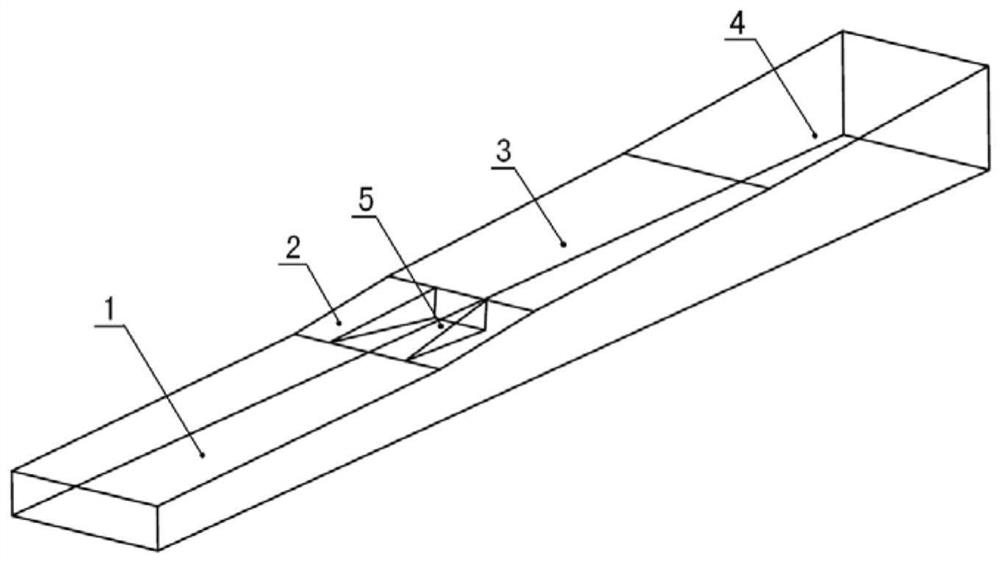

Combustion chamber of an rbcc engine with ramped rocket layout and its design method

A combustion chamber and slope-type technology, which is applied in the direction of combustion methods, combustion chambers, combustion equipment, etc., can solve the problem of unconstrained intake port type, so as to avoid the problem of starting multi-channel supersonic internal flow, and the combustion chamber channel is smooth and the channel smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

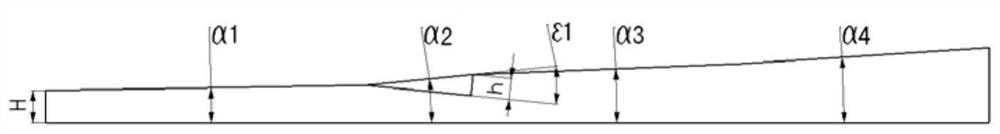

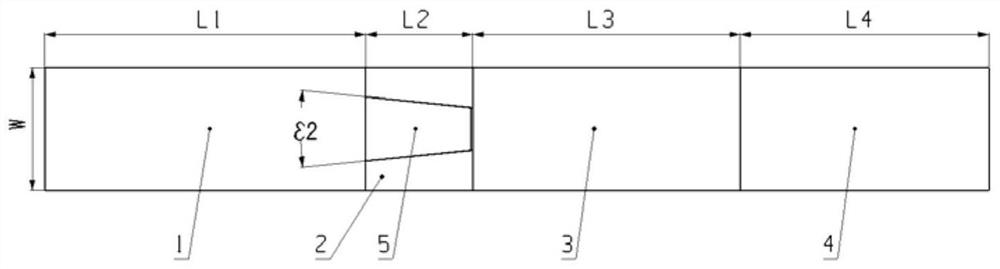

[0038] For RBCC combustion chambers in the Ma0-7 range:

[0039] (1) According to the design results of the air inlet, determine the combustion chamber inlet height H = 50mm, width W = 200mm;

[0040] (2) According to the entrance height H of the combustion chamber, the length of the isolation section is selected as L1 = 500mm; according to the calculation result of the boundary layer correction of the isolation section, the expansion angle of the isolation section is selected as α1 = 1.0°.

[0041] (3) According to the rocket thrust chamber size provided by the overall engine, determine the rocket installation slope length L2=200mm, compression angle ε1=11.4°, expansion angle ε2=11.4°;

[0042] (4) According to the length L2 of the rocket slope, the compression angle ε1, and the expansion angle ε2, the installation expansion angle α2 of the rocket slope is determined to be 5.7°;

[0043] (5) Determine the first-stage expansion section length L3=500mm, expansion angle α3=2.3 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com