Vibratory heat exchanger unit for low temperature conversion for processing organic waste and process for processing organic waste using a vibratory heat exchanger unit for low temperature conversion

a heat exchanger unit and low temperature conversion technology, which is applied in indirect heat exchangers, combustible gas purification/modification, lighting and heating apparatus, etc., can solve the problems of large equipment capacity, high equipment cost, and significant destruction of compounds during conversion, so as to reduce the fouling effect and the adhesion of materials, increase the efficiency of heat exchange of the particle wall system, and promote the distribution of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

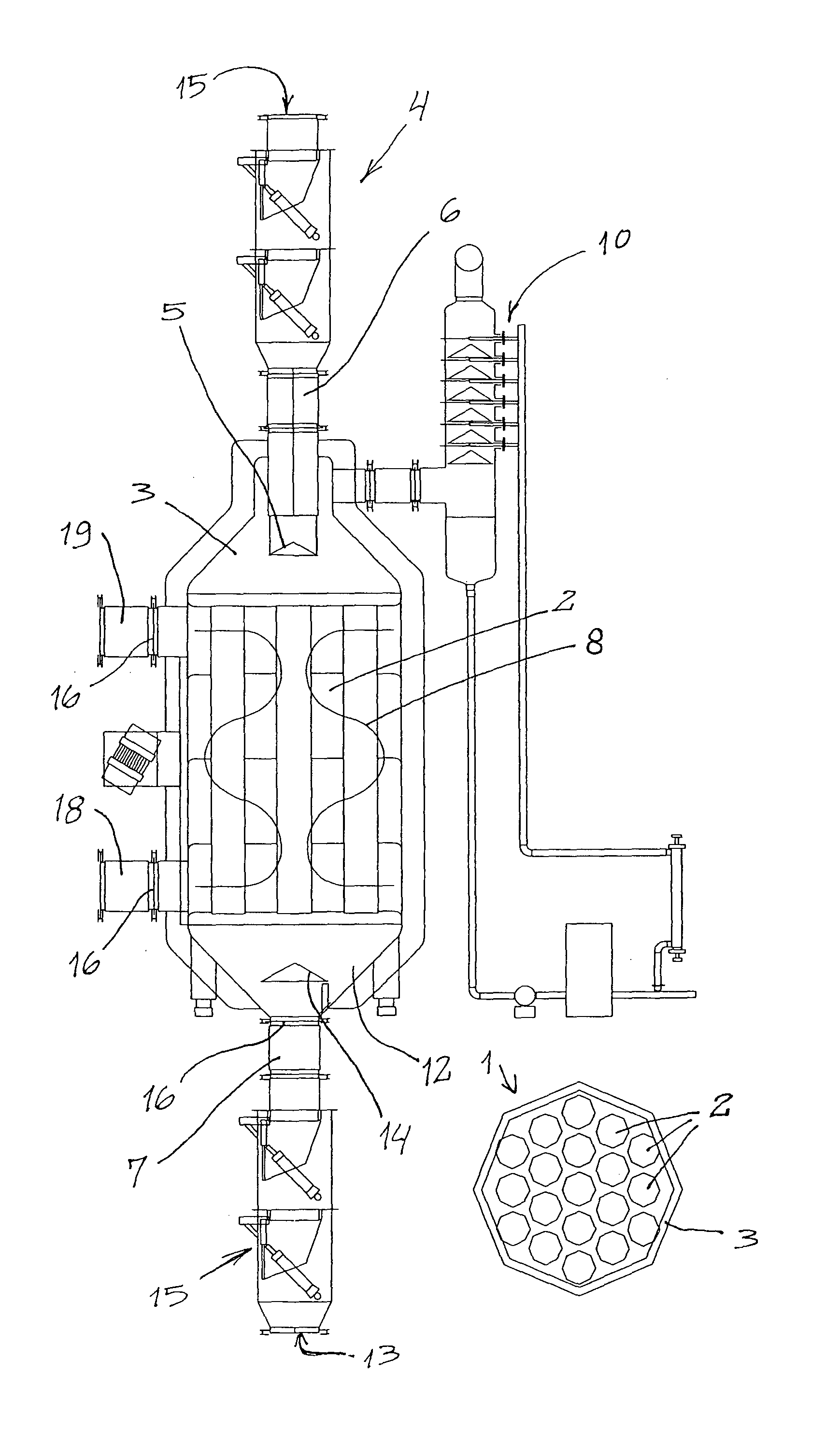

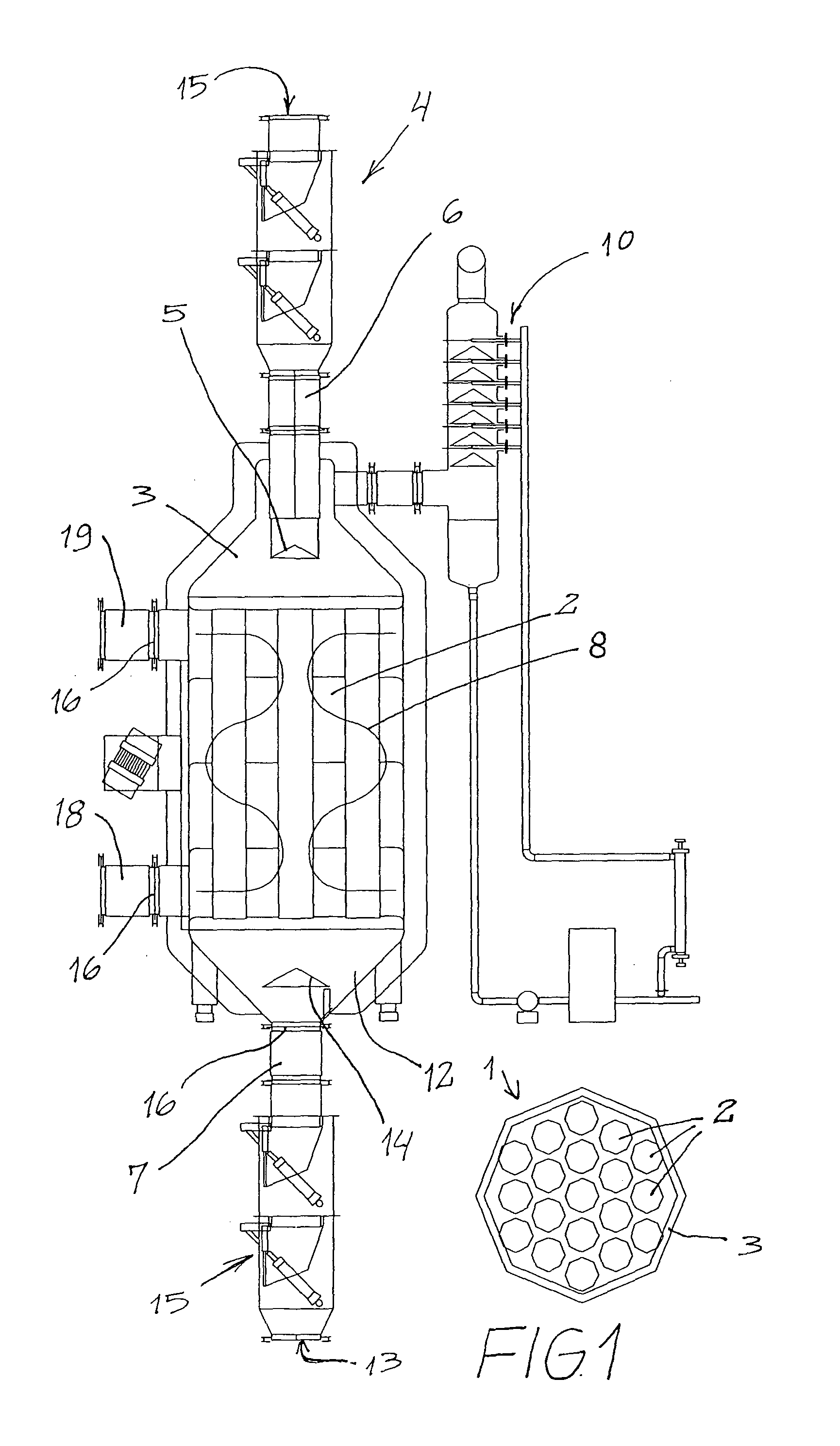

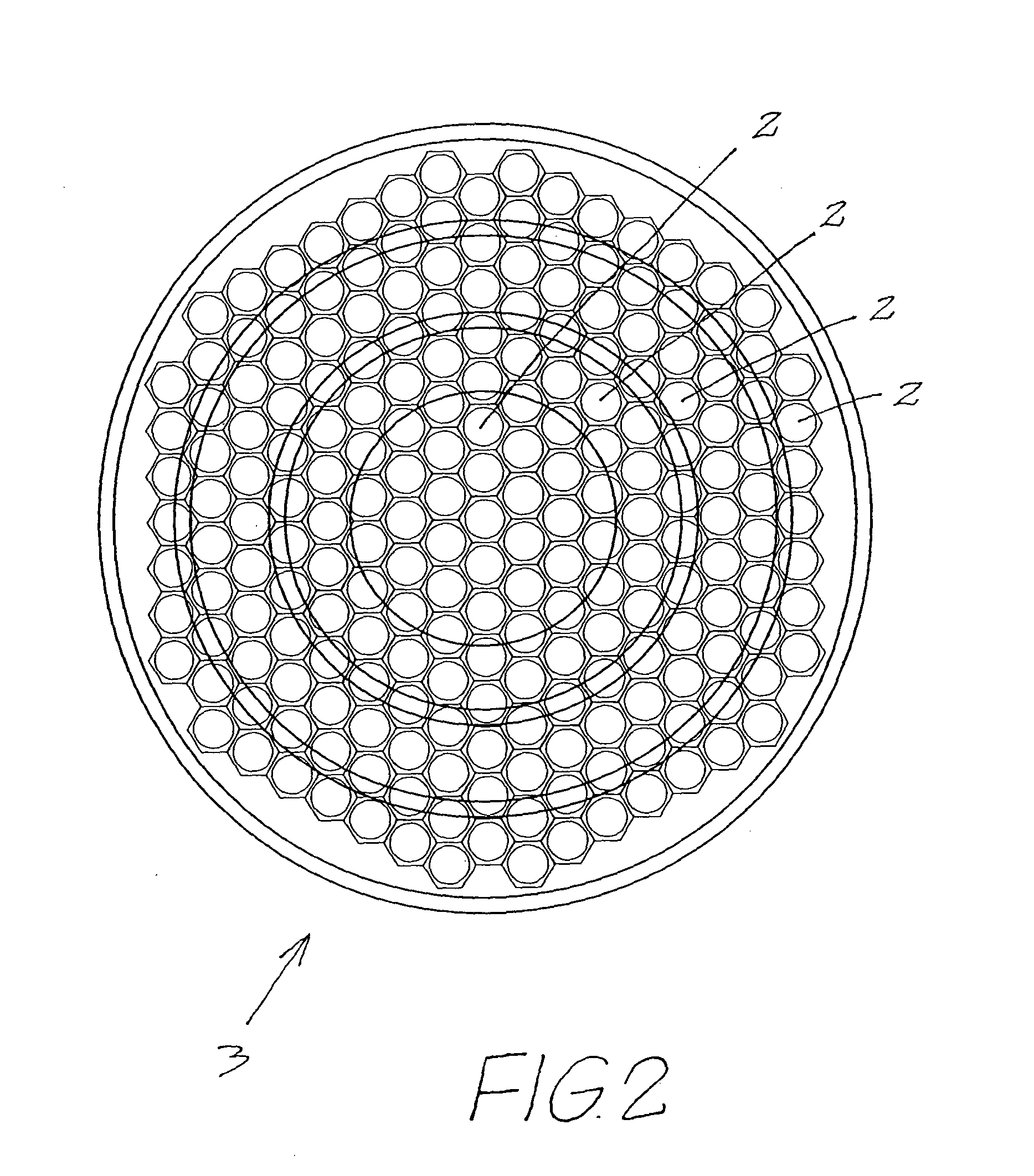

[0041]FIG. 1 shows a section of a first vibrating heat exchanger equipment 1 (19) with heating tubes. The material to be processed is unloaded via inlet valve for raw material (2) installed on the supply nozzle (4) located in the upper funnel (6) of the equipment (1), falling onto a distributor cone (5) which has the function to spread the material so that it has access to the internal space of all heating tubes (7). The material flows continuously from the inside of the tubes from top to bottom due to gravity. Naturally, when the reactor reaches the constant operating regime and is filled, the speed at which the material falls continuous withdrawal is dictated by the coal withdrawal via unload valve coal (17) installed in the unload nozzle (15) located below the funnel (33) of the equipment (1).

[0042]As the material goes down within the tube, it is gradually heated until it reaches the process temperature. The heating is performed indirectly by passing the hot combustion gas inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com