clockwise rotate; large high pressure exhausting and recirculation efficiency of the engine is achieved. The rotary multi-pipeline connecting system is rationally designed, simply structured and suitable for exhaust recirculation system of the engine.

Owner:张琨

Pressure control type exhausting recycling control device

InactiveCN103485904ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesElastic componentDetonation

The invention relates to a pressure control type exhausting recycling control device in the technical field of mechanical design. The pressure control type exhausting recycling control device comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, a volume cavity, a fixed body, penetrating pipes, an elastic component, a partition board, a rotating body and a connecting plate, wherein one end of the rotating body stretches into a first through pipe and is in seal contact with the wall surface of the first through pipe, the other end of the rotating body is fixedly connected with the partition board together, one end of a third connecting pipe is communicated with an air inlet pipe of the engine, and the other end of the third connecting pipe is communicated with the volume cavity after penetrating through the outer wall surface of the volume cavity. When the pressure of the air inlet pipe of the engine is higher, the rotating body drives the valve body to rotate clockwise, the exhausting recycling rate of the engine is higher, and the detonation pressure of the engine is lower; when the pressure of the air inlet pipe of the engine is lower, the rotating body drives the valve body to rotate anticlockwise, the exhausting recycling rate of the engine is lower, and the oil consumption of the engine is lower. The pressure control type exhausting recycling control device is reasonable in design and simple in structure and is suitable for exhausting recycling systems of supercharged engines.

Owner:刘飞

Mechanical valve body lift control system

InactiveCN103557097ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesControl systemExhaust gas recirculation

The invention relates to a mechanical valve body lift control system and belongs to the technical field of machine design. The mechanical valve body lift control system comprises a compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotary shaft, a volume cavity, a rotating body and an elastic part. The rotating body is mounted in the volume cavity and in seal contact with the inner wall face of the volume cavity. The left wall face of a partition is connected with the rotating body through the elastic part. The two ends of the first connecting pipe are respectively communicated with a volume cavity air inlet and a turbine exhaust pipe. The two ends of the third connecting pipe are respectively communicated with an engine exhaust pipe and the volume cavity on the right of the partition. When the pressure of an engine air inlet pipe is high, the rotating body drives the valve body to rotate clockwise, exhaust recycling rate of the engine is high, and engine detonation pressure is low; when the pressure of the engine air inlet pipe is low, the rotating body drives the valve body to rotate anticlockwise, the exhaust recycling rate of the engine is low, and oil consumption of the engine is low. The mechanical valve body lift control system is reasonable in design, simple in structure and suitable for the exhaust recycling system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

Controllable gas path device with elastic mechanism

InactiveCN104675577AExhaust gas recirculation rate increasedLow burst pressureInternal combustion piston enginesNon-fuel substance addition to fuelGas compressorEngineering

The invention discloses a controllable gas path device with an elastic mechanism and relates to the field of a mechanical design technology. The controllable gas path device comprises a gas compressor, an engine, a turbine, connecting pipes, a valve base, a valve body, a rotating shaft, a volume chamber, a fixing body, penetration pipes, an elastic assembly, a baffle, a rotating body and a connecting plate; one end of the rotating body stretches into a first penetration pipe and forms sealing contact with the wall surface of the first penetration pipe, the other end of the rotating body is fixed together with the baffle, one end of a second connecting pipe is connected with the exhaust pipe of the engine, and the other end of the second connecting pipe is connected with the volume chamber. When the air inlet pipe of the engine is relatively high in pressure, a butterfly valve is driven to rotate clockwise by the rotating body, so that the air exhaust recirculation rate of the engine is relatively great and the detonation pressure of the engine is relatively lower; when the air inlet pipe of the engine is relatively low in pressure, the butterfly valve is driven to rotate anticlockwise by the rotating body, so that the air exhaust recirculation rate of the engine is relatively low and the fuel consumption of the engine is also relatively lower. The gas path device is reasonable in design and simple in structure, thus the gas path device is applied to the air exhaust recirculation system of a supercharged engine.

