Composite mechanism full flow circulation supersonic velocity propulsion system and working method thereof

A technology of propulsion system and supersonic speed, which is applied to space vehicle propulsion system devices, combustion methods, charging systems, etc. It can solve the problems of increased fuel consumption, increased weight of combined engines, complex structure, etc., and achieves high specific impulse performance and economical efficiency. The effect on fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

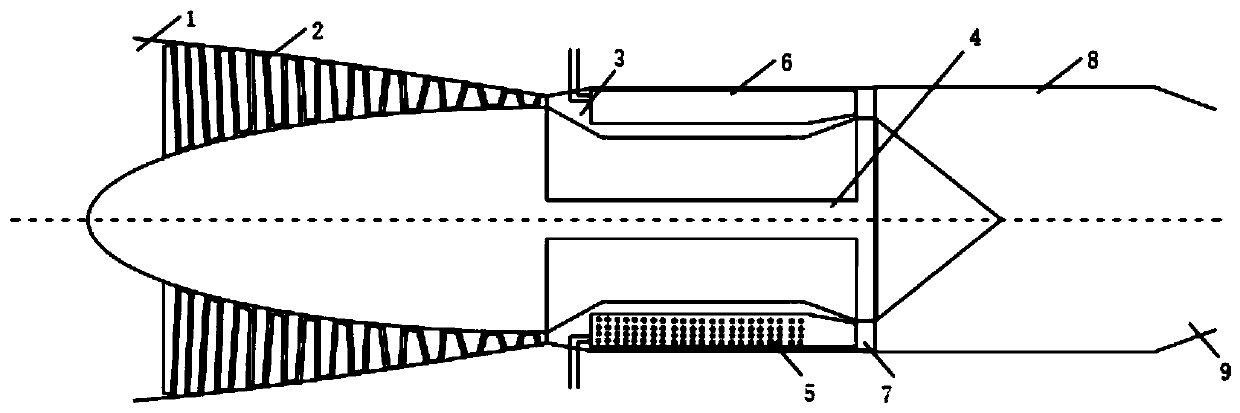

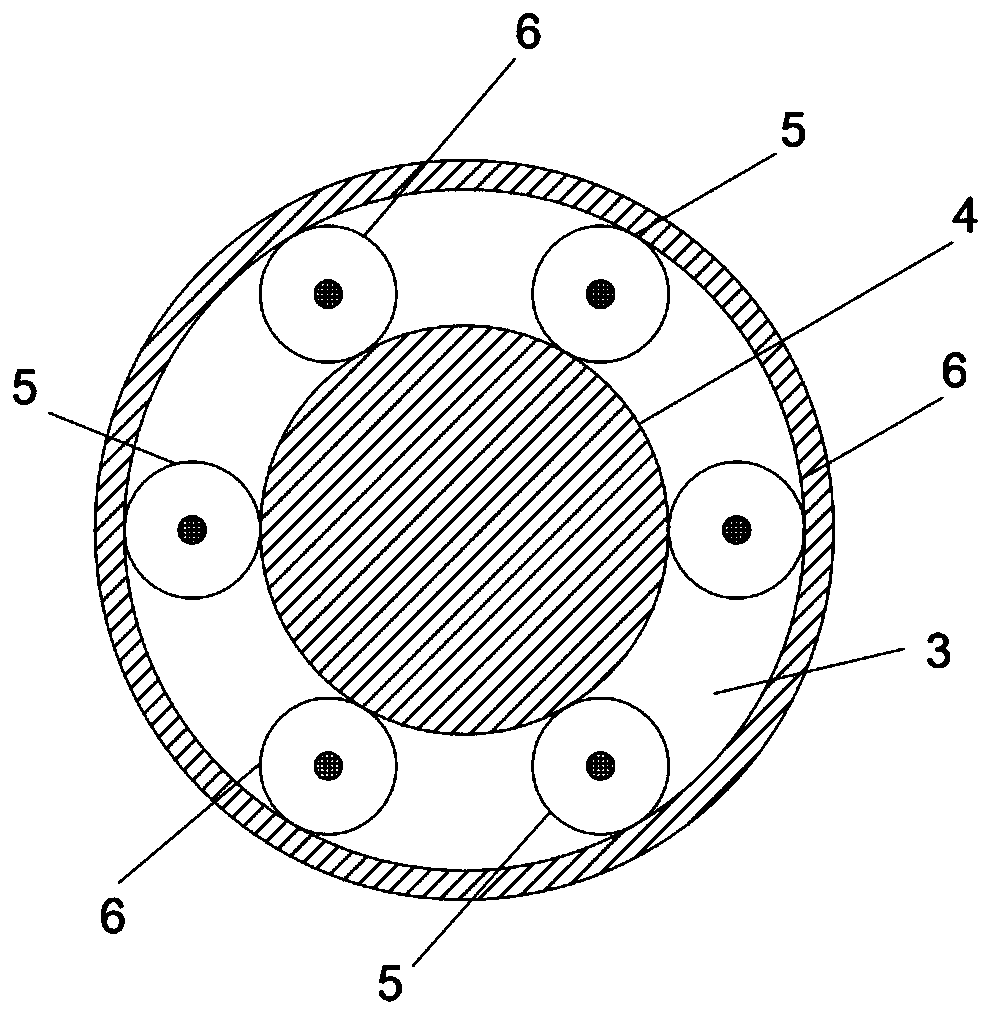

[0029] refer to figure 1 , the present invention proposes a composite mechanism full-flow cycle supersonic propulsion system, the system includes an inlet 1, a compressor 2, a diffuser duct 3, a shaft 4, an open pre-combustion driver 5, and a closed pre-combustion driver 6 , turbine 7, afterburning thruster 8, tail nozzle 9. The air inlet 1, the compressor 2, the shaft 4, the turbine 7, the afterburning thruster 8, and the tail nozzle 9 are connected in sequence. The compressor 2 and the turbine 7 are connected through the shaft 4, and the gas generated by the open pre-combustion driver 5 and the closed pre-combustion driver 6 pushes the turbine 7 to drive the compressor 2 to perform work on the incoming air. The function of the compressor 2 is to inhale air from the atmospheric environment and pressurize it. This design is full-flow supplementary combustion, and all the air enters the supplementary combustion thruster 8 after passing through the diffuser duct 3 . The turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com