Motive sealing structure of variable-geometry combustor of rocket based combined cycle engine

A combustion chamber and engine technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of difficult realization, high cost, and high research cost, and achieve the effect of simple structure, convenient processing, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is a dynamic sealing structure of a variable geometry combustion chamber of a rocket-based combined cycle engine.

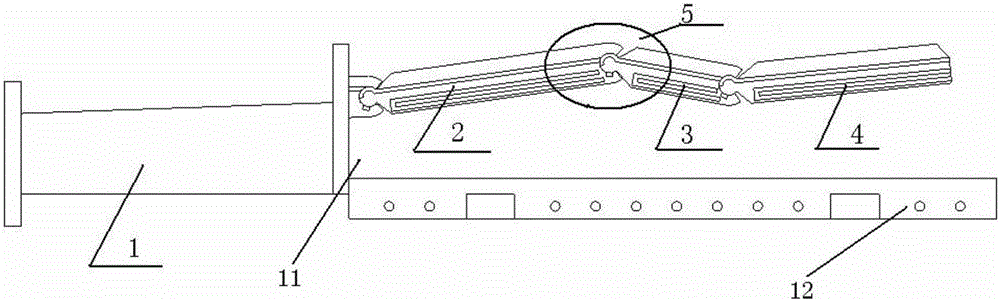

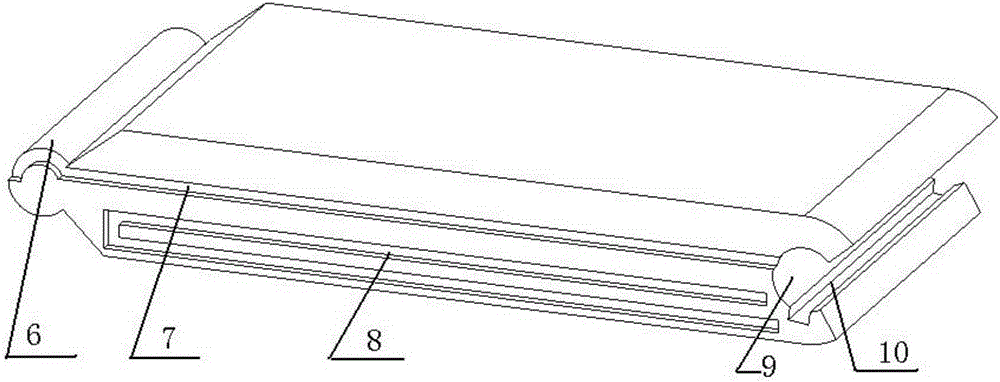

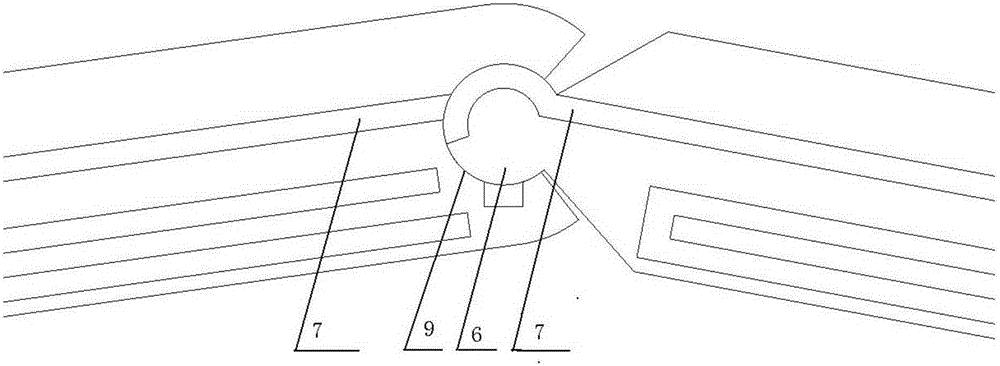

[0019] refer to Figure 1 ~ Figure 3 , The dynamic sealing structure of the variable geometry combustion chamber of the rocket-based combined cycle engine includes the rotary dynamic seal at the hinge joint and the translational dynamic seal between the upper top plate and the side plate.

[0020] Engine variable geometry combustion chamber dynamic sealing structure consists of combustion chamber fixed section 1, combustion chamber variable section 11, inner cavity bottom plate 12, first top plate 2, second top plate 3, third top plate 4, rotating shaft 6, and transverse groove 7 , labyrinth channel 8, arc groove 9, longitudinal groove 10 and side plates. The combustion chamber of the entire engine has a rectangular structure, and the fixed section 1 of the combustion chamber is installed on the front end of the variable section 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com