A rocket-based combined cycle engine variable structure tail nozzle

A tail nozzle and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as narrow application range and unfavorable attitude control, and achieve the effect of improving work performance and strong expansibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

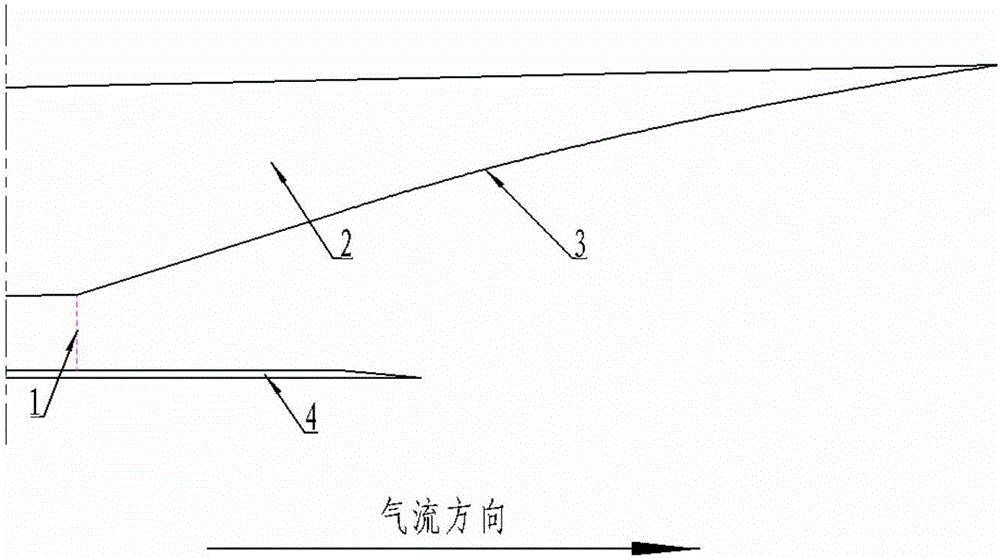

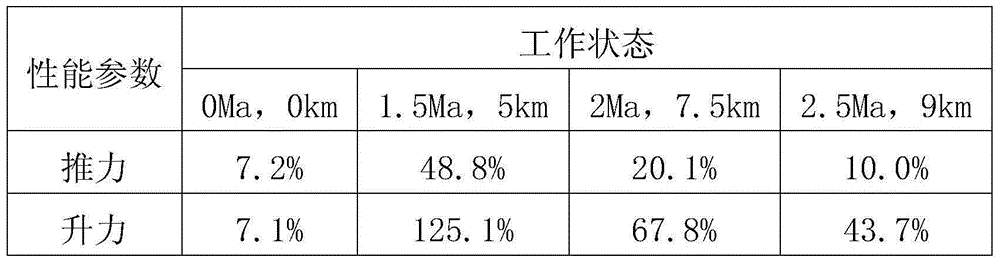

[0014] This embodiment is a variable structure tail nozzle of a rocket-based combined cycle engine. According to the characteristics that the flow field inside the nozzle of the rocket-based combined cycle engine is in an over-expansion state and the pressure inside the nozzle is generally lower than the ambient pressure at the non-design point, an openable suction slot is set on the upper wall of the nozzle to improve the flow rate of the nozzle. Performance at non-design points while keeping the performance of the nozzle at the design point constant.

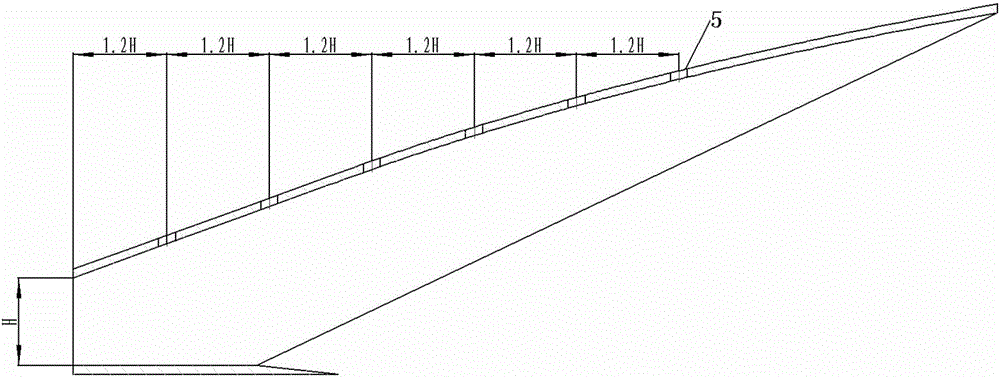

[0015] refer to figure 1 , figure 2 , the variable structure tail nozzle of the rocket-based combined cycle engine of the present invention comprises a tail nozzle inlet 1, an expansion edge 3 on the tail nozzle, an aircraft rear body 2, and a tail nozzle cover 4, wherein it also includes an upper cover plate and multiple A suction slot 5, the upper cover plate is located on the upper surface of the rear body 2 of the aircr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com