Owner:汪文辉

Adjustable low-pressure exhaust circulating system with rotating mechanism

InactiveCN103670813ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentGas compressor

The invention discloses an adjustable low-pressure exhaust circulating system with a rotating mechanism, and belongs to the technical field of mechanical designs. The adjustable low-pressure exhaust circulating system comprises a gas compressor, an engine, a turbine, connecting tubes, a volume cavity, an elastic component and a rotator. The rotator is connected with the right wall surface of a fixing plate by the elastic component, two ends of the first connecting tube are respectively communicated with a gas inlet tube of the gas compressor and an exhaust tube of the turbine, one end of the second connecting tube is communicated with a gas inlet tube of the engine, and the other end of the second connecting tube is communicated with the volume cavity. When the pressure of the gas inlet tube of the engine is high, the rotator drives a butterfly valve to rotate clockwise, so that an exhaust recycling ratio of the engine is high, and the explosive pressure of the engine is low; when the pressure of the gas inlet tube of the engine is low, the rotator drives the butterfly valve to rotate anticlockwise, so that the exhaust recycling ratio of the engine and oil consumption of the engine are low. The adjustable low-pressure exhaust circulating system has the advantages of reasonable design, simple structure and applicability to exhaust recycling systems of supercharged engines.

Owner:SHANGHAI JIAO TONG UNIV

Exhaust-gas recirculating system with volume cavity

InactiveCN102536523AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelLow speedEngineering

The invention relates to an exhaust-gas recirculating system with a volume cavity in the technical field of internal-combustion engines, which comprises an air-inlet pipe, an engine, an exhaust pipe, a connecting pipe, the volume cavity, a moving body and an elastic part, wherein the cross section of the volume cavity is rectangular, the moving body is installed in the volume cavity and is hermetically contacted with the inner wall surface of the volume cavity, and the moving body is connected with the upper wall surface of the volume cavity through the elastic part. When the engine is under a high-speed working condition, the moving body upwards moves in the volume cavity, the exhaust-gas recirculating rate is larger, the exhaust temperature is lower, and the overall performance of the engine is more excellent; and when the engine is under a low-speed working condition, the moving body downwards moves in the volume cavity, the exhaust-gas recirculating rate is smaller, the air-inlet quantity is larger, and the overall performance of the engine is more excellent. The exhaust-gas recirculating system has a reasonable design and a simple structure and is applicable to the exhaust-gas recirculating system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Pneumatic device with air exhaust as air source

InactiveCN104653346ATaking into account low and medium speed conditionsReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesElastic componentEngineering

A pneumatic device with air exhaust as air source belongs to the technical field of machinery design and comprises a compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, an accommodating cavity, a fixing body, through pipes, an elastic component, a separation plate, a rotation body and a connection plate. One end of the rotation body extends into a first through pipe and has a sealed contact with the wall surface of the first through pipe; the other end of the rotation body is fixedly connected with the separation plate; one end of a third connecting pipe is communicated with an exhaust pipe of the engine; and the other end of the third connecting pipe is communicated with the accommodating cavity. When the exhaust pipe of the engine possesses high pressure, the rotating body drives valve body to clockwise rotate; large exhausting and recirculation efficiency of the engine is achieved; low engine detonation pressure is acquired; when the exhaust pipe of the engine possesses low pressure, the rotating body drives valve body to counterclockwise rotate; low exhausting and recirculation efficiency of the engine is achieved; and low engine oil consumption is acquired. The pneumatic device with air exhaust as the air source is rationally designed, simply structured and suitable for exhaust recirculation system of the engine.

Owner:胡志龙

Pneumatic device with air inflow as air source

InactiveCN104653349ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelElastic componentEngineering

A pneumatic device with air inflow as an air source belongs to the technical field of machinery design and comprises a compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, an accommodating cavity, a fixing body, through pipes, an elastic component, a separation plate, a rotation body and a connection plate. One end of the rotation body extends into a first through pipe and has a sealed contact with the wall surface of the first through pipe; the other end of the rotation body is fixedly connected with the separation plate; one end of a third connecting pipe is communicated with an air inlet pipe of the engine; and the other end of the third connecting pipe passes through the fixing body to be communicated with the first through pipe. When an air inlet pipe of the engine possesses high pressure, the rotating body drives valve body to clockwise rotate; large recirculation efficiency of the engine is achieved; low engine detonation pressure is acquired; when the air inlet pipe of the engine possesses low pressure, the rotating body drives valve body to counterclockwise rotate; low recirculation efficiency of the engine is achieved; and low engine oil consumption is acquired. The pneumatic device with air inflow as the air source is rationally designed, simply structured and suitable for exhaust recirculation system of the engine.

