A rocket-based combined cycle engine variable geometry side pressure inlet

A technology of air inlet and engine, which is applied in the direction of machines/engines, mechanical equipment, jet propulsion devices, etc., to achieve the effect of improving performance, improving the total pressure recovery coefficient, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

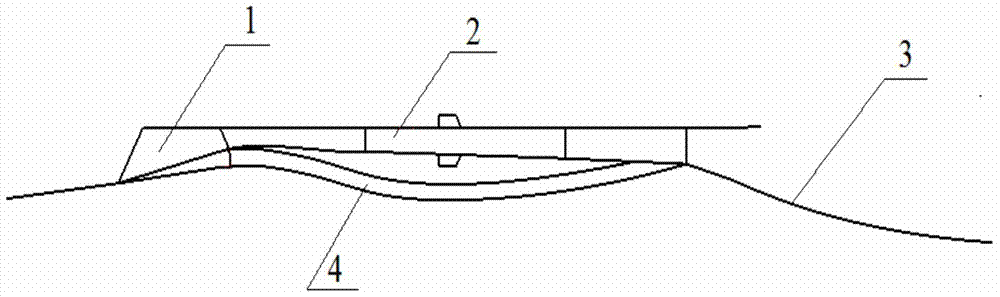

[0020] This embodiment is a rocket-based combined cycle engine variable geometry side pressure inlet.

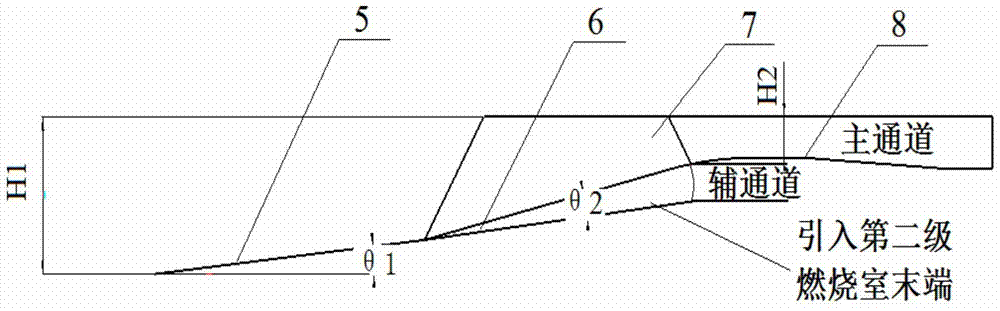

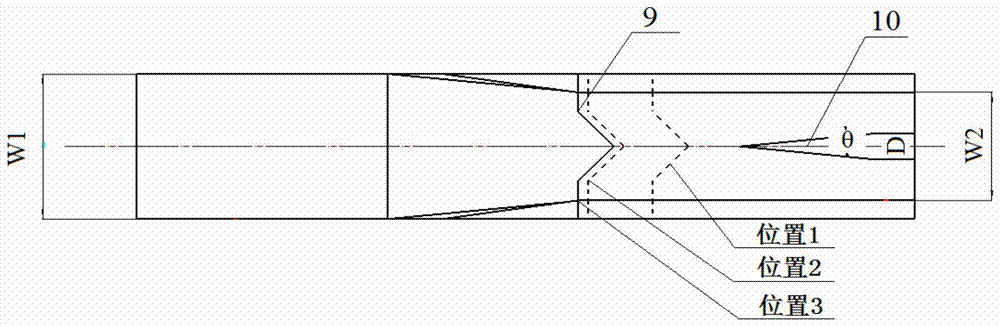

[0021] refer to Figure 1 to Figure 5 , the rocket-based combined cycle engine variable geometry side pressure inlet is composed of an air inlet 1, a combustion chamber 2, a tail nozzle 3, a draft pipe 4, a first top pressure plate 5, a second top pressure plate 6, a side plate 7, an isolation Section top plate 8, lip plate 9, and center support plate 10; the first top pressure plate 5, the second top pressure plate 6, and the isolation section top plate 8 are respectively installed at the bottom of the air inlet 1, and the isolation section top plate 8 is connected to the second top pressure plate At the rear end of 6, the draft pipe 4 is connected with the intake duct 1 to transition to the end of the combustion chamber 2, and the tail nozzle 3 is installed at the rear end of the combustion chamber 2. The lip plate 9 moves forward and backward along the side plate 7 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com