A Rocket-Based Combined Cyclic Ejection Modal Performance Experimental Engine

A technology of ejection mode and engine, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of large investment, long test period, large and complex system, etc., and achieve high specific impulse performance and convenient maintenance , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

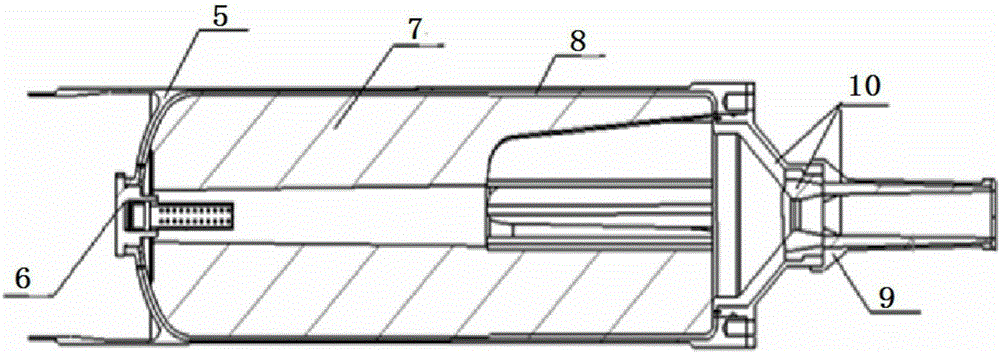

[0020] This embodiment is a rocket-based combined cyclic ejection modal performance experimental engine.

[0021] The combustion chamber of the main rocket adopts the combined charge form of a heptagonal star cast on the wall and an inner circular hole. The purpose of adjusting the gas flow of the main rocket is achieved by changing the combustion surface of the charge. The gas flow is relatively large at the initial moment, and the thrust is relatively large. The rear gas flow is reduced to ensure that the engine has high specific impulse performance. After the charge is ignited and burned, the gas flow rate of the main rocket remains basically unchanged, and the secondary combustion chamber has a fixed geometric configuration of expansion and equirectangularity, which can be used to verify the ejection modal performance of the rocket-based combined cycle engine with the change of flight Mach number and altitude purpose of the law.

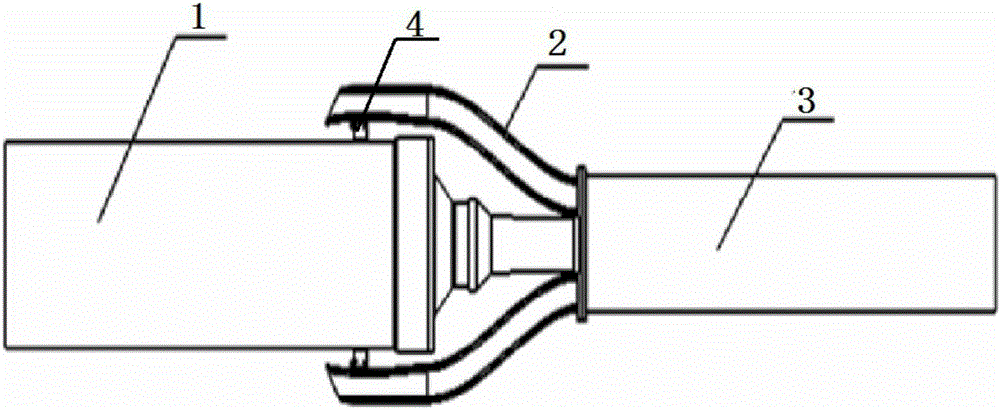

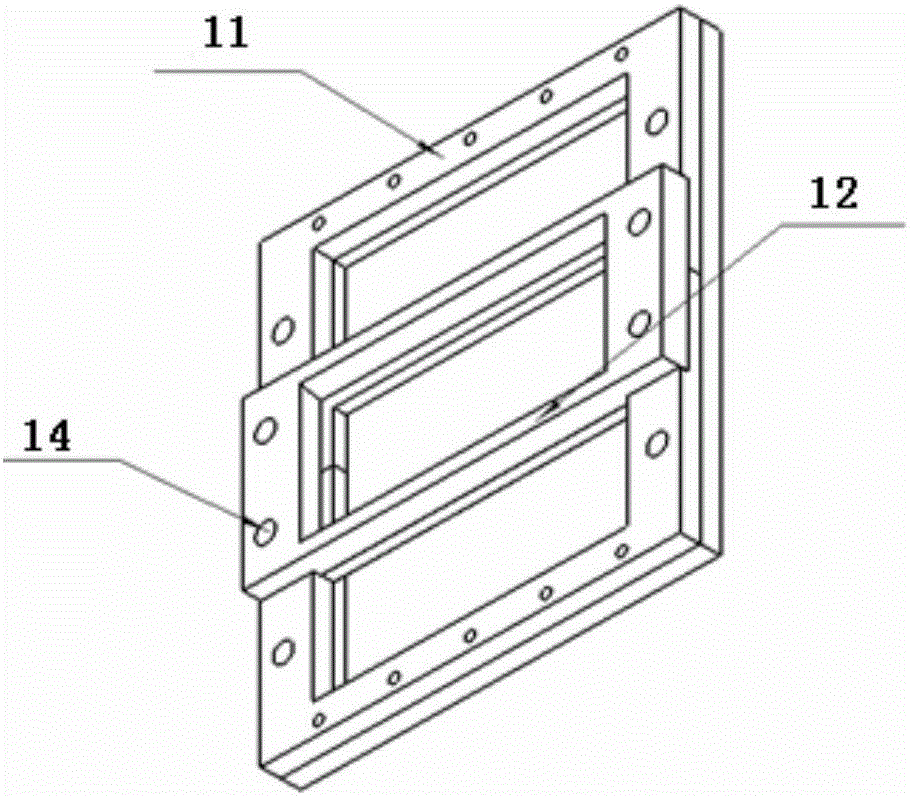

[0022] refer to figure 1 , figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com