Nozzleless rocket motor stepped combustion chamber and inner wall thereof

A combustion chamber and engine technology, which is applied to machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of weakened gas acceleration effect, small specific impulse, and small pressure gradient, so as to improve the gas acceleration effect and increase the ratio. Impulse performance, improve the effect of specific impulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

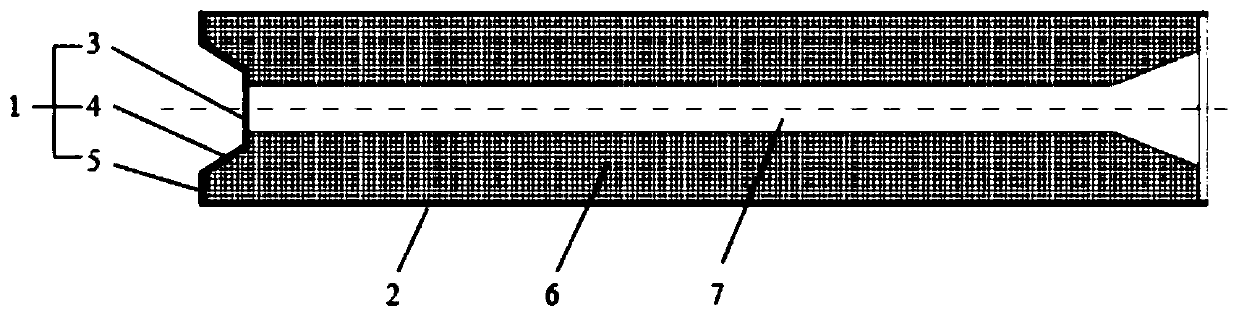

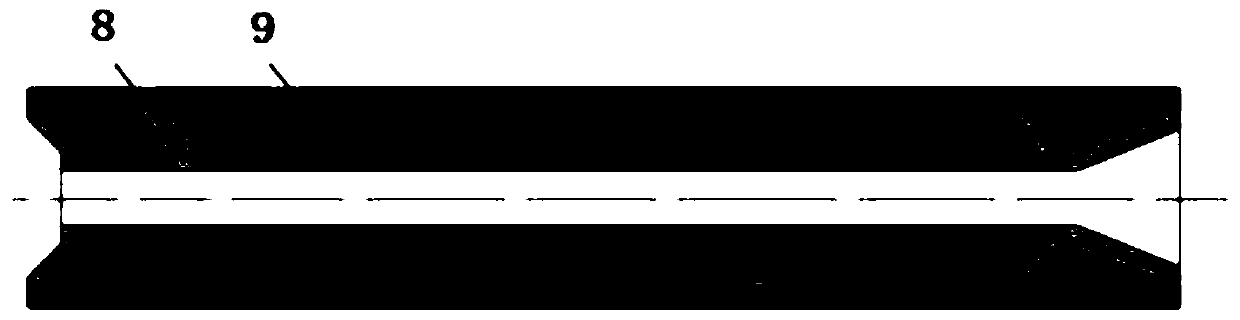

[0021] to combine figure 1 , a stepped combustion inner wall of a nozzleless engine, including a head radial wall surface 1 and an axial wall surface 2;

[0022] The head radial wall surface 1 is composed of an initial step wall surface 3, a transition wall surface 4 and a pressure-stabilizing step wall surface 5, and the initial step wall surface 3 and the pressure-stabilizing step wall surface 5 are the same plane and are perpendicular to the engine axis; the transition The wall surface 4 has a certain slope, and connects the initial stepped wall surface 3 and the voltage stabilizing stepped wall surface 5 as a whole.

[0023] The axial wall surface 2 is closely combined with the radial wall surface 1 of the head to jointly form the inner wall of the combustion chamber.

[0024] The axial distance between the initial stepped wall surface 3 and the tail of the engine is short, and the axial distance between the pressure stabilizing stepped wall surface 5 and the tail of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com