Structural design of the isolation section of the intake port of a rocket-based combined cycle engine

An intake port and isolation section technology is applied in the field of structural design of the intake port isolation section of a rocket-based combined cycle engine, which can solve problems such as poor achievability, improve overall performance, widen the working range, and increase the cross-sectional area of the effective flow area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is a structural design of the inlet isolation section of a rocket-based combined cycle engine.

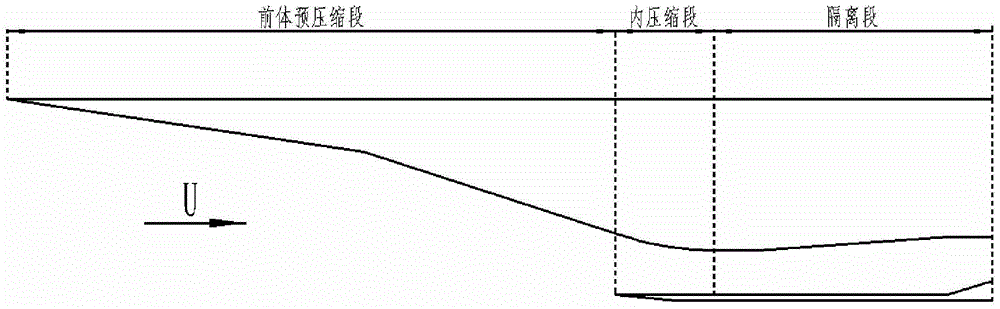

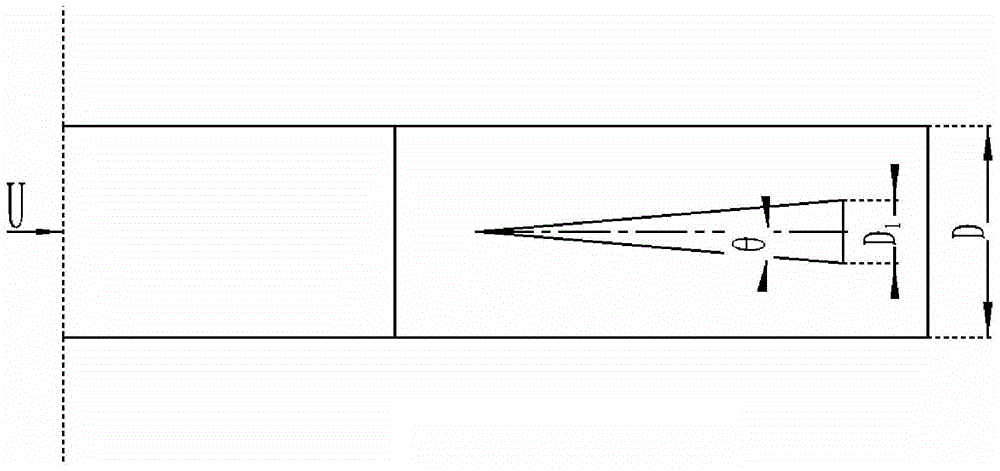

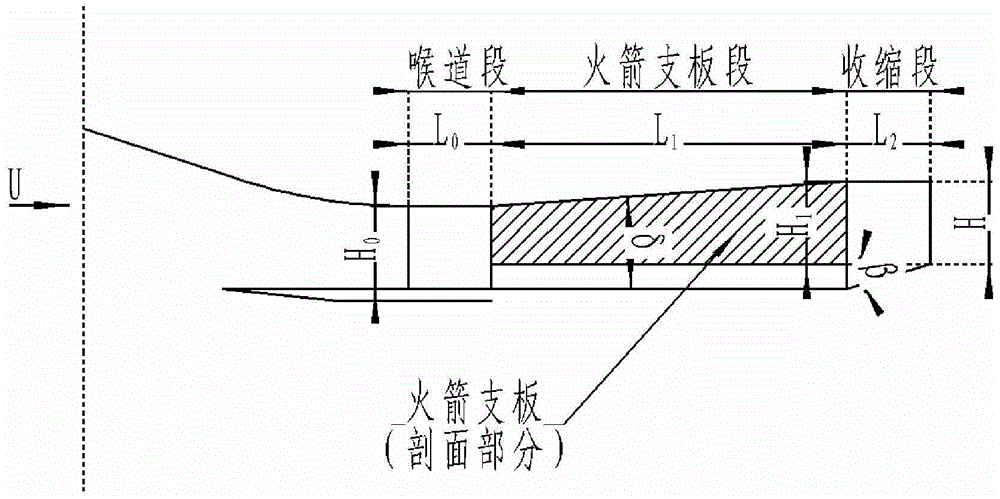

[0018] refer to Figure 1 ~ Figure 3 , the structural design of the inlet isolation section of the rocket-based combined cycle engine in this embodiment, under the constraint that the minimum cross-section of the inlet isolation section is located in the throat section, by improving the variation law of the effective flow domain cross-sectional area of the isolation section, an effective widening of the progress is obtained. The design scheme of the isolation section of the working range of the airway. The incoming flow direction is the direction indicated by U in the figure. The distant incoming flow flows into the isolation section after being compressed by the precursor pre-compression section and the internal compression section, and flows through the throat section, rocket strut plate section and Shrink segment. Among them, the throat section is an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com