Owner:胡志龙

Interleaving pressure control system

InactiveCN104675537ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelGas compressorControl system

The invention provides an interleaving pressure control system in the technical field of mechanical design. The interleaving pressure control system comprises a gas compressor, an engine, a turbine, a connecting pipe, a valve seat, a valve body, a rotating shaft, a receiving chamber, a stator, a penetrating pipe, a separator, a rotator and a connecting plate; one end of the rotator extends into the first penetrating pipe and is in sealing contact with the wall of the first penetrating pipe, while the other end of the rotator is fixedly connected with the separator; one end of the second connecting pipe is communicated with the intake pipe of the engine, while the other end of the second connecting pipe is communicated with the first penetrating pipe after penetrating through the stator. When the front and back pressure difference of the gas compressor is relatively high, the rotator drives a butterfly valve to rotate clockwise, and the exhaust gas recirculation rate of the engine is relatively high, while the detonation pressure of the engine is relatively low. The interleaving pressure control system is reasonable in design, simple in structure, and suitable for the exhaust gas recirculation system of a supercharged engine.

Owner:李华雷

Exhaust-controlled valve auto-rotating system

InactiveCN104675579ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

The invention relates to the technical field of mechanical design, in particular to an exhaust-controlled valve auto-rotating system comprising a compressor, an engine, a turbine, a connecting pipe, a rotating shaft, a volumetric cavity, a fixture, penetrating pipes, an elastic part, a partition, a rotor and a connecting plate. One end of the rotor penetrates the first penetrating pipe and is in hermetic contact with the wall of the first penetrating pipe; the other end of the rotor is connected with the partition; two ends of the first connecting pipe are communicated with a compressor intake pipe and a turbine exhaust pipe, respectively. When pressure of an engine exhaust pipe is high, the rotor drives a valve block to rotate clockwise, exhaust gas recirculation rate of the engine is high, and explosion pressure of the engine is low; when the pressure of the engine exhaust pipe is low, the rotor drives the valve block to rotate anticlockwise, exhaust gas recirculation rate of the engine is low, and oil consumption of the engine is low. The exhaust-controlled valve auto-rotating system is reasonable in design and simple in structure and is suitable for an exhaust gas recycling system of a booster engine.

Owner:汪文辉

Gas path system with drawing mechanism

InactiveCN104675578AExhaust gas recirculation rate increasedLow burst pressureNon-fuel substance addition to fuelInternal combustion piston enginesGas compressorEngineering

The invention discloses a gas path system with a drawing mechanism and relates to the field of a mechanical design technology. The gas path system comprises a gas compressor, an engine, a turbine, connecting pipes, a valve base, a valve body, a volume chamber, a fixing body, penetration pipes, an elastic assembly, a baffle, a rotating body, a connecting plate and a fixing plate; one end of the rotating body stretches into a first penetration pipe and forms sealing contact with the wall surface of the first penetration pipe, the other end of the rotating body is fixed together with the baffle, one end of a second connecting pipe is connected with the exhaust pipe of the engine, and the other end of the second connecting pipe is connected with the volume chamber. When the exhaust pipe of the engine is relatively high in pressure, a butterfly valve is driven to rotate clockwise by the rotating body, so that the air exhaust recirculation rate of the engine is relatively great and the detonation pressure of the engine is relatively lower; when the exhaust pipe of the engine is relatively low in pressure, the butterfly valve is driven to rotate anticlockwise by the rotating body, so that the air exhaust recirculation rate of the engine is relatively low and the fuel consumption of the engine is also relatively lower. The gas path system is reasonable in design and simple in structure, thus the gas path system is applied to the air exhaust recirculation system of a supercharged engine.

Owner:汪文辉

Pneumatic adjusting mechanism with penetrating pipes

InactiveCN103541836ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesNon-fuel substance addition to fuelGas compressorEngineering

A pneumatic adjusting mechanism with penetrating pipes belongs to the technical field of machine design and comprises a gas compressor, an engine, a turbine, connecting pipes, a valve seat, a valve body, a rotating shaft, a volumetric cavity, a fixed member, the penetrating pipes, an elastic part, a partition, a rotor, and a connecting plate. One end of the rotor extends into the first penetrating pipe and in hermetic contact with the wall of the first penetrating pipe. The other end of the rotor is fixed to the partition. One end of the third connecting pipe is communicated with an engine exhaust pipe. The other end of the third connecting pipe penetrates the fixed member and is communicated with the first penetrating pipe. When the engine exhaust pipe bears high pressure, the rotor drives the valve body to rotate clockwise; the engine is high in exhaust recirculation rate and low in blasting pressure; when the engine exhaust pipe bears low pressure, the rotor drives the valve body to rotate anticlockwise; the engine is low in exhaust recirculation rate and low in oil consumption. The pneumatic adjusting mechanism with penetrating pipes is reasonable in design, simple in structure and applicable to exhaust recirculation systems in supercharged engines.

Owner:刘洪涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com