Rocket-based combined cycle engine

An engine and rocket-based technology, applied in the field of combined cycle engines, can solve the problems of poor air ejection ability, non-starting of the intake port, and engine inoperability, etc., and achieve the effect of wide working range and wide range adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

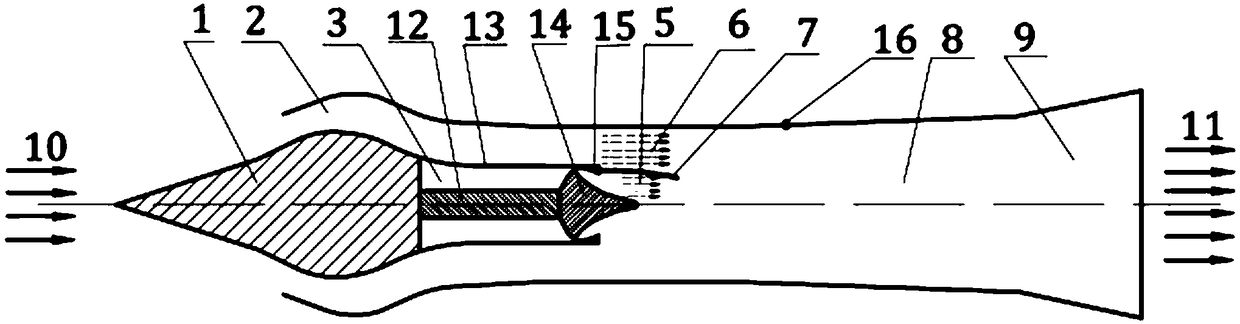

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

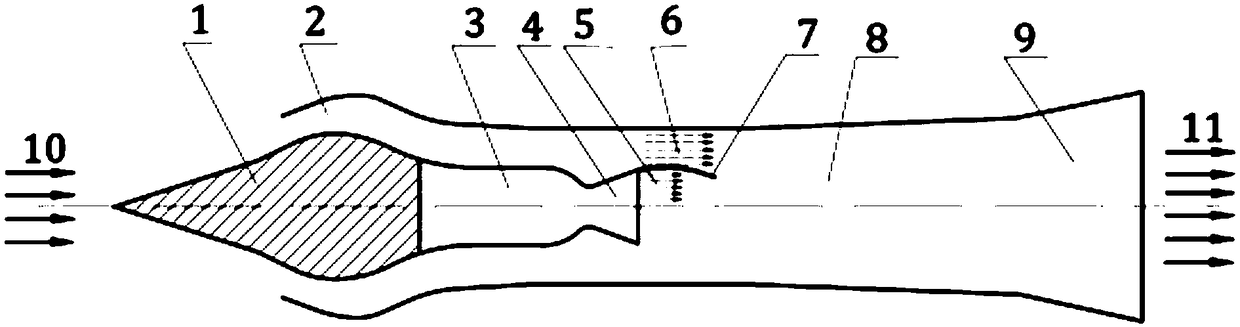

[0030] refer to figure 2 , The invention provides a rocket-based combined cycle engine, which is composed of a rocket engine and a scramjet; the rocket engine is composed of a central cone 1, a rocket combustion chamber 3 and a plug nozzle. The central cone 1, that is, the injector, can be designed according to the method introduced in "Zhu Ningchang, Rocket Engine Design, Aerospace Press, 1993". Rocket motor case ( figure 2 What is shown in is only the inner wall of the housing, the housing as a whole is not shown in the figure) in which an air inlet 2 and a super-combustion chamber 8 are arranged in sequence, and a central cone 1 is arranged in the air inlet 2, and the center A rocket combustion chamber 3 is connected to the end of the cone 1 . The rocket combustion chamber 3 includes a cylindrical casing 13 and a rocket combustion inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com