Ma4-level supersonic speed axisymmetric air inlet channel and method based on adjustable drainage seams

An air inlet, supersonic technology, which is applied to the air inlet of the turbine/propulsion unit, jet propulsion unit, gas turbine unit, etc., can solve the problems of low Mach number non-starting and mismatch of air inlet/engine flow, etc. Achieve the effect of reducing Mach number, simplifying structure and improving starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

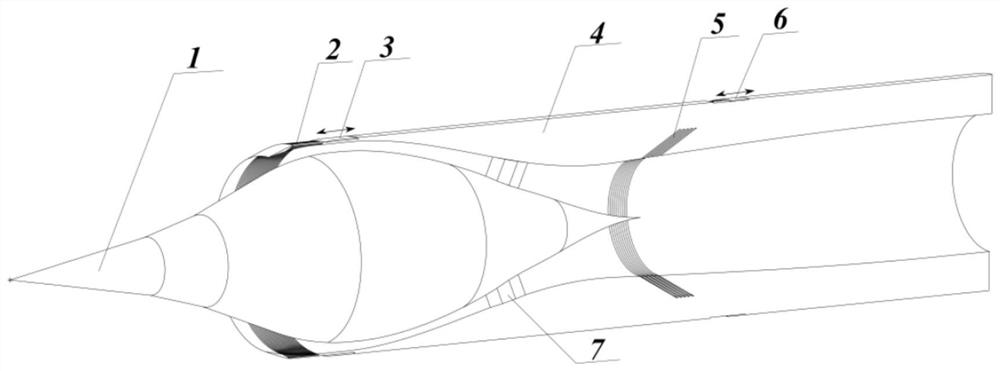

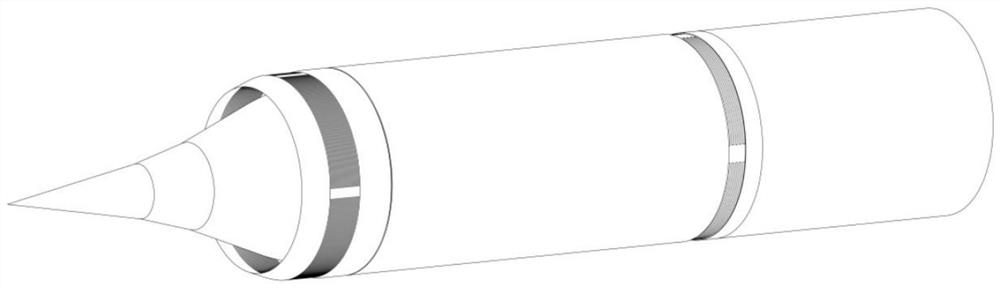

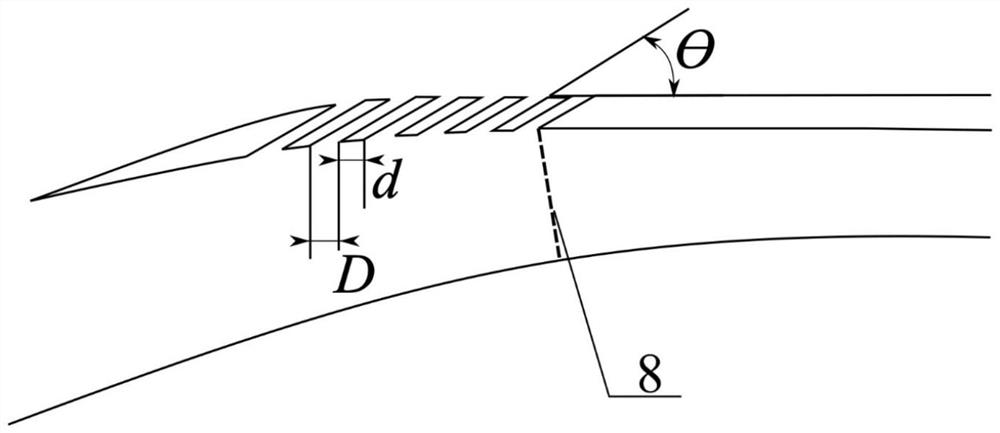

[0029] The present invention mainly aims at the start-up and flow matching problems of the fixed-geometry supersonic axisymmetric inlet in a wide speed range, and proposes a Ma0-4 supersonic axisymmetric inlet and a flow adjustment method based on the controllable switch of the discharge slot .

[0030] A turbine engine flow demand such as Figure 5 As shown by the middle dotted line, the lower triangular dotted line is the upper limit of the turbine engine flow, and the upper triangular dotted line is the lower limit of the turbine engine flow, that is, the flow demand is an interval. However, the captured flow of the intake port of the fixed geometry (without opening the slit) of the numerical simulation is greater than the engine flow demand, and the minimum starting Mach number Ma=3, there are problems of start-up and intake port / engine flow matching. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com