Integrated rocket ejector engine assembly and engine thereof

A technology for ejector rockets and engines, which is applied in the field of small-sized integrated ejector rocket engine components and their engines, can solve the problems of no module installation, poor mixing, and no consideration of the influence of air flow, so as to reduce the impact, The effect of improving the ejection ability and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

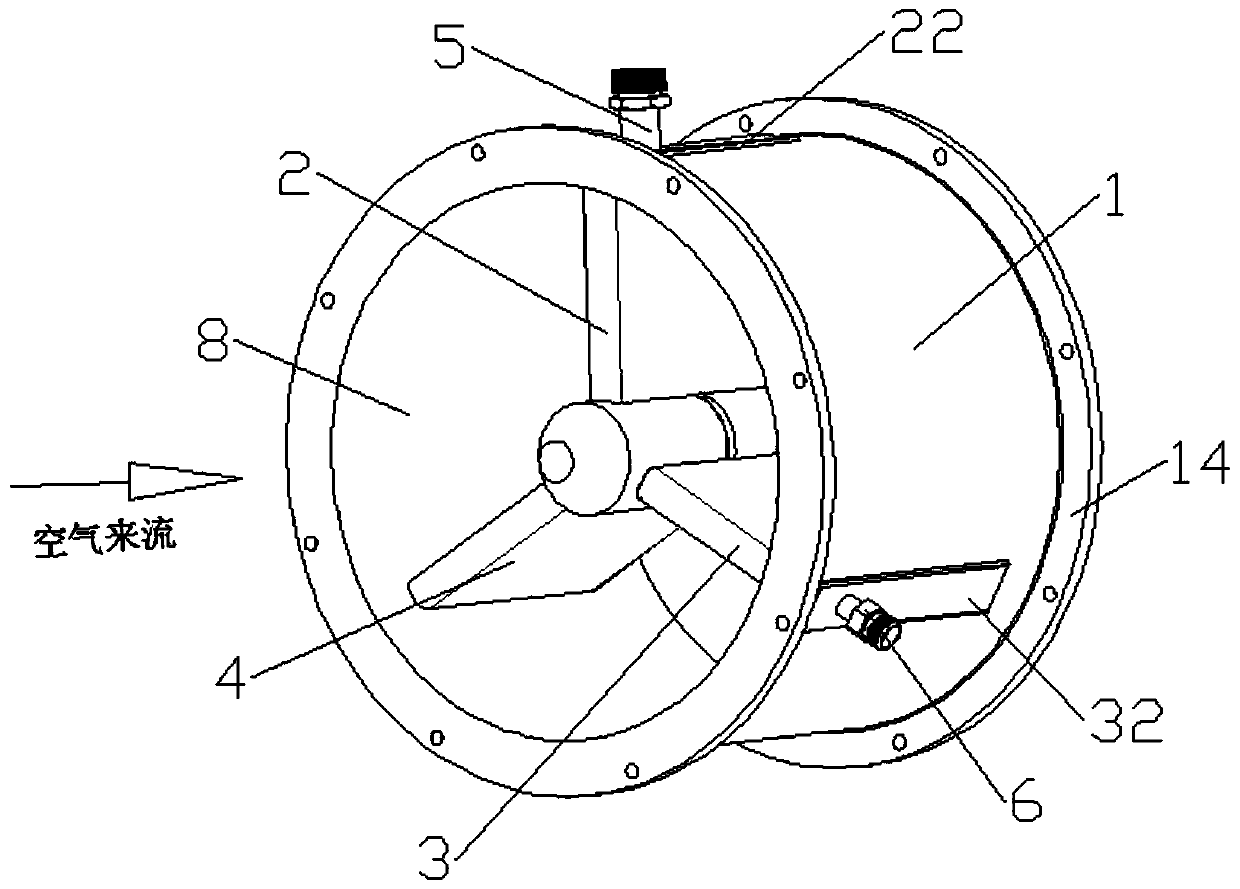

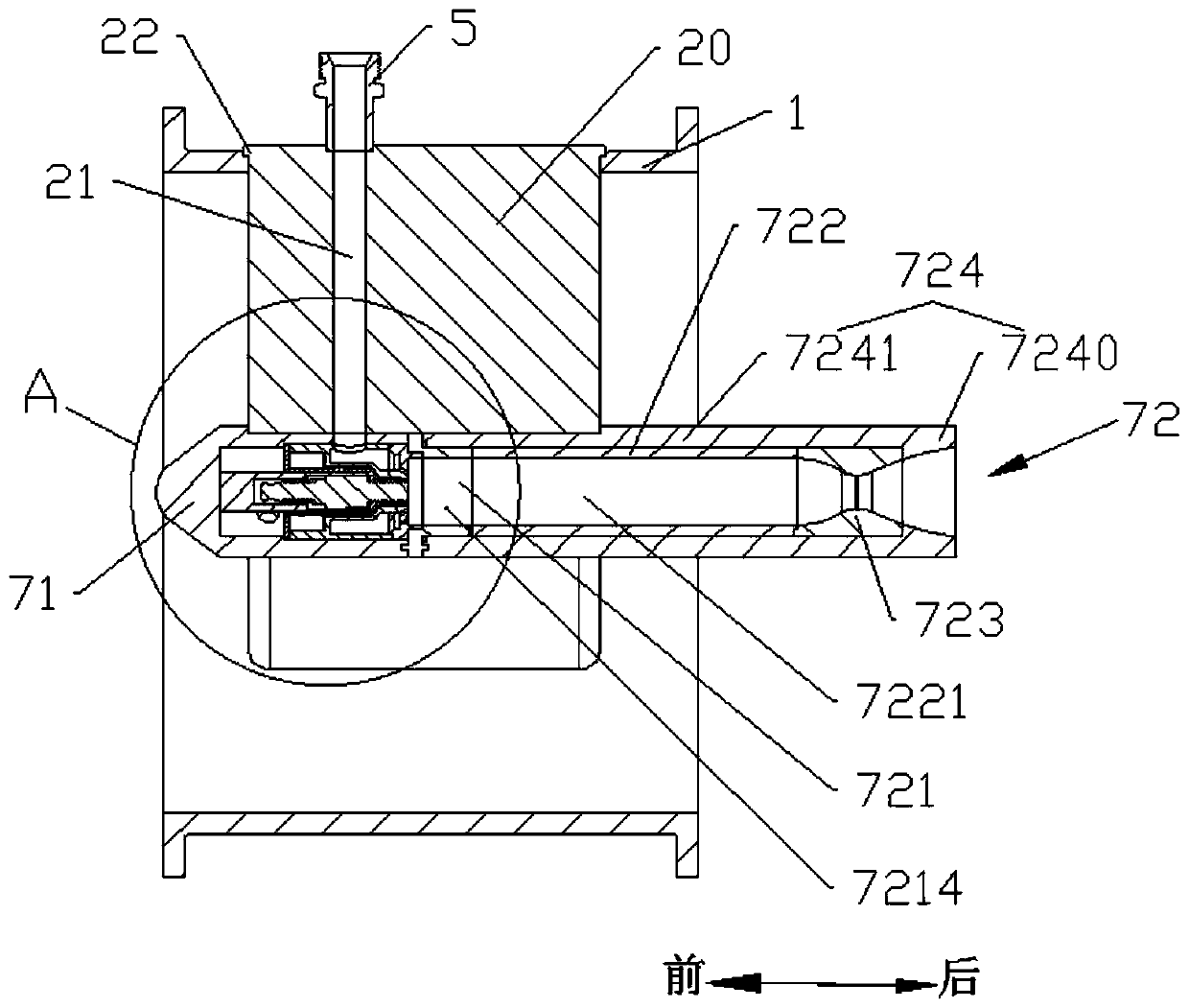

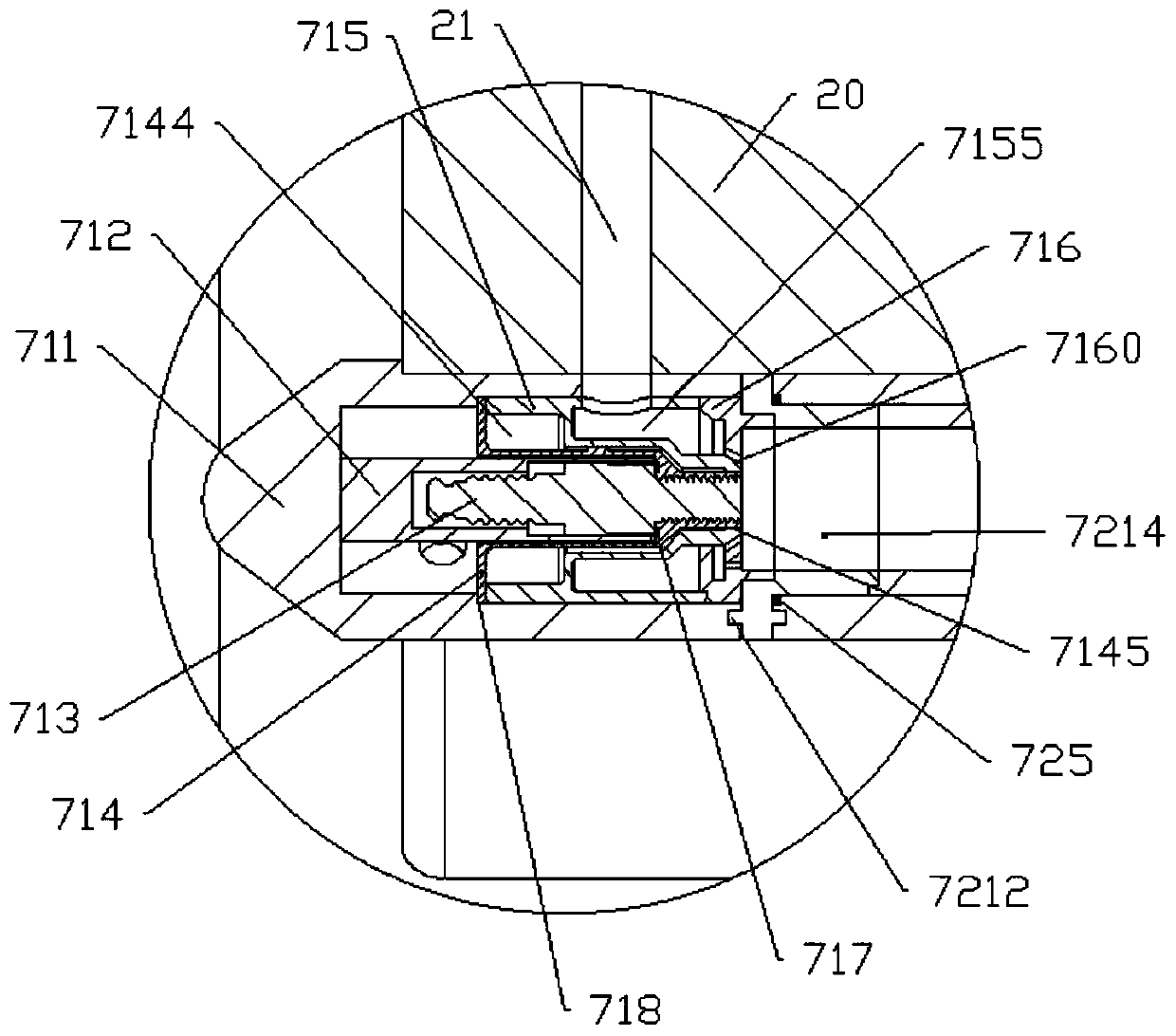

[0062] see Figure 1-12 , Embodiment 1 of the present invention provides an integrated ejector rocket engine assembly, comprising: a ram inlet 1, three support plates and an ejection rocket 7, and the three support plates are respectively an oxidant support plate 2 and a fuel support plate 3 1. Pressure measuring circuit board 4; the three boards hang the ejector rocket 7 in the ram inlet 1; the three boards in the embodiment of the present invention hang the ejector rocket 7 in the center of the ram inlet 1 place. One end of the oxidizer support plate 2, the fuel support plate 3, and the pressure measurement circuit board 4 is connected to the ejection rocket 7, and the other end of the oxidant support plate 2, the fuel support plate 3, and the pressure measurement circuit board 4 is connected to the ram air inlet 1;

[0063] The embodiment of the present invention adopts the mode of central layout, and the ejector rocket 7 is suspended on the ram air inlet 1 by three suppor...

Embodiment 2

[0109] Embodiment 2 of the present invention is a rocket-based combined cycle engine, comprising the engine assembly described in Embodiment 1, and the engine assembly is respectively connected to the flow channel of the previous stage and the flow channel of the latter stage by stamping the wall flange 14. connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com